V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

1

VIM552

Graphics Processor Module

User Manual

Revision 1.4

December 2015

The product described in this manual is compliant

with all related CE standards.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

2

Product Title: VIM552

Document name: VIM 552 User Manual

Manual version: 1.4

Reference document: ИМЕС.468459.005

Copyright © 2015 Fastwel Co. Ltd. All rights reserved.

Revision Record

Revision No.

Brief description of changes

Board index

Revision date

1.0

Initial version of the User Manual

VIM552

October 2012

1.1

Commercial versions are excluded

VIM552

November 2012

1.2

Modifications of mechanical characteristics

VIM552

November 2012

1.3

Adjustment were made according to PC comments

VIM552

November 2012

1.4

Compliance assessment

VIM552

December 2015

Contact Information

Fastwel Co. Ltd

Fastwel Corporation US

Address:

108 Profsoyuznaya st.,

Moscow 117437,

Russian Federation

6108 Avenida Encinas,

Suite B, Carlsbad,

CA92011, USA

Tel.:

+7 (495) 232-1681 Tel.:

+1 (858) 488-3663

Fax:

+7 (495) 232-1654

E-mail:

info@fastwel.com E-mail:

info@fastwel.com

Web:

http://www.fastwel.com/

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

3

TABLE OF CONTENTS

CONTENTS……….....………………………………………………………………………………..………………....3

Trademarks .............................................................................................................................................................. 7

Ownership Rights ..................................................................................................................................................... 7

Copyright.................................................................................................................................................................. 7

Safety Requirements ............................................................................................................................................... 8

High Voltage Safety Rules ....................................................................................................................................... 8

Board Handling Instructions ..................................................................................................................................... 8

General Board Operation Rules ............................................................................................................................... 9

The Manufacturer's Guarantees .............................................................................................................................. 9

a. Transportation............................................................................................................................................. 11

b. Unpacking ................................................................................................................................................... 11

c. Storage ....................................................................................................................................................... 11

APPLICATION NOTES AND GUIDELINES ................................................................................................... 12

1. INTRODUCTION ......................................................................................................................................... 13

1.1 The Purpose of the Product ........................................................................................................................ 13

2. SPECIFICATIONS ................................................................................................................................ 14

2.1. MODULE FUNCTIONALITIES.................................................................................................................... 14

2.2. GENERAL VIEW AND DIMENSIONS ........................................................................................................ 15

2.3. BLOCK DIAGRAM (BOARD LAYOUT) ...................................................................................................... 16

2.4. HARDWARE VERSIONS, ORDERING INFORMATION, DELIVERY CHECKLIST ................................... 17

2.4.1. Hardware versions, ordering information ................................................................................... 17

3. TECHNICAL CHARACTERISTICS ............................................................................................................ 18

3.1. POWER SUPPLY ........................................................................................................................................... 18

3.2. SOFTWARE REQUIREMENTS ..................................................................................................................... 18

3.3. OPERATING CONDITIONS ........................................................................................................................... 18

3.4. MECHANICAL CHARACTERISTICS .............................................................................................................. 18

3.5. WEIGHT AND DIMENSIONS ......................................................................................................................... 19

3.6. MEAN TIME BETWEEN FAILURES (MTBF) .................................................................................................. 19

4. DESCRIPTION AND OPERATION ............................................................................................................. 20

4.1. DESIGNATION AND PINOUTS OF CONNECTORS ..................................................................................... 20

4.2. Switching the graphics output to RearIO ......................................................................................................... 22

4.3. USB connector ................................................................................................................................................ 22

ANNEX A DISCLAIMER…………………………………………………...………………………………………………………..22

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

4

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

5

List of Tables

Table 2-1: Module structure depending on the hardware version…………………………………………………..15

Table 3-0: Power supply………………………………………………………………………………………………....16

Table 3-1: Module weight………………………………………………………………………………………………..17

Table 4-1: Designation of XP1 and XP2 connectors…………………………………………………………………19

Table 4-1: (Continued) – Designation of XP1 and XP2 connectors………………………………………………...20

Table 4-2: Designation of XS1 connector……………………………………………………………………………...20

Table 4-3: Designation of XS5 connector……………………………………………………………………………...21

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

6

List of Figures

Fig. 2-1: General view of the Module……………………………………………………………………………………14

Fig. 2-2: Module block diagram…………………………………………………………………………………………. 15

All information in this document is provided for reference only, with no warranty of its suitability for any specific purpose. This information has

been thoroughly checked and is believed to be entirely reliable and consistent with the product that it describes. However, Fastwel accepts no responsibility

for inaccuracies, omissions or their consequences, as well as liability arising from the use or application of any product or example described in this

document.

Fastwel Co. Ltd. reserves the right to change, modify, and improve this document or the products described in it, at Fastwel's discretion without

further notice. Software described in this document is provided on an “as is” basis without warranty. Fastwel assumes no liability for consequential or

incidental damages originated by the use of this software.

This document contains information, which is property of Fastwel Co. Ltd. It is not allowed to reproduce it or transmit by any means, to translate

the document or to convert it to any electronic form in full or in parts without antecedent written approval of Fastwel Co. Ltd. or one of its officially authorized

agents.

Fastwel and Fastwel logo are trademarks owned by Fastwel Co. Ltd., Moscow, Russian Federation. Ethernet is a registered trademark of Xerox

Corporation. IEEE is a registered trademark of the Institute of Electrical and Electronics Engineers Inc. Intel is a trademark of Intel Corporation. Pentium M

and Celeron M are trademarks of Intel Corporation. Microsoft is a trademark of the Microsoft corporation. In addition, this document may include names,

company logos and trademarks, which are registered trademarks and, therefore, are property of their respective owners.

Fastwel welcomes suggestions, remarks and proposals regarding the form and the content of this Manual.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

7

Trademarks

"Fastwel" logotype is a trademark belonging to Fastwel Group Co. Ltd., Moscow, Russian

Federation.

Besides, this document may contain names, corporate logotypes and trademarks being

registered trademarks; consequently, property rights to them belong to their respective legitimate

owners.

Ownership Rights

This document contains information being the property of Fastwel Group Co. Ltd. It can

neither be copied nor transferred with the utilization of known media nor be stored in data storage

and search systems without the prior written authorization of Fastwel Group Co. Ltd. To our best

knowledge, the data in this document does not contain errors. However, Fastwel Group Co. Ltd

cannot take responsibility for any inaccuracies and their consequences, as well as responsibility

arising as a result of utilization or application of any diagram, product or example cited in this

document. Fastwel Group Co. Ltd reserves the right to alter and update both this document and

the product presented therein at its own discretion without additional notification.

Copyright

This document cannot be copied, reproduced, transferred or converted to any electronic or

machine-readable form without prior written permission of Fastwel Co. Ltd

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

8

Safety Requirements

This product of Fastwel Group Co. Ltd has been developed and tested with the purpose of

ensuring its compliance with electrical safety requirements. Its design provides long-term troublefree functioning. The product service life can be significantly shortened because of its incorrect

handling during unpacking and installation. Therefore, for your safety and ensuring of the correct

operation of the product you should adhere to the recommendations given below.

High Voltage Safety Rules

Any work with this device must be performed only by sufficiently skilled personnel.

Before installing the board into your system, make sure that the mains power supply is

disconnected. This is also true for the installation of expansion boards.

There is a serious hazard of electrocution in the process of the product installation, repair

and maintenance; therefore, always unplug the power cord during work performance. This is also

true for other power cables.

Board Handling Instructions

Electronic boards and their components are static sensitive. Therefore, special attention is

needed to ensure safety and normal operation while handling those devices.

Do not leave the board without protective package when it does not operate.

Always work with the board on static-safe workplaces if possible. If it is impossible, the

user must remove static charge from him/herself before touching the product with

his/her hands or tools. This is best done by touching a metal part of the system body.

It is especially important to observe precaution while replacing expansion boards,

jumpers, etc. Since there is a battery powering memory and real-time clock on the

board, do not put it on conductive surfaces, like antistatic carpets or sponges. They

may cause a short circuit and inflict damage to the battery and the board conductors,

as well as loss of real-time clock (RTC) data.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

9

General Board Operation Rules

To preserve the manufacturer's guarantee, the product must not be reworked or altered

in any way. Any alterations and improvements not authorized by Fastwel Group Co. Ltd

company, except those described in this Manual or obtained from the Fastwel Group

Co. Ltd technical support service in the form of a set of instructions describing their

performance cancel the guarantee.

This device must be only installed into and connected to systems meeting all

necessary technical and climatic requirements. This relates to the operating

temperatures range of the specific board design version. The temperature limitations of

the batteries installed on the board should be taken into account as well.

Please follow only the instructions of this Manual while performing all necessary

installation and configuring operations.

Keep original package to store the product in the future or to transport it in case of a

guarantee event. Should it become necessary to transport or store the board, pack it in

the same way it was packed upon receipt.

Take particular care during handling the product and its unpacking. Act in accordance

with the instructions of the above section and Chapter Transportation, Unpacking and

Storage.

The Manufacturer's Guarantees

Guarantee Liabilities

The Manufacturer hereby guarantees the product conformity with the requirements of TU

4013-004-52415667-05 specifications, provided the Consumer abides by the conditions of

operation, transportation, storage, installation and assembly established by the accompanying

documents.

The Manufacturer hereby guarantees that the products supply thereby are free from defects

in workmanship and materials, provided operation and maintenance norms were observed during

the currently established guarantee period. The Manufacturer's obligation under this guarantee is

to repair or replace free of charge any defective electronic component being a part of a returned

product.

Products that broke down through the Manufacturer's fault during the guarantee period will

be repaired free of charge. Otherwise the Consumer will be invoiced as per the current labor

remuneration rates and expendable materials cost.

Liability Limitation Right

The Manufacturer shall not be liable for the damage inflicted to the Consumer's property

because of the product breakdown in the process of its utilization.

Guarantee Period

The guarantee period for the products made by the manufacturer company is 36 months

since the sale date (unless otherwise provided by the supply contract).

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

10

The guarantee period for the products made to special order is 60 months since the sale

date (unless otherwise provided by the supply contract).

The warranty set forth above does not extend to and shall not apply to:

1. Products, including software, which have been repaired or altered by other than

Fastwel personnel, unless Buyer has properly altered or repaired the products in

accordance with procedures previously approved in writing by Fastwel.

2. Products, which have been subject to power supply reversal, misuse, neglect, accident,

or improper installation.

Returning a product for repair

1. Apply to Fastwel company or to any of the Fastwel's official representatives for the

Product Return Authorization.

2. Attach a failure inspection report with a product to be returned in the form, accepted by

customer, with a description of the failure circumstances and symptoms.

3. Carefully package the product in the antistatic bag, in which the product had been

supplied. Failure to package in antistatic material will VOID all warranties. Then

package the product in a safe container for shipping.

4. The customer pays for shipping the product to Fastwel or to an official Fastwel

representative or dealer.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

11

TRANSPORTATION, UNPACKING AND

STORAGE

a. Transportation

The module should be transported in a separate packaging box (transport packaging) of the

manufacturing facility, which consists of an individual antistatic bag and a cardboard box, in the

closed transport (automobile, railway, air transportation in heated and pressurized compartments)

in storage conditions 5 defined in the GOST standard 15150-69 or in storage conditions 3 during

sea transportation.

It is possible to transport modules, packaged in individual antistatic packages, in multiple

packaging (transport packaging) of the manufacturing facility.

The packaged modules should be transported in accordance with the shipping rules,

operating with this particular type of transport.

During handling and transportation operations, the packaged modules should not undergo

sharp pounding, falls, shocks and exposure to atmospheric precipitation. Method of stowing

packaged modules to the carrier vehicle should exclude their moving.

b. Unpacking

Prior to unpacking, before transportation at subzero temperature of ambient air the modules

should be kept within 6 hours under storage conditions 1 defined in the GOST standard 15150-

69.

It is prohibited to place the packaged module close to the heat source, prior to unpacking.

While unpacking, it is required to comply with all safety precautions, which ensure its safety,

as well as marketable condition of consumer packaging of the manufacturing company.

At the time of unpacking it is required to check the module that it has no external mechanical

damages after transportation.

c. Storage

Module storage conditions for group 1 are defined in the GOST standard 15150-69.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

12

APPLICATION NOTES AND GUIDELINES

The modules should be used in the modes and under conditions set by the present User Manual,

as well as technical specifications (TU 4013-006-52415667-05).

Connection (disconnection) of external devices to the modules (from the module) in the running

mode is not allowed.

Connection (disconnection) of the module to the direct current external source (from the external

source) in running mode is not allowed.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

13

1. INTRODUCTION

1.1 The Purpose of the Product

This user manual (hereinafter referred to as the Manual) is meant for the insight into the

device, its operation principle and general information required for the commissioning, intended

use and maintenance of VIM552 (hereinafter referred to as the Module).

NOTE: THIS DOCUMENT PRESENTS THE ACTIVE VERSION 1.3 OF THE MANUAL1.

The Module is designed and suitable for the use on platform based on the CompactPCI ®

PlusIO specification (e.g. on the basis of CPC506, CPC508 Modules), and on platforms based on

CompactPCI ® Serial specification (e.g. on the basis of CPC510 Module). It enables to expand

graphics capabilities as compared to the processor module integrated video subsystem and can

connect two monitors via DVI-I and VGA interfaces.

SM750 graphics controller, used in the module, has a low power consumption, which enables to do

without the passive cooling and place SATA 2.5” Storage Carrier in the module.

WARNING: THE MODULE OPERATION WITHOUT OBSERVING SAFETY

REQUIREMENTS, UTILIZATION AND OPERATION INSTRUCTION IS

NOT PERMITTED!2)

ATTENTION: THE MODULE CONTAINS STATIC SENSITIVE COMPONENTS! 3)

FORBIDDEN: OPERATION, MAINTENANCE AND REPAIRS OF THE MODULE BY

PERSONS LACKING THE RESPECTIVE SKILLS AND THE REQUIRED

LEVEL OF SPECIAL TRAINING! 4)

1

The graphic symbol (sign) is hereinafter used together with the explanatory word "Note" and the

explanation text

2

The graphic symbol (safety sign as per GOST R 12.4.026-2001) is hereinafter used jointly with the warning

word "WARNING" and the warning text (as per GOST 2.601-2006).

3

The graphic symbol (safety sign as per GOST R 12.4.026-2001) is hereinafter used jointly with the warning

word "ATTENTION" and the warning text (as per GOST 2.601-2006).

4

The graphic symbol (safety sign as per GOST R 12.4.026-2001) is hereinafter used jointly with the warning

word "FORBIDDEN" and the warning text (as per GOST 2.601-2006).

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

14

2. SPECIFICATIONS

The Module has the following I/O channels structure:

DVI-I output (DVI1+RGB1) + USB (contacts 12, 13, option)

VGA output (RGB0) on the front panel

USB output on the front panel

1xSATA + SATA Power corner on the board

Compact PCI Plus Type A (Power 12V, x1 PCI-E, 1 SATA, 1 USB)

Compact PCI Plus Type B (option, RearIO 16 lines, rooted to RGB0, DVI1, I2C)

2.1. MODULE FUNCTIONALITIES

LynxExp SM750 Graphics Processor:

o 1x PCI-Express 1.1 (up to 2.5 GB/s)

o 16 MB internal DDR RAM (32 bit)

o DDR RAM interface, 64 bits, up to 64 MB

o 2x independent RGB outputs

o 1x digital 24-bit output

System memory:

o DDR333 SDRAM 64 MB, soldered

Video output:

o VGA connector (resolution up to 1920х1440 @ 60Hz), rooted to the front panel

o DVI-I connector (resolution up to 1920х1200 @ 60Hz, one channel mode) rooted to

the front panel

o Further optionally to RearIO via CPCI Plus Type B connector:

o Copy of DVI (digital) output

o Copy of VGA0 output

o 2x channels I2C (DDC), rooted to RearIO via SA1 switch

PCI-E bus

o 1x PCI-Express in accordance with PlusIO PICMG 2.30 specification

o Compatibility with PCI-E 1.1 specification (2.5 Gb/sec.)

SATA interface:

o 1 x onboard corner SATA connector with power

o The revision type and the interface speed are defined by the CPU board;

o The power consumption is limited by 1 А @ +5 V

USB ports:

o 1x USB port is rooted to the front panel

o T1xUSB port can be rooted to DVI connector (upon request);

FLASH BIOS:

o 512 kbit SPI-Flash

Supported OS:

o Windows XP (Embedded)

o Linux 2.6

o Windows 7

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

15

2.2. GENERAL VIEW AND DIMENSIONS

General view and dimensions of the devices are shown on Figure 2.1:

Figure 2.1 – General view of the module

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

16

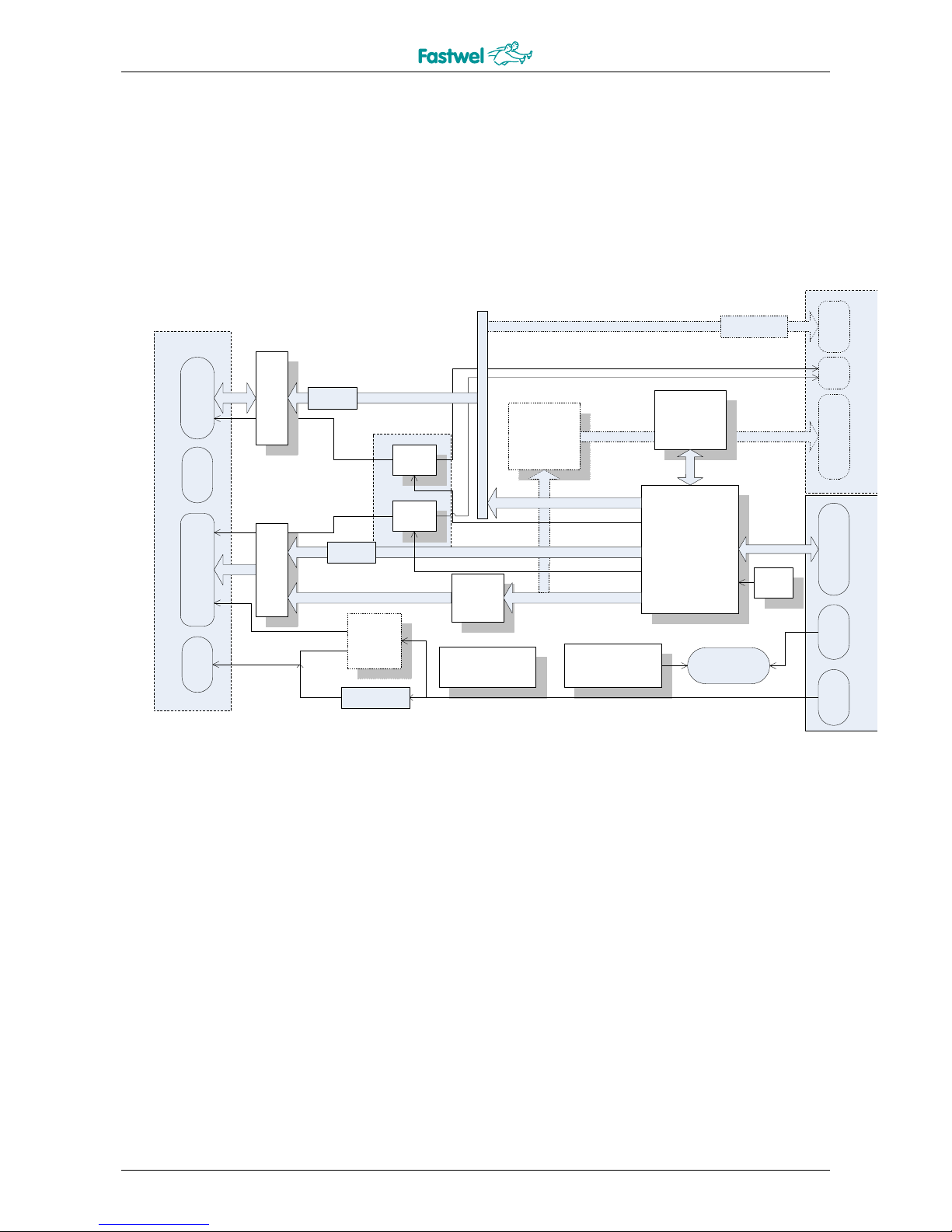

2.3. BLOCK DIAGRAM (BOARD LAYOUT)

The block diagram of the module is shown on 2.2., the spot lines mark elements installed

only in VIM552-02 versions.

(VIM552-02)

Compact PCI Serial Connector Type A

Лицевая панель

DD1

GPU

SM750

RGB DB15

Connector

1x PCI-Express Link

DVI Phy

TFP410

1x PCIe

DC/DC

12V -> 5V, 2.5A

DC/DC

Vin: 12V

Vout: 2.5V, 2A

SATA

SATA

Connector

DVI-I

Connector

USB

Compact PCI Serial Connector Type B

(VIM552-02)

USB

DVI Phy

TFP410

(VIM552-02)

FP1

DVI-D

RearIO Output

DD3-DD6

DDR SDRAM

MT46V8M16

64-bit

Interface

DVI1 Copy

DDC0

I2C

Switch

DDC RGB0

Filter

(VIM552-02)

DD8

VBIOS

Protection circuit

DD10

USB Hub

(по

запросу)

I2C

Bypass

I2C

USB

Protection circuit

Filter

DDC1

I2C

Switch

LED

RGB0

RGB1

Filter

Figure 2.2 – Module block diagram

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

17

2.4. HARDWARE VERSIONS, ORDERING INFORMATION,

DELIVERY CHECKLIST

2.4.1. Hardware versions, ordering information

Module hardware versions and notations (ordering information) in FASTWEL product

catalogs are specified in table 2.1.

Table 2.1. – Module structure depending on the hardware version

Name

Notation at the

time of order

Note

Module VIM552

VIM552-01-I

VIM552 64Mb RAM, DVI-I, VGA, USB,

SATA, industrial temperature range (–

40°С to +85°С)

VIM552-02-I

VIM552 64Mb RAM, DVI-I, VGA, USB,

SATA; DVI-D, VGA on RearIO, industrial

temperature range (–40°С to +85°С)

Available options:

/COATED – Conformal coating

2.4.2. Delivery checklist

1. VIM552 module

2. Antistatic bag

3. Package

4. Installation kit: 4 × M3×5 DIN7985 screws

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

18

3. TECHNICAL CHARACTERISTICS

3.1. POWER SUPPLY

The board is supplied with a voltage of +12V. Electric power supply of the module must meet

the requirements cited in the table below.

Voltage

(V)

Minimum (V)

Maximum

(V)

Consumption current

(A)

+12 В

11.4

12.6

0.4

To provide the voltage +5 V for SATA and USB, use the pulse converter from +12 V to +5 V with a

design efficiency of 85%. The current in the SATA power supply circuit is limited to 1 А, USB – to

0.5 A.

3.2. SOFTWARE REQUIREMENTS

The device is compatible with the following OS:

Windows XP (Embedded)

Windows 7

Linux 2.6

Drivers for Windows XP (in binary form) and for Linux (with source code) are provided by the

manufacturer of SM750 - Silicon Motion company.

3.3. OPERATING CONDITIONS

The module must be used under the following operating conditions:

-Operating temperature range: Industrial: - 40° С to + 85° С

-Relative air humidity: 5 to 95 % at + 25° С (noncondensing);

-Use of \COATED option for increased humidity environment.

3.4. MECHANICAL CHARACTERISTICS

Vibration resistance for frequencies from 10 to 50 Hz – amplitude 0,5 mm

Vibration resistance for frequencies from 50 to 500 Hz acceleration – 5 g;

Resistance to single shocks, peak acceleration – 100 g;

Resistance to multiple shocks, peak acceleration – 50 g.

NOTE: MECHANICAL CHARACTERISTICS DO NOT APPLY TO REMOVABLE CONNECTIONS.

UNDER SEVER OPERATING CONDITIONS AND RESONANCE PHENOMENA, THE REMOVABLE

CONNECTIONS SHOULD BE ADJUSTED.

RESONANCE PHENOMENA ASSOCIATED WITH THE CRATE ELEMENTS FIXING RIGIDITY AT

FREQUENCIES 100-300 HZ WITH A 5 TIME INCREASE IN THE ACCELERATION RATE.

VIM552 Graphics Processor Module Specifications

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

19

3.5. WEIGHT AND DIMENSIONS

Module weight should not exceed the values specified in table 3.1.

Table 3.1 – Module weight

Hardware version

Weight, kg, no more than

Weight with packaging, kg, no

more than

VIM552-01-I

0,15

0,47

VIM552-02-I

0,16

0,48

Module dimensions: 212,8 x 130,5 x 20,3 mm.

Packaging dimensions: 350,0 x 260,0 x 70,0 mm.

3.6. MEAN TIME BETWEEN FAILURES (MTBF)

MTBF value for the module is: 340 000 hours.

NOTE: THIS MTBF VALUE HAS BEEN CALCULATED ACCORDING TO THE TELCORDIA

ISSUE 1 CALCULATION MODEL, METHOD I CASE 3 CALCULATION

PROCEDURE, FOR CONTINUOUS OPERATION ON EARTH UNDER THE

CONDITIONS MEETING UKHL4 UNDER GOST 15150-69, AT AMBIENT

TEMPERATURE +30С.

VIM552 Graphics Processor Module Appendices

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

20

4. DESCRIPTION AND OPERATION

4.1. DESIGNATION AND PINOUTS OF CONNECTORS

The Module has the following structure of I/O channels:

DVI-I output (DVI1+RGB1) + USB (option, contacts 12, 13)

VGA output (RGB0) on the front panel

USB output on the front panel

1 SATA + SATA Power corner on the board

Compact PCI Plus Type A (Power 12V, x1 PCI-E, 1 SATA, 1 USB)

Compact PCI Plus Type B (option, RearIO 16 lines, rooted to RGB0, DVI1, I2C)

Designation of XP1 and XP2 connectors according to PICMG CPCI-S.0 3U specification is stated

in the table 4.1:

Table 4.1 – Designation of XP1 and XP2 connectors

XP2 - 08

GND

HOT PLUG

DETECT

DVI_ANALOG

VERT. SYNC

GND

DVI_DDC CLOCK

DVI_DDC DATA

XP2 - 07

IO

IO

GND

T.M.D.S

DATA 1-

T.M.D.S DATA 1+

GND

XP2 - 06

GND

IO

IO

GND

IO

IO

XP2 - 05

IO

IO

GND

IO

IO

GND

XP2 - 04

GND

IO

IO

GND

IO

IO

XP2 - 03

IO

IO

GND

IO

IO

GND

XP2 - 02

GND

1_PE_Tx06+

1_PE_Tx06-

GND

1_PE_Rx06+

1_PE_Rx06-

XP2 - 01

1_PE_Tx0

4+

1_PE_Tx04-

GND

1_PE_Rx04+

1_PE_Rx04-

GND

XP1 - 06

GND

1_PE_Tx02+

1_PE_Tx02-

GND

1_PE_Rx02+

1_PE_Rx02-

XP1 - 05

1_PE_Tx0

0+

1_PE_Tx00-

GND

1_PE_Rx00+

1_PE_Rx00-

GND

XP1 - 04

GND

1_USB2+

1_USB2-

GND

PE_CLKIN+

PE_CLKIN-

XP1 - 03

1_USB3_T

x+

1_USB3_Tx-

GA0

1_USB3_Rx+

1_USB3_Rx-

GA1

XP1 - 02

GND

I2C_SCL

I2C _SDA

GND

reserved

reserved

XP1 - 01

+12V

STNDBY

GND

+12V

+12V

GND

Pin

A B C D E

F

VIM552 Graphics Processor Module Appendices

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

21

Table 4.1 (continued) – Designation of XP1 and XP2 connectors

XP2 - 08

IO

GND

IO

IO

GND

DVI_ANALOG

BLUE

DVI_ANALO

G HORZ

SYNC

XP2 - 07

GND

T.M.D.S

DATA 2-

T.M.D.S

DATA 2+

GND

T.M.D.S

CLOCK-

T.M.D.S

CLOCK+

GND

XP2 - 06

IO

GND

DVI_ANALO

G RED

DVI_ANAL

OG GREEN

GND

VGA_DDC

CLOCK

VGA_DDC

DATA

XP2 - 05

GND

IO

IO

GND

IO

IO

GND

XP2 - 04

IO

GND

IO

IO

GND

IO

IO

XP2 - 03

GND

IO

IO

GND

IO

IO

GND

XP2 - 02

1_PE_Rx0

6-

GND

1_PE_Tx07+

1_PE_Tx07-

GND

1_PE_Rx07+

1_PE_Rx07-

XP2 - 01

GND

1_PE_Tx05+

1_PE_Tx05-

GND

1_PE_Rx05

+

1_PE_Rx05-

GND

XP1 - 06

1_PE_Rx0

2-

GND

1_PE_Tx03+

1_PE_Tx03-

GND

1_PE_Rx03+

1_PE_Rx03-

XP1 - 05

GND

1_PE_Tx01+

1_PE_Tx01-

GND

1_PE_Rx01

+

1_PE_Rx01-

GND

XP1 - 04

PE_CLKIN-

GND

1_SATA_Tx

+

1_SATA_Tx

-

GND

1_SATA_Rx+

1_SATA_Rx-

XP1 - 03

GA1

SATA_SDI

SATA_SDO

GA2

SATA_SCL

SATA_SL

GA3

XP1 - 02

reserved

GND

RST_IN#

WAKE_OU

T#

GND

PCIE_EN#

SYSEN# *)

XP1 - 01

GND

+12V

+12V

GND

+12V

+12V

GND

Pin F G H I J K

L

Designation of XS1 connector (DVI output) is stated in table 4.2.

Table 4.2 – Designation of XS1 connector

Output No.

Signal notation

Output

No.

Signal notation

1

T.M.D.S DATA 2-

16

HOT PLUG DETECT

2

T.M.D.S DATA 2+

17

T.M.D.S DATA 0-

3

GND

18

T.M.D.S DATA 0+

4

NC

19

GND 5 NC

20

NC

6

DDC CLOCK

21

NC 7 DDC DATA

22

GND

8

ANALOG VERT. SYNC

23

T.M.D.S CLOCK+

9

T.M.D.S DATA 1-

24

T.M.D.S CLOCK-

10

T.M.D.S DATA 1+

C1

ANALOG RED

11

GND

C2

ANALOG GREEN

12

USB DATA-

C3

ANALOG BLUE

13

USB DATA+

C4

ANALOG HORZ SYNC

14

USB +5V POWER

C5

ANALOG GROUND

15

GND

-

-

XS5 connector designation (SATA 2.5”) is described in table 4.3.

VIM552 Graphics Processor Module Appendices

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

22

Table 4.3 – Designation of XS5 connector

Contact

No.

Signal

Designation

Signal

Description

Contact

No.

Signal

Designation

Signal Description

1

GND

Ground

P5

GND

Ground

2

A+

Transmit +

P6

GND

Ground

3

A-

Transmit -

P7

V5

5v Power

4

GND

Ground

P8

V5

5v Power

5

B-

Receive -

P9

V5

5v Power

6

B+

Receive +

P10

GND

Ground

7

GND

Ground

P11

DAS/DSS

Pulled low-immediate spin-up

P1

V33

3.3v Power

P12

GND

Ground

P2

V33

3.3v Power

P13

V12

12v Power

P3

V33

3.3v Power

P14

V12

12v Power

P4

GND

Ground

P15

V12

12v Power

4.2. Switching the graphics output to RearIO

Switching the graphics output from the front panel to the board of Rear I/O (only in VIM552-02

versions) is carried out via SA1 switch. Switch position opposite to R symbol that conforms to

rooting to RIO, position F – to rooting to the front panel.

NOTE: IN THE BOARD VERSION 1.1 THE SWITCH IS NOT INSTALLED.

4.3. USB connector

The USB connector is rooted to the module front panel enables to connect various external

devices. The permitted cable length for some peripheral devices may be limited as compared to

the standard one.

VIM552 Graphics Processor Module Appendices

V I M 5 5 2 U s e r M a n u a l © 2015 F a s t w e l V e r . 1.4

23

APPENDIX A: DISCLAIMER

This Disclaimer contains special operating conditions of Fastwel in the following areas: intellectual property, warranty

policy, conditions of the order and delivery.

1 INTELLECTUAL PRORETY

1.1 If any infraction, interference, improper use, illegitimate exploitation and/or violation of the industrial and/or intellectual

property rights of any third party and/or property, exploitation during the use of Fastwel Embedded Module will take place

– Fastwel does not guarantee to replace the materials, computer programs, procedures or equipment affected by the

complaint and under no circumstances doesn't bear responsibility in any form for possible refusal in case of such a

replacement.

1.2 Use of the Fastwel products as well as the objects of intellectual property containing in them, in the ways and for the

purposes, not provided by the present user manual and datasheet isn't allowed without preliminary written approval of

Fastwel.

1.3 Fastwel is not responsible for possible incidents and losses, related to the operation of end devices, in which the

original Fastwel equipment is used.

2 WARRANTY POLICY

2.1 When the detected flaws in an element can be corrected without decreasing the foreseen technical features and

functionality for it, User may demand Fastwel the urgent correction of the failures in additionally agreed period and an

increasing of the period of the guarantee of the element equal as the time elapsed from the formal request to repair the

failures, until the receipt of the repaired element. All costs associated to the correction of failures, included those of

assembly, dismantle, transport, tests, etc, if they exist, shall be prosecuted according the Warranty Policy of Fastwel.

3 ORDER AND DELIVERY CONDITIONS

3.1 The general rule is that all Fastwel equipment prices are determined with due consideration of delivery under the

EXW terms and conditions (Incoterms 2010). Delivery of the products under other terms and conditions should be

preliminary agreed and stated in writing between the parties.

3.2 Unless otherwise expressly agreed with Fastwel, all the deliveries of Fastwel equipment will be carried out only after

the official purchase order is obtained and provided that the ordered products have been prepaid in full. Other terms and

conditions of cooperation should be made in writing.

3.3 Any delivery of Fastwel electronics is submitted with the right package in accordance with the current rules and

standards in the Member States of the European Economic Area. The purchaser independently bears all risks regarding

the compliance of package and marking of Fastwel products with legislation requirements being in effect at the place of

purchased products destination (in the buyer’s country). The specified condition excludes unequivocally any liability of

Fastwel for possible non-compliance of package and marking of products with the requirements of legislation of the

country of products destination.

3.4 In general, all components of the supply are properly protected with respect to freight, in order to avoid any damage

to the supply, third parties, environmental damages or unrelated goods, as consequence of wrong packaging.

3.5 Each package unit is labeled on the exterior area with the indications of product’s Part Number and Serial Number.

3.6 The support documents for the order should be made either in English or in Russian unless otherwise agreed

between parties in writing.

3.7 Fastwel does not pay penalties and does not cover costs associated with delay in the delivery of the products caused

by actions of the third parties, force-majeure etc. - Fastwel doesn't bear any responsibility for non-execution or

inadequate execution of the obligations in a case when it is caused by actions of the third parties (for example producers

or suppliers of accessories), force majeure etc.

3.8 Fastwel declares that independently and at any time without damage, it has an exclusive right to define and change

functionality architecture, bill of materials of its products without any preliminary coordination and approvals of the third

parties.

4 OTHER CONDITIONS

4.1 Fastwel has the obligation to respect the current Russian legislation (including, but not limited to environmental,

labor, social laws) in each moment and to apply it to its embedded electronics considering all and each execution phase,

that is to say, from the design until the commissioning and subsequent maintenance. In this regard Fastwel is not liable

to the user or other persons in connection with possible changes of the company’s rules (including, but not limited to

warranty, ordering policy) caused by changes of the Russian legislation.

4.2 Unless otherwise expressly agreed in writing, Fastwel provides no training for assembly\installation\adjustment\operation of its

equipment.

Loading...

Loading...