FAULHABER 3564K024B CC User Manual

/

FAULHABER 运动控制器

操作手册

FAULHABER

FAULHABER GROUP

We create motion

3564K024B CC

MCBL3003/06 C

MCDC3003

06 C

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

目 录

0、关于版本、版权和免责申明 ··················································8

0.1、原文版本、版权和免责申明 ································································ 8

0.2、中文版说明和免责申明······································································ 8

1、简介···············································································9

1.1、概述 ···························································································· 9

1.1.1、3564K024B CC ························································································9

1.1.2、MCBL3003/06 C·······················································································9

1.1.3、MCDC3003/06 C ······················································································9

1.1.4、应用领域······························································································10

1.1.5、备注 ··································································································· 10

1.2、快速入门······················································································10

1.2.1、通过 Motion Manager 执行控制 ··································································10

1.2.2、通过其它上位机执行控制··········································································11

2、安装············································································· 13

2.1、端口说明与安装维护 ·······································································13

3564K024B CC··························································································13

MCBL3003/06 C ························································································ 13

MCDC3003/06 C························································································ 13

电源的连接(+24V 和 GND)········································································ 14

模拟信号输入(AnIn、AGND)······································································ 14

连接到 CAN······························································································14

故障输出端(Fault)··················································································· 14

第三输入端(3.In)····················································································15

第四、第五输入端(4.In、5.In,仅对 MCDC 类驱动器有效) ································· 15

2.1.1、安装 ··································································································· 15

2.1.2、日常维护······························································································15

2.1.3、专业维护······························································································15

2.2、关于 CAN 的连线 ············································································15

2.3、电机的接线···················································································16

MCBL3003/06 C ························································································ 16

MCDC3003/06 C························································································ 16

2.4、波特率和节点地址 ··········································································17

2.5、基本设置······················································································17

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 2 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

3、驱动器功能 ···································································· 19

3.1、位置控制······················································································19

3.2、速度控制······················································································20

3.2.1、通过 CAN 执行速控 ·················································································20

3.2.2、通过模拟信号执行速控············································································· 21

设置调速比例(最高速度) ·········································································· 21

设置最低速度 ···························································································21

设置启动电压 ···························································································21

设置电机旋转方向······················································································22

采用 PWM 信号执行速控(SOR2)··································································22

3.3、寻零功能和限位开关 ·······································································22

设置数字输入端的电平规格 ·········································································· 23

设置 Fault 为定位或限位开关信号输入端··························································· 23

在 FAULHABER 模式下配置寻零功能和限位开关··················································23

定义触发极性和限位开关功能········································································ 24

定义寻零方式 ···························································································24

寻零速度 ·································································································24

通过 HA、HL 和 HN 指令直接编程···································································25

HL 和 SHL 指令·························································································· 25

3.4、附加工作模式 ················································································25

3.4.1、步进模式······························································································25

输入信号参数 ···························································································26

3.4.2、减速电机(电子齿轮)模式 ······································································· 26

3.4.3、模拟电压位控模式 ·················································································· 27

通过 PWM 信号执行位控(SOR2)··································································27

单圈以内的绝对位置定位 ············································································· 28

3.4.4、双闭环工作模式(MCDC 类驱动器不适用)···················································· 28

输入信号参数 ···························································································28

设置编码器分辨率······················································································28

3.4.5、调压器模式··························································································· 29

在 SOR0 下使用 CAN 设置 ············································································29

在 SOR1 下使用模拟电压设置········································································29

在 SOR2 下使用 PWM 信号设置······································································29

3.4.6、模拟限流模式 ························································································ 29

3.4.7、MCDC 类驱动器的开环速控模式··································································29

3.5、Fault 的特殊功能 ······················································································ 29

作为故障指示 ···························································································30

作为脉冲信号输出(MCDC 类驱动器无效) ·······················································30

作为数字输出 ···························································································30

3.6、技术信息······················································································31

3.6.1、正弦换向······························································································31

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 3 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

3.6.2、电流控制器与 I2t 电流限制 ········································································ 31

电流控制器的工作模式 ················································································31

3.6.3、过热保护······························································································32

如何获取驱动器外壳和功放模块的温度 ····························································32

3.6.4、欠压监测······························································································32

3.6.5、过压调节······························································································32

3.6.6、驱动器参数调节 ·····················································································32

常规调节方式 ···························································································33

4、CANopen······································································· 34

4.1、简介 ···························································································34

4.2、PDO(过程数据对象) ·····································································34

RxPDO1:控制字 ······················································································· 35

TxPDO1:状态字 ·······················································································35

RxPDO2:FAULHABER 指令 ·········································································· 35

TxPDO2:FAULHABER 应答数据·····································································35

RxPDO3:参数解析配置 ··············································································35

TxPDO3:被解析的参数···············································································35

4.3、SDO(服务数据对象) ·····································································36

4.4、紧急对象(错误消息)·····································································37

4.5、NMT—网络管理 ·············································································38

Boot-Up(启动成功的消息)········································································· 39

节点保护 ·································································································39

标识符的分配 ···························································································40

4.6、对象字典入口 ················································································41

所有可用的对象分类 ··················································································· 41

4.7、驱动控制(设备控制)·····································································43

5、扩展的 CAN 功能 ····························································· 45

5.1、FAULHABER 通道············································································45

5.2、参数解析······················································································45

6、参数详解 ······································································· 47

6.1、遵从 DS301 的通讯对象····································································47

设备类型 ·································································································47

错误寄存器 ······························································································ 47

设备制造商名称························································································· 47

制造商硬件版本························································································· 48

制造商软件版本························································································· 48

监测保护时间 ···························································································48

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 4 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

寿命因数 ·································································································48

参数存储 ·································································································48

参数重置 ·································································································48

紧急消息的通讯对象标识符 ·········································································· 49

身份对象 ·································································································49

SDO 服务参数 ···························································································49

PDO1 接收上的通讯参数 ·············································································· 49

PDO2 接收上的通讯参数 ·············································································· 49

PDO3 接收上的通讯参数 ·············································································· 50

PDO1 接收上的映射参数 ·············································································· 50

PDO2 接收上的映射参数 ·············································································· 50

PDO3 接收上的映射参数 ·············································································· 50

PDO1 发送上的通讯参数 ·············································································· 50

PDO2 发送上的通讯参数 ·············································································· 51

PDO3 发送上的通讯参数 ·············································································· 51

PDO1 发送上的映射参数 ·············································································· 51

PDO2 发送上的映射参数 ·············································································· 51

PDO3 发送上的映射参数 ·············································································· 51

6.2、制造商定义的对象 ··········································································51

FAULHABER 指令 ······················································································· 51

FAULHABER 指令的返回值 ············································································52

解析配置 ·································································································52

解析的数据 ······························································································ 52

限位开关设置 ···························································································52

应答开关 ·································································································53

FAULHABER 错误寄存器···············································································53

6.3、DSP402 下的概要对象······································································54

设置波特率 ······························································································ 54

6.3.1、设备控制······························································································54

控制字 ···································································································· 54

状态字 ···································································································· 55

操作模式 ·································································································56

显示操作模式 ···························································································56

6.3.2、商群 ··································································································· 56

位置因数 ·································································································56

速度因数 ·································································································56

加速度因数 ······························································································ 57

加速度因数 ······························································································ 57

6.3.3、复合位控模式 ························································································ 57

目标位置 ·································································································57

软限位 ···································································································· 57

最大复合速度 ···························································································57

复合加速度 ······························································································ 58

复合负加速度 ···························································································58

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 5 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

制动的负加速度························································································· 58

复合运动类型 ···························································································58

控制效果 ·································································································58

位控参数设置 ···························································································58

6.3.4、寻零模式······························································································60

寻零偏移 ·································································································60

寻零方式 ·································································································60

寻零速度 ·································································································62

寻零加速度 ······························································································ 62

6.3.5、位控功能······························································································62

目标位置查询 ···························································································62

实际位置查询(增量) ················································································62

实际位置查询(比例) ················································································62

位置窗口 ·································································································62

位置窗口时间 ···························································································63

6.3.6、复合速控模式 ························································································ 63

实际速度查询 ···························································································63

目标速度查询 ···························································································63

速度实际值 ······························································································ 63

速度窗口 ·································································································63

速度窗口时间 ···························································································63

阀值速度 ·································································································63

阀值速度时间 ···························································································64

目标速度 ·································································································64

速控参数设置 ···························································································64

6.3.7、其它项目······························································································64

电机型号 ·································································································64

6.4、FAULHABER 指令············································································64

6.4.1、基本设置指令 ························································································ 65

6.4.1.1 用于 FAULHABER 操作模式的指令 ························································· 65

6.4.1.2、用于基本设置的指令 ·······································································66

6.4.1.3、用于设置常规参数的指令··································································67

6.4.1.4、用于设置 Fault 和数字输入端的指令····················································· 68

6.4.1.5、FAULHABER 模式下设置寻零和限位开关的指令 ·······································68

6.4.2、基本查询指令 ························································································ 69

6.4.2.1、查询操作模式和常规参数的指令 ························································· 69

6.4.2.2、查询 Fault 和数字输入端状态的指令····················································· 71

6.4.2.3、查询 FAULHABER 模式下寻零功能的配置的指令 ······································72

6.4.3、其它指令······························································································72

6.4.4、运动控制指令 ························································································ 72

6.4.5、常规查询指令 ························································································ 73

7、附录············································································· 75

7.1、关于电磁兼容性(EMC) ··································································75

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 6 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

进一步减少来自电源的干扰 ·········································································· 75

7.1.1、预期用途······························································································ 75

7.1.2、CE 标志 ·······························································································75

7.2、出厂设置······················································································76

3564K024B CC··························································································76

MCBL3003/06 C ························································································ 77

MCDC3003/06 C························································································ 77

7.3、全部 FAULHABER 指令索引 ································································78

7.4、英文词汇与术语的中文解释说明··························································79

7.5、关于 CAN 连接时的疑难解答 ······························································82

7.6、联系信息······················································································83

7.6.1、FAULHABER 集团总部 ··············································································83

7.6.2、FAULHABER 集团中国总代理······································································ 83

7.6.3、北京信达恒科贸有限公司 ··········································································83

7.7、中文版本信息 ················································································84

7.8、中文版勘误与修订记录 ·····································································84

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 7 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

0、关于版本、版权和免责申明

0.1、原文版本、版权和免责申明

文本版本:第二版,2006 年 7 月 1 日发行。

运动控制器(以下简称“驱动器”)固件版本:

¾ 无刷(MCBL)系列与 3564K024B CC:605.3150.51O;

¾ 有刷(MCDC)系列:605.3150.52O。

FAULHABER 集团版权所有。未经 FAULHABER 集团书面许可,对本文(包括本文所有语种的译本)内

容的转载、摘录、引用和收录等行为,均有可能违反版权法。

尽管编著时几经审核,但 FAULHABER 集团并不保证本文所记载、描述的内容和通过本文内容推断出

的任何结果的正确性。同时,对用户误操作而导致的所有直接和间接损失,FAULHABER 集团不承担任何

责任。

本文所有关于系统安全和干扰抑制的说明,请用户遵照执行以达到理想效果。

FAULHABER 集团保留对本文内容的修改权。

0.2、中文版说明和免责申明

FAULHABER 原文不包括此章节。

本文译自 FAULHABER 集团发布的 3564K024 BCS、MCDC3003 /06 S 和 MCBL3003/06S驱动器用户手

册英文版。为方便用户阅读,文中采用了不同颜色和格式的文字,其代表的意义如下:

¾ 红色:需要特别注意的地方。忽略红色文字的说明内容,将可能导致设备无法使用甚至损坏;

¾ 粉红:FAULHABER指令或FAULHABER Motion Manager 3中的菜单项、对话框等;

¾ 紫色:中文版添加的注释和说明等;

¾ 绿色:专用术语等;

¾ 橙色:代表驱动器端口名称;

¾ 浅绿底色:在文中首次出现英文缩写或专用术语,点击可跳转到附录,查看对应的详细解释说明;

¾ 蓝色下划线:带有超级链接,点击后可以跳转到相关内容,有可能需要访问互联网资源。

因编译者水平有限,本文的疏漏错误在所难免,因此本文内容仅供用户参考,最终说明均以FAULHABER

的官方版本(可能是德语或英语版)为准。因引用、采信、执行本文所描述、记载和说明的任何内容而可

能引起的所有不良后果,FAULHABER 集团和其中国代理商、本文编译者均不承担任何责任。

注意:您一旦参考本文内容,就意味着您完全知道、理解并且接受上述申明。

如果您对本文有任何疑问或建议,欢迎发送电子邮件到

9411 进行指正,更多联系方式请参阅我们的

联系信息。

zh-jane@bjxdh.com.cn或拨打电话 010-8811

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 8 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

1、简介

1.1、概述

本文介绍以下几款带有CANopen接口的驱动器的功能和使用方法等:

1.1.1、3564K024B CC

将直流无刷伺服电机 3564K024B、高分辨率的绝对式编码器和驱动器集成为一体。

1.1.2、MCBL3003/06 C

用于驱动控制带线性霍尔传感器(订货代码:K1155)的无刷伺服电机。无需外加编码器,即可实现

高精度的速度和位置控制。

1.1.3、MCDC3003/06 C

用于控制 FAULHABER 集团的各种直流微电机。

驱动器基于高速DSP开发,可对电机执行速度和位置控制(以下分别简称“速控”与“位控”),在极

低的转速下,也能保证非常高的位置精度。驱动器主要功能如下:

¾ 速控: PI调节器确保电机速度的实际值与目标值高度一致,调节速度时,电机扭矩波动极低;

¾ 曲线运动:可以实现斜线、三角形、梯形和更复杂的曲线轮廓运动,支持软启动与制动;

¾ 位控:零点可任意定义,对于带线性霍尔传感器的无刷伺服电机,其位置精度高达 1/3 000 圈;

¾ 参考信号与限位开关:运动过程中可随时捕捉和定义;

¾ 多种工作模式:例如步进模式、模拟电压位控模式、调压器模式、减速电机(电子齿轮)模式等

不一而足,其中 MCDC3003/06 C 还具有开环速控模式、MCBL3003/06 C 还具有双闭环模式;

¾ 扭矩控制:通过调整电流限制值来实现;

¾ 参数存储:所有配置参数均可写入驱动器,不会因为断电而丢失。

各输入、输出端口的功能如下:

¾ 设定目标速度的信号输入端:可接收模拟电压或者PWM信号,也可作为数字信号输入端,信号源

可以是频率信号发生器与增量式编码器等。

¾ 故障输出(集电极开路)端:也可被定义为电机旋转方向控制端、数字信号输入端、脉冲或数字

信号输出端。

¾ 附加的数字输入端口 1~3:作为数字信号输入端,用于配置限位开关等。

各驱动器端口的详细功能说明,请参阅第 2.2 章节

具备CANopen接口,数据传输速率最高可达 1 兆字节每秒,接口遵从DS301 V 4.02和DSP402V 2.0行

规,提供CiA关于从设备规范的如下功能与服务:

¾ 1 路SDO;

¾ 3 路PDO发送,3 路接收;

¾ 静态 PDO 映射;

¾ 带节点保护的NMT;

¾ 紧急对象。

波特率和节点地址可通过DSP305 V1.1 的LSS协议设置,波特率也可选择自动匹配。

另外,驱动器所有参数和功能设置,均可通过FAULHABER PDO专用通道——PDO2 轻松实现。每一个

FAULHABER指令,都通过PDO2 映射成为一个CAN帧并传输。类似操作同样适用于CAN上任意节点的连续

端口说明与安装维护。

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 9 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

变量。对于Windows用户,可辅助以F AULHABER Motion Manager 3 专用软件(以下简称“Motion Manager”)

简化所有工作,该软件还提供系统状态和参数的实时监测功能。

1.1.4、应用领域

驱动器结构紧凑、易于连接,可轻松融入用户系统。可选的柔性连接方式,更为各领域的设计者开创

了新思路。因此,驱动器在各种自动化系统、动力系统和机械工具等方面的应用中大放异彩。

1.1.5、备注

驱动器的运算控制与功放电路可实行分离供电(请注意自行配置相关的保险),此时驱动器的3.In为运

算控制电路单独供电。FAULHABER还可将用户要求的参数作为出厂设值,最大限度地方便用户。以上两点

需要在订货时说明。

Motion Manager可免费索取或从

还可从

http://www.bjxdh.com.cn/免费获取中文版。

http://www.faulhaber.com/下载德文和英文版,习惯使用中文的用户

1.2、快速入门

本节简要介绍在 Motion Manager 下,通过 CAN 接口快速配置驱动器和试车的方法。

若要深入了解和掌握具体操作方法,请参阅第 2.5 章节

新的驱动器并未分配有效的网络节点地址(节点标示符=0xFF),其默认波特率为自动匹配。

要设置波特率和网络节点地址,必须先将驱动器和相应的配置工具通过 CAN 连接。配置工具应支持

CiA DSP305 中的 LSS 协议。如果您的计算机支持 CAN 接口,建议使用 Motion Manager 作为驱动器的配

置工具,即可进行设置。

驱动器联网后,若网络中仅有单台设备,则可采用全局方式,通过兼容LSS协议的工具设置波特率和

节点地址;对于多台设备,则应使用独选方式,通过各设备的标识符一一设置(详情参阅第 2.4 章节波特

率和节点地址)。

采用 Motion Manager 作为配置工具时,请按以下步骤操作:

1、 将驱动器和计算机通过 CAN 接口连接;

2、 启动 Motion Manager;

3、 选择通讯Æ配置计算机通讯参数,激活 CAN 接口;

4、 选择配置Æ通讯参数;

5、 选择配置模式:

A)、若网络中只有一个 LSS 从站,或者说网络中仅有一台驱动器,请选择全局方式;

B)、若网络中有多个LSS从站,或者说网络中有多个驱动器,通常应使用独选方式,如果某设备未能

被节点管理器搜索到,请将输入该节点上驱动器的设备序列号,同时检查其它配置是否正确。

6、 在接下来的对话框中,选择需要的波特率或选择自动匹配,然后输入一个节点地址;

7、 按下发送;

8、 Motion Manager将开始寻址并将结果列入节点管理器。驱动器断电重启后,上述设置依然有效。

基本设置。

系统启动后,CANopen上所有节点都将处于一种预操作状态。要进一步操作,需让系统进入到操作状

态。PDO无法在预操作状态下通讯。因此,在此状态下,所有的FAULHABER指令均无法执行。除NMT功能

之外,要设置对象字典中的参数,只能采用SDO通讯(详情参阅第 4 章节

CANopen)。

1.2.1、通过 Motion Manager 执行控制

通过指令ÆCANopen或在节点管理器内鼠标右击,Motion Manager可以方便地访问CANopen上的状态

机。要对某一节点执行操作,必须首先在节点管理器中鼠标双击以激活目标节点,激活后的目标节点当前

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 10 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

状态,将在Motion Manager底部的状态提示栏显示。

下文用到的FAULHABER指令可从指令输入框输入,也可使用指令菜单选取。指令发送后,Motion

Manager自动调用译码器将其翻译并映射为CAN报文帧,通过PDO传输。

要通过 Motion Manager 控制电机,请按如下操作(假设节点地址有效且波特率已匹配):

1、 启用网络节点(远程节点):在节点管理器中鼠标右击,打开关联菜单,选择 CANopen 网络管理

Æ启用远程节点,或者通过菜单栏上的指令ÆCANopen,接下来即可使用 FAULHABER 指令;

2、 配置驱动器功能:通过配置Æ驱动器功能调出配置驱动器功能对话框。

注意:对于MCBL3003/06 C,必须确保所连接的电机型号,与基本参数选项卡中所显示的一致;而对

于MCDC3003/06 C,则必须确保在附加参数选项卡中,编码器的分辨率(ENCRES)设置无误。(详情参阅

第 2.5 章节

接下来选择控制模式。可供选择的控制模式(OPMOD)代码为 1、3、6 和-1,分别代表选择标准的

通用 CANopen 对象控制模式和更简洁的 FAULHABER 模式,要保存该设置,请按下写入。

3、 初始化驱动器:

1)、 FAULHABER 模式 OPMOD-1:

A)、EN:在指令输入框中输入 EN 后按下发送;或通过菜单指令Æ运动控制指令Æ初始化驱动器,然

2)、 CANopen 控制模式 OPMOD1、3、6:

A)、关闭设备:使用菜单指令ÆCANopen 或在节点管理器中鼠标右击,打开关联菜单,选择设备Æ关

B)、打开设备:使用菜单指令ÆCANopen 或在节点管理器中鼠标右击,打开关联菜单,选择设备Æ打

4、 驱动电机(举例):

以 100rpm的速度驱动电机:

1)、 FAULHABER 模式 OPMOD-1:

V100:在指令输入框中输入 V100 后发送,或选取指令Æ运动控制指令Æ启动并执行速控菜单,在弹

出的对话框中输入“100” (不含外侧双引号,下同)后按下 OK,然后按下发送。

2)、 CANopen 下的复合速控模式 OPMOD3:

设置目标速度值为 100(对象 0x60FF)。

5、 制动电机:

1)、 FAULHABER 模式 OPMOD-1:

V0。

2)、 CANopen 下的复合速度模式 OPMOD3:

设置目标速度值为 0(对象 0x60FF)或选择脱离受控。

6、 让电机在当前位置前进 10 000:

1)、 FAULHABER 模式 OPMOD-1:

LR10000 :指定目标位置为相对位置 10 000,然后使用 M 指令启动电机向目标位置运动。

2)、 CANopen 下的复合位置模式 OPMOD1:

设置目标位置值为 10 000(对象 0x607A)然后执行。(通过设置目标位置并将状态字设为相对)。

基本设置)。

后按下发送。

闭设备;

开设备。

1.2.2、通过其它上位机执行控制

启动 CANopen 节点:通过广播指令启动远程节点,可将网络上某节点或整个网络切换到操作状态。

11 位标识符 2 字节用户数据

0x000 01 00

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 11 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

数据首字节包含启动远程节点这个启动指令,第二字节包含目标设备在网络中节点地址或者为零。

节点启动后,所有功能也一并激活。采用遵从 CiA DSP402 的设备控制功能、或在 PDO2 中使用

FAULHABER 指令,均可启动和控制驱动器。

各设备标识符的分配依照预设值并由节点地址确定(详情参阅第 4.5 章节

最为重要的若干对象:

对象 功能 标识符 对象 功能 标识符

TxPDO1

RxPDO1

TxPDO2

驱动器启动时,工作在 OPMOD1(复合位控模式)下。该模式是通过状态机控制器来控制驱动器:通

过控制字(对象 0x6040 或 RxPDO1)执行控制;通过状态字(对象 0x6041 或 TxPDO1)执行查询。

以下指令是用以激活驱动器功放输出以驱动电机:

¾ 关闭设备:控制字=0x06

¾ 打开设备/可操作状态:控制字=0x0F

此时驱动器已处于受控状态,可使用复合位控模式执行控制(详情参阅第 4.7 章节

制)和 6.3.3 章节复合位控模式)。

利用对象字典中的对象,通过SDO可设置驱动器的功能。当然,采用FAULHABER模式,通过PDO2 对

驱动器进行设置更加方便。同时,并非所有功能的设置都支持对象字典方式,许多附加工作模式只能在

FAULHABER模式下实现。(详情参阅第 6 章节

用户无需深入了解 CANopen 方面的知识,例如关于设备控制、SDO 协议和对象字典等,也可轻松使

用驱动器的全部功能。FAULHABER 模式支持驱动器所有指令并大幅度简化操作,这一切只需要将模式设

置为 OPMOD-1(FAULHABER 模式):

状态字 0x180+ 节点地址

控制字 0x200 + 节点地址

FAULHABER 数据 0x280 + 节点地址

参数详解)

RxPDO2

TxSDO

RxSDO

FAULHABER 指令 0x300 + 节点地址

读取对象 0x580 + 节点地址

写入对象 0x600 + 节点地址

NMT—网络管理)。以下是

驱动控制(设备控

RxPDO2:FAULHABER 指令 OPMOD-1。

11 位标识符 5 字节用户数据

0x300(768D)+ 节点序号

按照以下格式,所有 FAULHABER 指令均可应用于驱动器控制:

11 位标识符 5 字节用户数据

0x300(768D)+ 节点序号 指令 LLB LHB HLB HHB

举例:ID301:93 F4 01 00 00 Æ节点 1 的驱动器,控制电机速度为 500rpm(V500)。

关于所有可用的指令列表,请参阅 6.4 章节

0xFD 0xFF 0xFF 0xFF 0xFF

FAULHABER指令。

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 12 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

2、安装

2.1、端口说明与安装维护

3564K024B CC

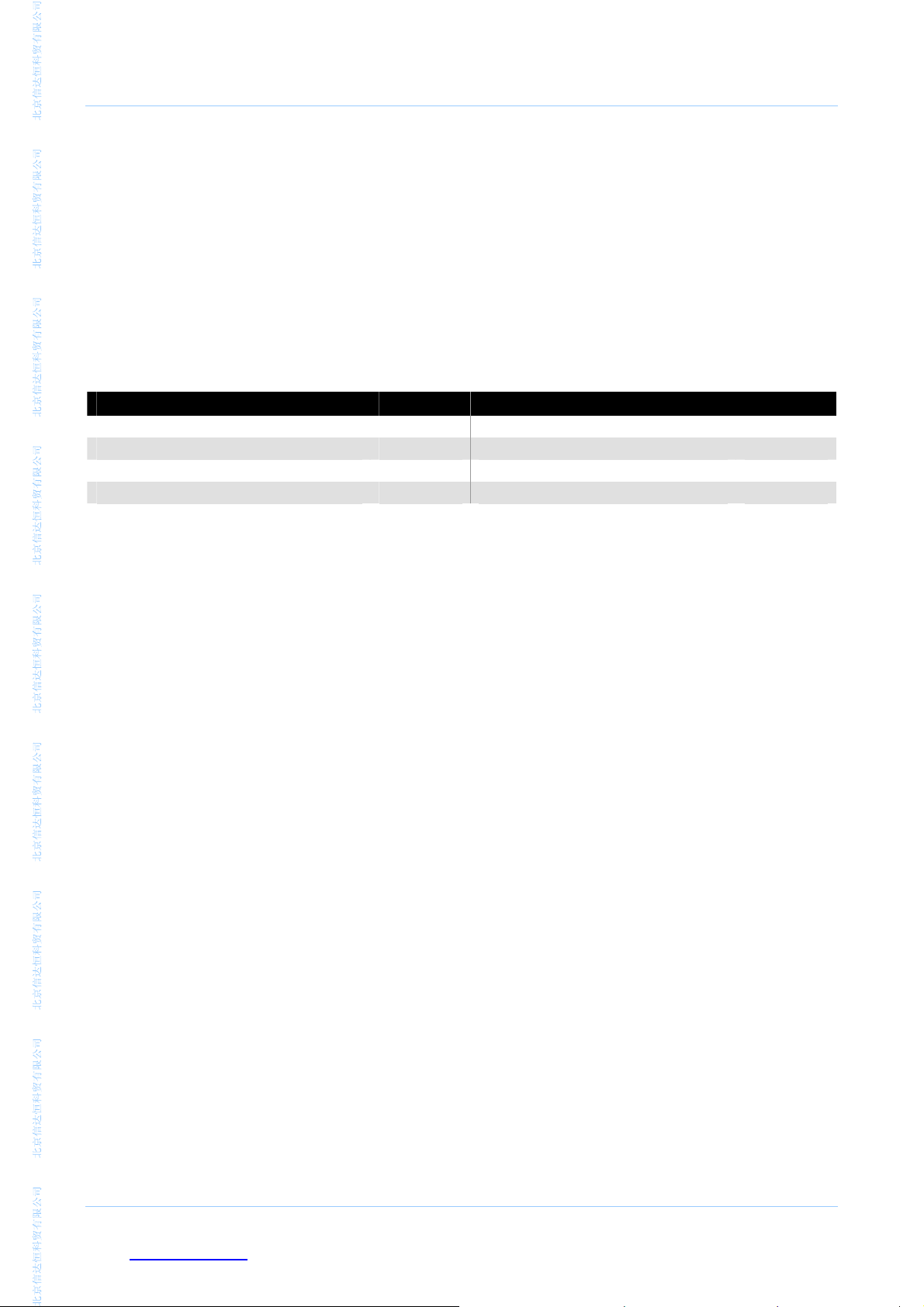

标准产品的出线以颜色区分,功能如下:

线色 名称 含义与功能

蓝色

粉红

褐色

白色

灰色

黄色

绿色

红色

MCBL3003/06 C

GND

+24V

AnIn

Fault

AGND

CAN_L

CAN_H

3. In

电源地

24V 电源电压输入端

模拟信号输入端

故障输出端

模拟信号地

CAN_L / RS-232 接收端 *

CAN_H / RS-232 发送端 *

第三输入端 / 运算控制电路电源 **

连接端定义与功能如下:

电源端

端口 含义与功能 端口 含义与功能

CAN_H

CAN_L

AGND

Fault

AnIn

+24V

GND

3. In

驱动器集成标准串行数据接口样式的“D”型 9 芯插头,其针脚与功能如下:

针脚序号 含义与功能

2

3

7

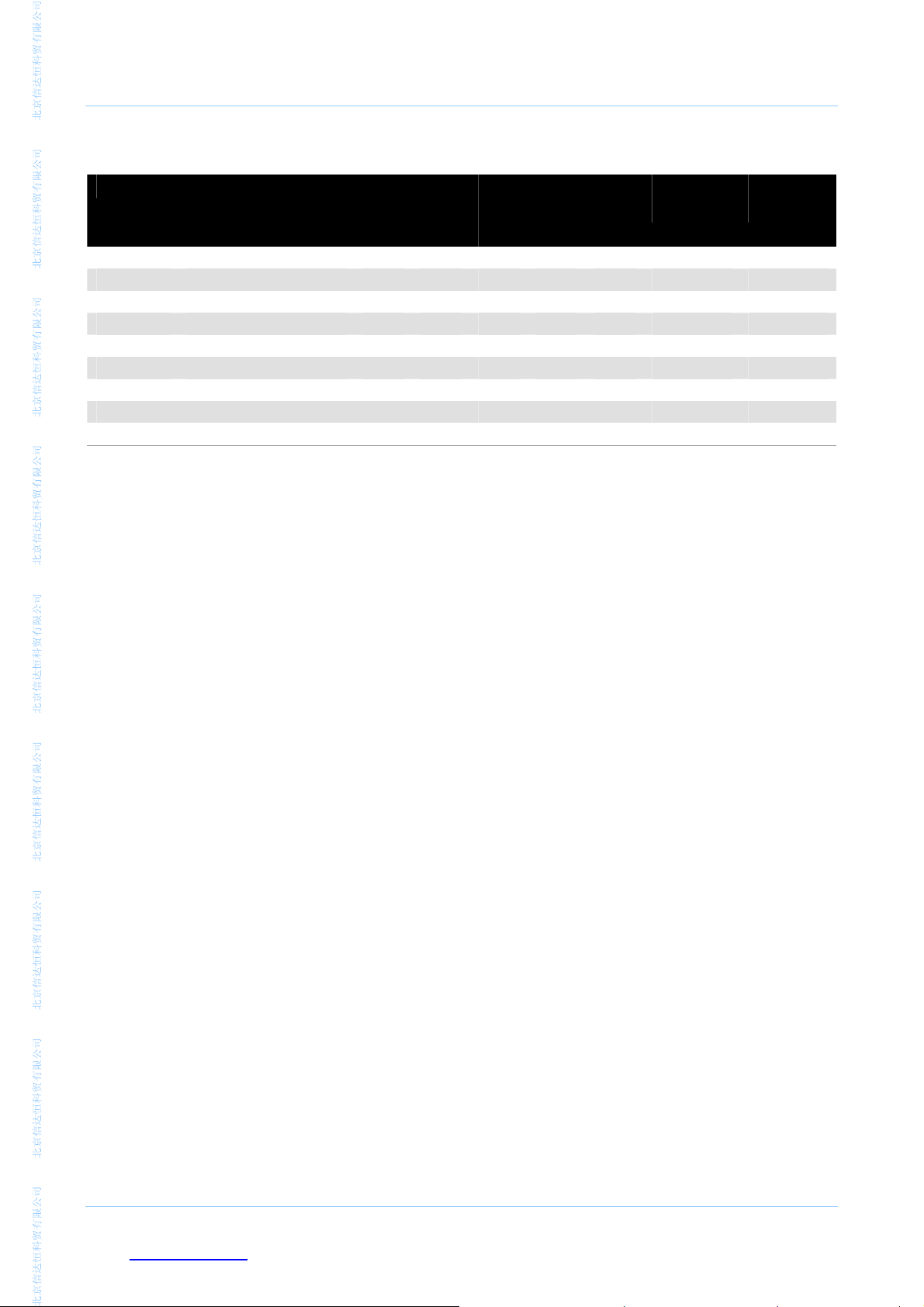

MCDC3003/06 C

电源端

端口 含义与功能 端口 含义与功能

CAN_H

CAN_L

AGND

Fault

AnIn

+24V

GND

3. In

CAN_H / RS-232 发送端 *

CAN_L / RS-232 接收端 *

模拟信号地

故障输出端

模拟信号输入端

24V 电源电压输入端

电源地

第三输入端 / 运算控制电路电源 **

CAN_L / RS-232 接收端 *

地

CAN_H / RS-232 发送端 *

CAN_H / RS-232 发送端 *

CAN_L / RS-232 接收端 *

模拟信号地

故障输出端

模拟信号输入端

24V 电源电压输入端

电源地

第三输入端 / 运算控制电路电源 **

电机端

Ph A

Ph B

Hall C

Hall B

SGND

+5 V

Hall A

Ph C

电机端

Mot Mot +

SGND

+5 V

Ch B

Ch A

4.In

5.In

电机绕组 A 相(褐色)

电机绕组 B 相(橙色)

霍尔传感器 C(灰色)

霍尔传感器 B(蓝色)

信号地(黑色)

+5V 电压输出端 Vcc (红色)

霍尔传感器 A(绿色)

电机绕组 C 相(黄色)

电机电源负

电机电源正

编码器信号地

编码器电源正

编码器信号 B 通道

编码器信号 A 通道

第四输入端

第五输入端

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 13 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

驱动器集成标准串行数据接口样式的“D”型 9 芯插头,其针脚与功能如下:

针脚序号 含义与功能

2

3

7

* RS232 功能仅限升级软件时使用。

** 为可选配置。

电源的连接(+24V 和 GND)

选择电源时,应充分考虑到所连电机的最大功率。请一定注意电源极性,电源反接将导致驱动器内置

保险烧毁。烧毁保险后,驱动器只能返厂维修。

模拟信号输入(AnIn、AGND)

AnIn 可接受多种信号的输入。

AGND 应与 GND 共地,以避免零点漂移和导线电阻所引起的压降而影响控制精度。

根据不同配置,AnIn 可以有以下功能:

CAN_L / RS-232 接收端 *

地

CAN_H / RS-232 发送端 *

¾ 输入模拟电压以控制电机的速度;

¾ 输入 PWM 信号以控制电机的速度;

¾ 输入模拟电压限制电流;

¾ 输入模拟电压以控制电机的位置;

¾ 作为限位开关,通过输入数字信号来控制;

¾ 减速电机或 MCBL 类驱动器的双闭环模式下,外接编码器信号(AnIn 接 A 通道;AGND 接 B 通道)。

连接到 CAN

CAN_H、CAN_L 和 GND 三个端口。对驱动器行固件升级时,这三个端口还可直接与计算机 RS-232

串口连接。

故障输出端(Fault)

Fault 特性如下:

¾ 接地开关功能,可转为接地(集电极开路);

¾ 开路状态下的输出阻抗(高电平):100 kΩ;

¾ 当驱动器出现故障时,切换到开路状态(高电平);

¾ 最大负载电流不超过 30mA,最高电压不超过电源电压 U

B

;

¾ 防短路设计。

以下情形将导致 Fault 动作:

¾ 限流功能启动;

¾ 过压保护启动(电源电压超过 32V);

¾ 过热保护启动,关闭功放输出电路;

¾ 电机实际速度与目标速度的偏差超过 DEV 的限定。

Fault 还可配置成以下功能:

¾ 脉冲输出(对 MCDC 系列驱动器无效);

¾ 数字信号输出;

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 14 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

¾ 限位开关;

¾ 电机转向控制信号输入。

第三输入端(3.In)

数字信号输入端或限位开关。当驱动器的运算控制与功放输出电路分离供电时,在驱动器功放电路关

闭后,运算控制电路还可由 3.In 供电单独工作。

第四、第五输入端(4.In、5.In,仅对 MCDC 类驱动器有效)

作为数字输入端使用。

2.1.1、安装

驱动器设计为室内环境工作,应避免大量尘土或高浓度化学污染,保证环境清洁干燥、通风良好。将

驱动器置于机架或机盒内时,更需注意通风散热。

MCBL3006 C 与 MCDC3006 C 的外壳兼作散热片,工作时其表面最高温度可能超过 85℃。为使驱动器

正常工作并发挥最高性能,请确保电源电压在规定范围内。接线操作必须在驱动器断电后进行。

2.1.2、日常维护

原则上驱动器无需专门维护,MCBL3006 C 与 MCDC3006 C 的鳍状散热片需视其环境状况,作定期地

检查和清洁。清除散热片上附着的污物时,不可使用含卤素的清洁剂。

2.1.3、专业维护

如果驱动器发生意外,只有在下列专业领域具有丰富经验的工程师方可处理:

¾ EMC(电磁兼容)相关专业;

¾ 低压电器相关专业;

¾ 机械设备相关专业;

¾ 精通VDE相关的DIN(如DIN VDE 0100、DIN VDE0113/EN 0204、DIN VDE 0160/EN 50178 等);

¾ 意外事故预防相关专业。

安装和使用驱动器之前,请仔细阅读以上内容。

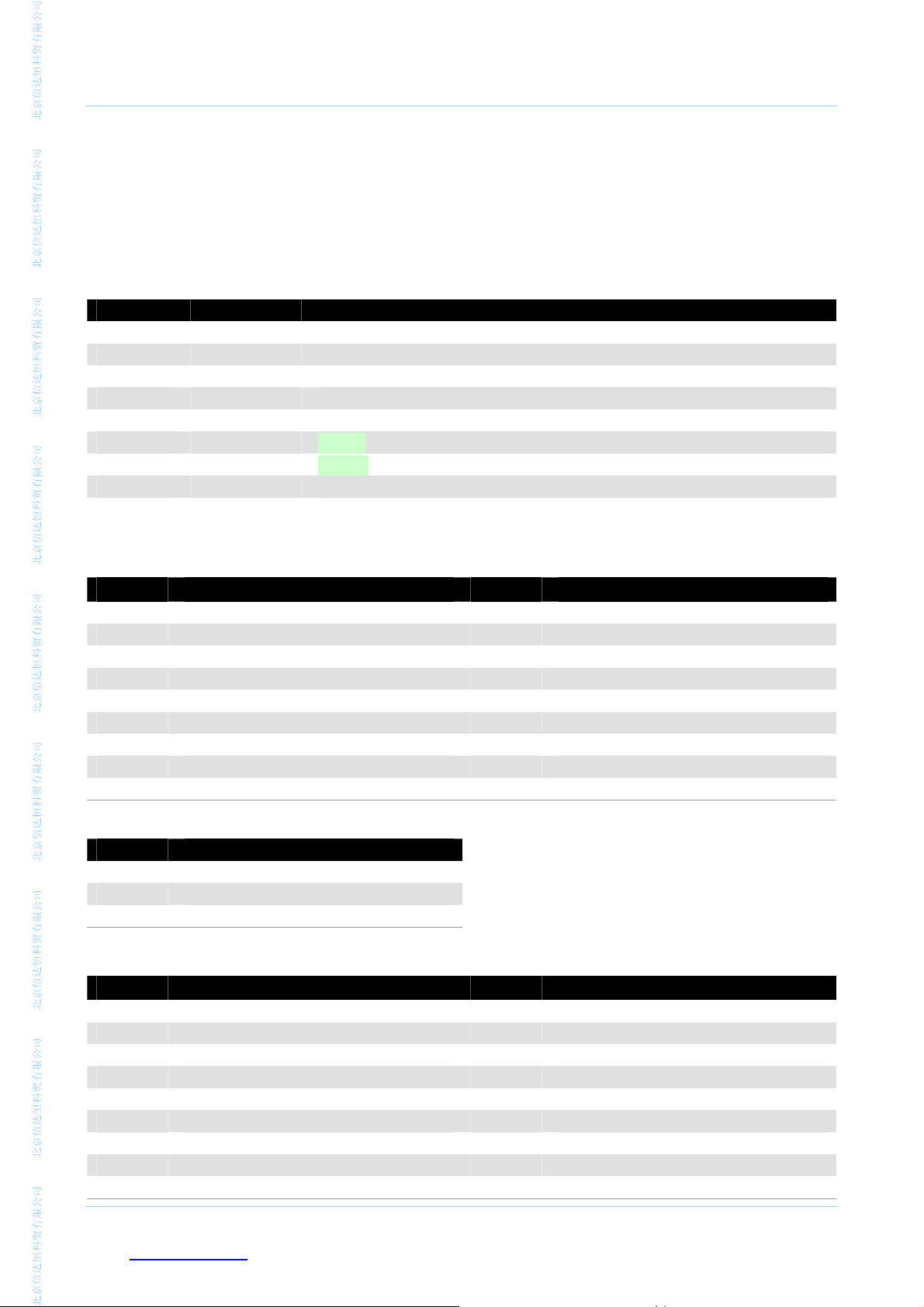

2.2、关于 CAN 的连线

节点

1

GND

CAN_ H

节点

n

CAN

总线

CAN_ L

作为一个双线总线系统,CAN 上的所有节点是并行连接的,总线终端必须外加一 120 Ω 的电阻跨接在

CAN_H 和 CAN_L 之间。除此之外,所有节点还应共地。

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 15 页,共 84 页

120Ω120Ω

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

受信号传输时间与波特率限制,节点连线的最大长度应遵循以下对应关系:

波特率 最大线长 波特率 最大线长

1 000 千比特/秒 25 米 50 千比特/秒 1 000 米

500 千比特/秒 100 米 20 千比特/秒 2 500 米

250 千比特/秒 250 米 10 千比特/秒 5 000 米

125 千比特/秒 500 米

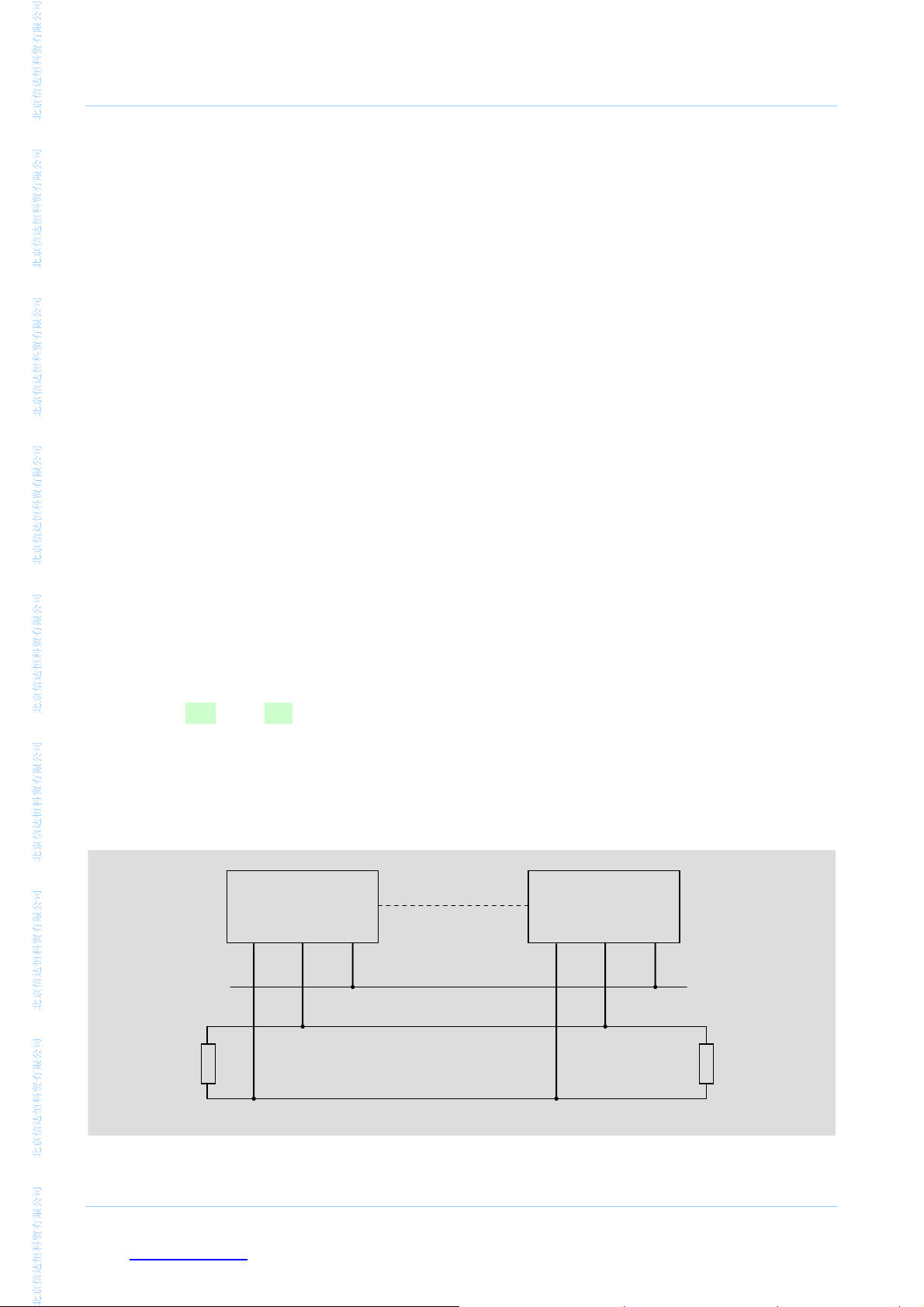

2.3、电机的接线

MCBL3003/06 C

由于霍尔信号易受干扰,因此虽然未规定最大线长,但长度超过 300mm 时,推荐采用屏蔽线。示意

图如下:

电机A相

电机B相

电机C相

外壳

信号地

+5V

霍尔传感器

霍尔传感器

霍尔传感器

外壳

褐色

橙色

黄色

黑色

电机A相

电机B相

电机C相

无刷伺服电机

红色

A

灰色

B

蓝色

C

绿色

霍尔传感器

霍尔传感器

霍尔传感器

A

B

C

MCDC3003/06 C

由于编码器信号易受干扰,因此虽然未规定最大线长,但长度超过 300mm 时,推荐采用屏蔽线。如

果采用了带信号差分放大的编码器(例如长线驱动),请考虑使用 FAULHABER 提供的 HEDL 适配板,代码

为 6501.00064(HEDL 是 HP 公司出品的一款带长线驱动的编码器)。示意图如下:

电机 +

电机 -

外壳

信号地

+5V

编码器A通道

编码器B通道

外壳

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 16 页,共 84 页

直流电机

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

2.4、波特率和节点地址

设置节点地址和波特率,需遵循 CiA DSP305 下的 LSS 协议。因此配置工具必须支持该协议——例如

Motion Manager。

将配置工具作为 LSS 主站,配置对象(驱动器)作为 LSS 从站。从站有以下两种配置方法:

¾ 全局方式:一条切换指令将所有节点的从站设备切换到配置模式。当然,在切换后,要设置节点

波特率和地址等,仅能对针对某唯一节点进行。

¾ 独选方式:一条切换指令只将网络中某一 LSS 从站切换到配置模式,使用该方式必须知道每一 LSS

从站设备的标识符、产品代码和序列号。通过序列号可以对每一个 LSS 从站设备进行独立的配置。

以下是可选择的波特率(速率参数):

波特率 索引 波特率 索引

1 000 千比特/秒

800 千比特/秒

500 千比特/秒

250 千比特/秒

另外,通过发送索引值 0xFF,可自动匹配波特率。

0

1

2

3

125 千比特/秒

50 千比特/秒

20 千比特/秒

10 千比特/秒

4

5

6

7

可使用的节点地址范围为:1~255。

地址 255(0xFF)表示节点尚未配置。LSS 初始化系统时,该地址将被系统占用,直到接收到一个有

效节点地址之后,NMT 才能继续。

LSS 协议还可读取设备的节点序号之外的其它信息,例如生产厂家标识符、产品代码、版本号和序列

号等。

在 LSS 协议中,标识符 0x7E5(主站)和 0x7E4(从站)用于 LSS 通讯,属系统占用的资源。

配置完成后,所有参数都存储于驱动器内的闪存中,不会随电源关闭而丢失。

若启用独选方式,FAULHABER 驱动器信息只包含生产厂家标识符、产品代码和序列号,版本号可输

入“0.0”,此协议下,该数值将被忽略。

¾ 生产厂家标识符:327;

¾ 产品代码:3150。

有关 LSS 协议的具体内容,请参阅 CiA 相关文档,文档编号为 DSP 305。

如果选择了波特率自动匹配,驱动器将通过报文帧探测和确定适当的波特率,通过最多 3 个报文帧的

测试,即可完成并自动调整就绪。请注意第一个报文帧有可能丢失,由此将导致探测过程的时间稍微延长。

2.5、基本设置

对于 MCDC 和 MCBL 类驱动器,为调校与驱动器连接的电机,试车前应进行一系列基本设置。该操作

可通过 Motion Manager 快速轻松地完成。

注意:忽略或错误的基本设置有可能损坏驱动器或电机!

MCBL3003/06 C 出厂时,默认所连接的电机为 MOTTYP5(2444S024B K1155)。若实际连接的电机与

此不同,您必须首先对此进行更改。更改之后,Motion Manager 将校准霍尔传感器信号的同步性,以使电

机转动更平稳;接着调整驱动电流的波形,使电机功效达到最高。所连接的电机型号一旦更改,都必须重

新执行以上操作。(选择配置Æ驱动器功能Æ基本参数,按下按选定型号电机执行参数校准。)

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 17 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

驱动器参数和电流限制值也必须符合所使用的电机和实际应用需求。

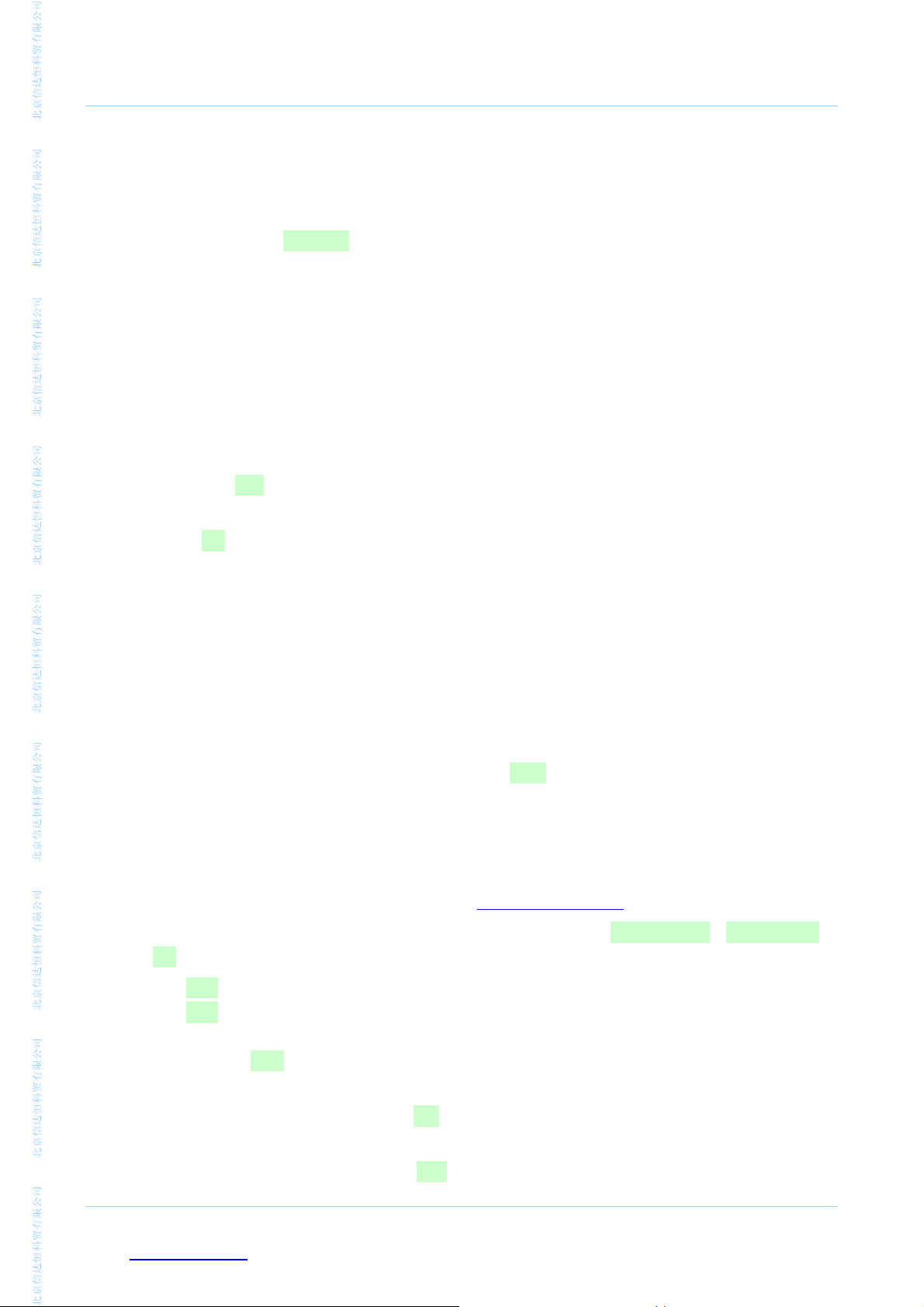

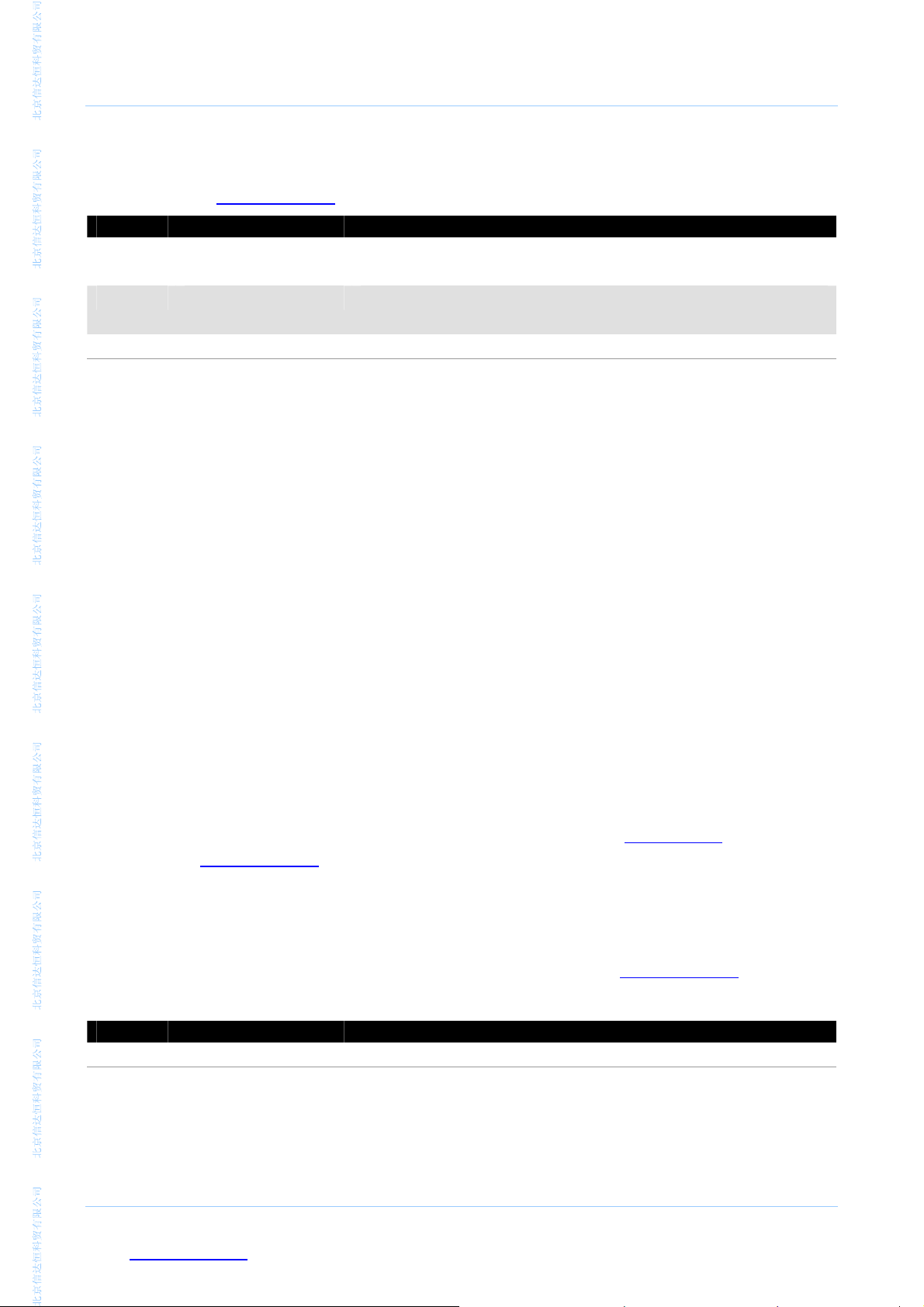

下表是 MOTTYP 所对应的实际电机型号,电机型号改变后,表中所列的内部参数也随之改变:

MOTTYP

电机型号 速控

比例

系数

速控

积分

系数

位控

比例

系数

位控

微分

系数

电流

系数

峰值电流

(mA)

连续电流

(mA)

1 1628T012B K1155 12 25 24 2 40 3 000 770

2 1628T024B K1155 12 22 8 10 40 3 000 410

3 2036U012B K1155 6 45 10 14 50 3 000 980

4 2036U024B K1155 14 25 17 6 50 3 000 480

5 2444S024B K1155 7 40 16 9 50 5 000 1 370

6 3056K012B K1155 8 30 22 13 50 7 000 1 940

7 3056K024B K1155 10 40 22 12 50 3 000 930

8 3564K024B K1155 8 40 12 6 50 8 000 2 800

9 4490H024B K1155 8 40 12 6 20 10 000 6 000

通过 MOTTYP 指定了电机型号后,上表中的各参数还可单独修改,RN 可以恢复参数到默认值。若所

连接的电机未在列表框中,请选择 MOTTYP0 并用 KN 和 RM 设置 Kn(速度常数)和 R

(电枢电阻),这

M

两个参数可从电机参数表中查询。

MCDC3003/06 C 出厂时,默认的编码器分辨率为 512 线( ENCRES2048,因为脉冲信号的每一周期可

以有 4 个采样点,所以为其物理分辨率的 4 倍)。修改此参数请使用 ENCRES 或在配置Æ驱动器功能Æ附

加参数中设置。

为防止电机在高速运行下、突然制动时所产生的反电动势击穿 MCDC3003/06 C 的功放输出电路,必

须依照电机参数表输入 K

(速度常数)和 R

n

(电枢电阻)。同样,驱动器的其它参数,例如最大电流限制

M

值(LPC 与 LCC)等,也必须适合具体应用需求,同时与所连接的电机相匹配。

若要将 Fault 作为输入端使用(使用 REFIN 或 DIRIN 设置),务必先设置完成、再输入控制信号!

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 18 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

Δφ

A

3、驱动器功能

通过设置,驱动器可以有不同的操作和工作模式。

驱动器出厂时,默认为遵从 CiA DSP402 行规的复合位控模式(OPMOD-1),可通过配置Æ驱动器功

能菜单进行修改。修改后的设置若需保存,请按下写入或使用 SAVE(以前的 EEPSAV)。

要设置不同的工作模式,首先应保证驱动器处于NMT中的操作状态、功放输出电路已经打开(处于打

开或受控状态)。所有指令和对象列表,请参阅第 6 章节

则请参阅 6.4 章节

FAULHABER指令在各工作模式下的说明。

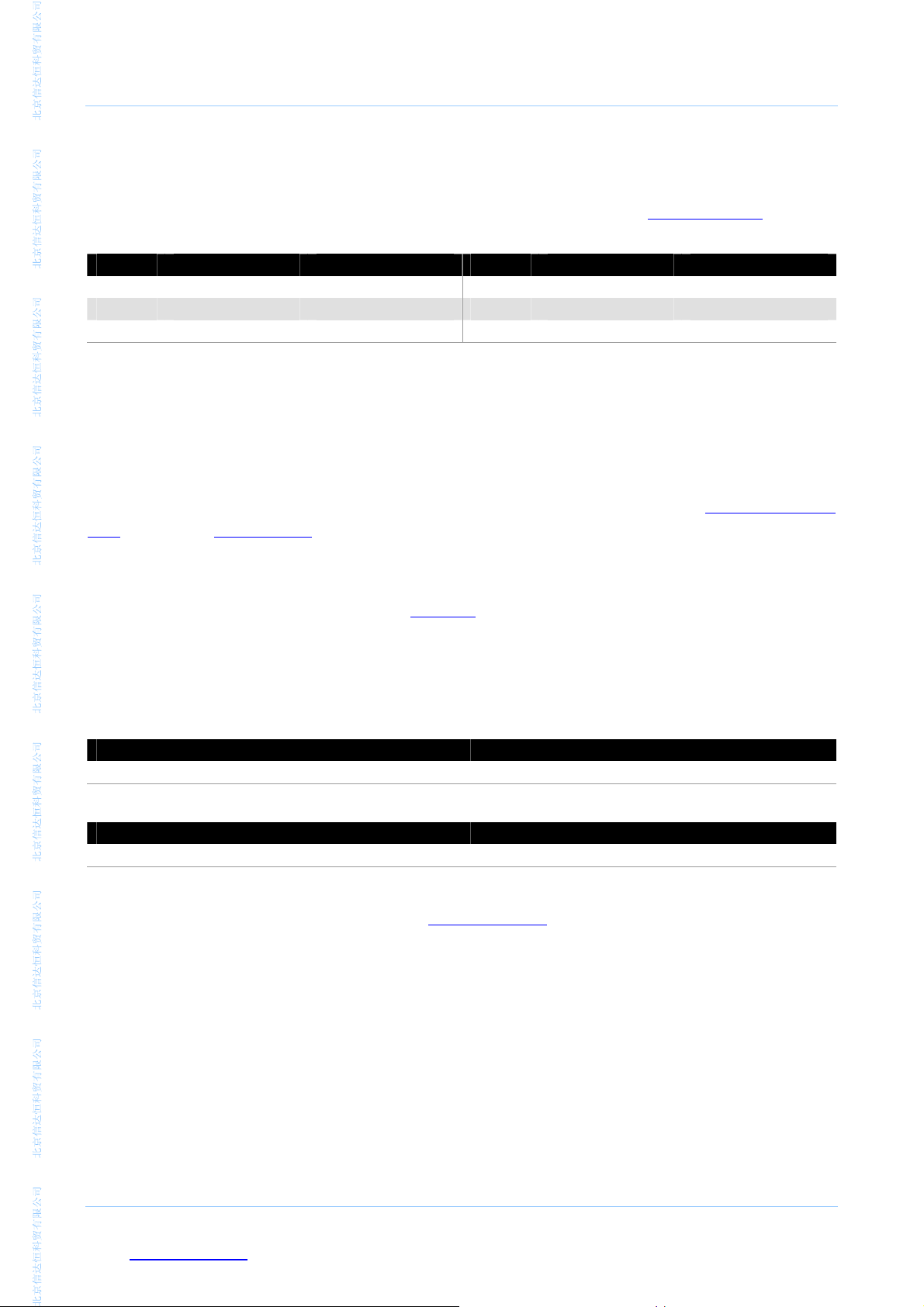

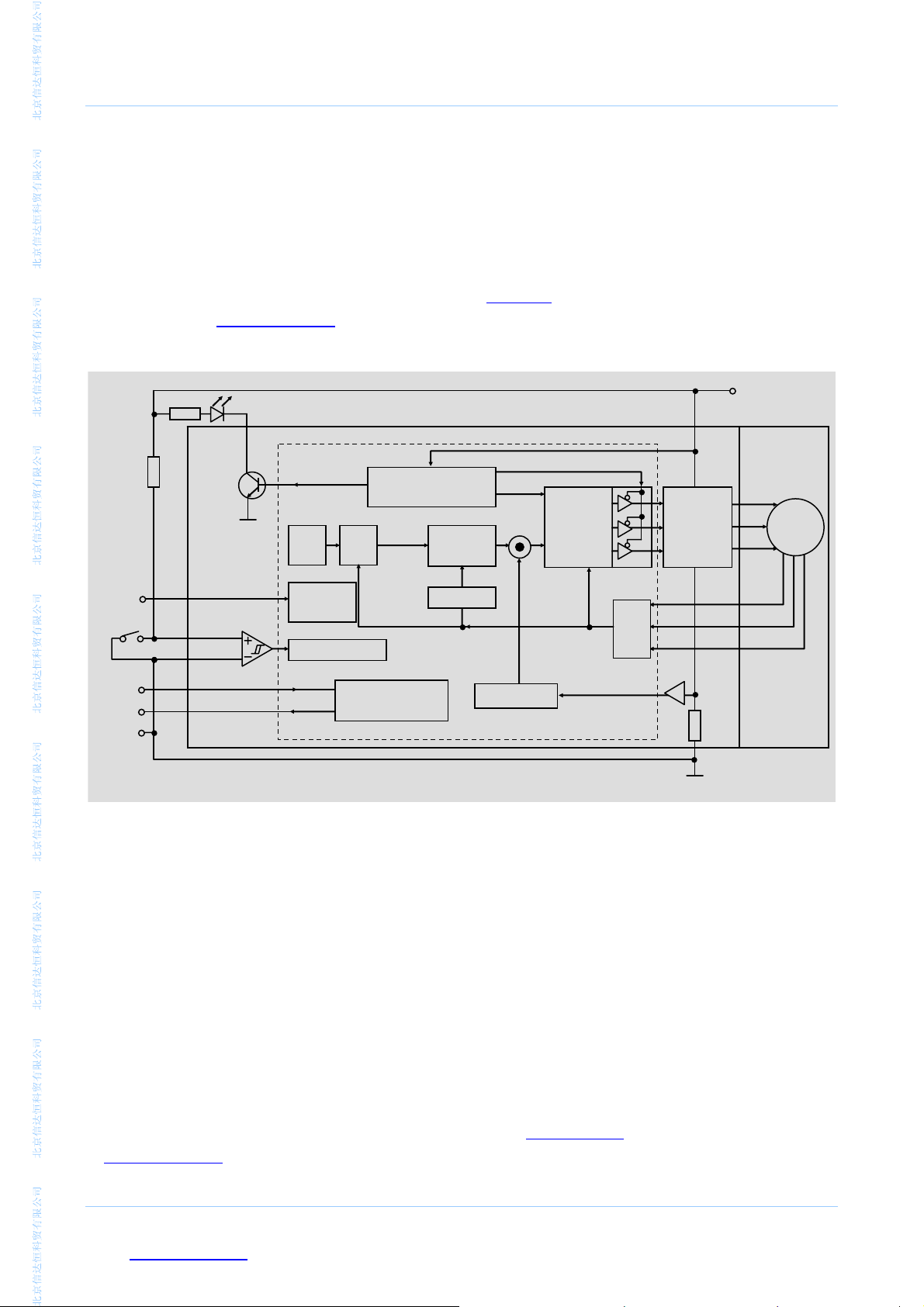

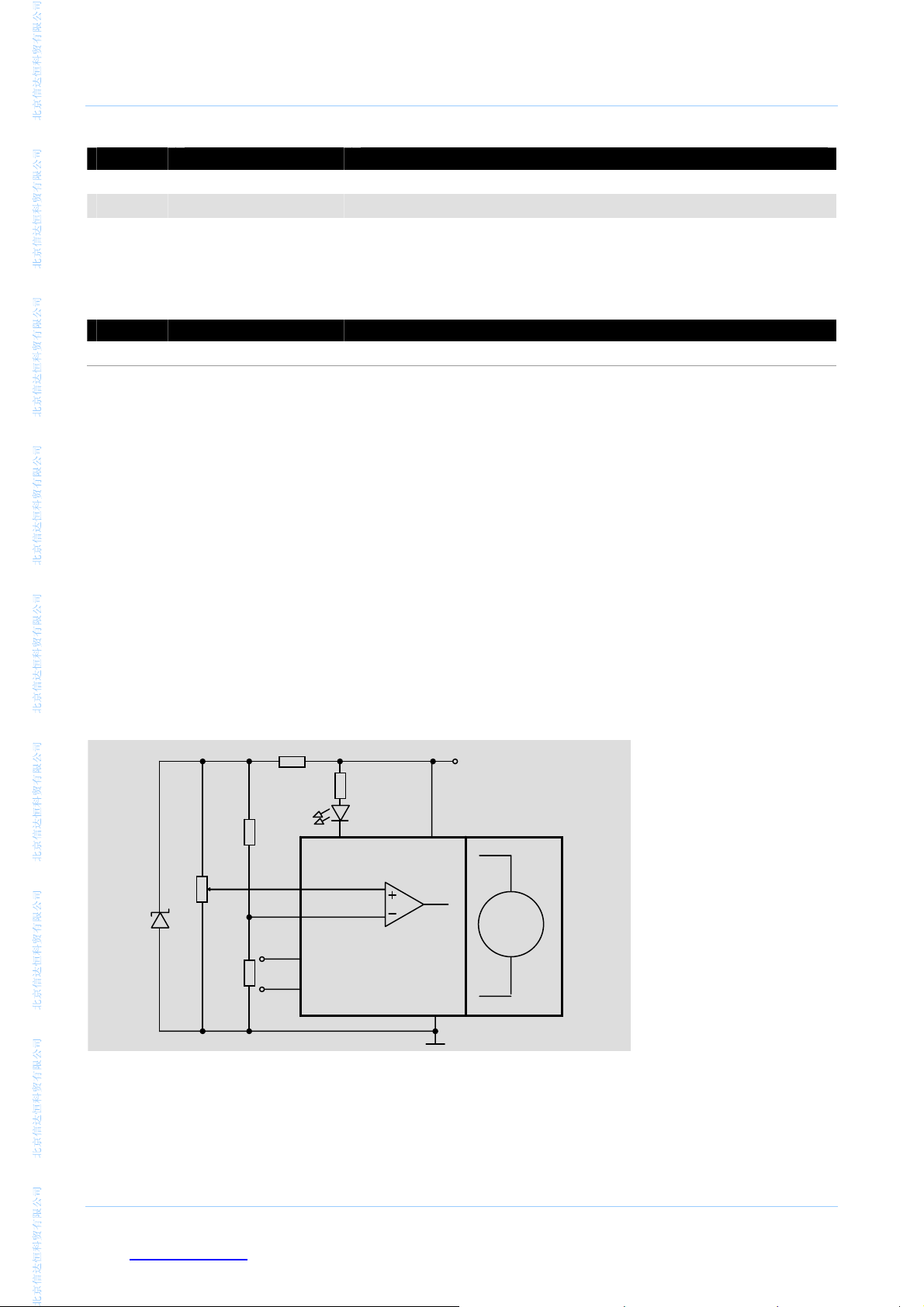

电路示意:带限位开关的 3564K024B CC:

参数详解;可通过PDO2传输的FAULHABER指令,

U

Rs

B

蓝色

+24V

粉红

B

C

霍尔

霍尔

霍尔

相

相

相

无刷

电机

A

B

C

10K

CAN

总线

CAN_ L

CAN_ H

GND

2.7K

红色

褐色

灰色

黄色

绿色

LED

故障

输出端

第三输入端

模拟

输入端

模拟地

CAN_L

CAN_H

白色

目标

位置

定义第三

输入端

定义限位开关

保护:

过热、过流、过压

n

位置

控制

CANo pen

配置模块

target

连接和

PI

速度控制

n

速度计算

I2t

actual

电流限制

Ua

三相

脉宽调制

正弦换向

信号

φ(t )

I

微处理器

场效应

三极管

功放输出

电枢

位置

计算

actual

GND

Motion Manager 提供 Windows 风格对话框,用户对驱动器进行操作时一目了然。所有指令都可直接

输入或通过菜单选取,CANopen 状态机的操作也通过菜单完成。状态提示栏会自动显示当前设备的状态。

注意:驱动器仅可在操作状态下接收 FAULHABER 指令(指令ÆCANopenÆ网络管理Æ启用远程节点

可将驱动器切换到操作状态)。

3.1、位置控制

在该操作模式下,可通过 CAN 接口预设目标位置,具体操作有如下两种方式:

1、 遵从 DSP 402 行规的“复合位控模式”:

首先将操作模式设置为OPMOD1。目标位置和其它各参数,可通过对象字典或FAULHABER指令,根据

实际需要进行设置和调节。例如AC(0x6083)、DEC(0x6084)、SP(0x607F)、LPC和LCC等等,同时还

包括POR、I、PP和PD(0x60FB和 0x60F9)等数字滤波参数。LL或对象 0x607D可用于限制位置范围。位

控由控制字启动执行并由状态字检验(详情参阅第 6.3.3 章节

FAULHABER指令)。

节

2、 FAULHABER 模式:

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 19 页,共 84 页

复合位控模式,以上指令含义请参阅 6.4 章

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

首先将操作模式设置为OPMOD-1、速度控制的信号格式设置为SOR0、工作模式设置为CONTMOD或

ENCMOD。其它参数可使用FAULHABER指令,根据实际需要设置和调节。例如AC、DEC、SP、LPC和LCC

等等,同时还包括POR、I、PP和PD等数字滤波参数。LL可设置位置范围并通过APL使其生效(以上指令含

义请参阅 6.4 章节

指令 功能 详细说明

LA

LR

M

举例:

¾ LA400000 Æ指定目标位置;

¾ M Æ开始运动。

在以上两种操作模式下,如果 RxPDO1 的传输类型设置为 255(对象 0x1800),当电机到达目标位置

时,TxPDO1 上的状态字(第 10 位,目标位置到达)将会有所提示。

线性霍尔传感器还能反馈无刷伺服电机的位置。对于 3564K024B CC 和 MCBL3003/06 C 而言,位置

精度高达 1/3 000 圈。

使用 APL0 可让电机运动不受±1.8×10

FAULHABER指令)。执行位控的关键指令如下:

指定绝对目标位置 以系统启动时的原点为零位,设置一个目标位置。

9

范围:±1.8×10

之间。

指定相对目标位置 以当前位置作为零位,设置一个目标位置。目标位置的范围受系统

启动时的原点限制,必须在原点的±2.14×109的范围内。

开始运动 启动执行位控。

9

的位置范围限制。超过此范围后,位置清零并重新开始计数。

3.2、速度控制

3.2.1、通过 CAN 执行速控

通过 CAN 执行速控有以下两种方式:

3、 遵从 DSP 402 行规的“复合速控模式”:

首先将操作模式设置为OPMOD3,其它参数可通过对象字典或FAULHABER指令,根据实际需要设置和

调节。例如AC(0x6083)、DEC(0x6084)、LPC和LCC等等,同时还包括POR和I(0x60F9)等数字滤波参

数。速控通过对象字典(0x60FF)设置的目标速度启动执行并由状态字检验。要让电机制动,可使用控制

字(脱离受控),也可将对象的目标速度值设置为 0(详情参阅第 6.3.6 章节

请参阅 6.4 章节

FAULHABER指令)。

4、 FAULHABER 模式:

首先将操作模式设置为OPMOD-1、速度控制的信号格式设置为SOR0、工作模式设置为CONTMOD或

ENCMOD。其它参数可使用FAULHABER指令,根据实际需要设置和调节。例如AC、DEC、SP、LPC和LCC

等等,同时还包括POR、I等数字滤波参数。(以上指令含义请参阅 6.4 章节

执行速控的关键指令如下:

指令 功能 详细说明

V

切换到速控模式 切换到速控模式并设置目标速度。单位:rpm。

复合速控模式,以上指令含义

FAULHABER指令)。

举例:

¾ V100 Æ指定电机以 100 rpm 的速度运行。

输入一个负的速度值即可改变电机转向(例如:V-100)、输入 V0 则电机制动。

使用 APL0 可让电机运行不受 LL 设置的位置范围限制,另需注意 SP 不能低于目标速度。

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 20 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

3.2.2、通过模拟信号执行速控

本功能只针对 FAULHABER 模式有效,因此应设置操作模式为 OPMOD-1,同时还需要把驱动器设置为

SOR1 或 SOR2、工作模式设置为 CONTMOD。

其它参数可使用FAULHABER指令,根据实际需要设置和调节。例如AC、DEC、LPC和LCC等,同时还

包括POR和I等数字滤波参数(以上指令含义请参阅 6.4 章节

控所可能用到的指令:

设置调速比例(最高速度)

在 AnIn 输入的模拟电压达到最高值(默认设置为 10V)时,电机所能获得最高转速。

指令 功能 详细说明

SP

设置最高速度 设置电机的最高转速,适用于除 VOLTMOD 外的所有工作模式。单

位:rpm。

举例:

¾ SP5000 Æ设置最高转速为 5 000rpm,该速度在 AnIn 接收的模拟电压为 10V 时获得。

设置最低速度

FAULHABER指令)。以下为进一步设置模拟速

指在 AnIn 输入的模拟电压绝对值为最低时,电机的转速。

指令 功能 详细说明

MV

设置最低启动速度 设置允许的电机最低转速,指在 AnIn 输入的模拟电压的绝对值最

低时,电机的转速。单位:rpm。

设置启动电压

又称之为“死区电压”,指电机启动时,所需要的模拟输入电压的最低绝对值。

指令 功能 详细说明

MAV

设置最低启动电压 电机启动时,需要在 AnIn 输入的模拟输入电压最低绝对值,低于

该值时电机将不会转动。单位:mV。

举例:

¾ MAV100 ÆAnIn 接收的模拟电压高于 100mV(或低于-100mV)时,电机才开始转动。

设置启动电压用以避免干扰信号通过 AnIn 扰动电机。因为在实际应用中,通常很难将 AnIn 的输入电

压精确地保证为零,不设置启动电压,则很难保证电机完全静止。

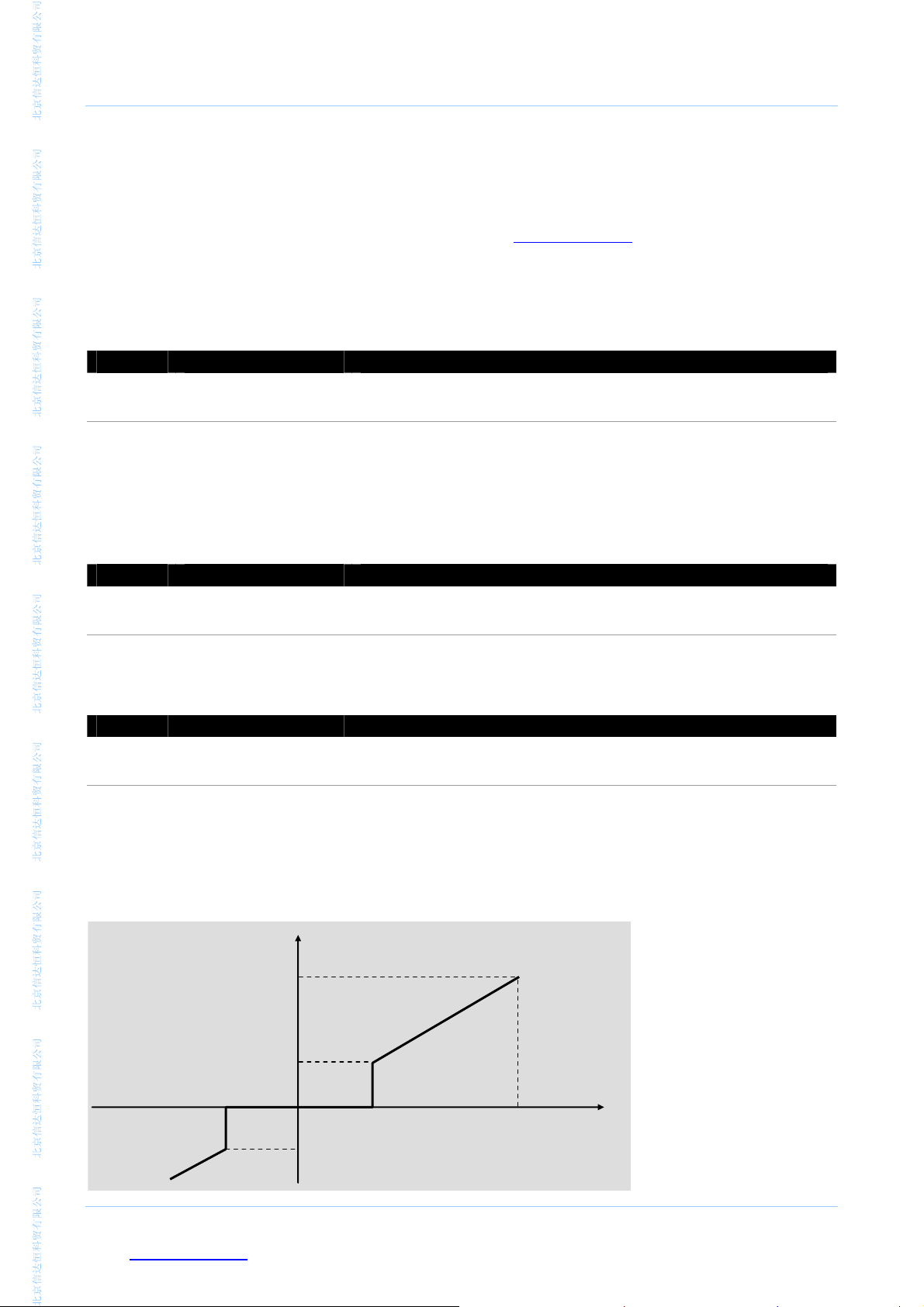

目标速度

最高速度限制

n

SP

target

MV

启动电压

最低速度

-MV

MAV

模拟输入电压

U

in

启动电压

最低速度

-MAV

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 21 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

D

K

K

K

设置电机旋转方向

指令 功能 详细说明

ADL

ADR

举例:

¾ ADR Æ设置当输入 AnIn 模拟电压信号为正时,电机顺时针方向旋转。

Fault 也可被设置为数字输入端,以控制电机的转向:

指令 功能 详细说明

DIRIN

输入的数字信号电平与电机转向的对应关系:

¾ 低电平:电机逆时针旋转(与 ADL 效果一致);

¾ 高电平:电机顺时针旋转(与 ADR 效果一致)。

用此方法控制电机的转向,其优先权高于 ADL 和 ADR。

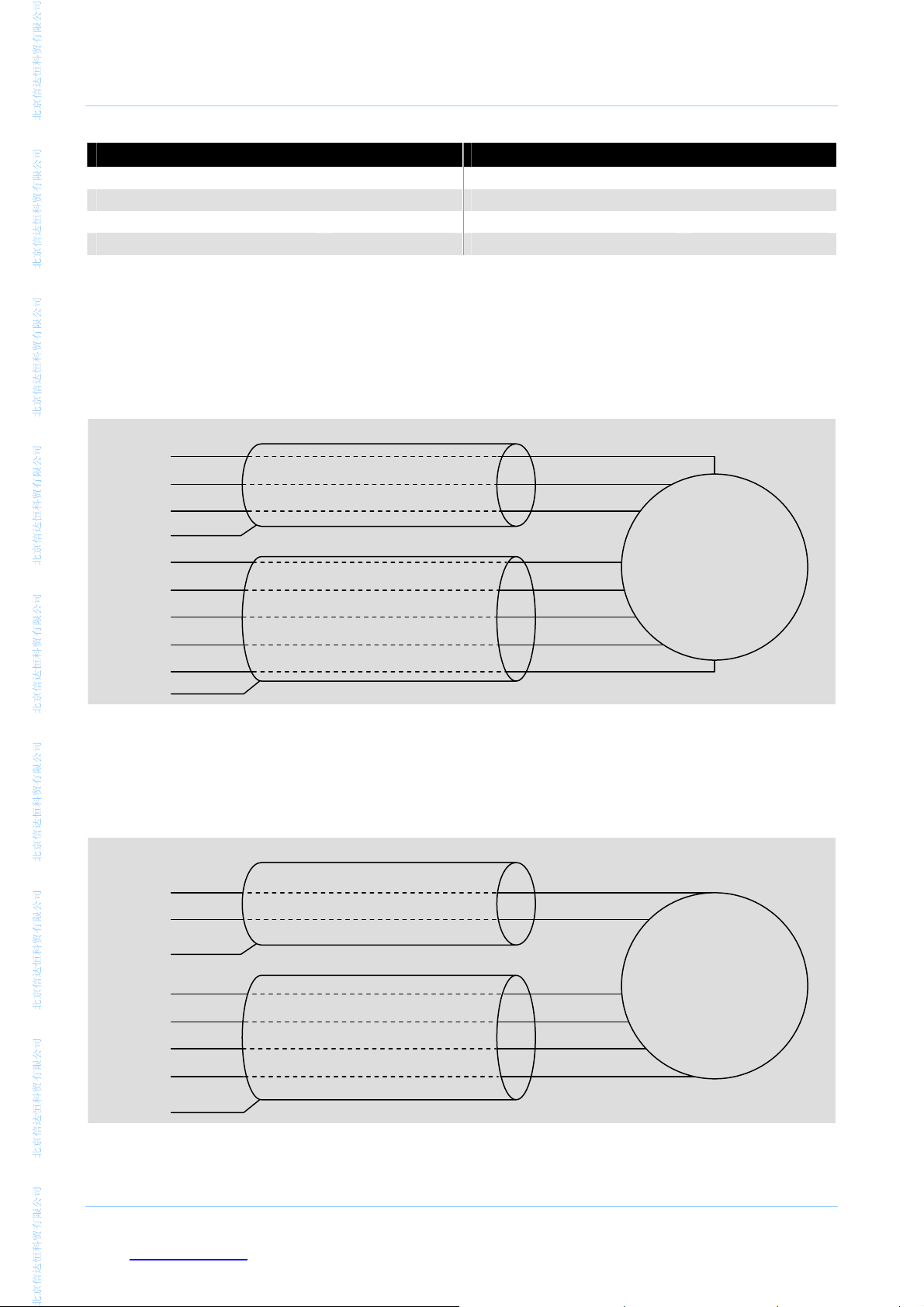

采用 PWM 信号执行速控(SOR2)

定义逆时针方向为正 输入正的电压信号,电机逆时针方向旋转(面向电机轴观测,下同)。

定义顺时针方向为正 输入正的电压信号,电机顺时针方向旋转。

转向控制输入 将 Fault 设置为数字输入端,输入信号的高低电平决定电机的转向。

在 AnIn 输入 PWM 信号以控制电机运动,效果如下:

¾ 占空比>50%:电机顺时针旋转;

¾ 占空比=50%:电机静止;

¾ 占空比<50%:电机逆时针旋转。

此时还可使用 SP、MV、MAV、ADL 和 ADR 等指令。

要让电机运行不受 LL 设置的位置范围限制,请确认使用了 APL0。

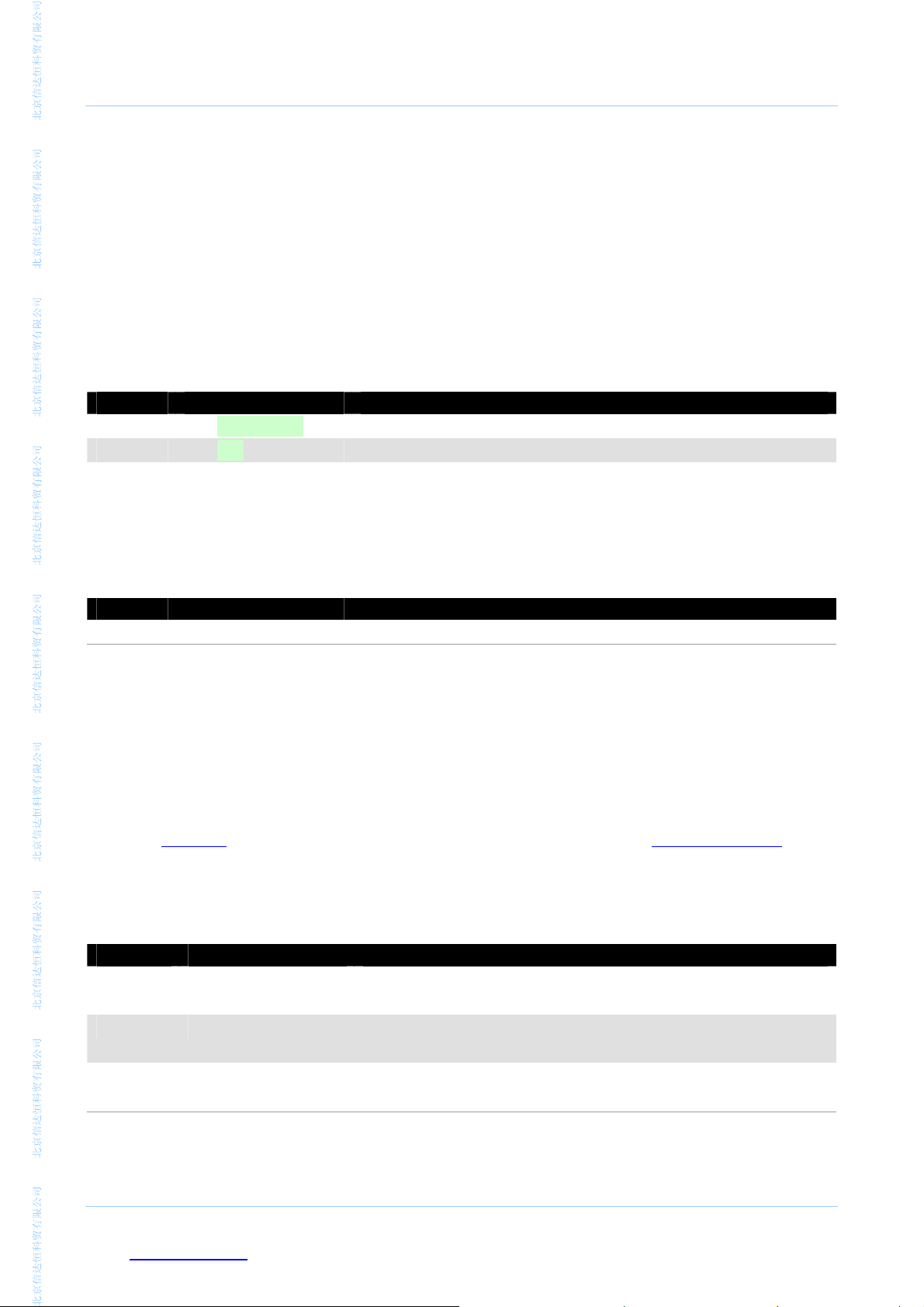

3564K024B CC 通过电位计输入模拟电压调速的电路示意图:

+24V DC

1

2.7

LED

n

GN

粉红

U

B

target

电机

20V

10K

4.7K

4.7

褐色

灰色

黄色

绿色

白色

模拟输入端

模拟地

CAN_ L

CAN_ H

蓝色

需要注意的是,实际应用中,AnIn 通常接收外部的模拟电压。AnIn 开路时,电机可能会以不确定的

速度旋转。要让电机静止不动,则应保证 AGND 与 GND 处于同一电平,最简单的方法是将这两端共地。

3.3、寻零功能和限位开关

以下端口可用于电机寻零和作为限位开关:

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 22 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

¾ AnIn;

¾ Fault;

¾ 3.In;

¾ 4.In 和 5.In(仅对 MCDC 类驱动器有效)。

无刷伺服电机每旋转一圈,线性霍尔传感器所输出的信号都会产生一个零交叉点,该点可作为零位索

引。对于带索引通道的编码器,则可将该通道的输出信号直接输入 Fault。对于往复运动系统,引入零位索

引可确保运动精度。

AnIn 和 Fault 可作为中断信号输入,同时仅此两端口可作为边沿触发器,可靠触发时间为 100μs。另

外,驱动器所有输入端的电平跳变最大响应时间都为 100μs。

设置数字输入端的电平规格

指令 功能 详细说明

SETPLC

SETTTL

以上指令可设置输入端可接收的信号规格,具体如下:

匹配PLC(SPS) 设置输入信号规格为 PLC 规格(高电平 24V)。

匹配TTL 设置输入信号规格为 TTL 规格(高电平 5V)。

¾ PLC(出厂默认值):低电平:0~7.0V,高电平:12.5V~驱动器电源电压 U

¾ TTL:低电平:0~0.5V,高电平:3.5V~驱动器电源电压 U

B

。

B

;

设置 Fault 为定位或限位开关信号输入端

指令 功能 详细说明

REFIN

定位或限位开关输入 将 Fault 设置为数字输入端,接收定位或限位开关信号。

仅当 REFIN 生效后,Fault 的限位开关功能方可使用(必须按下写入或使用 SAVE 保存 REFIN)。

若要将 Fault 作为输入端使用,务必先设置完成、再输入控制信号!

以下两种方式可设置寻零功能:

1、 遵从 DSP402 行规的寻零方式:

首先将操作模式设置为OPMOD6。寻零方式、寻零补偿、寻零速度和寻零加速度等可通过对象字典(对

象 0x6098、0x607C、0x6099 和 0x609A)设置。寻零程序通过控制字启动并由状态字检测(详情参阅第

6.3.4 章节

寻零模式)。输入端功能则通过对象 0x2310 设置(详情参阅 6.2 章节制造商定义的对象)。

2、 FAULHABER 模式:

首先将操作模式设置为 OPMOD-1。该模式下,包括端口功能设置和寻零方式等操作,均由本节后文

列表的 FAULHABER 指令完成。寻零通过以下指令启动:

指令 功能 详细说明

GOHOSEQ

开始寻零 开始执行寻零,寻零程序(若编写的有)的执行不受驱动器的工作

模式限制。

GOHIX

霍尔位置清零 启动无刷电机向霍尔零位运行(零位索引)并将电机位置清零。(对

MCDC 类驱动器无效)

GOIX

编码器索引清零 启动电机向编码器索引信号零位运行(该信号由 Fault 接收)并将

电机位置清零。(直流电机或外带编码器控制时适用)

在 FAULHABER 模式下配置寻零功能和限位开关

配置限位开关功能时,指令后需要跟随各输入端的掩码,掩码定义如下:

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 23 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

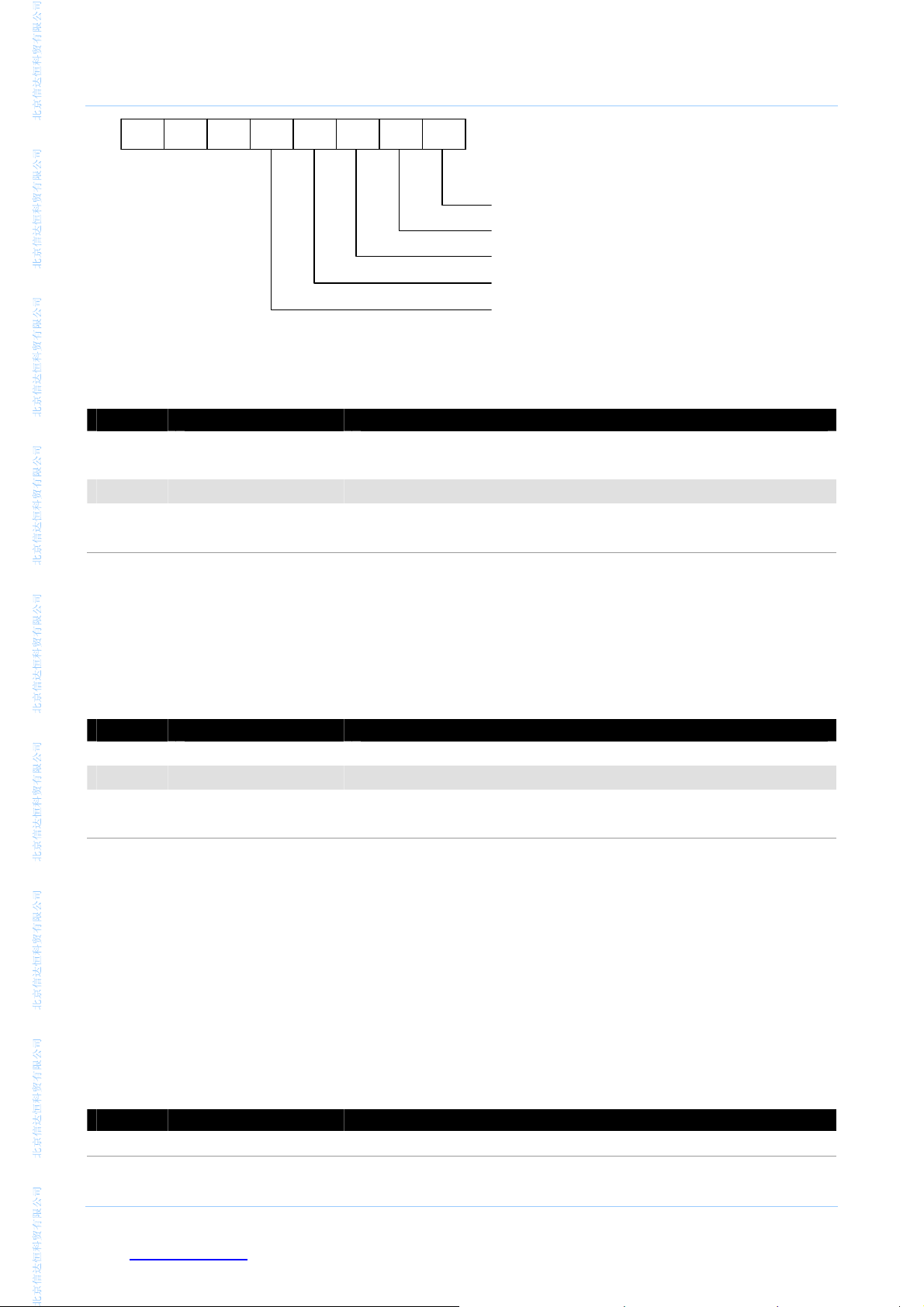

A

7 6 5 4 3 2 1 0

nIn

,模

拟输入端

Fault

,故

障输出端

3.In

,第

三输入端

4.In

,第

四输入端(仅限

MCDC

类驱动器)

5.In

,第

五输入端(仅限

MCDC

类驱动器)

针对需要设置的输入端,选择掩码并使用以下各指令:

定义触发极性和限位开关功能

指令 功能 详细说明

HP

设置触发极性 定义各限位开关的触发条件,包含触发沿和触发极性:

1:在上升沿和高电平触发;0:在下降沿和低电平触发。

HB

HD

强制限位 激活对应限位开关的强制限位功能。

强制定向 各限位开关通过 HB 设置了强制限位功能后,预设的电机转向:

1:顺时针方向被封锁;0:逆时针方向被封锁。

强制限位功能可切实保证电机不会过冲、运行至限位开关以外。HB 生效时,电机转向受 HD 限制,也

就是说,电机只能向远离限位开关的方向运动,如果速度指令的方向错误,则电机将保持静止。

举例:

¾ HB10 Æ在 Fault 和 4.In 启用强制限位(2

1+23

=2+8=10,1 和 3 分别为 Fault 和 4.In 的掩码)。

定义寻零方式

指令 功能 详细说明

SHA

SHL

SHN

寻零位置清零 寻零时(GOHOSEQ),对应限位开关触发后电机位置清零。

寻零制动 寻零时(GOHOSEQ),对应限位开关触发后电机制动。

寻零信息应答 寻零时(GOHOSEQ),对应限位开关触发后发消息至主机(状态字

字位 14=1)。

要成功地使用 GOHOSEQ 执行寻零,必须对各限位开关功能详细定义。

调用 GOHOSEQ 执行寻零时,如果电机已经在限位开关内,它将尝试向限位开关之外运行。此时电机

将以 HOSP 所设置的寻零速度远离限位开关,速度方向与 HOSP 的设置相反。

举例:下列指令将达到的效果为:3.In 被触发跳变为高电平之后,电机制动、位置清零并应答主机:

¾ HP4;

¾ SHA4;

¾ SHL4;

¾ SHN4。

寻零速度

指令 功能 详细说明

HOSP

设置寻零速度 设置寻零时(GOHOSQ 或 GOHIX)电机的速度与方向,单位:rpm。

举例:

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 24 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

¾ HOSP-100。

通过 HA、HL 和 HN 指令直接编程

指令 功能 详细说明

HA

HL

HN

以上指令独立于寻零程序之外,定义了驱动器各输入端被限位开关信号触发后,驱动器和电机的各种

动作,所设置的功能在寻零完毕前始终有效。同时,无论寻零程序是否已经启动,只要指令尚未执行,都

可以对它们进行修改。

由于上述设置不可保存,因此系统断电后,这三个指令都将失效。

HL 和 SHL 指令

¾ 位控模式:触发后,电机以最大加速度向定位点运行。

¾ 速控模式:触发后,电机以预设的负加速度开始减速向定位点运行。这将有可能造成过冲,但可

寻零位置清零 对应限位开关触发时将位置清零,同时清除该开关上的 HA。(本指

令为一次性,无法保存。)

寻零制动 对应限位开关触发时将电机制动,同时清除该开关上的 HL。(本指

令为一次性,无法保存。)

寻零信息应答 对应限位开关触发时发送消息至主机(状态字字位 14=1),同时清

除该开关上的 HN。(本指令为一次性,无法保存。)

通过追加一个位控指令(LA0,M)使电机重新回到定位点。速控模式的优势在于没有运动突变。

3.4、附加工作模式

附加工作模式仅在 FAULHABER 模式下有效,亦即必须设置为 OPMOD-1。

使用 CONTMOD,可从附加工作模式切回到普通模式。

3.4.1、步进模式

指令 功能 详细说明

STEPMOD

在步进模式下,AnIn作为脉冲信号输入端,电机转向通过 ADL 和 ADR 控制。若要通过数字信号改变

电机转向,则必须使用 DIRIN 定义 Fault。

指令 功能 详细说明

DIRIN

该模式为仿真步进电机的工作方式,在 AnIn 每输入一个(组)脉冲,电机将按所设定的角度(等同

步进电机的步进角)前进一步。

与真正的步进电机相比,步进模式下的直流电机具有以下优势:

¾ 电机完成旋转一圈所需的步数(步进角)可自由设置,范围仅受编码器分辨率限制;

¾ 步宽(指一个脉冲使电机旋转多少步)也可在一定范围内自由设置;

¾ 不存在步进电机中,锁定电机所需要的转矩,因此没有转矩损失;

¾ 全速度范围内的高速动态响应能力;

¾ 运行安静;

¾ 由于有编码器信号作为反馈,因此不会发生步进电机特有的“丢步”现象(即使在最大负载下);

¾ 静止状态下(到达目标位置后),电机不再耗电;

¾ 系统功效非常高;

步进模式 切换到步进工作模式。

转向控制输入 将 Fault 设置为数字输入端,输入信号的高低电平决定电机的转向。

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

电子邮件:sales@bjxdh.com.cn 第 25 页,共 84 页

MCxx3003/06C 与 3564K024 BCC 驱动器用户手册中文版

¾ 对于 3564K024B CC 而言,已经集成驱动器。

输入信号参数

¾ 最大输入信号频率:400 kHz;

¾ 电平规格:根据不同配置,可选择+5V 的 TTL 或+24V 的 PLC 规格。

步进模式下可精确控制电机的速度与位置,通过对步数和步宽的设置,输入信号的频率与电机速度之

间的比率可任意调节,它们之间的关系如下:

STW

输入的脉冲数电机的转数 ×=

¾ 电机的转数:电机所旋转的圈数,或理解为电机的位置;

¾ 输入脉冲数:驱动器所接收的脉冲个数(电机所要前进的总步数);

¾ STW:步宽,意思是每收到一个脉冲,电机所前进的步数;

¾ STN:步数,意思是电机每旋转一圈需要走多少步,相当于步进电机中的 360÷步进角。

STN 和 STW 的数值范围为 0~65 535。

指令 功能 详细说明

STW

STN

设置步宽 在步进或减速电机模式下,每收到一个脉冲,电机将要前进的步数。

设置步数 在步进或减速电机模式下,电机每旋转一圈所需要走的步数。

步宽

步数

STN

举例:每输入 1 个脉冲,电机前进 1/1 000 圈,指令:

¾ STW1;

¾ STN1000。

电机的转向可由 ADL 和 ADR 控制,也可在 Fault 输入方向控制信号(使用 DIRIN 设置)。

在步进模式下,AC、DEC、SP 等指令同样有效,合理设置它们有利于保证电机平稳运行。LL 所设置

的位置范围,在该模式下同样可以通过 APL1 启用。

3.4.2、减速电机(电子齿轮)模式

若电机带有附加的编码器,则还可使用减速电机模式驱动。

指令 功能 详细说明

GEARMOD

编码器信号的两个通道分别连接到驱动器的 AnIn 和 AGND,两个信号通道与编码器的+5V 电源端之

间,可能需要使用 2.7kΩ 的上拉电阻。

以下公式可以计算出减速比:

¾ 电机的转数:电机所旋转的圈数,或理解为电机的位置;

¾ 输入脉冲数:驱动器所接收的脉冲个数(电机所要前进的总步数);

¾ STW:步宽,意思是每收到一个脉冲,电机所前进的步数;

¾ STN:步数,意思是电机每旋转一圈需要走多少步,相当于步进电机中的 360÷步进角。

减速电机模式 切换到减速电机工作模式。

STW

输入的脉冲数电机的转数 ×=

步宽

步数

STN

STN 和 STW 的数值范围为 0~65 535。

指令 功能 详细说明

STW

STN

公司地址:北京市海淀区阜成路 115 号 北京印象 7号楼 1006室 邮编:100036

联系电话:010 - 8811 9411 8811 9400 传真:010-8811 4288

网址:www.bjxdh.com.cn

设置步宽 在步进或减速电机模式下,每收到一个脉冲,电机将要前进的步数。

设置步数 在步进或减速电机模式下,电机每旋转一圈所需要走的步数。

电子邮件:sales@bjxdh.com.cn 第 26 页,共 84 页

Loading...

Loading...