FastenMaster TrapEase Stainless Steel User Manual

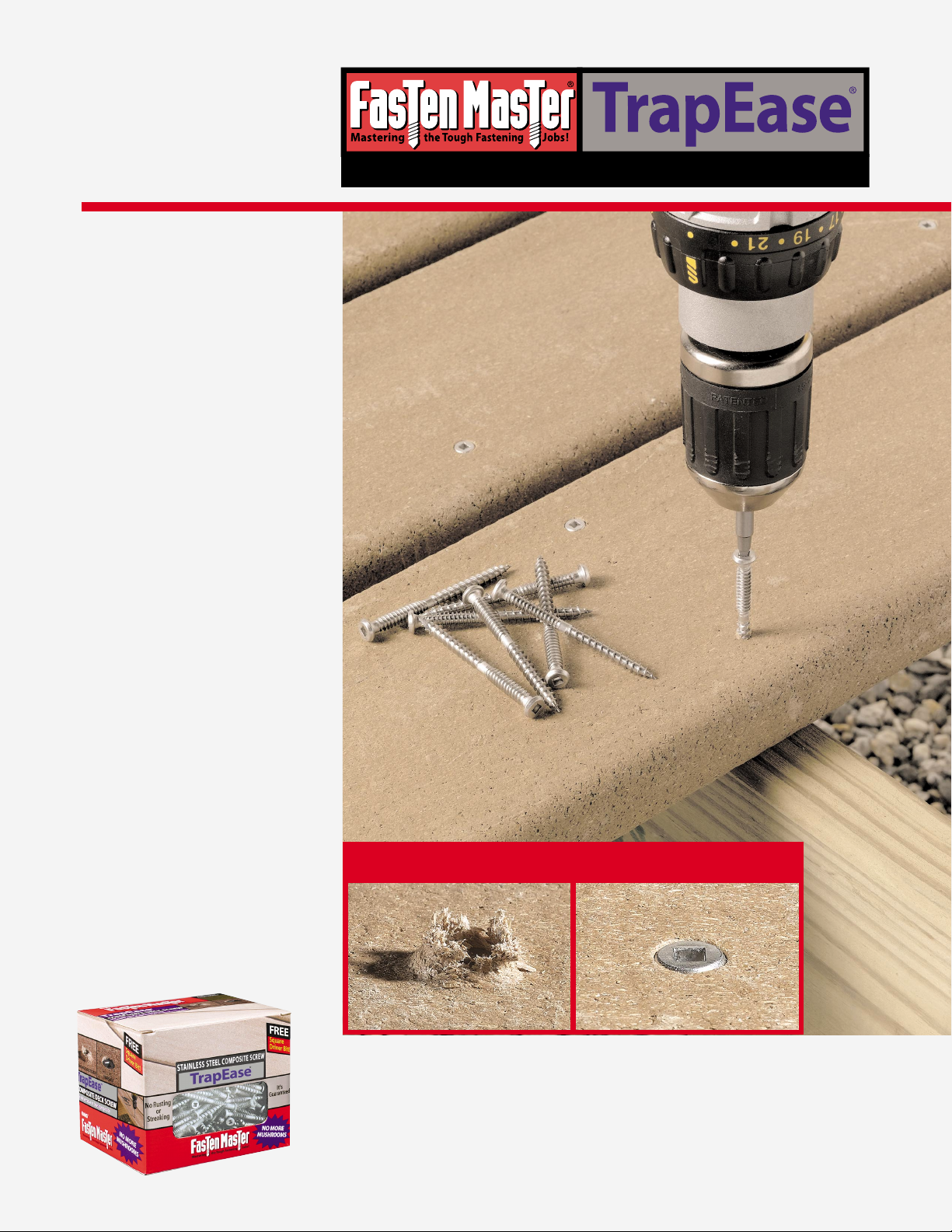

NO MORE MUSHROOMS!

Specifically designed

to eliminate the

“mushrooming” effect

caused by standard deck

screws in composite deck

materials.

The design features of this

FastenMaster product

include:

•

Oversized top thread traps

most loose composite

material during installation

•

Concave underside of the

head traps any additional

loose material as the

fastener is driven flush,

pushing it back into the

hole

•

Guaranteed not to rust or

cause streaking; ideal for

high salt and acid

environments

•

Sharp slotted point cuts

through the composite

material in the first rotation

•

Deep #2 square-drive

provides the best bit

engagement

OLYMPIC MANUFACTURING GROUP, 153 BOWLES ROAD, AGAWAM, MA 01001 WWW.FASTENMASTER.COM

For more information or free samples,

call FastenMaster at 800•518•3569.

STANDARD DECK SCREW

TRAPEASE STAINLESS

NO MORE MUSHROOMS!

STAINLESS STEEL COMPOSITE SCREW

BP03017-10M-AML

DEEP #2 SQUARE DRIVE

PROVIDES BEST BIT

ENGAGEMENT

CONCAVE UNDERSIDE

OF HEAD PUSHES

EXCESS MATERIAL

BACK INTO THE HOLE

OVERSIZED TOP

THREADS TRAP MOST

LOOSE COMPOSITE

MATERIAL DURING

INSTALLATION

INSTALLATION PROCEDURE

GUARANTEED NOT TO

RUST OR CAUSE

STREAKING; IDEAL FOR

HIGH SALT AND ACID

ENVIRONMENTS

SHARP SLOTTED POINT

CUTS THROUGH

COMPOSITE MATERIAL IN

THE FIRST ROTATION

OLYMPIC MANUFACTURING GROUP, 153 BOWLES ROAD, AGAWAM, MA 01001

800.518-3569 WWW.FASTENMASTER.COM

Part Color Screw Quantity Sq. Ft. of

Number Code Length per Box Deck Surface*

FMTR9212-350SS Stainless Steel 21⁄2" 350 100

FMTR9212-1750SS Stainless Steel 21⁄2" 1750 500

*Based on a fastening pattern of 2 screws per joist, spaced every 16 inches, into standard 6 inch wide decking

TrapEase

STAINLESS STEEL COMPOSITE SCREW

®

NO MORE MUSHROOMS!

Due to the non-hardenable nature of 305-grade stainless steel, a proper

installation technique is important to improving overall fastener

performance.

• Use a 0-1800 RPM variable speed corded or 18V cordless drill.

• Use the #2 square driver bits provided.

• Install fastener perpendicular to deck, increasing drill speed as the screw

threads into the deck.

• Installing screws at a slower speed and maintaining proper bit angle and

pressure is important.

• Drive the screws flush; do not overdrive.

• Predrilling may be required for extremely dense composites and

colder temperatures.

• It is recommended that you test drive some TrapEase Stainless Steel

screws on a separate board, under jobsite conditions, to assess

whether predrilling is needed.

Refer to the composite wood manufacturer’s technical literature for fas-

tening pattern and requirements.Commonly accepted fastening practices

include:

• Installing two screws at every joist

• Predrilling pilot holes when fastening the ends of boards to avoid

splitting (within 11⁄2" of end of board, based on manufacturer’s specs)

• Installing screws no closer than 3/

4" from the edge of the board

Note:

When building with Correct Deck, quickly “dimple” or “divot”the top

surface of the material with a 1⁄4" bit before installing the TrapEase

Stainless Steel.This divot should be 1⁄16" to 1⁄8" deep. After “dimpling”the

surface, drive the fasteners flush. Do not overdrive the fastener as spin out

is likely to occur.

Loading...

Loading...