FB Jets Dolphin S Assembly Manual

FB Jets Dolphin S

FB Jets / Feibao

Dolphin S Assembly Manual

Written By Rich Miller in Collaboration with Fei Bao Jets

Cove r Photos by Robert J . Eng l e

Rev. 0

1

FB Jets Dolphin S

Contents

DISCLAIMER: 4

Introduction 5

Specifications 7

Component Size (Length) 7

Adhesives 8

Standard Pneumatic LG Systems 8

Optional Electric LG Systems 8

Parts List: 8

Optional Equipment 9

Additional Equipment 9

Optional Equipment (Builders choice) 9

Servo List (Hi-Tec) based on 6V torque specifications 10

Servo List (JR) based on 6V torque specifications 10

Construction 10

Pneumatic Landing gear 11

General 11

Step 1: Nose Gear 11

Step 2: Main Landing Gear 12

Step 3: Forward Fuselage 13

Optional Battery Box 14

Step 4: Fuel Tanks 14

Tank Assembly 16

Tank Mounting 17

Saddle Tanks: 17

Optional Mounting: 17

Step 5: Final Fuel System plumbing: 20

Step 6: Air Tank Installation 21

Step 7: Aft Fuselage 21

Step 8: Wing – Servo Installation 22

Step 9: Vertical Fin and Rudder servo installation 24

Step 10: Horizontal Stabilizer and Elevator servo installation 25

Front equipment t ray 27

Step 12: Turbine Mounting Rails and Tail Pipe 28

Step 13: Turbine Accessory Installation 28

Step 14: Cockpit 29

2

FB Jets Dolphin S

Step 15: Radio Channel Assignments 30

Step 16: C.G. 30

Step 17: Setting of throws 31

Maintenance Tips: 31

Annex A Drawings 32

3

FB Jets Dolphin S

DISCLAIMER:

THIS IS NOT A TOY

This is a high-performance miniat ure aircraft, capable of high speeds and dam age to life, limb, and

property. The manufacturer and its distributors and auth or of this man ual cannot control how you

assemble t his model, what equipment you use to fi t it out, or how you fly it, and can assume no

liability whatsoever for any damages that may occur when you f ly your aircraft. B y assembling t his

model, y ou are agreeing to indemnify and hold blameless the ma nufacturer and/or his agents from

any and all torts and liability associated wit h the use of this product.

Please i nspect all parts before beginning asse mbly. If any part appears to be suspect, contact your

dealer or the manufactur er for repair or repl acement BEFORE you begin.

Once you have assembled the aircraft, you are the pilot in command and assum e any and all

responsibi lity for t he use of the model and any damages that might occur by fl ying or attempting to

fly this aircraft.

R/C model jets requir e a high level of skill in both their assembl y and their fl ying. If you do not feel

confident in either your building or flying skills, PLEASE seek assistance from more experi enced

modelers. It is a wise idea, no matter what level of skills you possess, to have a second

experi enced modeler go over your installati on after asse mbly. A second set of eyes may spot a

problem you have missed. If you have not flown a high performance model like this before, it is

HIGHLY recommended that you get an experienced turbine pilot to do your maiden flight. Very

often, the first few seconds of a mai den flight are cr itical until the aircraft is trim med out, and havi ng

an experi enced pil ot at the control s can make the difference between a wrecked aircraft and once

that enjoys many hundreds of flights. Be sure to select a suitable field for flying...take the time to

find a large paved runway if at all possible, especially for test flights, until you f eel comfortable

getting the aircraft in and out of smaller grass fields.

Note: In the USA it is mandatory that you belong to the Academy of Model Aeronautics and hold a valid Turbine Waiver, please check

the local governing rules for operation of R/C model jets of your location before flying.

Congratulati on s on your purchas e of t he FB Jet s Dolphi n S

4

FB Jets Dolphin S

Introduction

You have chosen a model that represents the pinnacle of ARF technology and factory testing with

the new manufacturing processes implemented by FB Jets. While there is not a lot of building to

do, there is enough to keep y ou busy for quite a few evenings. Even if you ha ve assembled other

ARF jets, w e highly r ecomm end foll owing the assembly sequence and procedures presented in

this manual.

Please remem ber that just because the model i s almost completely built it does not mean that you

can rush through the fi nal install / assembly. It is this authors recommendation that any factory

installed systems suc h as hardware, linkages, fuel lines, retracts, wheels and brakes, be inspected

for any possible defects, loose parts etc., and al l fastener s should be secured with Loctite. Wheels

and brakes should be che cked for lubrication and for proper fit to the axel; threads on linkages

should be inspected for tightness.

The Dolphin S was designed to be modular to make for easy transportation, see “compone nt size”

in the specification section. The forward and aft fuselage se ctions bol t together with four bolts.

The thrust tube (pipe) remains in the aft section of the fuselage when the halves are separated.

When attaching the front and rear hal ves of the fuselage, the thrust tube can be slid towards the

back to allow clearance to gain access t o the four fuselage mounting bol ts. After joining the two

halves, the thrust tube can then be sl id forwar d to allow the mounting tab s of the bell mouth to be

screwed to the motor mou nt rails.

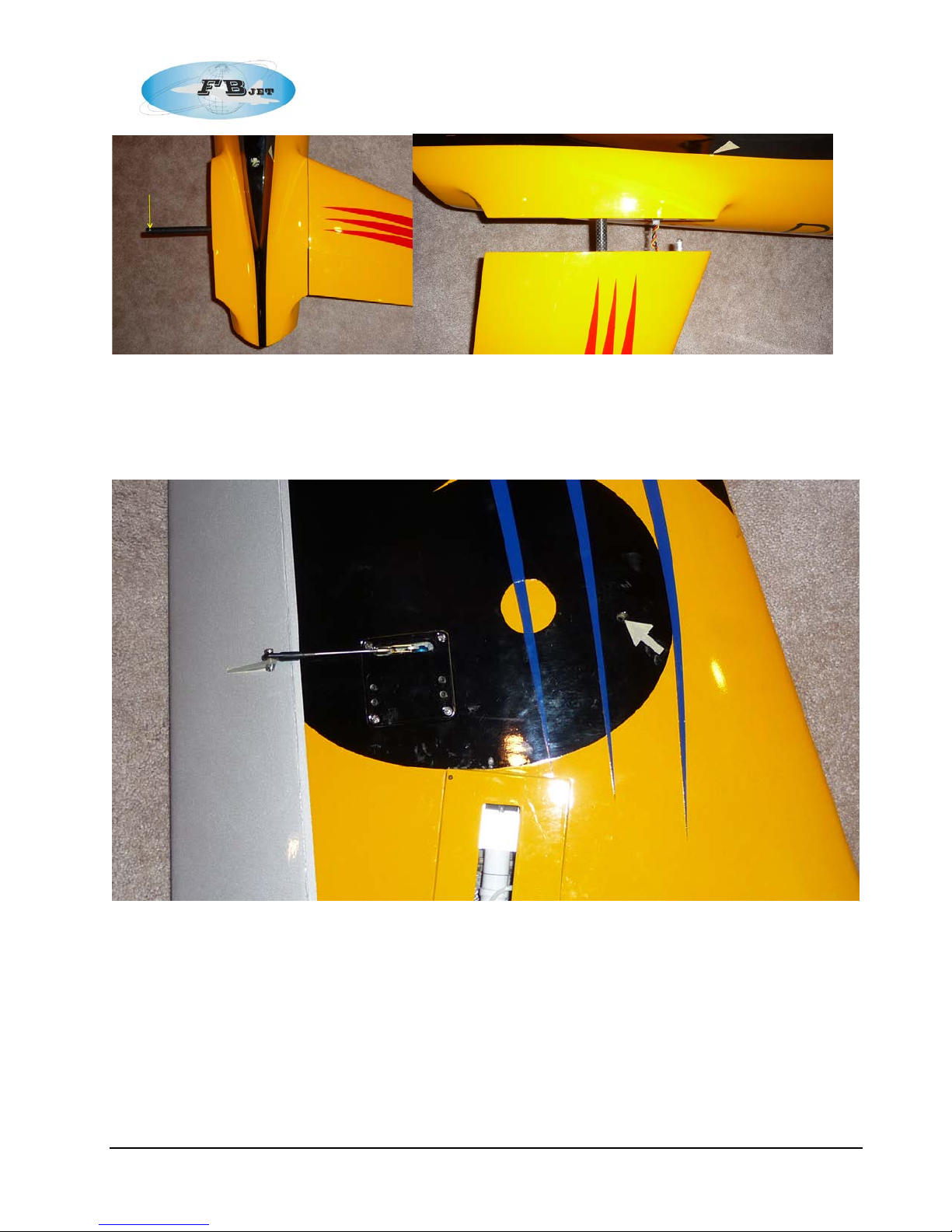

The Vertical fin is easi ly removed / installed utilizing the two internal clamping mechanisms that are

easily tightened with hex (Allen) wrenches through the access holes in rear fuselage as shown.

The right horizontal stabilizer has an integral carbon fiber spar, the left has a built in tube sock et.

Both have an ant i-rotation pin locat ed towards the leading edge. The right stabilizer is inserted into

the integral tube in the aft section of the fuselage.

through the fusel age allowing the left stabilizer to be slid onto the spar tube. The l eft stabiliz er is

then attached with one allen bolt into the CF spar, the spar bolt location is shown in photo, the

retaining bolt is i nserted from the b ottom of the left stabilizer.

Upon compl ete insertion, the spar w ill protr ude

5

FB Jets Dolphin S

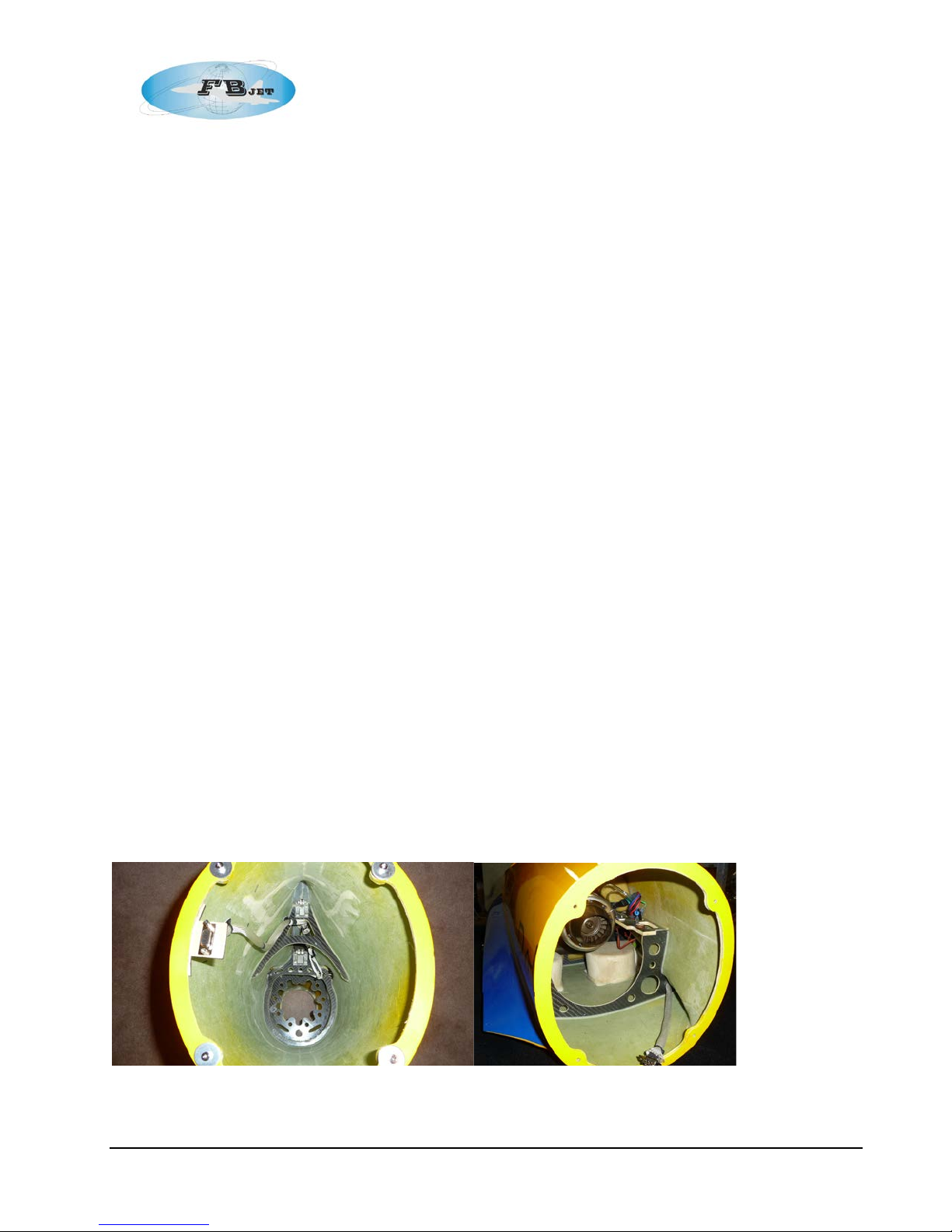

The wings utilize one carbon fiber main spar and have two anti-rotation pins, with one towards the

front and one towards the r ear of the root rib. The main spar has a 4 mm tapped hole in each

outer end, there is a hole location in of the wings that accepts a flat head 4 mm bolt to secure the

wing spar, locati on shown in photo.

When the model is completely t aken apart it will fit in a small area for transportation.

6

FB Jets Dolphin S

Specifications

Total Length: 92 1/8” (2340 mm)

Total Wingspan: 81 5/8" (2073 mm)

C.G. Location 28% MAC: 10 1/2” (267 mm) from LE of Wing

Prototype Dry Weight with all components: 30 lbs (13.6 Kg)

Thrust Class: 22 to 36 l bs (100N to 160N) “Jet Central Cheetah use d in prototype”

Servos for Flight Sur faces & Steering (8)

Servos for pneumatic controls (2) or pneumatic valves

Fuel Capacity Right and Left Saddle Tanks: 34 oz ea (1000 ml ea)

Supplied Center Tank 68 oz (2000 ml)

Total Capacity 135 oz (4000 ml)

Component Size (Length)

Vertical Fin – 16 ¾” (425 mm)

Horiz ontal Stab (ea.) – 14 ½”” (368 mm)

Wing Panel (ea.) – 35” (890 mm)

Canopy – 39 1/2” (1003 mm)

Forward Fuselage – 62 1/8” (1578 mm)

Aft Fuselage – 30” (762 mm)

Total Pipe Length with Bell Mouth: 37 1/2” (952.5 mm)

Main Tir e Diameter 3 7/8” (98 mm)

Nose Tir e Diameter 2.9” (74 mm)

Prelim in ar y St e p s bef or e y o u be gin

Keep thi s in mind as you pro ceed

Look at EVERY assembly step you fi nish, and ask yourself:

“Could this cause a malfunction and crash my aircraft?”

A chain i s only as strong as its weakest li nk, and thi s is a high-performance aircraft that will be

intolerant of sloppy assembly t echniques. Even the smallest component is important and can

cause the loss of your airframe, so take the time to do things right, or redo them if they are wr ong.

Careful work will result in a long l asting aircraft that will give you years of pleasure, one loose

component could resulting the complete loss of the aircraft and all of t he component inside of it,

additionally someone c ould even get hurt. So please pause every once in a while when building

and double check your w orkmanship.

• Clean and i nspect all parts. Inventory them agai nst the parts list at the end of the manual and

notify the kit supplier of any missing component s as soon as possible.

• If the paint scheme you have selected is glossy, it is recommend ed that you apply a coat of

wax. Thi s will help resist dirt, stains and fingerpr ints during construction, and wi ll provide some

limited protection against errant glue.

• Vacuum out the remnants of packing materials that remain in the fuselage.

7

FB Jets Dolphin S

Adhesives

The author prefers Loctite Hysol 9462 adhesive for all procedures. This is a very strong epoxy that is

thixotropic. “Thixotropic” means it does not run at all, but stays only where you put it. It is superior to

regular epoxy, even slow setting epoxy, because of this characteristic. Regular epoxy will run with

gravity as it dries, taking it away from where it is supposed to be. The downside of Hysol is it takes

overnight to dry properly. It is recommended that you only use a proper Hysol dispensing gun and only

the long-type mi xi ng nozz les.

Be careful if using adhesives such as “shoe goo” or Zap-a-Gap-a-Goo, as these contain solvents that

may att ac k t he f i berglass an d could ruin t h e surf a ce f i ni sh of y o ur mo del.

Standard Pneumatic LG Systems

Pneumatic retracts typically are the number one maintenance issue with most models however with

proper installation procedures and preventive maintenance this need not be the case. The Dolphin S

uses pneuma tic retract and brakes. If you follow a few tips you should have a very reliable leak free

operation. Factory installed systems should be inspected for kinked lines, proper insertion of hoses on

fittings and the hose routings should be neat and secure. Special at tention should be m ade to ensur e

that the length of tubing at “T” fitting is equal to both sides to ensure balance operation, epically in the

brake s ystem. Take special precautions to route hoses away from moving landing gear parts and hot

engine areas. It is recommended that the factory valves, cylinders and brakes be disse m bled, cleaned

and lub ed w ith a goo d O-ring lubricant t o e n sur e reli abl e op er ati o n.

If installing your own pneumatic components it is important to make all cuts in the pneumatic tubing

dead square before installing on the nipples, also make sure that the lines are pushed all of the way

onto the nipples. They should not need to be secured otherwise however you can add fine safety wire

for extra security.

Optional Electric LG Systems

FB Jets off ers opti on al electri c ret r acts f or t his model .

Parts List:

Major components

• Fuselage front Section with nose retract inst alled

• Fuselage af t section

• Canopy

• Forward and Af t Equipment trays

• Right and Left Wing panels with main retracts i nstalled

• Right and Left Horizontal Stabilizer

• Vertical Stabilizer

• Tail Pipe with Bell M outh

• Right and Left Saddle Tanks

• Center Tank

• Tank Hardware/Heavy Clunks/Aluminum Bung Fittings

• Linkages / Hardwar e kit

• Air Kit: Tanks, Lines, Valves, Fittings

8

FB Jets Dolphin S

• 79” (200c m) Blue Air Line

• 79” (200c m) R ed Air Li ne

• 79” (200c m) White Air Line

• 79” (200c m) Yellow Air Line

• 3 Three port valves (Gear & Doors)

• 1 One Port Valve (Brakes)

• 2 Air Tanks

• 1 Fill Fitting

• 6 Three port Y’s

• 4 four port Tees

• 4 Disconnects

Optional Equipment

• Sport Scale C ockpit

• Electric Retracts Optional

Additional Equipment

While t he kit is comprehensive, there are addit ional parts required as follow s:

• Turbine – 22 to 36 lbs. (100N to 160N) “Jet Central Cheetah used in prototype” (Users

Preferen ce of Manufact urer)

• Radio Syst em (Users Preference of Manufacturer)

• Servos (Users Preference of Manufa cturer, S ee List on next page)

• Servo Extensions Various Lengths depending on equipment locations

• Servo lead b ulkhead connectors (ideal for fuselage junction and wi ng connections)

• Batteries / Regulator / Switch / Power system

• Adhesives (Thin CA, Medium CA, Hy-Sol, Loctite Red/Blue)

• 3/16” Ty gon fuel line

• 3/16”(5 mm) Brass Fuel Line (K&S P/N 1147) 5 mm (K&S P/N 3923)

• S.S. Tie wire

• Ty-Raps

• Bulkhead f ittings (Fuel Fill and Vent Fittings)

• Miscellaneous small screws

• Sullivan 4-40 Gold-N-Clevises or equivalent

• UAT (optional / but hi ghly recommend)

• Air Pressure Gauge(s)

Optional Equipment (Builders choice)

• (Optional Internal Finishing) Grey Pri mer and Paint such as RUST-OLEUM Stone T ext ur ed

Paint (G rey)

9

FB Jets Dolphin S

Servo List:

(Hi-Tec) data based on 6V torque specifications

• Ailerons: (1) HS-5625MG or HS-7985MG

• Elevator: 2) HS-7955TG

• Flaps: (2) HS-7955TG

• Rudder: ( 1) HS-7955TG

• Nose Steering: (1) HS-645MG or HS-5645MG

• Mechanical Retract V alve: (1) HS-225 (MG) or Electronic Pneumatic Dual A ction Valve

• Mechanical Brake Valve: (1) HS-225 (MG) or Electronic Pneumatic Single Acti on Valve

(JR) data based on 6V torque specifications

• Ailerons: (2) DS8411

• Elevator: (2) DS8611A or DS8711

• Flaps (2) DS 8611A or DS8711

• Rudder: ( 1) DS8611A or DS 8711

• Nose Steering: (1) 4721

• Mechanical Retract V alve: (1) 351 or Electronic Pneumatic Dual Action Valve

• Mechanical Brake Valve: (1) 351 or Electronic Pneumatic Single Action Valve

Construction

The order of construction may be chan ged to suit your personal preference; however, due to the

size of the Dolphin S it is recommend ed to complete as much of the w ork as possible on the

individual components before the final assembly. The major ity of the assembly takes place in the

forwar d fuselage section. It is recommended installing a ser vo lead bulkhead connect or at the

fuselage junction; this will allow easy disassembly for transportat ion.

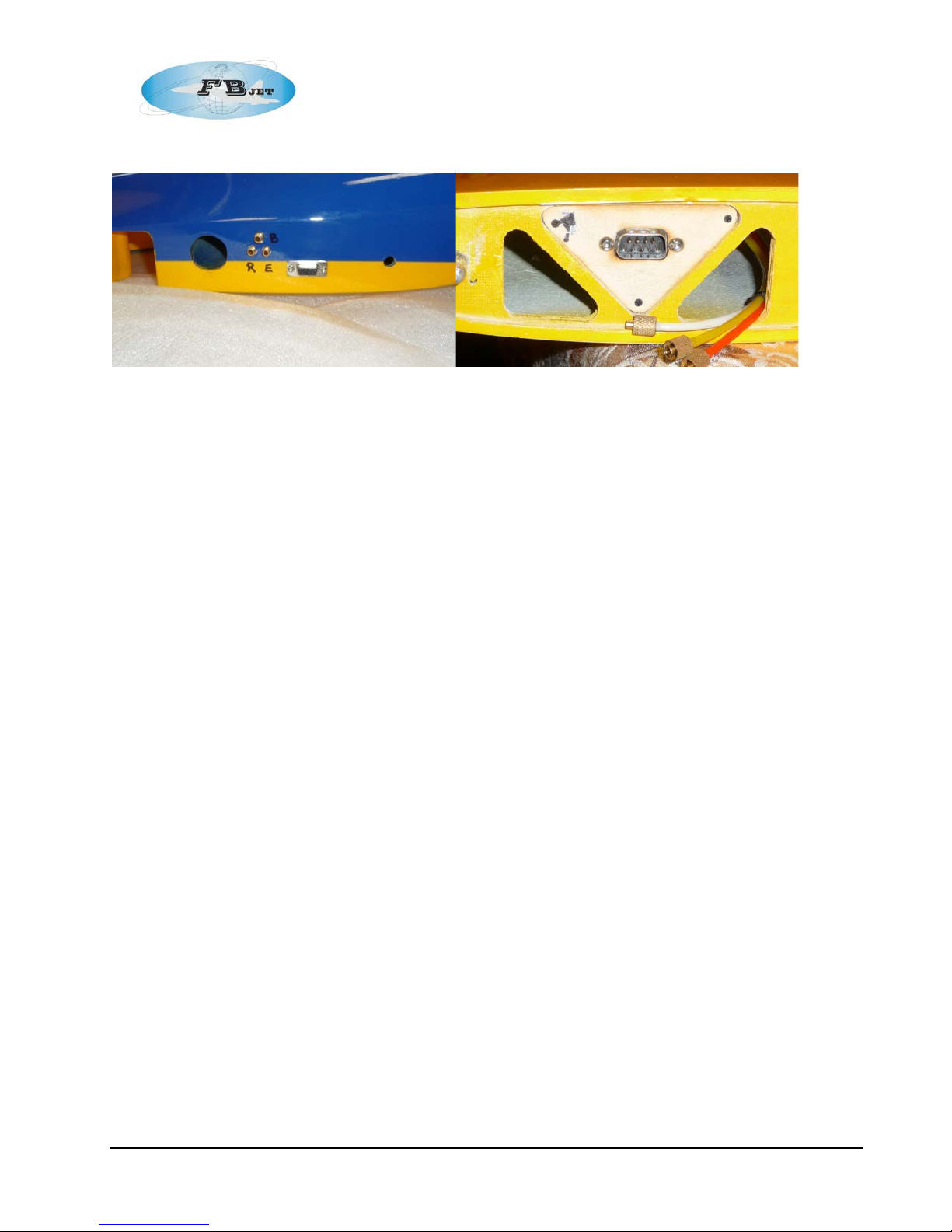

The prototype used for the cre ation of this manual uti lized a standard DB-9 “D-Type” connector

(See photo) ; however, any connector sy stem could be utilized.

Note: If using individual servo ext ensions, i t is a good idea to mark each lead with an identifier to

aid during assembly.

Aft Fuselage Front Fuselage

The proto t ype’s wing connections also utili zed DB-9 D-Type connectors for the connection of the

servos, w hen the wing i s slid onto the spar and mates with the fuselage the servo connecti ons are

made.

10

FB Jets Dolphin S

Fuselage Ce nter Root section Wing Root sect ion

Note: any fiberglass sur faces on the inside of the airframe that requires components to be bonded

should be cleaned with mild detergent and water to make sure that any mold release agent is

removed, and then scuffed wit h medium grit sandp aper in t he area of the intended bond to

promote adhesion prior to applying the adhesive.

Pneum at ic Lan ding gear

General

The landing gear are pre-installed from the factory; it is recommended that the all retract unit s

should be r em oved and inspected for air leaks. This is easily done by submersing the retract unit

in a pan of w ater and applying pressure t o each of the cylinder inlets while maintaining pressure

see if any air bubbles are detected. If leaks are detected they sh ould be corr ected by

disasse mbling the cylinders, cleaning, and applying O-ring lube, then reasse m ble and re-test.

Check the fu nction of eac h gear wit h a hand pump or other suitable air source while they are

removed fr om the airf rame. Make sure the extension and retr action of the gear is smooth b efore

final installation. Check for free rotation of the wheels on the axels, t he wheel bushi ng will require

lubrication or even may require reaming of the I.D. of the bushings to create a better fit.

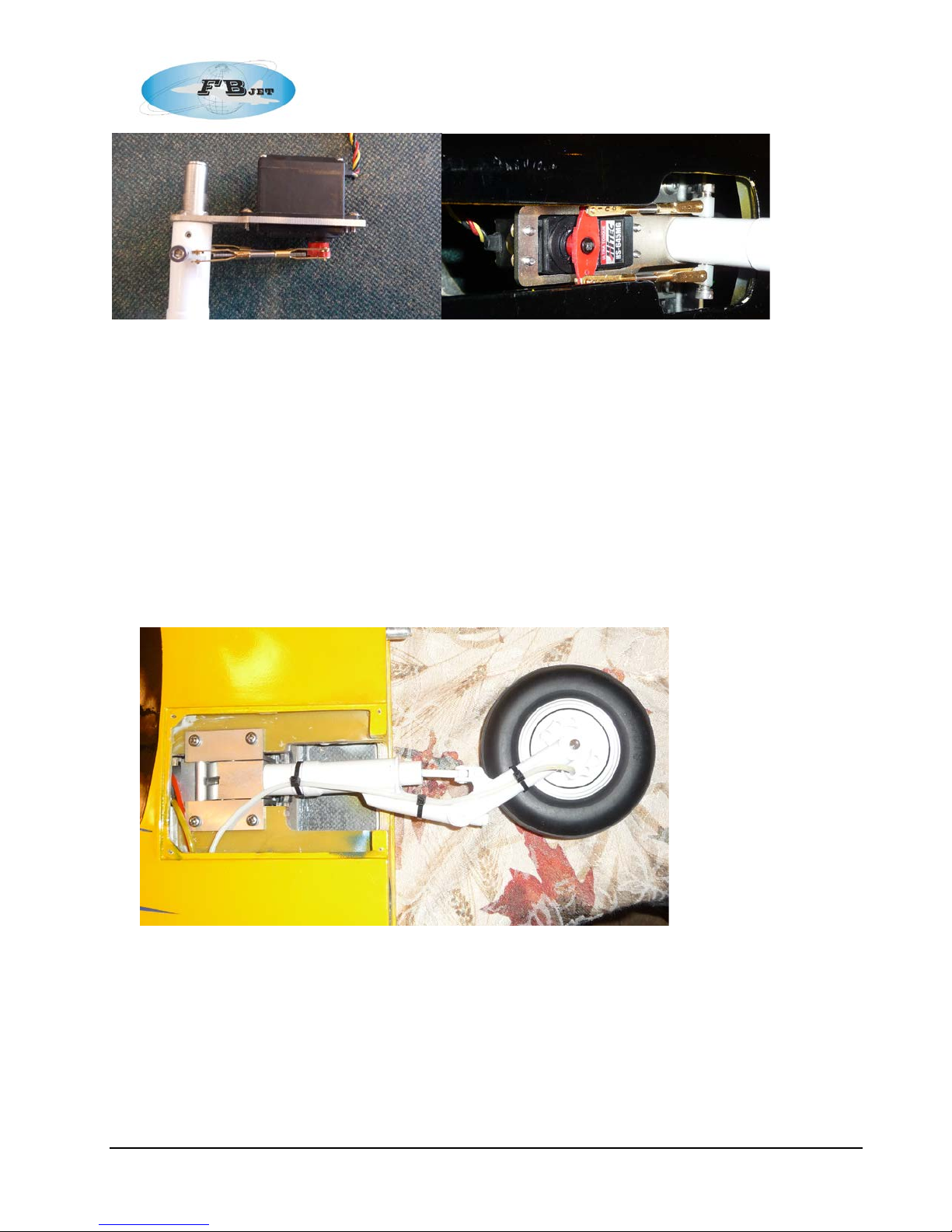

Step 1: Nose Gear

Remove nos e gear from fus elage and perform leak checks as describe above.

After performing the ab ove checks, a ssemble the steering servo into the nose strut steering

bracket as shown using the supplied mounting hardware. The servo is mounted from the

top side of the bracket to get better alignment with the provided holes for the strut control

horns; the servo output shaft is mounted away from the strut.

11

FB Jets Dolphin S

Using a receiver or ser vo driver find servo neutr al and attach a suitable double sided

servo ar m perpendicul ar to the servo m aking sure t o tighten the servo arm screw .

The threade d rod supplied with the kit was 2-56 style all thread and clevises as shown

in the photos, it recom me nded to change these to 4-40 parts.

Step 2: Main Landing Gear

Remove main gear from wings and perform leak checks as describe above.

After performing the ab ove checks, reassemble the main gear back into the wings using the

supplied screws or replace with bui lder supplied optional allen head bolts and bli nd nuts.

12

Loading...

Loading...