Email: tigerclaw@deckfastener.com

®

Tech Support: 800-518-3569 tol l free

Customer Service: 800-518-3569 toll free

Fax: 413-786-1760

153 Bowles Road • Agawam, MA 01001

GETTING STARTED / INSTALLATION TIPS

⁄4" (19mm) decking

3

IMPORTANT! Read all instr uctions

carefully a nd complete ly to ensu re

proper instal lation.

WARN ING! Par ts have sh arp

points & edges. Us e extreme

caution when hand ling & installin g.

Wear safety glas ses at all times.

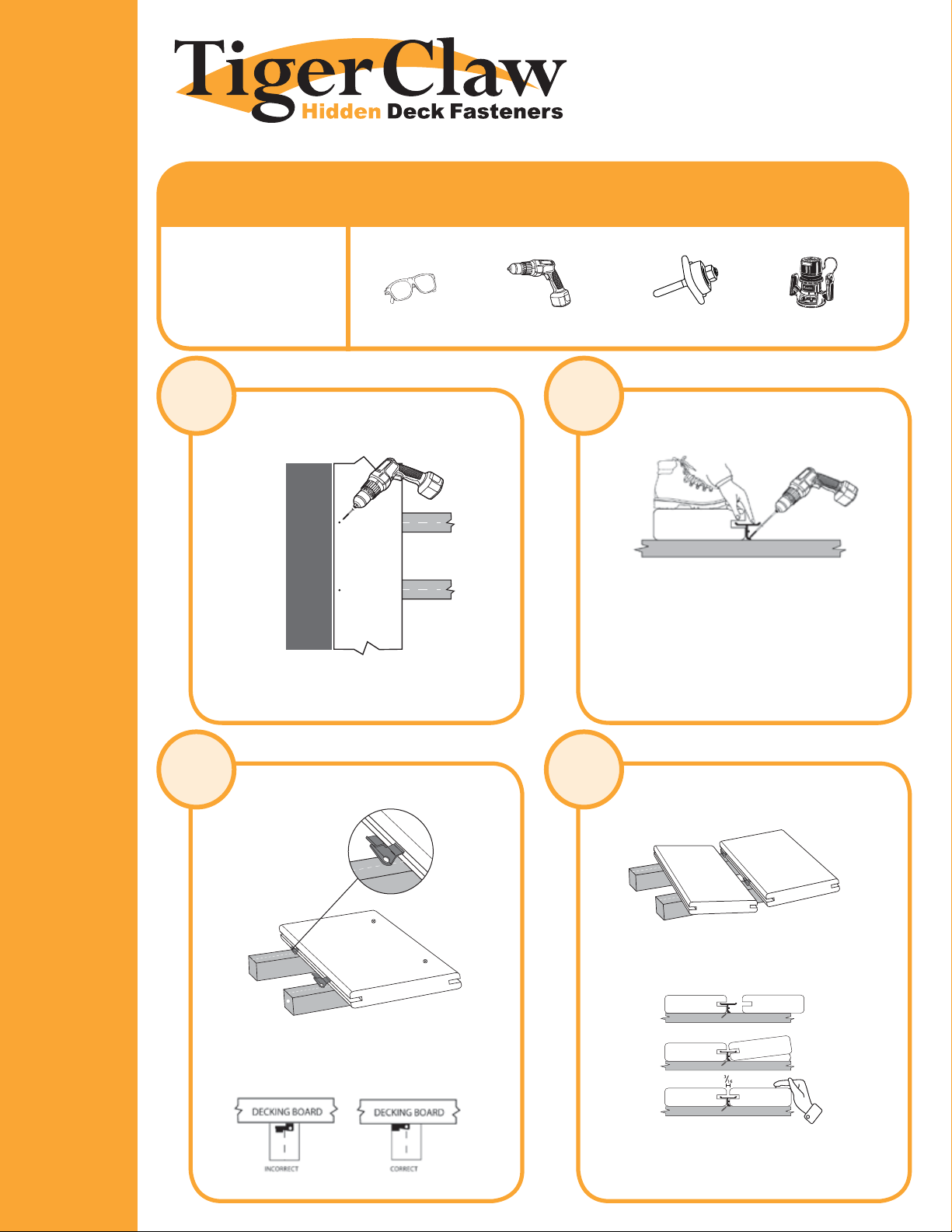

Step

1

Tools & Materials Needed

Safety Glasses

INSTALL

FIRST BOARD

HOUSE

Fasten one edge of the first board at each framing

support using a quality 2½" (64mm) deck screw. It is

important that this board is straight and well secured.

Power screw gun with

ratcheting torque setting

Step

3

Whi le standing on deck board, install provided

screw at 45° angle through fastener and into joist,

while applying pressure on fastener. Install one

fastener and screw at each support joist.

Make sure fastener body is vertical to deck

board and the screw is holding fastener down

tight to support joist. adjust torque setting on

screw gun to prevent spin out of the screw head.

Tiger Claw

Slot Cutter

Router

INSTALL

FIRST FASTENER

Step

2

Fully insert TC- G or TC-120 fastener into grooved

For TC-G (TC-150) for use with 1" (25mm) or thicker decking TC-120 for use with

INSTALLATION PROCESS

edge of deck board. Screw hole should line up with

the center of support joist.

POSITION FASTENERS

JOIST

Step

4

COMPLETING

INSTALLATION OF BOARDS

a Place next deck board into position against

fasteners. Slightly raise outer edge of board

being instal led and slide board onto fastener

until board contacts spacer tabs.

b Check gap between boards for consistency.

Apply force to ensure board is fu lly installed .

Repeat steps 2 thru 4 until deck is complete.

HELPFUL TIPS

INCORRECT

CORRECT

Coverage

a. Multiply the number of joists by the number of decking

boards to equal the number of fasteners needed.

b. 90 fasteners will cover approximately 50 sq. ft. (4.6 m ) using

5.5" (140mm) decking boards on 16" (410mm) centers or

35 sq. ft. (3.3 m ) using 3.5" (90mm) decking boards on

16" (410mm) on centers.

How do you attach the last board?

To finish, we recommend using either finish nails or trim screws

to secure the last board along its edge. Or, you can angle a screw

through the deck frame and into the bottom of the deck board.

45° angle installation

When deck is in the walled corner of the house: always start with

small piece of decking in that corner and work your way out. W hen

installing TC Fasteners, offset the center 1/2" (13mm) towards the

long point of joist, so screw will not exit side of joist when driven.

DECKING BOARD

DECKING BOARD

SHIFT 1/2"

(13mm)

How to do a butt seam

DECKING BOARD

For TC -G (TC -150): Butt Seam clip is

available to use with the TC-G (TC-150)

For TC -120: F irst, install a small framing

TC-G (TC-150)

Butt Seam Clip

board 10-12" (250-300mm) alongside the

joist on which the seam is going to land.

Install additional fastener into previous

board above small framing block. Line

up your first board in the center of the

joist and the small framing board. Install

DECKING BOARD

fasteners and screw at each joust of the

first board including the joist at the seam.

Then install your second board in the

same fashion, and place a second fastener

at the seam attaching it to the small

framing block. Be sure you follow the

end-to-end gapping instructions provided

by decking manufactu rer.

How to replace a board

a. Make two parallel cuts down the center of the board to be

replaced, and remove the center piece.

b. Using a small pry bar, remove the remaining pieces of decking

from the tabs.

c. Using a reciprocating saw, remove the tabs on the side of the

board with the screw heads showing.

d. Position new board into place, and carefully slide onto

remaining tabs.

e. Once board is set into position, secure the lead edge with finish

nail, finish screw, or counter drill, screw and plug.

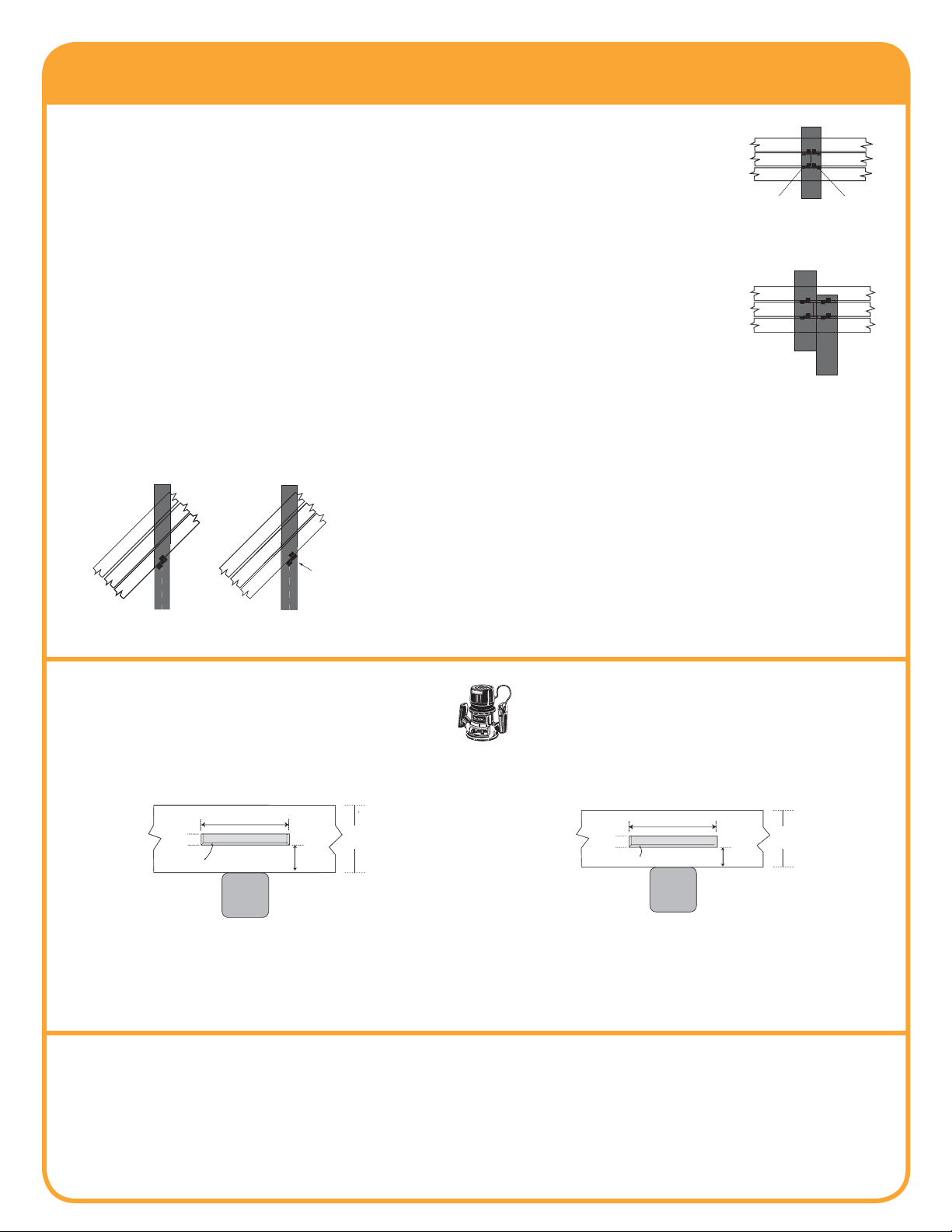

To use the TC-G or TC-120 fastener on solid-edge boards

Use a router to create a groove at every intersection of the deck board

and support joists, or groove the entire edge of the deck board.

For TC-G (for use in 1" (25mm) or thicker decking:

Use the Tiger Claw TC-G Slot Cutter to create the groove shown below.

3

/

(16mm)

"

8

2" (50mm)

DEPTH DECKING BOARD

JOIST

13

/

(10mm)

5

(4mm)

/

"

32

NOTE: The g roove should start 13/32" (10mm) above the BOTTOM of the

deck board. Groove should be at least 7/16" (11mm) deep.

NOTE: When using material with expected ex pansion greater than

1

/8" (3mm), in width allow additional spacing bet ween deck boards.

(Check with your lumber supplier for ex pected expansion in your a rea.

Remember: Tiger Claw has a fastener for all your decking needs:

TC Pne umatic I nstal lation Gun

For the fa stest in stallation of TC -G

TC-1 S oftwood Deck Fa stener

Coated Steel fastener for Pressur e-Treate d,

Cedar, and Redwood

TC- 2 Soft wood Dec k Fastene r

Stai nless Steel fastener for Pressur e-Treate d,

Cedar, and Redwood

1"

(25mm)

"

32

TC- 3 Composite D eck Faste ner

Stai nless Steel fastener for Composite,

PVC & Ma hogany

TC- 4 Hardwoo d Deck Fast ener

Stai nless Steel fastener for Exotic Hardwoods

Proc lip Cellular PVC Deck Fast ener

Stai nless Steel fastener for A ZEK de cking

For TC-120 (for use with 3/4" (19mm) decking):

Use with Tiger Claw TC-120 Slot Cutter to create the grooves

shown below.

1

(3mm)

2" (50mm)

/

8

"

3

/

(16mm)

"

8

DEPTH DECKING BOARD

JOIST

5

(8mm)

3

/4"

(19mm)

"

16

/

NOTE: The groove should start 5/16" (8mm) above the BOTTOM of the

deck board. Groove should be at least 7/16" (11mm) deep.

NOTE: When using material with expected ex pansion greater than

1

/8" (3mm), in width allow additional spacing bet ween deck boards.

(Check with your lumber supplier for ex pected expansion in your a rea.

TC- G Grooved Board Fast ener

Stai nless Steel fastener for 1" (25mm) groov ed decki ng

TC-12 0 Groov ed Board Fastener

Stai nless Steel fastener for 3/4" (19mm)

grooved decking

Butt Seam Groo ved Board Clip

Stai nless Steel clip to use in conjustion with the

TC-G (TC-150) fastener.

FM12036/R-4009-TCII

Loading...

Loading...