Fastron Parts 500 Series, 580 Series, 590 Series, 690 Series General Manual

For Henny Penny

Pressure Fryers

500, 580, and 600 Series Fryers

590 and 690 Series Fryers

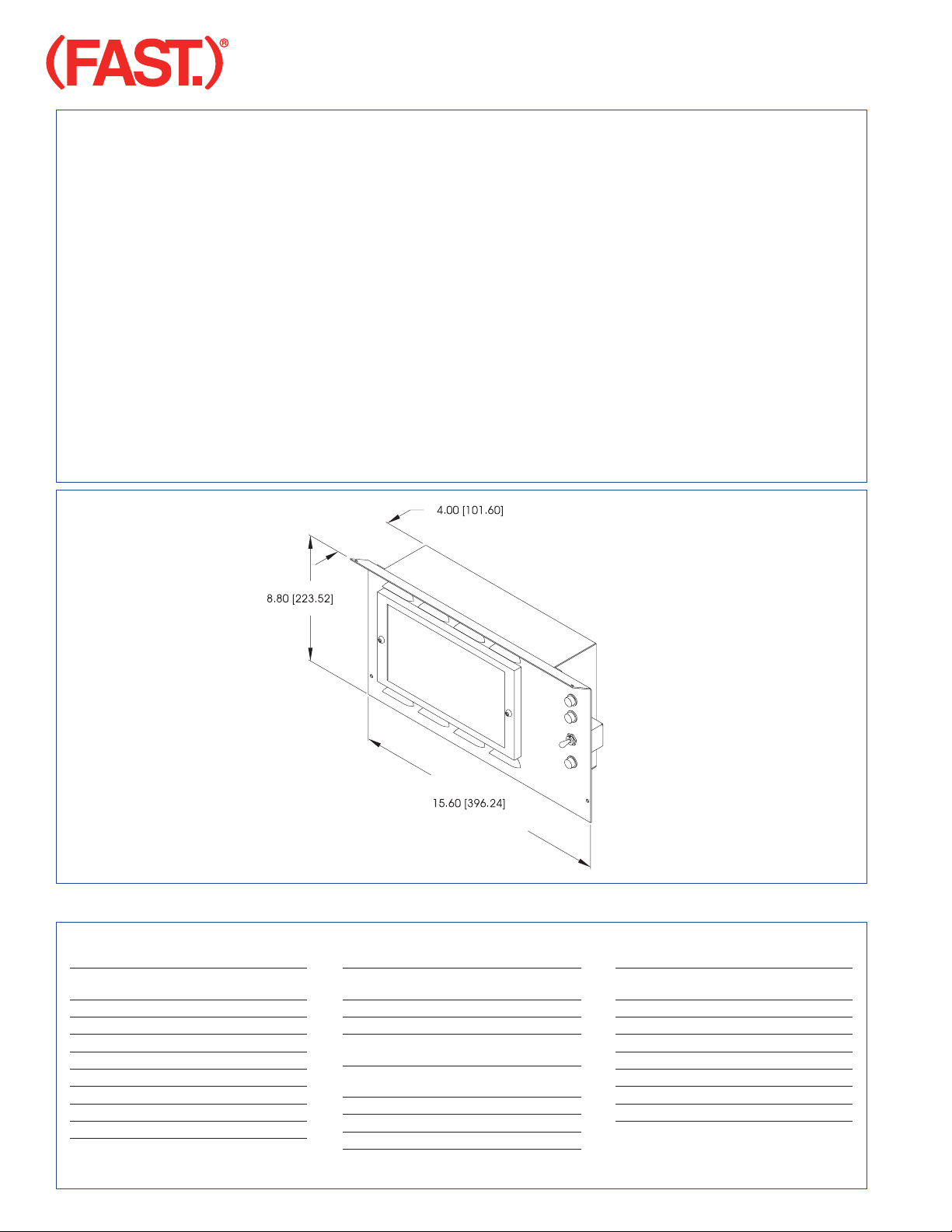

Upgrade Kit for the 690 Series Shown

The FAST Upgrade Kits for Henny

Penny Pressure Fryers give higher

and more consistent yields than any

electromechanical controls or other

electronic controllers already installed

in your kitchen.

Easiest To Install & Use

Simply remove the original controls

from the fryer manufacturer and slide

in the FAST controller made by the

industry’s controller specialists.

Ensure Food Safety and Quality

Product that is undercooked or held

too long in the Danger Zone (40°140°F/5°-60°C) can potentially expose

your customers and crew to dangerous food-borne illness. Bacteria

multiplication can be prevented by

controlling the time a product is

cooked and/or held. The (FASTRON.)

helps operators avoid food safety dangers by automatically monitoring these

cook and hold times. Precisely timed

products deliver consistently goodtasting food to your customers.

Hold timers also ensure that expired

product is never served.

Increase Yields

Independent tests show the

(FAST.Flex)

the best and most consistent yields

across load sizes and cooking temperatures, regardless of product

temperature and moisture content. A

reduction in food waste can also be

realized.

TM

cooking curve provides

Easy to Program

(FAST.Nav)TMmobile phone style and

predictive text programming reduces

training time and increases

productivity.

User-Friendly Messaging

Enhanced graphical display allows a

greater range of names and prompts

to be used. Create your own product

w

w

w

.

f

a

s

t

i

n

m

c

o

.

c

0

8

-

1

T

S

A

F

-

0

menu and action alarm names, or

choose from a pre-programmed library

of standard menu items.

Interchangeable with Other Fryers

Easily move your (FASTRON.) to

another fryer eliminating the need to

purchase a new control. The controller

can be configured to work on fryers

from a variety of manufacturers.

Secure Operation

Separate pass codes for store managers and employees prevent

unauthorized re-programming.

Energy Savings (optional)

Save energy dollars with the FAST

patented Set Back feature. The controller will automatically lower the

appliance’s temperature during inactive periods.

Filter Lockout Oil Management

(optional). Reduce costs by extending

the usable life of your oil with FAST’s

patented SmartStat

control technology. Filtering your oil at

pre-set time(s) of the day will not only

give you longer oil life, but will also

improve product flavor and reduce the

amount of time and labor it takes to

change out the oil.

TM

temperature

24/7 Technical Support

As with all FAST products, the

(FASTRON.) comes with 24-hour

programming assistance via toll-free

phone.

Standard (FASTRON.) Features

R

10 or 20 Product Keys to support

ever-changing menus. More space

for LTOs (limited time offers).

R

Fully RoHS compliant

R

Easy to read displays.

N

O

R

R

Appliance mode front-panel

selectable: gas, electric,

propane, etc.

R

Replaceable menu strip for quick

and easy menu changes.

R

SCK XwireTMwireless

communications compatible for

the networked kitchen

R

(FAST.Edit)®and (FAST.Transfer)

compatible. Reduces time and

cost to change recipes. Ensures

consistent recipes across all

appliances/restaurants.

Optional (FASTRON.) Features

R

Product and Action Alarm name

library programming

R

Adjustable audio alarm levels

R

Diagnostic feature to assist with

testing all inputs and outputs

R

3 pre-programmed fryer types

(Universal Appliance Control)

R

Energy-saving “set back” mode

R

3 action alarms per key

R

10 cooking stages instead of one

R

Twice the hold times

R

Filter lockout oil management

R

SCK Link®software giving you the

most advanced communications

capability available for HACCP

reporting and automated on-line

kitchen management.

the time is right.

TM

(FASTRON.) For Henny Penny Pressure Fryers

500, 580, and 600 Series Fryers

SPECIFICATIONS – 500, 580, 600 Series Fryers; 590 and 690 Series Fryers

MECHANICAL

n

Header: 16 ga. stainless steel

n

Front panel: .080 aluminum

n

Chassis: .040 aluminum

n

Polyester face with back-printed text

n

Maximum ambient temperature: 158°F / 70°C

ELECTRICAL

n

Power: 120 or 208/230VAC, 50/60 Hz, 40 VA Max.

n

Solid-state integrated circuit design

n

Switch life rating: >1 million cycles

n

Status indicators rated life: 50,000 hours

n

Input: 1 temperature sensing thermistor probe

n

Output: Pressure solenoid valve and heat control output, contact closure 240VAC @ 10A max. Relay 10A DPDT SLD 24V DC coil

n

Noise spike protection: 4,000 volt minimum (on timers and all properly installed controls)

SHIPPING WEIGHT

n

Approx. 3 lbs. (1.4 Kg)

SHIPPING DIMENSIONS

n

L 22 X W 16 X H 5 inches)

500, 580, and 600 Series

The FAST Upgrade Kit consists of everything you need to easily and quickly replace the existing controller with the Upgrade Kit.

Picture depicts (FASTRON.) VC-210. Also available with Meridian.

ORDERING INFO

4-HEAD ELECTRIC 500 SERIES FRYER

HP4EI081MA for a Complete

Upgrade Kit

Included with the kit are the following:

231-60210-09 Controller

140-60020-17 Probe Inpot, Elec.

213-50405-02 Contactor Assy. Kit

222-50207-02 Adaptor Harness

233-50071-02 Header Assy. 208V

213-50429-02 Installation Kit

233-50071-05 Header 240V

233-50071-10 Header 230V

*Ordering information contains a Meridian. Consult factory for part numbers of other available models.

8-HEAD ELECTRIC 580 SERIES FRYER

HP8EI081MA for a Complete

Upgrade Kit

Included with the kit are the following:

231-60210-09 Controller

140-60020-17 Probe Inpot, Electric or

(for use with the -09 and -11 Hdr. Ass’y.)

140-60020-34 Probe Inpot, Electric

(for use with the -07 Hdr. Ass’y.)

222-50207-02 Adaptor Harness

233-50071-07 Hdr. Ass’y. 208V, or

233-50071-09 Hdr. Ass’y. 240V

233-50071-11 Hdr. Ass’y. 230V

4-HEAD GAS 600 SERIES FRYER

HP4GI081MA for a Complete

Included with the kit are the following:

231-60210-09 Controller

140-60039-01 Probe Inpot, Gas

213-50402 Terminal Kit

222-50125 Harness

222-50207-02 Adaptor Harness

233-50071-01 120V Header (or)

233-50071-03 230V Header CE

Upgrade Kit

Loading...

Loading...