Fastron Parts VC-220 Operation Manual

VC-220 VISION Series

8 Product Keys / VFD Display

Operating Guide

Toll-Free Technical Support

24 Hours A Day, 365 Days A Year

(from the U.S., Canada and the Caribbean)

1-800-243-9271

This document contains confidential

information. The dissemination, publication,

copying, or duplication of this document or

the software described herein without prior

written authorization is strictly prohibited.

w

w

w

.

f

a

s

t

i

n

c

m

.

o

c

F

-

0

0

8

-

1

the time is right.

N

O

R

T

S

A

$5.00 USD

Notices–Before You Start, Please Read Entire Manual

NOTE: This manual will thoroughly familiarize you with

the operation of the (FASTRON.) Controller so that you

(FAST.) is not liable for any use of product not in

accordance with its installation and operating

instructions.

may use it in the most effective way to enhance the

smooth running of your restaurant’s cooking

operations.

There are four modes of operation on the Controller:

Before using this equipment, or for any questions on

the operation of the appliance, consult and follow all

instructions and safety warnings found in the

appliance operator’s manual supplied from the

manufacturer of the appliance.

Not all features are available on some models.

CONTROLLER OPERATING ENVIRONMENT

The solid state components in this controller are

designed to operate reliably in a temperature range up to

158°F/70°C. Before installing this controller, it should be

verified that the ambient temperature at the mounting

location does not exceed 158°F/70°C.

CLEANING THE CONTROLLER

Using a clean damp cloth, wipe down your controller

daily using a commercial quality foodservice-approved

detergent.

Do not allow oil to build up on any part of the controller.

• Operating Mode — used to time various menu

items

• Product Program Mode — used to add or modify

menu items or change settings

• System Program Mode — used to modify

operating parameters

• Diagnostic Mode — used to test product key

LEDs, product key audible signals, the VFD display,

and cook status LEDs

This instruction booklet covers (FASTRON.) Vision

Controller Model VC-220.

If any problems occur, or if you have any questions

about the instructions, contact FAST technical support

toll-free at 1-800-243-9271.

INSTALLING THE CONTROLLER

1. Use supplied mounting screws and brackets to

secure controller to appliance.

2. Attach the grill control cable to controller and the gas

control valve on the grill.

NEVER use chemical or abrasive cleaners on your

controller. The controller’s overlay may be damaged.

This document contains confidential information. The dissemination, publication, copying, or duplication of this document or the software described herein without prior written authorization is strictly prohibited.

2

(FASTRON.) VC-220

www.fastinc.com 1-800-243-9271

229-51300 E © 2005-2010 FAST

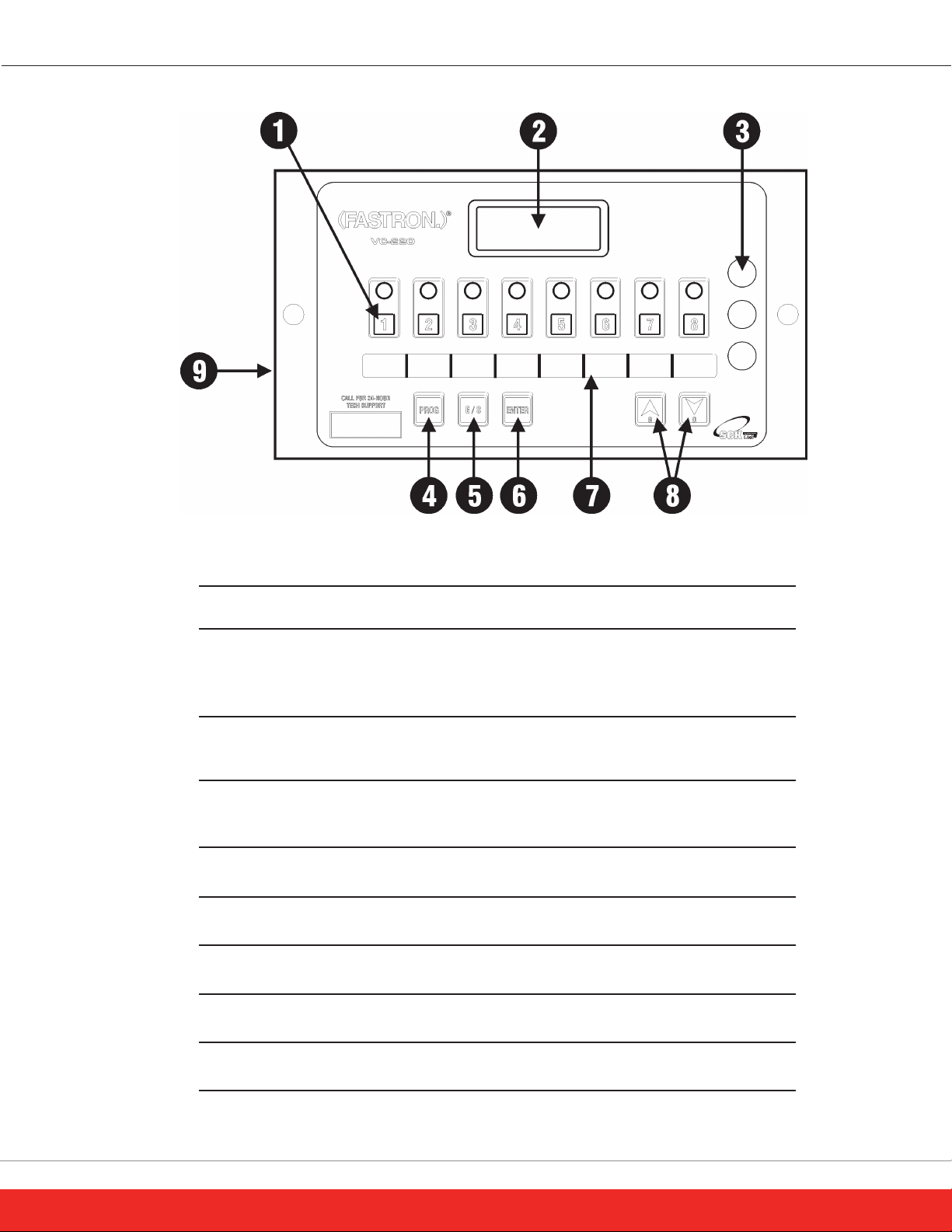

Controller Features

NOTE: The controller operates in minutes and seconds.

1 PRODUCT KEY: In “Programming” mode used to program product cooking

times. In “Operating” mode, used to start product timing cycles.

2 ACROSS-THE-KITCHEN MONITORING: Easy-to-read, VFD (vacuum fluores-

cent) display allows crew members to quickly check the status of any food

product from across the kitchen. The display will show the countdown or

name of product.

3 STATUS LAMPS: Red, yellow and green lamp lights provide visual indication

of stage time (cooking, hold, discard, and idle). See page 6 for further explanation.

4 PROGRAMMING KEY: In “Operating” mode, allows access to the program-

ming mode. In “Programming” mode, steps to the next function to be programmed.

5 ENGLISH/SPANISH KEY: User can toggle between English and Spanish lan-

guages during or prior to a cook cycle.

6 ENTER KEY: Used to save “Programming” changes. It is also used during sys-

tem information, system program and disgnostic modes.

7 UP and DOWN ARROW KEYS: In “Programming” mode, scrolls through fea-

tures forwards (up) or backwards (down).

8 Clear window for replaceable menu strip.

9 ON/OFF SWITCH: Located in the rear of unit.

This document contains confidential information. The dissemination, publication, copying, or duplication of this document or the software described herein without prior written authorization is strictly prohibited.

(FASTRON.) VC-220

www.fastinc.com 1-800-243-9271

229-51300 E © 2005-2010 FAST

3

Feature Definitions

Stage Timing

Each product key has up to eleven (11) timing stages.

Each stage has:

1. Product name

2. Auto preheat flag

3. Stage or preheat time

4. Stage name

5. Heat ON time

6. Lamp color

7. Lamp state

8. Stage done

9. Hold mode flag

10. Cancel mode

11. Beep frequency

Cancel Mode

The VC-220 offers a choice of Manual or Automatic

canceling of each product stage.

English/Spanish Mode

The user can switch from English to Spanish languages

by pressing this key on the front panel either before or

during a timing cycle.

Cook Status Lamp Lights

a. SOLID RED: Idle Mode

b. FLASHING RED: Discard Mode (until someone

presses the product button to

return to idle mode).

c. SOLID YELLOW: Last Hold Mode

d. SOLID GREEN: Ready to Serve, Initial Hold Modes

e. FLASHING GREEN: Pre-Heat/Cooking Modes

NOTE: These are default settings that can be

configured in each stage.

Power Loss Protection

In the event of a momentary power loss, the controller

will resume its current operation from the point power

was interrupted. Programmed recipes are always

saved.

Free Technical Support

24x7x365 toll-free, no charge, technical support for

programming assistance.

Alarm Frequency — 6 Different

The VC-220 can be programmed for one of six (6)

different alarm frequencies. Choices are NONE, 1, 2, 3,

4, 5 or 6 beeps per second.

Hold Mode

Each recipe stage has an associated hold mode flag.

The hold mode flag is used by the auto-preheat

function, and the auto cancel and restart function. If an

active recipe stage has its hold mode flag set to

enabled, then the stage is referred to as a “Hold

mode” stage and is used to warm and/or hold the

product for a programmable amount of time. If the flag

is set to disabled, then the stage is a cook stage and is

used to cook the product or dissipate excess steam. A

“Hold Mode” stage uses the same programmable

parameters as a cook stage. However, one unique

functional difference of an active “Hold Mode” stage is

that the recipe may be restarted while performing this

type of stage.

Intuitive User Interface

a. Bright blue 16x2 (16 characters x 2 lines) VFD

(vacuum flourescent display).

b. Red LED lights for each product key.

This document contains confidential information. The dissemination, publication, copying, or duplication of this document or the software described herein without prior written authorization is strictly prohibited.

4

(FASTRON.) VC-220

www.fastinc.com 1-800-243-9271 229-51300 E © 2005-2010 FAST

Loading...

Loading...