FAWDE 4DW81-46 Operation Manual

FOREWORD

4DW series diesel engines (code: 800) have two options of cylinder bores (i.e., 85 and 90)

and strokes (i.e., 95 and 100). Aspiration modes of 4DW series are natural aspiration, supercharge

and supercharge inter-cooled etc. 4DW series have two options of speed, i.e., 3000 r/min and 3200

r/min. Power of 4DW series diesel engines ranges 34kW~62kW, maximum torque ranges

124.3N·m~230N·m, and speed (at max. torque) ranges 1800 r/min~2200r/min .

In this Manual, only natural aspiration type diesel engines, of which power ranges 34kW~

46kW, are described. 4DW series diesel engines with a natural aspiration mode are suitable for use

as power, completed for light-duty automobiles, 0.75-2t agriculture-use transport vehicles,

small-size construction machinery, tractors, combines, electric generator sets etc.

This Manual describes main specification, adjusting methods, operation and maintenance

requirements etc of 4DW series diesel engines. Correctly using and maintaining the diesel engines

are extremely important to both travel safety and their longer service life. Users are kindly

requested to read carefully this Manual and operate and maintain the diesel engines complying

with its requirement.

As this series engine is in the process of ceaseless improvement and modification, the diesel

engine you purchase in the future may somewhat deviate from this Manual.

When ordering engine accessories, please tell us the Model, declared power and speed, order

No., month and year of manufacture, and serial No. of the diesel engine(s) you purchased, so that

our company can provide you with correct accessories.

FAW Jiefang Automotive Company, Ltd.

Wuxi Diesel Engine Works

August 2006

Written by: Zhai Yonghui Huang Qiwei Yang Xueming

Reviewed by: Wang Xinze Li Peiran Yao Zugen

To Users

Dear Users :

When new diesel engines or engines just subjected to an overhaul (e.g., main parts such

as piston, crankshaft or connecting rod etc are replaced) are used on automobiles, the automobile

must not run at normal or heavy-load condition until it has run for a wear-in distance of 2000 km,

in which engine speed should be no more than 2200 r/min and power should be 70% of full-load.

This is very important to the reliability and after-overhaul service life of the engine. 4DW engines

will bring you more economic effectiveness if you timely maintain them as per this Manual.

Contact phone numbers of our Works are as follows:

Sales Company: 0510-85013436 (fax)

Main engine dept.: 0510-85014990-8362, 8363

Accessories dept.: 0510-85014990-8370, 85010814

Service dept.: 0510-85014990-8372, 8373

FAWDE 24h hotline: 0510-85017315

Production License No.: XK06-002-00014

FAW Jiefang Automotive Company, Ltd.

Wuxi Diesel Engine Works

August 2006

CONTENTS

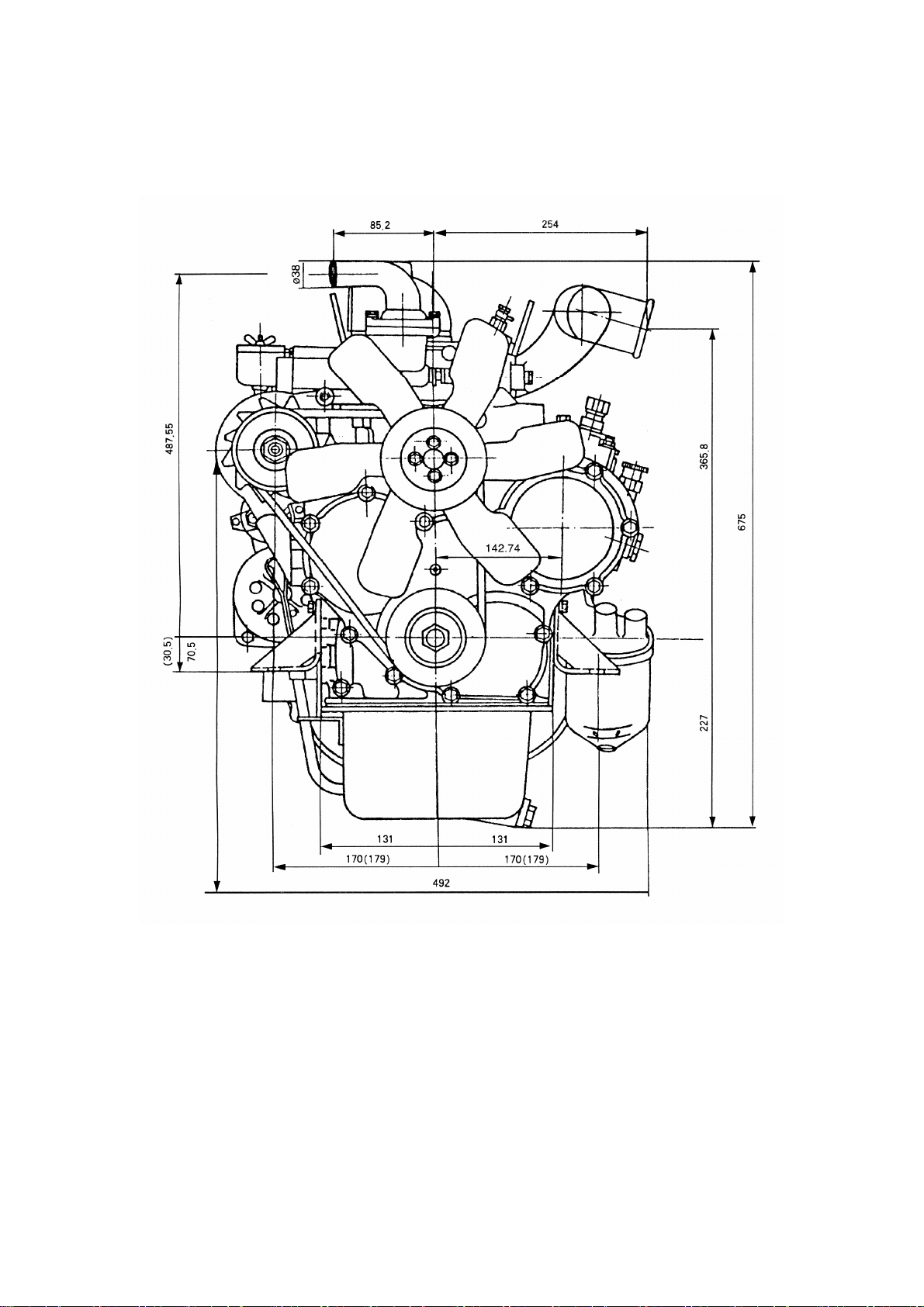

(I) Right view of 4DW81-46 diesel engine ………………………..……………………… 1

(II) Left view of 4DW81-46 diesel engine ………………………………………………… 2

(III) Front view of 4DW81-46 diesel engine ……………………………………………….. 3

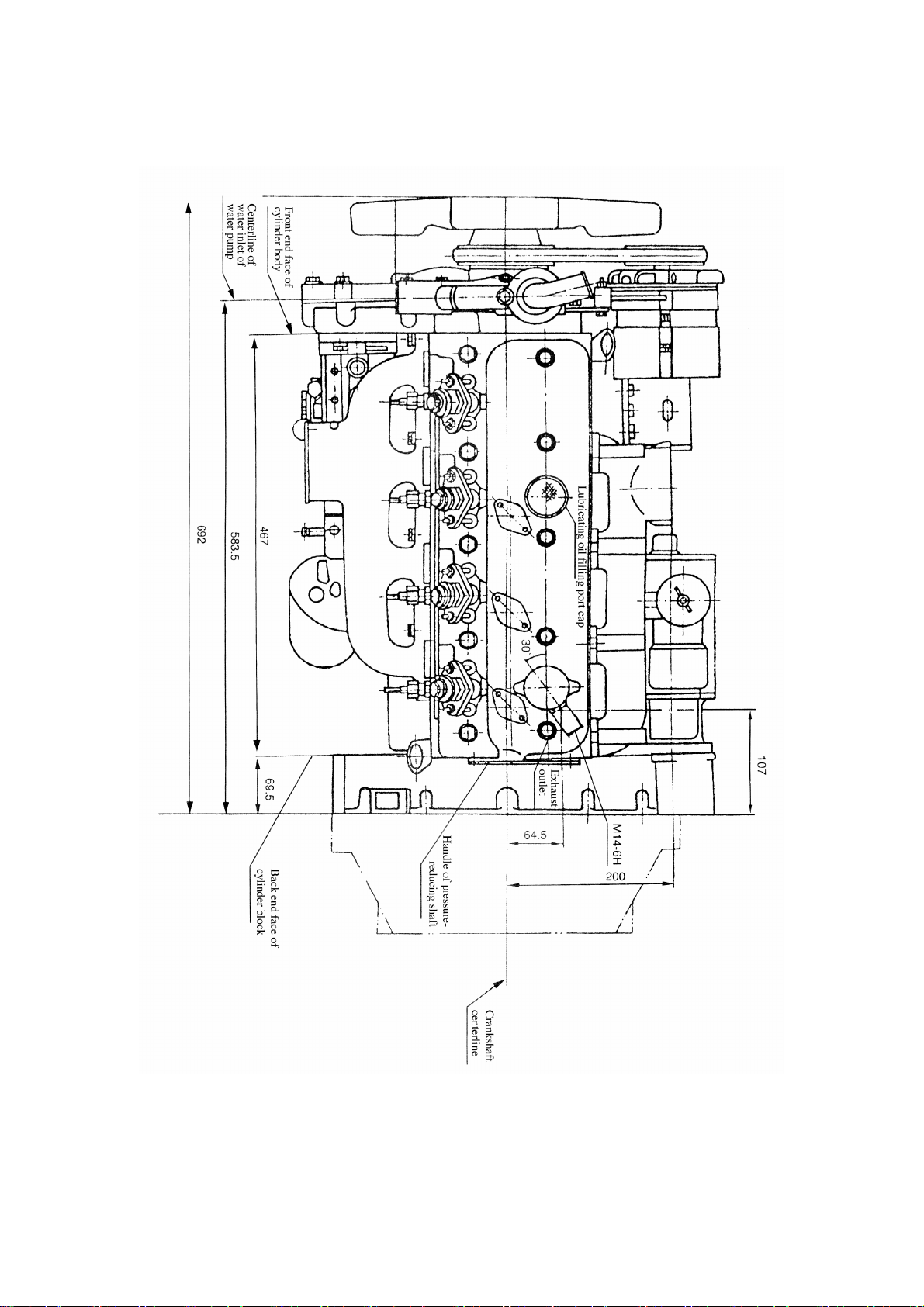

(IV) Vertical view of 4DW81-46 diesel engine ……………………………………..……… 4

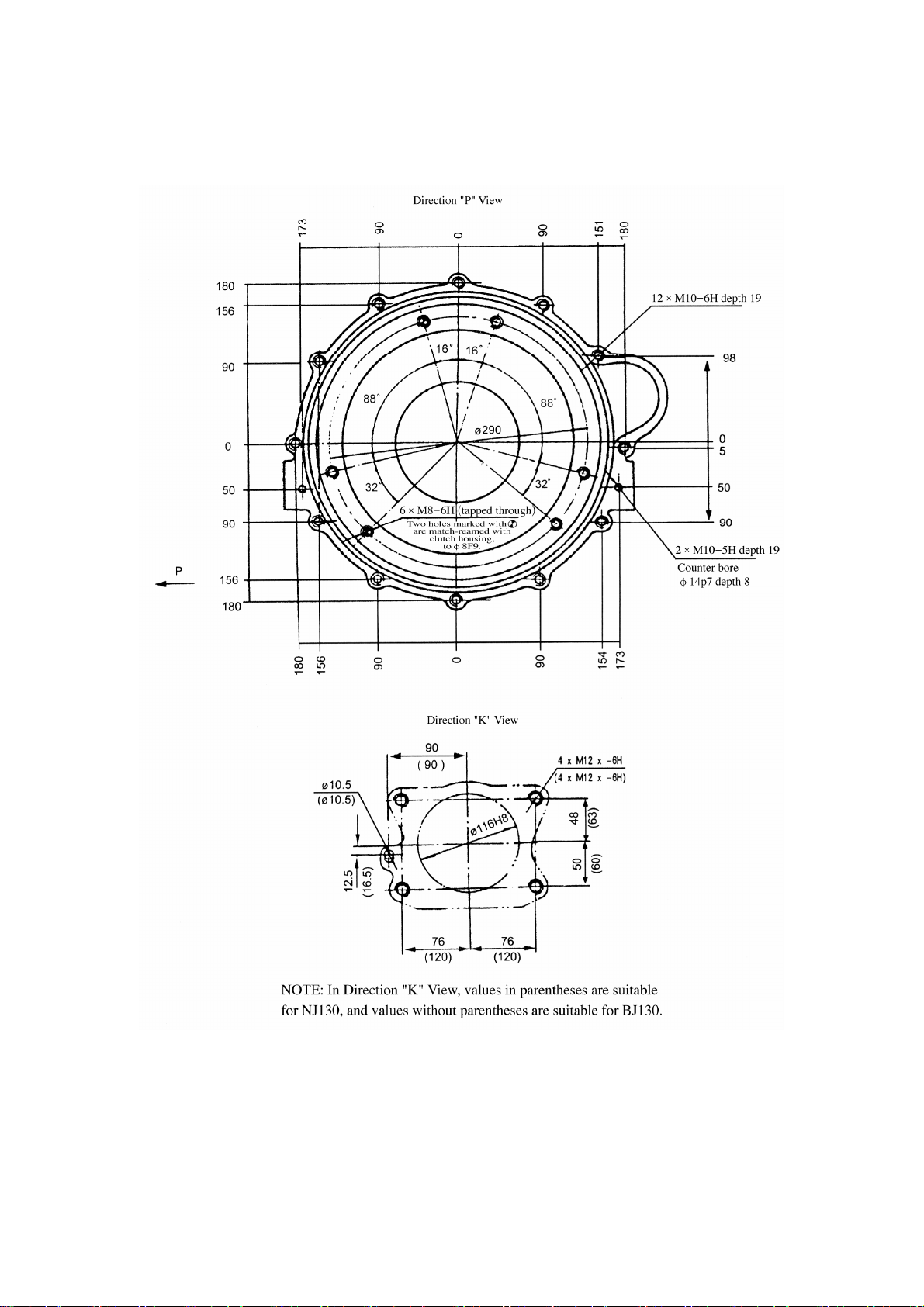

(V) Power output end of 4DW81-46 diesel engine ………………………………………… 5

Chapter I Technical Characteristics ……………………………………………………..……… 6

I. Technical parameters for 4DW(B00) diesel engine & its variants ……………………… 6

II. Main technical data ………………………………………………………………..…… 7

III. External characteristic curve of 4DW engines ………………………………………… 9

Chapter II Operation ………………………………………………………………...……… 11

I. Precautions ………………………………………………………………………...…… 11

II. Operation ……………………………………………………………………………… 11

Chapter III Maintenance …………………………………………………………………….… 15

I. Daily care ………………………………………………………………………….… 15

II. Maintenance after running every 100h ……………………………………………..… 15

III. Maintenance after running every 500h …………………………………………..… 16

IV. Storage ……………………………………………………………………..……… 17

Chapter IV Structure ………………………………………………………………………… 18

I. Cylinder head …………………………………………………………………...……… 18

II. Engine body …………………………………………………………………………… 20

III. Piston & connecting rod ……………………………………………………………… 21

IV. Crankshaft & flywheel …………………………………………………………..…… 23

V. Camshaft …………………………………………………………………….………… 24

VI. Gear system ………………………………………………………………...………… 25

VII. Fuel & speed-governing system ……………………………………...…………… 26

VIII. Lubricating system …………………………………………………..…………… 31

IX. Cooling system ………………………………………………………..…………… 33

X. Electrical system ……………………………………………………………………… 36

XI. Oil-pressure sensor & water-temperature sensitive plug ……………………..……… 38

Chapter V Adjustment ………………………………………………………………………… 39

I. Adjustment of valve lash .………..……………………………………………..……… 39

II. Adjustment of fuel-supply advance angle .…………………………………….……… 39

III. Adjustment of fuel injector …………………………………………………...……… 40

IV. Fuel injection pump …………………………………………………………...……… 41

Chapter VI Troubles & Troubleshooting ……………………………………………………… 42

I. Engine does not start ……………………………………………………………..……… 42

II. Abnormal engine-oil pressure ………………………………………………………… 43

III. Smoke emitted in exhaust gas ……………………………………………………..…… 43

IV. Insufficient power ……………………………………………………………………… 44

V. Abnormal sound ………………………………………………………………………… 45

VI. Severe vibration .………………………………………………………………..……… 45

VII. Engine overheat ………………………………………………………………..……… 46

VIII. Too much engine-oil consumption …………………………………………………… 46

IX. Speed increased greatly …………………………………………………………….… 46

X. Engine stops by itself …………………………………………………………...…… 46

XI. Rough idle ………………………………………………………………...………… 47

XII. Engine-oil raised high ………………………………………………………….……… 47

Annex Fit Clearance Table ……………………………………………………………..……… 48

(I) Right view of 4DW81-46 diesel engine

1

(II) Left view of 4DW81-46 diesel engine

2

(III) Front view of 4DW81-46 diesel engine

3

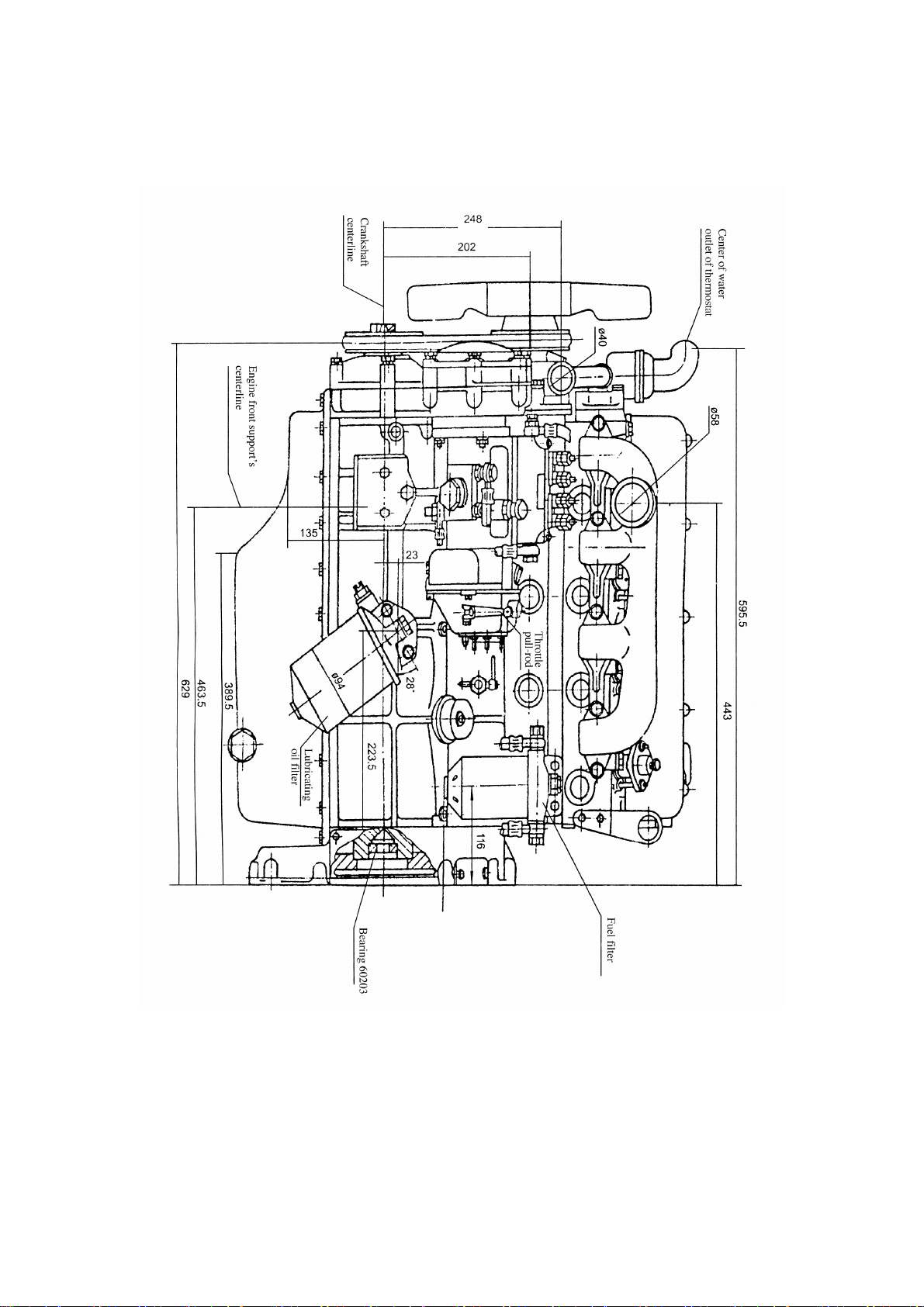

(IV) Vertical view of 4DW81-46 diesel engine

4

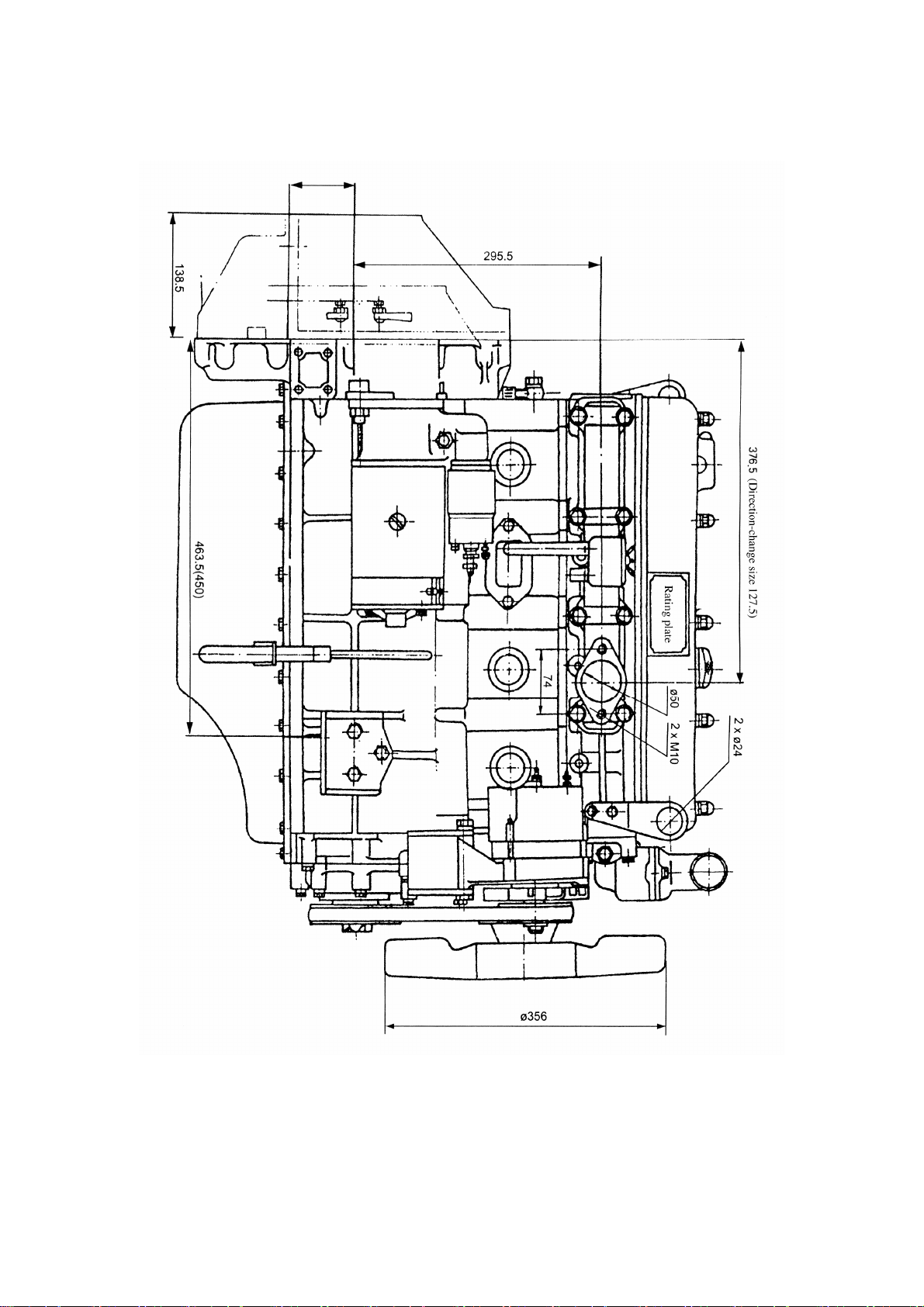

(V) Power output end of 4DW81-46 diesel engine

5

Chapter I Technical Characteristics

I. Technical parameters for 4DW(B00) diesel engine & its variants

1 Model/designation

2 Type 4-cylinder, in line, 4-stroke, water-cooled, direct-injection

3 Aspiration mode Natural air-suction

4 Ignition sequence 1-3-4-2

Cylinder diameter (mm) × piston stroke

5

(mm)

6 Piston total displacement (L) 2.16 2.27 2.54

7 Rated power (kW) 34 37 36 46

8 Rated speed (r/min) 3000 3200 3000 3200

9 Max. torque (N·m) 124.3 131 155

10 Speed at max. torque (r/min) 2200 1900 2100

11 Minimum steady idling speed (r/min) 800 ± 50

12 Steady regulation rate (%) ≤ 10

Minimum fuel consumption at full load

13

(g/kW·h)

Consumption ratio of engine-oil to fuel-oil

14

(%)

15 Maximum smoke at full load (Bosch) ≤ 3.5

16 Free acceleration smoke (Bosch) ≤ 3.0

Crankshaft rotation direction (viewing

17

towards flywheel)

18 Lubrication mode Pressure lubrication & splash lubrication

19 Starting mode By electricity

Overall dimensions (excluding clutch

20

housing) L × W × H (mm)

21 Net weight (kg) 205

4DW81-46/B01 4DW81-50/B05 4DW81-49/B71 DW91-63/B41 4DW91A63/B45

85×95 85×100

≤ 235

0.8

Anticlockwise

696 × 492 × 650

90×100

Note: Declared power denotes the power, under atmospheric pressure of 100kPa (750 mmHg),

ambient temperature of 25℃ and relative humidity of 30%, and without air filter and muffler,.

When atmosphere condition is different from standard atmosphere, check-calculation should be

made as per GB/T6072.1-2001 《Performance of Reciprocating Internal Combustion Engine, Part

1: Declaration and Testing Methods of Standard Basic Information, Power, Fuel and Engine Oil

Consumption》.

6

II. Main technical data

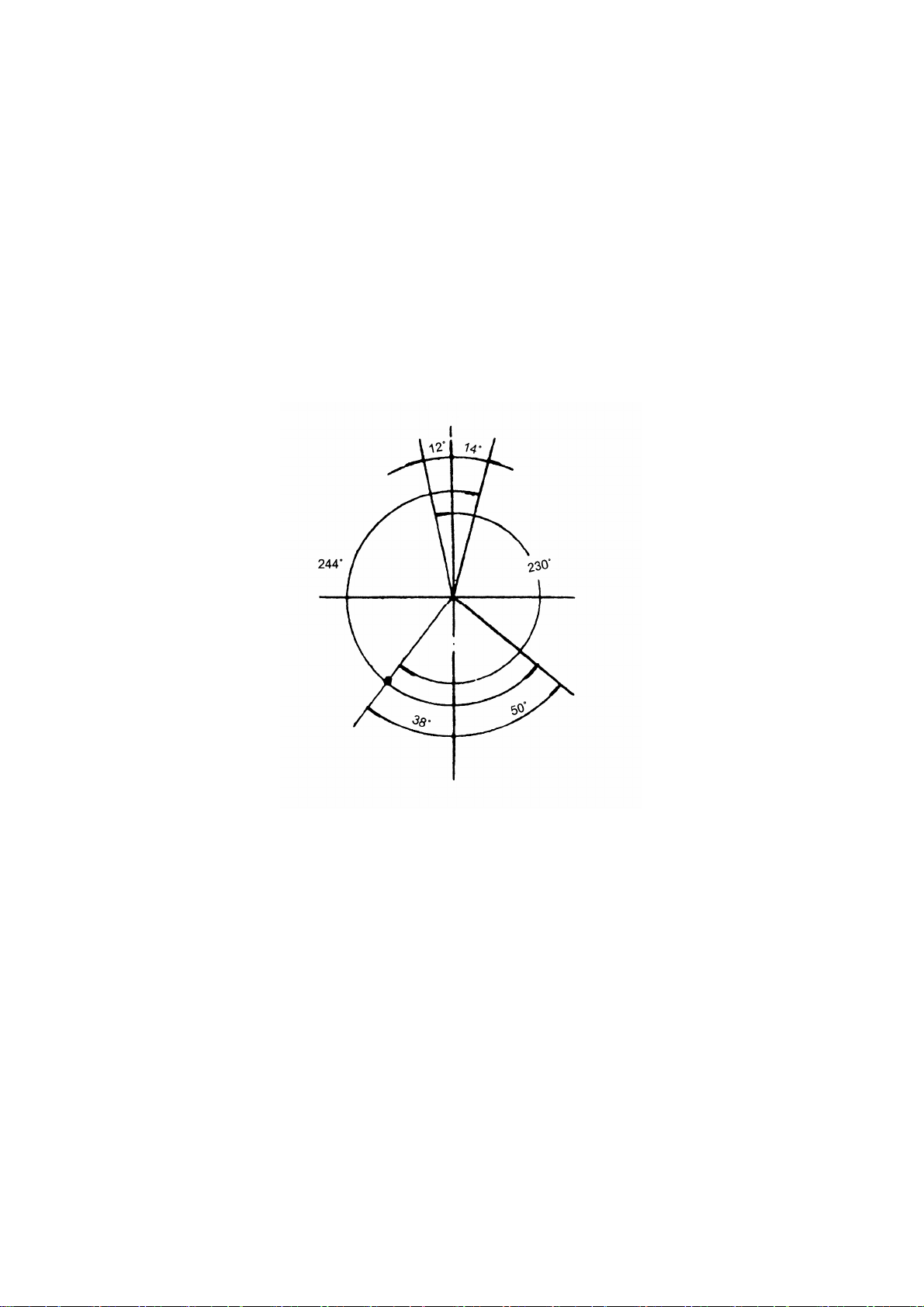

1. Valve timing

Intake valve opens 12°±2° before T.D.C.

Intake valve closes 38°±2° behind B.D.C.

Exhaust valve opens 50°±2° before B.D.C.

Exhaust valve closes 12°±2° behind T.D.C.

Valve lash (at cold state) Intake valve: 0.28-0.33 mm

Exhaust valve: 0.28-0.33 mm

T.D.C.

Intake valve opens Exhaust valve closes

Exhaust valve opens

Intake valve closes

B.D.C.

Fig. 1 Valve timing diagram

2. Fuel-supply advance angle 16°±1° before T.D.C.

3. Temperature and pressure values of the engine

(1) Exhaust temperature (℃)

At 15-minute rated power ≤ 620

At one-hour rated power ≤ 550

At 12-hour rated power ≤ 500

(2) Engine-oil temperature (℃) ≤ 95

(3) Water-out temperature (℃) 70~90, maximum.≤ 95

7

(4) Main oil-duct engine-oil pressure

(at declared working condition) 196 ~ 441 (2 ~ 4.5) kPa

Engine-oil pressure when idling (kPa) no less than 98

4. Tightening torque for important bolts (N·m or kgf·m)

(1) Bolts on connecting rod 60~70 (6 - 7)

(2) Bolts on cylinder head 118~137 (12 - 14)

(3) Bolts on main bearings 120~140 (12 - 14)

(4) Bolts on flywheel 110~130 (10 - 12)

(5) Starting bolts 110~130 (10 - 12)

5. Lube oil capacity (L) ≈ 7

8

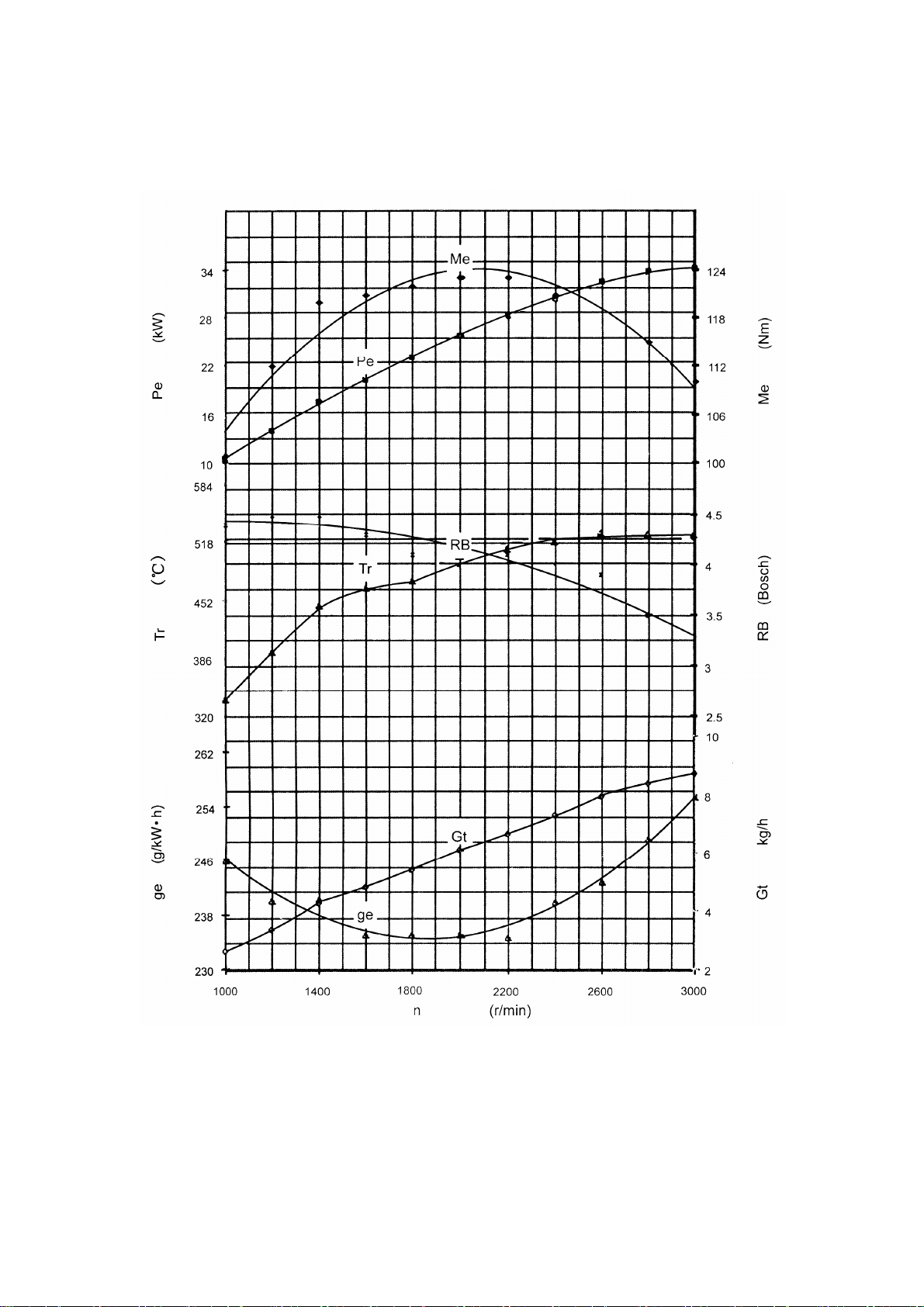

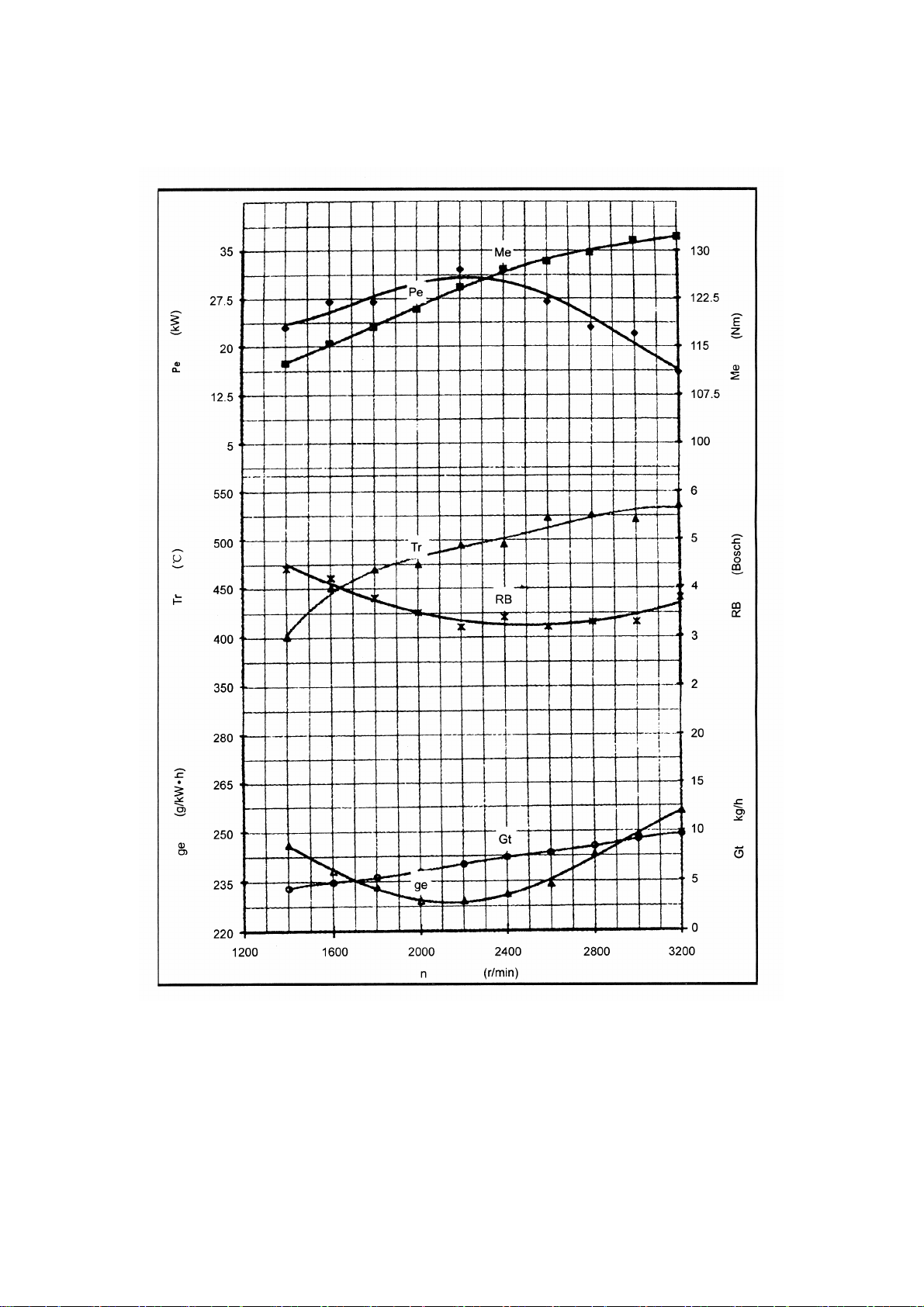

III. External characteristic curve of 4DW engines

1. External characteristic curve of 4DW81-46 (B01)

9

2. External characteristic curve of 4DW81-50 (B05) (37kW, 3200 r/min)

10

Chapter II Operation

I. Precautions

1. When using the diesel engine, it is necessary to make adjustment and maintenance as per

this Manual.

2. When the engine is cold-started, pre-heating is necessary. Pre-heating time should be

20s~30s, and no more than 40s.

3. The starting motor should be used at one time no more than a duration of 5s. Interval

between every two starting operations should be more than 2min.

4. New diesel engines or engines just subjected to an overhaul must not work at high speed or

at full load, until they have worked for a wear-in period of 50~100h, during which they run at a

low speed (no more than 2200 r/min) or less load (no more than 70% of full-load).

5. Fuel oil for the engines must be clean. Before use, the fuel oil must at least be precipitated

for more than 4 days or filtered with silk cloth.

6. Normal water temperature (75~90℃) should be kept. Normal engine oil pressure, when

the engine is running at a medium speed, should be 196~392 kPa.

II. Operation

1. Fuel oil, engine oil and cooling water

(1) Diesel oil specification

The diesel oil should have a sulfur content of less than 0.5%. Diesel oil with low freezing

point should be used in winter. Diesel oil brands should be selected basically as per ambient

temperature conditions (see Table 2-1). For example, #-35 diesel oil should be used for ambient

temperature of -29℃.

Table 2-1 Relations between diesel oil brands and suitable lowest temperature

Diesel oil brand #10 #0 #-10 #-20 #-35

Sulfur content (%) 0.2 0.2 0.2 0.2 0.2

Cetane value 45 45 45 45 45

Freezing point (℃)

Suitable lowest temperature (engine's

operating ambient temp.) (℃)

Diesel oil must be kept highly clean, free of pollution by dust or impurities. Before being

injected into the fuel tank, the diesel oil should be kept still for more than 27h. Then upper

part/layer of diesel oil should be taken for use. This is extremely important for preventing the fuel

injection pump and plunger from being earlier worn off.

(2) Engine oil specification

Correct selection of engine oil directly helps ensure reliable working and prevention of parts

from being abnormally worn-off. A natural air-intake type engine should use oil of Class CC (or

Class CD), while a supercharge type engine should use oil of Class CD. In addition, selection of

engine oil brands also bases on engine's operating ambient temperature (see Table 2-2). For

example, 15W/40# oil should be selected for Class CC or CD, when ambient air temp is -15℃.

10 0 -10 -20 -35

18 4 -5 -14 -29

11

Loading...

Loading...