Page 1

2008 200MM FAT TIRE KIT

INSTALLATION MANUAL

FAT BAGGERS, INC.

138 EAST LINCOLN

CHARITON, IOWA

50049

641-774-7499

641-774-7505 (FAX)

Page 2

2008 200MM FAT TIRE KIT INSTALLATION MANUAL FOR 2008

HARLEY-DAVIDSON FL’S

WARRANTY

Fat Baggers, Inc.™ warrants to the original purchaser that the parts of this 200mm kit to be

free of manufacturing in materials and workmanship for a period of 1 year from the date of

purchase. In the event warranty service is required, you must call Fat Baggers, Inc.™

immediately with description of the problem. If it is deemed necessary for Fat Baggers, Inc.™

to make an evaluation to determine whether the part is defective, a return authorization

number will be given by Fat Baggers, Inc.™ The parts must be packaged properly so as to not

cause further damage and returned prepaid to Fat Baggers, Inc.™ with a copy of the original

invoice of purchase and a detailed letter outlining the nature of the problem. If after the

evaluation by Fat Baggers, Inc.™ the part was found to be defective it will be repaired of

replaced at not cost to you. If we replace it, we may replace it, with a reconditioned one of

the same design. Fat Baggers shall not be held liable for any consequential or incidental

damages resulting from the failure of a Fat Bagger’s Inc.™ part. Fat Bagger’s shall have no

obligation if a part be comes defective as a result of improper installation or abuse.

IMPORTANT NOTICE

Before installing this kit, read through these instructions completely; this will familiarize you

with the way in which parts fit together and the tools needed to complete the Fat Tire Kit.

Fat Baggers, Inc.™ 200mm tire kit involves significant alterations of your motorcycle and may

void your factory warranty. Fat Baggers, Inc.™ STRONGLY recommends this conversion be

done by an experienced motorcycle mechanic. Before performing any installation steps,

disconnect the motorcycle’s battery to eliminate any possibility of damage to the electrical

system or injury to yourself due to short circuit.

DISCLAIMER

These Fat Bagger parts are designed for high performance motorcycle applications and are

intended for the very experienced rider only. The installation of these Fat Bagger, Inc.™

parts may adversely effect or void your factory warranty.

FAT BAGGERS, INC.

138 EAST LINCOLN

CHARITON, IOWA

50049

641-774-7499

641-774-7505 (FAX)

Page 3

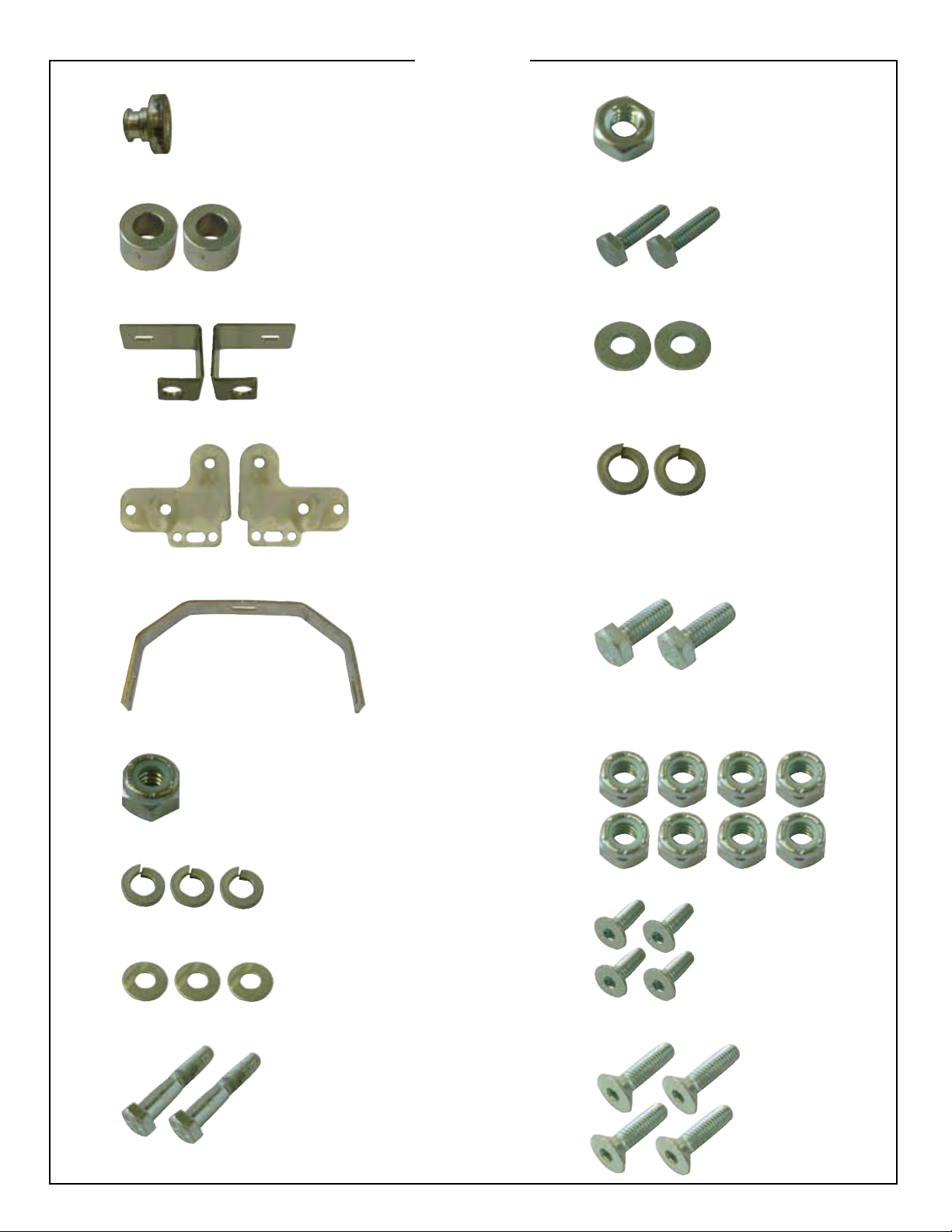

FBI101 SEAT BOLT STUD (1)

PARTS

1/4-20 NUT (1)

FBI102 SHOCK SPACER (2)

FBI205 SADDLE BAG BRACKET (2)

FBI100 FENDER STRUT BRACKET (2)

FBI401 FENDER BRACE (1)

5/16-18X1” HEX CAP (2)

5/16” FLAT WASHERS (2)

5/16” LOCK WASHERS (2)

1/4-20X1” HEX CAP SCREWS

1/4-20 LOCK NUT (1)

1/4” LOCK WASHERS (3)

1/4” FLAT WASHER (3)

1/2-13X2 3/4” HEX CAP SCREWS (2)

5/16” LOCK NUTS (8)

5/16-18X1 1/4” FHCS (4)

5/16-18 1” FHCS (4)

Page 4

PARTS

FBI650L SWINGARM (1)

FBI150 AXLE (1)

FBI151 WHEEL SPACERS (VARIES FOR ALL

CUSTOM WHEELS)

WHEEL SPACER INCLUDED IN YOUR KIT

FBI151RC USE

WITH RC WHEELS

CALL WITH WHEEL BRAND IF YOU WANT

FBI151WB USE

WITH WELD WHEELS

RUBBER BUMPERS (6)

EPOXY (1)

FBI800-17 SMOOTHIE CHROME WHEEL

FBI151PM USE

WITH PM WHEELS

FBI151WP USE

WITH WELD WHEELS

FBI851 WIDE REAR FENDER (1)

FBI860 TAILLIGHT (1)

200MM TIRE

FBI105 STAINLESS STEEL BACKREST

MOUNTING HARDWARE

Page 5

641-774-7499

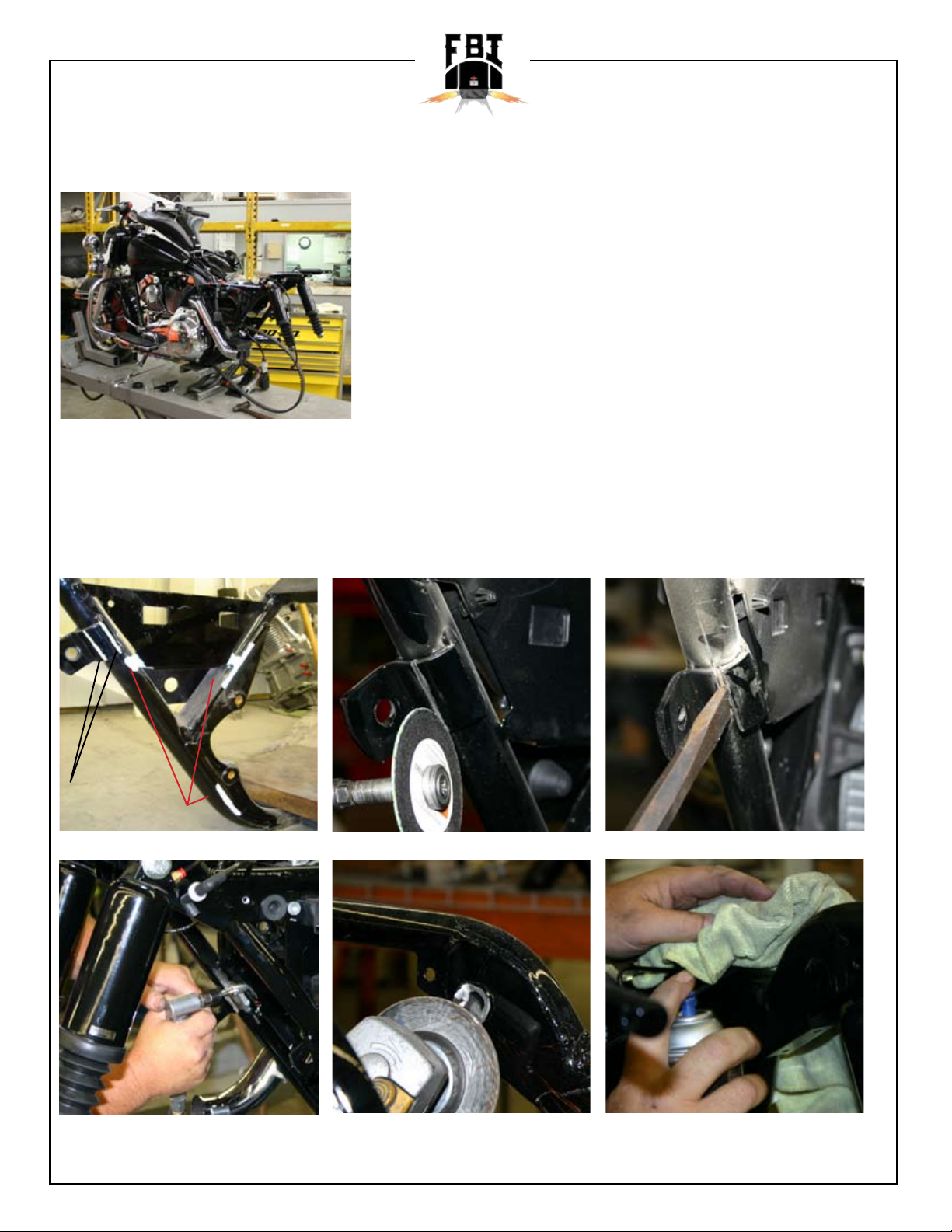

1. Disconnect the battery before starting any of the installation process. Then remove saddle bags,

seat, rear fender, rear wheel, swing arm, side covers, and exhaust system.

2. Locate the left side saddlebag frame rail that is welded to the frame, use a cut off wheel to cut

vertically in between the two welds, and cut through the inside weld. Making sure not to cut into

frame tube. Use chisel and hammer to knock inside of mounting tab off. Grind the remaining weld

off the inside of the frame tube. You must also grind welds down were belt passes through and

inside of the frame and the excessive material where the shocks mounts through the inside of the

frame for belt and tire clearance (see Image A) use touch up paint to cover any bare metal.

www.fatbaggers.com

CUT LINES

GRIND LINES

Image A

Grinding welds for belt

clearance.

Cutting part of mounting tab.

Grinding shock mounts for tire

clearance.

Removing part of mounting tab.

Use touch up paint to cover all

bare metal.

Page 6

641-774-7499

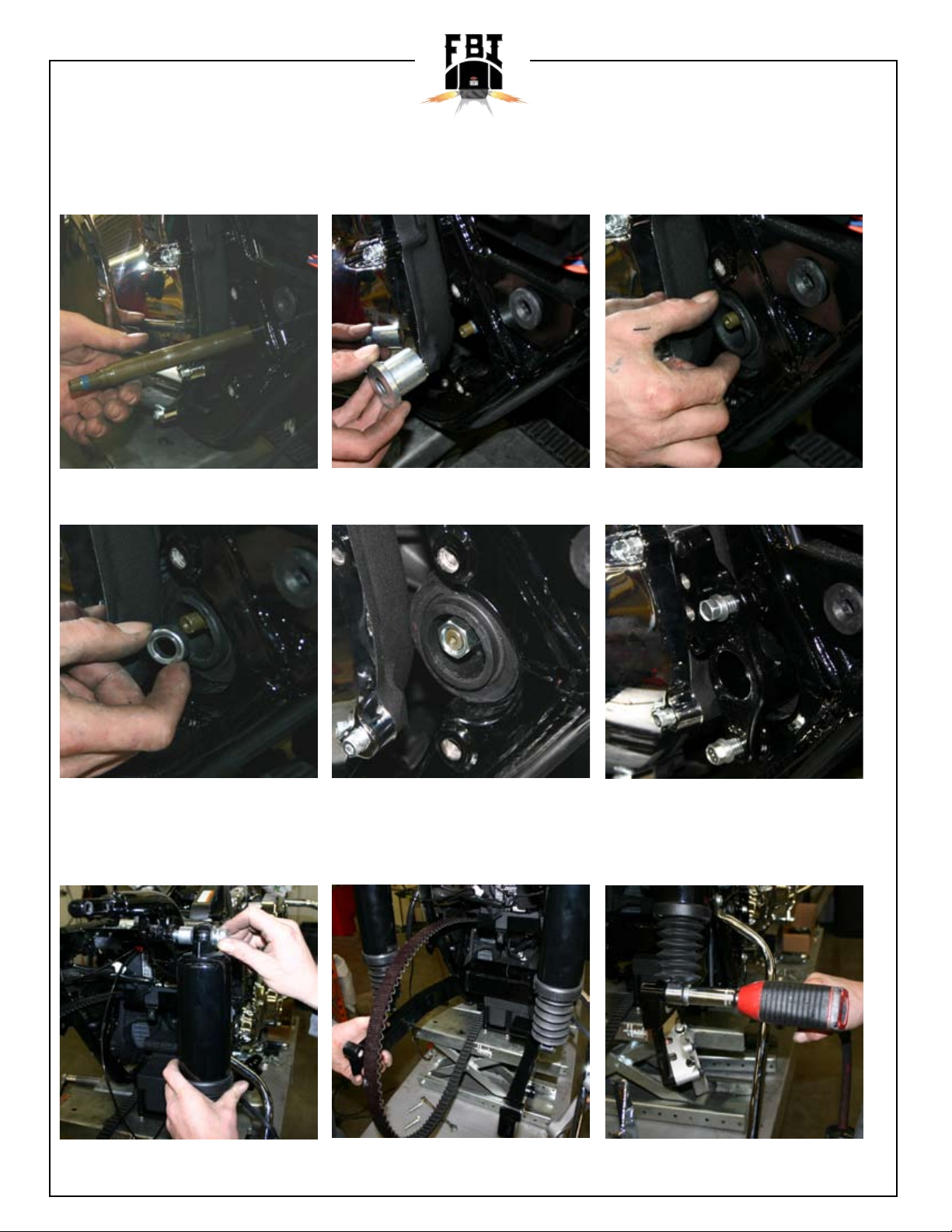

3. Now you are ready to install the new swing arm, all the bearings and bushing are already installed

in the swing arm. Reinstall the swing arm just like it was a stock motorcycle, after installing the

swing arm you will be ready to install the shock spacers.

www.fatbaggers.com

Reinstall swingarm pivot.

Reinstall

4. You will reuse the stock shock bolts for the bottom of the shocks, for the top of the shocks you will

use the new 1/2” x 13 x 2 3/4 long shock bolts, with 5/8 inches shock spacers FBI102.

Reinstall

Reinstall

Reinstall

Reinstall

Reinstall shock and shock

spacer.

Reinstall new swingarm.

Tighten down shocks to new

swingarm.

Page 7

641-774-7499

www.fatbaggers.com

Backside view of shocks bolted

Reattach air lines for shocks.

to new swingarm.

5. The spacers install between shocks and frame to space out shocks reuse washer from top stock

shock bolts. Now you can install the new fender strut brackets part FBI100 use 5/16x 1 ¼ at head

allen in the top to holes that go through frame with 5/16 lock nuts, use 5/16x1 allens in the bottom

two holes of bracket with 5/16x1 at head allens.

New fender strut brackets

5/16 Lock Nut

FBI100

Image B

5/16 1x1/4” FHCS

5 1/4x1” FHCS

FBI205

installed.

6. Replace rear saddlebag mounting brackets with new saddlebag mounting brackets.

New saddlebag bracket. Slide on gold clip to new bracket.

Reuse gold saddlebag clip.

Page 8

641-774-7499

8. First you are going to start by removing quick release receptacle from rear saddle bag mounting

brackets, and install them on the new FBI200 mounting bracket.

www.fatbaggers.com

New saddlebag bracket.

7. Now we need to mock up saddles bags and backrest hardware, for adjustment.

Saddlebag mock up. Saddlebag mock up. Backrest mock up.

10. With FBI205 mounting, in place leave loose for adjusting saddlebags.

Reuse gold saddlebag clip.

Saddlebag adjusting. Saddlebag adjusting. Backrest hardware adjusting.

Page 9

641-774-7499

11. Install front saddle bag mounting brackets (leave loose for adjustments).

Leave loose for adjusting.

12. Put side cover back on the motorcycle.

www.fatbaggers.com

13. Reinstall saddlebags.

Installing saddlebages. Installing saddlebages. Installing saddlebages.

14. Now adjust saddlebags so bags do not rub side cover.

Page 10

641-774-7499

15. Tighten rear mounting bracket, after adjusting the bag into proper position

www.fatbaggers.com

Tighten them down.

brackets into position.

16. Remove saddlebags.

17. Remove front saddlebag mounting bracket.

18. Leave rear saddlebags mounting bracket attached.

19. Loosely install FBI saddle bag support bracket bridge FBI401.

Tighten them down.Getting rear mounting

Leave loose.

FBI401 installed.

Page 11

641-774-7499

20. Install your new FBI105 backrest mounting hardware, if you are going to be running a backrest

for proper placement. Leave rear mounts loose.

Installing rear mounts.

21. Tighten rubber mounts down, and tighten rear mounts down.

www.fatbaggers.com

Tighten the rubber mounts. Tighten down rear mounts.

22. Install backrest.

Installing backrest checking

alignment of mouting hardware.

Page 12

641-774-7499

23. Tighten rear backrest mounting hardware again if there is any adjustment.

24. Now remove and reinstall backrest making sure there is now binding. If there is binding, present loosen your new FBI100 fender strut brackets, pull or push forward and back as needed to make

backrest install smoothly and easily and reinstall fender support brackets bolts.

www.fatbaggers.com

25. Leave rear backrest mount installed, remove front rubber mount. NOTE: You must spread back-

rest apart to t over FBI fender you can pull apart by hand. Be careful installing over painted fender.

26. Drilling frame for fender tment. Use 1/8 drill bit to drill through frame where front backrest

rubber mount bolt is located, go through threaded hole, drilling through inside of frame, repeat on

other side.

27. With 3/16 drill bit go through the hole where the front saddlebags support bracket was located.

And start drilling through the inside of the frame.

Page 13

641-774-7499

28. Slide fender into place.

If fender is already paint

becareful not to scratch fender.

29. Use palm tap fender down, making sure that fender is tight down against frame struts.

www.fatbaggers.com

Make sure fender is tight

against frame struts.

30. Stand few feet behind motorcycle, sight down the top of fender to top the gas tank to make sure

fender is sitting level on motorcycle.

31. Once you have the fender positioned properly use right angle drill, to drill through holes that you

previously drilled. Drill from the inside of the frame out with fender in place, use 1/8 drill bit.

Page 14

641-774-7499

32. Remove fender

33. Drill pilot holes out with a 21/64 drill bit.

www.fatbaggers.com

Drilling pilot holes. Use a 21-64

drill bit.

34. Before painting fender, install part# FBI101, into fender for mounting a two up seat, the fender

has marked indentation on fender where you need to drill use drill bit. Use plastic clip off of factory

seat to hold in place FBI101, then you can berglass or epoxy the seat bolt stud to fender on

berglass. If you received a painted fender this step has already been done for you.

Fiberglassed seat bolt

installed.

35. Now your fender is ready for painting, after fender is painted you are ready to install FBI860.

Turn fender upside down on something soft. Use a 60 second epoxy (is included) to install the

taillight. With fender upside down place taillight into hole, use cardboard shims to shim taillight until

it is ush with outside of fender, then apply 60 second epoxy through the holes on each side of

taillight. We recommend scufng the inside of fender, so the epoxy with properly adhere to inside of

fender. Then use RVT silicon go around taillight to water tight taillight to fender. Then place wiring

into clips on inside of fender. NOTE: Use instructions provided with FBI860 for wiring 2008 bikes

have to have wire placed different in the plug. Too wire the taillight take the white connector, and

take slot 4 and 5 and reverse them so that 4 will now be 5 and 5 will now be 4.

Drilling pilot holes.

Seat bolt in position.

Page 15

641-774-7499

www.fatbaggers.com

Locate wires. Remove wires and change

there positions.

Tape down FBI860 for epoxy it

into place. Epoxy sets up in 60

seconds.

36. Reinstall fender.

Taped areas are areas we

recommend that you epoxy.

Do not use tape that is for

showing you where to epoxy.

Plug wires back into position.

Finished silicon look. Silicon

needs to dry.

Installing rear fender.

Page 16

641-774-7499

37. Loosely install front saddle bag mounting brackets using shims as needed inside, in between

fender and frame to insure you will not crack fender when you tighten down. This can be done with

washers.

www.fatbaggers.com

Sliding shim into place to

prevent fender from cracking.

38. Reinstall saddlebags attach to rear saddlebag brackets rst.

Reinstalling saddlebags. Reinstalling saddlebags. Reinstalling saddlebags.

40. Install front saddlebag pin then tighten front saddlebag mount.

Reusing front saddlebag

mount.

Reinstalling saddlebags. Reinstalling saddlebags. Reinstalling saddlebags.

Page 17

641-774-7499

41. Make stud go through slot in center of saddlebag support bracket bridge FBI401.

Fender stud through FBI401.

43. Put ¼ inch lock nut on stud sandwiching the bridge. Leave loose.

www.fatbaggers.com

1/4 lock nut on stud.

44. Center fender in between saddlebags when fender is in center position tighten ¼ inch lock nut on

stud locking bottom of fender into place.

Getting fender centered into

position.

Tighten down 1/4 lock nut to

hold fender in position.

Page 18

641-774-7499

45. Now install 3 rubber bumpers on ller strips as show in g this will prevent saddlebags coming

contact with fender.

Rubber bumpers installed on

rear fender.

46. Before installing the rear wheel, you will need to remove the 08” pulley and bolts from the

wheel. This is where you need to install the 2008 Upgrade Kit pulley and bolts for proper tment.

www.fatbaggers.com

Install 2008 Upgrade Kit pulley

and pulley bolts.

46.5 Remove saddlebag again. Install rear wheel, with sprocket on, rotor off. NOTE: If using 17

inch rim, you must grind corner of caliper off to make sure it does not contact rim.

Slide wheel into position. Wheel in position and ready for

rear axle to be installed.

Page 19

641-774-7499

www.fatbaggers.com

Grinding caliper so it does not

Finished grinding caliper.

contact the rim and damage it.

47. Refer to chart for wheel spacing.

2007

Sprocket

Side #1

1.490

RC

FBI151RCP

PM

STOCK

WELD

1.3”

HD106002

STOCK

STOCK

Pulley

Spacer

Side #2

.125

Inbetween

Hub and

Caliper #3

STOCK

STOCK

STOCK

Between

Caliper and

Swingarm #4

.475

FBI151RC

.530

.190

Image F

#1

#2

#3

#4

DRIVE PULLEY

Tire

BRAKE CALIPER

Swingarm

48. Install rear wheel axle half way through wheel, go to caliper side, install caliper and rotor at the

same time, and tighten one of the rotor bolts. Use stock spacers in between hub and brake

caliper, use supplied spacer in between brake caliper and swing arm. NOTE: Spacers vary with

wheel manufacturer.

Sliding axle through swingarm. Axle coming through hub on

right side.

Lining up rotor and caliper for

axle to slide through.

Page 20

641-774-7499

49. Slide axle through, tighten belt and torque axle nut to manufactured specications.

50. Install remaining rotor bolts. Reinstall exhaust pipes saddlebags seat, side cover.

www.fatbaggers.com

Tighten down last rotor bolts. Exhaust system installed. Installing sidecovers.

Installing saddlebags. Finished Look!

Loading...

Loading...