The FastenMaster OlyLog

is engineered for log

home construction.

Design features include:

•

No predrilling

•

Self-countersinking head style

•

Strong pull down and

holding power

•

Removable

•

Corrosion resistant

•

No sledgehammer damage

•

Greatly reduced labor time

•

American made

OMG, INC., 153 BOWLES ROAD, AGAWAM, MA 01001 WWW.FASTENMASTER.COM

For more information or free samples,

call FastenMaster at 800

.

518.3569.

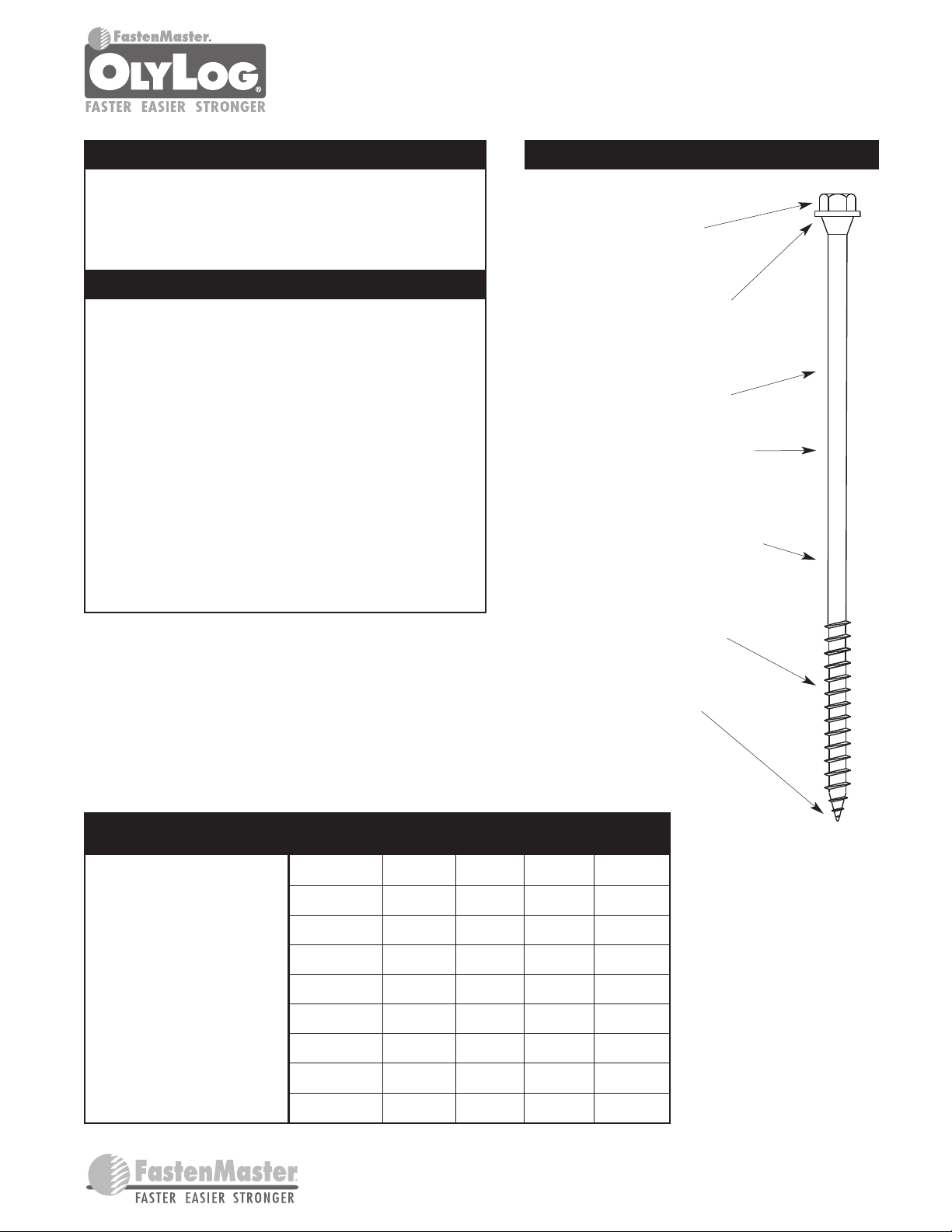

LOG212 21⁄2"15⁄8" 500 12 lb

LOG04 4" 2" 250 10 lb

LOG06 6" 2" 250 14 lb

LOG08 8" 2" 250 18 lb

LOG09 9" 2" 250 20 lb

LOG10 10" 2" 250 23 lb

LOG12 12" 2" 250 25 lb

LOG14 14" 2" 250 29 lb

LOG16 16" 2" 250 36 lb

Thread Diameter: .245

Shank Diameter: .190

Head Style: Hex Head

*Indicates quantity per

box. One special hex

head driver bit is

included in each box.

Thread

PHYSICAL DATA Cat. No. Length Length Packaging* Weight

5

⁄16" HEX HEAD

(1 FREE DRIVER BIT IN EACH BOX)

PATENTED HEAD STYLE

COUNTERSINKS ITSELF DURING

INSTALLATION

3

⁄16" SHANK DIAMETER

MADE OF HEAT-TREATED STEEL

FOR DRAMATICALLY INCREASED

STRENGTH AND DRIVABILITY

ULTRA COATED FOR UNMATCHED

CORROSION RESISTANCE

2" OF THREAD WITH

1

⁄4" MAJOR DIAMETER

GIMLET POINT FOR

FAST DRILLING

OMG, INC., 153 BOWLES ROAD, AGAWAM, MA 01001

800.518.3569 WWW.FASTENMASTER.COM

FastenMaster and OlyLog are trademarks of OMG, Inc.

FM07009-10M-AML

PRODUCT FEATURESINSTALLATION PROCEDURE

•

Use a 1⁄2", high torque, low rpm drill.

•

Install OlyLog perpendicular to the log.

•

Countersink the OlyLog a minimum of

1

⁄4".

BENEFITS

•

Installs much faster and easier than lags and spikes

–Saves time and fatigue

–Dramatically lowers installed cost

•

Requires no predrilling

–Eliminates on-site predrilling

–Eliminates manufacturing drill stations

•

Countersinks into log

–Allows log to settle naturally

•

Draws warped logs down

•

Removable and reusable

•

Eliminates jarring and damage caused by a sledgehammer

•

Engineered for increased strength and performance

For complete engineering data, please see our official ICC ESR-1078

report at: www.icc-es.org/reports/pdf_files/ICC-ES/1078.pdf

A Professional Engineer (PE) is responsible for designing all connections,

which include the number and location of all fasteners to meet the

national and local code requirements. All minimum end, edge and

spacing distances of the OlyLog should follow minimums set forth in

ICC ESR-1078 (see www.fastenmaster.com). This report should be

reviewed thoroughly when designing connections.

Loading...

Loading...