INSTALLATION MANUAL

APPLICATION:

T UIM 220G (220GPH @ 16-18psi)

Unit Injected Mechanical Engines

*Requires a Fuel Line Kit*

Revision Date: 10/12/2015

Dear Valued Customer,

“Made in the USA” is not just a slogan at FASS; it’s what we live by! FASS is not only

assembled in the USA but 98%+ of the FASS product is manufactured in the USA, helping to employ Americans and strengthen America. At FASS, we scrutinize our suppliers and demand the

highest quality American-made components. However, this does come at a price, which is one of

the main reasons FASS products are more expensive than the competition. Remember price does

not dictate quality but quality does dictate price! Here at FASS, we believe it’s worth the commitment and will continue this practice to support America! Our competition is doing exactly the opposite by using foreign-made components.

Building extremely “High-Quality” fuel products is our business. We concentrate all of our

efforts in this arena. No one else is as specialized as FASS in what we do! This is one of the ingre-

dients to insure you are running with the “Highest-Quality” fuel system in the world! We have implemented very rigorous testing procedures to provide the “Highest Quality” we have become

known for. Not only is our product superior, but customer satisfaction is #1 at FASS. It is our goal

to provide the best service possible. Our confidence is evident in the products we make as each

product is backed by an industry leading warranty!

Our R & D department, in conjunction with our Dealer Support department, is continually

searching for ways to improve quality, expand our product line, and provide superb support to our

network of dealers so our customers’ needs and expectations will be exceeded.

To help insure you receive the proper system and customer support at the local level, FASS

has a VIP and Authorized Dealer network representing FASS products. This is one reason you

must purchase through a dealer to comply with our warranty policies. If you do not, there is no

warranty! We recommend you go to www.FASSride.com, click “Find A Dealer”, put in their ZIP

code, select the type of dealer, and see if the company you purchased from is listed. If they are not,

put their phone number in the field below the ZIP code field to see if they are listed. Below these

two fields is a list of “Terminated/Unauthorized” dealers. You may want to review this list. If the

company is not listed or is on the “Terminated/Unauthorized” list, we suggest you return the product immediately to that dealer and call FASS. We’ll recommend you to the nearest dealer.

VERY IMPORTANT: Make sure to fill out your product registration form and return the

original form to FASS Fuel Systems within 30 days of purchase accompanied with a copy of the

purchase receipt. Complying with these guidelines will qualify you for the Extended Warranty!

See the Owner’s Manual online at www.FASSride.com for full Limitation of Warranty. In

the event that the buyer does not agree with this agreement: the buyer may promptly return this

product, in a new and unused condition, with a dated receipt, to the place of purchase within thirty

(30) days from date of purchase for a full refund less shipping.

The installation of this product indicates that the buyer has read and understands the

Limitation of Warranty agreement and accepts its terms and conditions.

¡WARNINGs!

WARNING: Do not tie FASS Return in

with engine return. Back pressure can

cause damage to engine.

Read all instructions before starting installation of this product!

Installing the improper FASS Pump can cause severe engine damage.

Use this (T UIM 260G) kit to prevent fuel flow into any ‘open’ injectors during start-up.

Once crankcase pressure is observed, power will be applied to the FASS pump.

Operating your engine without the oil pressure switch (included) may cause engine damage.

Do Not Remove any factory installed secondary fuel filter! Removal of a factory installed

Be sure that the serial # on this installation manual matches that of the outside of the box.

Keep debris from entering the internals of the system during installation. Getting debris in

FASS Recommended Application

T UIM 220G

secondary fuel filter may void the engine manufacturer’s warranty. This is the fuel filter

between the engines fuel pump and the injectors.

the water separator nipple can lock up the motor. If the motor does lock up from debris call

FASS for technical assistance.

Class 1– Class 8, Agriculture, Industrial, Recreational, Hwy and off-road.

Applications requiring fuel flow demands of 16-18psi and less than 220gph

Properly secure lines to prevent chaffing.

Use caution when drilling. Steer clear of any electrical wires , air lines or other damageable

components.

INSTALLATION MANUAL

Follow these steps to ensure a simple installation of your new

FASS TITANIUM FUEL SYSTEM

1. Read the installation manual completely before attempting installation. The instal-

lation of this product indicates that the buyer has read and understands the limita-

tions of the FASS manufacturers warranty agreement and accepts the responsibility

of its terms and conditions.

2. Inventory the package components. Notify the place of purchase immediately of

any parts missing or damaged.

3. The installation recommendations contained herein are guidelines. Use good judg-

ment and take into consideration your vehicles' accessories.

4. For best results in accuracy and efficiency (due to training, communication, and our

relationship with our dealer network), we recommend a ViP FASS dealer for the

installation. They are prepared to install the FASS fuel pumps with the most effi-

ciency. If a situation/problem arises during the installation, they are the most pre-

pared for that situation/problem. DPPI is not responsible for any installation mis-

takes.

5. If you have any questions or concerns that can not be addressed with your dealer,

email or call FASS.

6. If any installation procedure is uncertain, contact FASS technical support.

Email techsupport@FASSride.com with the following information:

Your Name, address and daytime phone number

Model

Serial Number

Last 6 of vehicles’ VIN

Date of purchase

Nature of Your Concern

Call customer service; 636-433-5410 with the following information:

Model

Serial Number

Last 6 of vehicles’ VIN

Date of purchase

(T UIM 220G)

Serial # Found Here….

(T UIM 220G)

Titanium Series

220 GPH

16-18 PSI (Approximately)

A fuel pressure gauge is highly recommended to identify fuel filter life and to prevent engine damage!

“H”

Coolant Heater

“E”

To Engine

‘R’

Fuel Return to Tank

‘T’

Fuel Inlet

2nd

Electric Heater Port

Installation

Step 1: Install Electrical Harness

Step 2: Prepare Suction and Return Lines

‘G’

Fuel Pressure

Electric Heater

Port

Serial Number Location

Step 3: Mount Fuel System

Step 4: Install Fuel Line

Step 5: Check Installation

Contents

BR-2001

MP-9050

78143

Oil Pressure Switch

WH-1005

*WE-1001*

Mounting Package Contents

10-273

Ring Terminal

4 3/8-16”x 1 1/2” Hex Bolt

RS-2684

Spade Terminal

4 Locking Nut 3/8”

RS-1001

3 Hex Bolt 1/4-20 13/4"

Mounting template

3 WA-1001D

Step 1: Installing Electrical Harness

The installation of the electrical harness is done first, allowing power to be applied to the pump for

lubrication purposes.

A. Select best location in firewall for passage of wiring harness from cab to engine compartment.

B. Find or drill a 7/8” hole in firewall. Install RS-2684 grommet for ease of installation and protection of

wire harness.

C. Connect WE-1001 wire extension to the WH-1005. The use of a

corrosion preventative on electrical connections is recommended.

D. Route red wire/ loom of the wire extension through the grommet in the firewall to the ignition or

fuse panel.

E. Connect the “Red” lead of the wire extension to the “ON” terminal of

the ignition switch or a terminal on the circuit breaker board that is

“hot” when the key is on. Use a test probe to locate the “hot side”

of the circuit in the fuse block.

F. Install Hobbs Oil Pressure Switch 78143 in the oil gallery. Using a

spade terminal, connect the green wire of the WH-1005 wire harness

to the terminal on the oil pressure switch.

G. Using a ring terminal, connect the red wire of the WH-1005 wire har-

ness to the positive post of the battery.

H. Secure relay in an upright position, preferably on the firewall out of

the weather.

I. Properly secure all electrical leads and harness.

Note: When connecting ground make sure connection is on a clean and not painted surface, ie Engine,

Frame, or Battery.

NOTE

ATTENTION: While installing fittings into Titanium pump

DO NOT Apply side pressure to draw

tube of pump

Proper

Improper

Step 2: Mounting the FASS

Some of the photo’s are of a different application, procedures are the same.

A. Remove primary fuel and/or water separator. If primary filter is part of the fuel pump, ignore this step.

NOTE: Before installing fittings make sure to inspect for burs or flare imperfections.

When cutting fuel line make sure to blow out line to keep debris from moving forward.

B. Using thread tape, install the fittings into the “E” and the “T” ports (on opposite end). Torque to 40 lb./

ft.² Note: Do Not Put Thread Tape on Flare of Fitting ***The use of thread sealant

is not recommended***

C. Attach BR-2001 to back of system using the spacers and 1/4” bolts. Use the two bottom bolts and the

very top one bolt opening.

Step 2: Mounting the FASS

Some of the photo’s are of a different application, procedures are the same.

D. Position system where it will be mounted. Mark the (4) mounting points (using the template located on

the contents page). Pr ior holes may be used. Dr ill these marked locations with a 13/32 bit.

E. Connect factory plug into the FASS harness. Turn key to “on”. With pump operating, turn pump over,

liberally spray WD-40 (or equivalent) into water separator nipple lubricating the Gerotor.

F. Assemble to frame using the (4) - 3/8” bolts & flange nuts placing the RS-1001 between the frame and

bracket. An optional accessory is SFB-1001.

G. Apply motor oil to O-rings located on filters. Attach to system and tighten appropriately

Note: O-Ring must be put back on suction side of pump. Failure to do so can result in

priming issues, cavitation, or pressure loses.

Step 3: Identify Fuel Line Configuration

For optimal engine performance gains, the return line should return to its own port.

Below is a chart of available fuel line kits FASS has to offer. Using one of these kits will make

the installation cost effective and easier. This manual will refer to these FLK #’s

Take caution when producing extra ports. Do only as directed as to be careful not to cause

back pressure to engine return or severe engine damage.

Application Accessory

#10 Feed Line Kit

Single pick up/ Single Return

Double pick up/Double Return

Mercedes 4000 Series

Volvo D12-D15

FLK-S01

FLK-S02

FLK-S03

FLK-S03, FLK-S06, FLK-S04

FLK-S03, FLK-S06, FLK-S05

A. Fuel lines, excluding nylon type fuel lines, in excess of 6 years old should be replaced due to interior

lining deterioration. This condition can cause many problems including but not limited to: fuel starva-

tion, uneven fuel tank levels and etc.

B. When routing the return line from the FASS Fuel System, you will need to first identify your current

fuel system. Now match with the correct fuel line section below and follow the corresponding proce-

dures. Uneven fuel level conditions can occur between the tanks if the pickup/return lines are improp-

erly installed.

B1. Most Popular - Usually on 1994 Trucks & Newer including Volvo and Mercedes Engines:

Double Draw/Double Return Line System. FASS fuel line kit (FLK-S03) or Double Vent Return

Line Kit for trucks without the extra port of the fuel tanks(FLK-SO6)should have all of the pr oduct to

complete this process

B2. 2nd Most Popular - Usually on 1993 Trucks & Older (except 359 Peterbilt - next selection):

Single Draw/Single Return Line System. FASS fuel line kit (FLK-S02) should have all of the pr oduct

to complete this process

B3. 359 Peterbilt: Single Dr aw Out of Cr oss Over Fuel Line/Single Return Line System

Dual Tank Recommendation:

1st Choice - Conver t to a complete Double Draw/Double Return Line System(FLK-S03) or Dou-

ble Vent Return Line Kit (FLK-S06).

2nd Choice - Conver t to a tr ue Single Dr aw/Single Retur n Line System FL K-S02).

Step 4: Double Draw/Double Return Fuel Line System

Caution: Do Not use sealant on AN fittings. Only use sealant on threads installed into pump assembly or joining fittings.

Note: No extra ports? - Refer to the option located at the back of the manual.

Return line from

FASS with straight

ends to cross member where the line

will “T” off.

These lines must be the exact length on both sides.

From “T” to each fuel tank with

1-straight fitting &

1-90° fitting on each line.

A. Locate extra bung on the fuel tanks, most KW’s have a 1/4”, Peterbilt have

3/8” or 1/2” extra pipe plug located by the fuel lines at the top of the fuel tank.

Other models may have an extra port some where at the top of the fuel tank.

Remove the plugs and install a –8 AN fitting into each tank. It maybe neces-

sary to use a bushing to adapt fitting to tank.

B. Install (90° or straight) fitting into fuel line using the following procedures: refer to this procedure

when necessary.

B1. Assemble fuel line into female hose fitting (reverse threads), then

apply a modest amount of oil to the interior lining.

B2. Secure female end in vise.

B3. Oil male JIC swivel (90° or straight) and assemble into female end.

B4. The male portion should tightened all the way, as seen.

Step 4: Double Draw/Double Return Fuel Line System

C. Assemble the “T” using (1) 3/8 NPT ‘T’, (2) -8 ANx3/8 MPT & (1) -8 ANx3/8

MPT 90° as seen in the photo.

D. Attach the line completed in Step 4b to the return port of the FASS labeled with

an “R”. Route to the center of the nearest cross member aligned with the ports in

the fuel tank being used for return fuel. Measure & mark this line as it will connect to the 90° fitting of the “T” in this location.

E. Cut the fuel line and assemble a –8 AN hydraulic fitting in the opposite end of

the line connecting to the “R” port of the FASS.

F. Assemble a –8 AN hydraulic fitting into one end of the remaining fuel line.

Route this fuel line from straight fitting of the “T” to the return port in the

fuel tank, mark & cut.

G. Caution: Route the side with the exhaust first as it will be necessary to trav-

el below the frame to avoid the exhaust, each side has to be the exact same

length. Later it will install as seen.

H. Cut the remaining fuel line to the “Exact” same length line as the line in Step 4f.

I. Assemble (1) of each –8 AN 90° & -8 AN Straight into each line addressed in

Steps 4f & 4g.

J. In the same manner as previously covered, route and loosely connect the assem-

bled fuel lines discussed in this section to the appropriate points of connection

including the ‘T’.

K. Torque all connections to 18 ft./lbs. Secure the fuel line and all fittings. Continue

to Step 5

Step 4: Single Draw/Single Return Fuel Line System

Caution: Do Not use sealant on AN fittings. Only use sealant on threads installed into pump assembly or joining fittings.

Note: No extra ports? - Refer to the option located at the back of the manual.

A. Locate a fuel return port into the fuel tank. Most KW’s have a 1/4”, Peterbilts

have 3/8” or 1/2” extra pipe plug located by the fuel lines at the top of the fuel

tank. Other models may have an extra port some where at the top of the fuel

tank. Remove the plugs and install the –8 ANx5/16 NPT into each tank, it maybe necessary to use a brass bushing.

B. Install –8 AN hydraulic fitting into fuel line using the following procedures: refer to this procedure

when necessary.

B1. Assemble fuel line into female hose fitting (reverse threads), then

apply a modest amount of oil to the interior lining.

B2. Secure female end in vise.

B3. Oil male end of 90° JIC swivel fitting and assemble into female end.

B4. The male portion should tightened all the way, as seen.

Step 4: Single Draw/Single Return Fuel Line System

C. Attach the line completed in Step 4b to the return port of the FASS labeled

with an “R”. Route to the port in the fuel tank being used for return fuel.

Measure, mark & cut.

D. In the same manner as previously covered, route and loosely connect the fuel

lines discussed in this section to the appropriate points of connection.

E. Torque all connections to 18 ft./lbs. Secure all fuel lines and fittings. Continue to Step 5

Step 5: Fuel Supply Line

A. Attach the fuel supply line from the fuel tank to the FASS using a 10-273L

or one of the fitting from the filter housing removed in step 2. IF fuel supply

line connects directly to engine-the primary fuel filter is not remote

mounted-skip to step C (Usually, not always, on NTC/STC’s and N14’s).

B. Attach the fuel supply line from the FASS to the engine pump using a 10- 273L or

one of the fittings from the filter housing removed in step 2. Once completed, you

are finished with step 5 and you may go directly to step 6.

C. Disconnect fuel line from engine. Connect to “T” port of the FASS.

D. Assemble a –10 AN hydraulic fitting into one end of the #10 fuel line and loosely

connect to either the FASS or the engine.

E. Route fuel line to open port (engine or FASS) measure and cut.

F. Assemble a –10 AN hydraulic fitting into the cut end. Remember, clocking of the fuel fittings may be

necessary to connect to ports in discussion.

G. Attach the assembled fuel line to the FASS and engine. CAUTION: IT IS VERY IMPORTANT TO

BLOW THIS FUEL LINE OUT BEFORE FINAL ASSSEMBLY TO ENGINE!!

Note: Secure all fuel lines with cable ties. Cable ties are an economical way to prevent the

possibility of problems occurring!

Step 6: Double Vent Line Return System

Caution: Do Not use sealant on AN fittings. Only use sealant on threads installed into pump assembly or joining fittings.

Return line from

FASS with straight

ends to cross member

where the line will

“T” off.

From “T” to each fuel tank with

2-straight fittings on 2 of the lines going to the Vent Line &

1-90° fitting on Return line connecting to the FASS

These lines must be the exact length on both sides.

A. Assemble fuel line into female hose fitting (reverse threads), then

apply a modest amount of oil to the interior lining.

B. Secure female end in vise.

C. Oil male JIC swivel (90° or straight) and assemble into female end.

D. The male portion should tightened all the way, as seen.

E. Assemble the “T” using (1) 3/8 NPT ‘T’, (2) -8 ANx3/8 MPT & (1) -8 ANx3/8

MPT 90° as seen in the photo.

Step 6: Double Vent Line Return System

F. Attach the line completed in Step 4b to the return port of the FASS labeled with

an “R”. Route to the center of the nearest cross member aligned with the ports in

the fuel tank being used for return fuel. Measure & mark this line as it will connect to the 90° fitting of the “T” in this location.

G. Cut the fuel line and assemble a –8 AN hydraulic fitting in the opposite end of

the line connecting to the “R” port of the FASS.

H. Assemble a –8 AN hydraulic fitting into one end of the remaining fuel line.

Route this fuel line from straight fitting of the “T” to the return port in the fuel

tank, mark & cut.

I. Caution: Route the side with the exhaust first as it may be necessary to travel below the frame to

avoid the exhaust, each side has to be the exact same length. Later it will install as seen.

J. Cut the remaining fuel line to the “Exact” same length line as the line in Step 4f.

K. Assemble (2) of each -8 AN Straight into each side of the line addressed in Steps 4f & 4g.

L. In the same manner as previously covered, route and loosely connect the assembled fuel lines discussed

in this section to the appropriate points of connection including the ‘T’.

M. Torque all connections to 18 ft./lbs. Secure the fuel line and all fittings. Continue to Step 5

Step 6: Double Vent Line Return System

N. Locate Fuel Tank Vent Line and remove vent and vent line from tank. Thread tape reducer on both

ends and install reducer into tank. Once reducer has been secured install “T” onto reducer and secure.

Thread tape bushings and install them on the “T” . NOTE: Not all configurations will be able to be

assembled this way. Install the vent line on the top por tion of the “T” and the FASS r eturn line

into the middle of the “T”. Repeat previous steps on other tank to install the Double Vent Line Return Kit.

Fuel Tank Vent Line

FASS Return

Fuel Tank

O. The below picture illustrates the configuration previously mentioned..

Step 7: Review Installation & Secure Connections

A. Bolts and fasteners properly tightened?

B. Electrical harness and fuel lines secured and properly tightened?

C. Has the system been primed, refer to owners manual?

D. Check for leaks.

E. Start the engine

F. Recheck all fluid and filter connections for leaks

G. Product registration filled out and ready to be mailed or faxed.

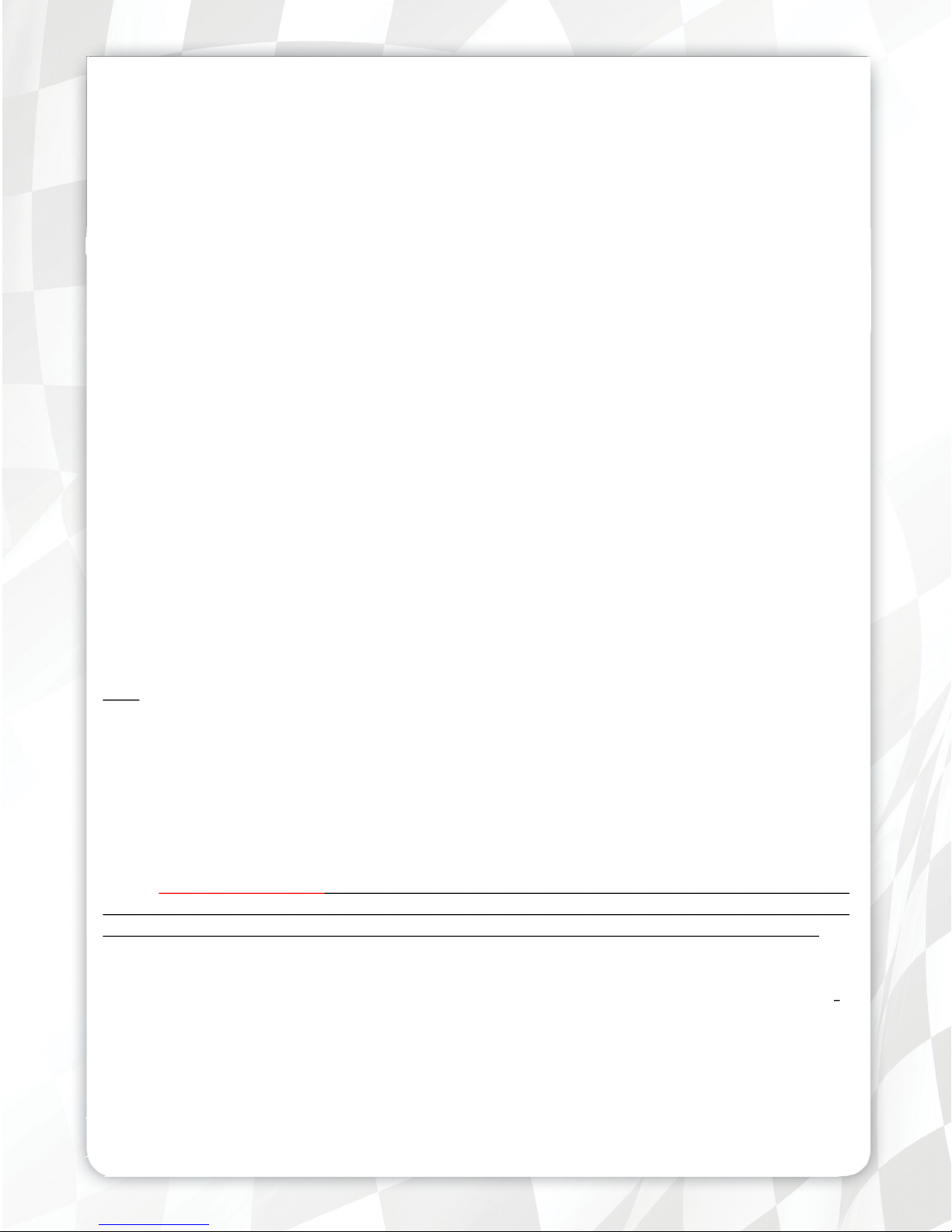

Option: 2 Ways of Producing Extra Ports (Bung fitting)

A. Most Preferred & Easiest

1. Drill and tap a 3/8”fpt in the thicker band of aluminum as seen.

2. If possible, install the fuel tank vent in this port and connect the FASS

B. Weld a Bung Fitting

1. Fire Hazard, must be accomplished by a professional.

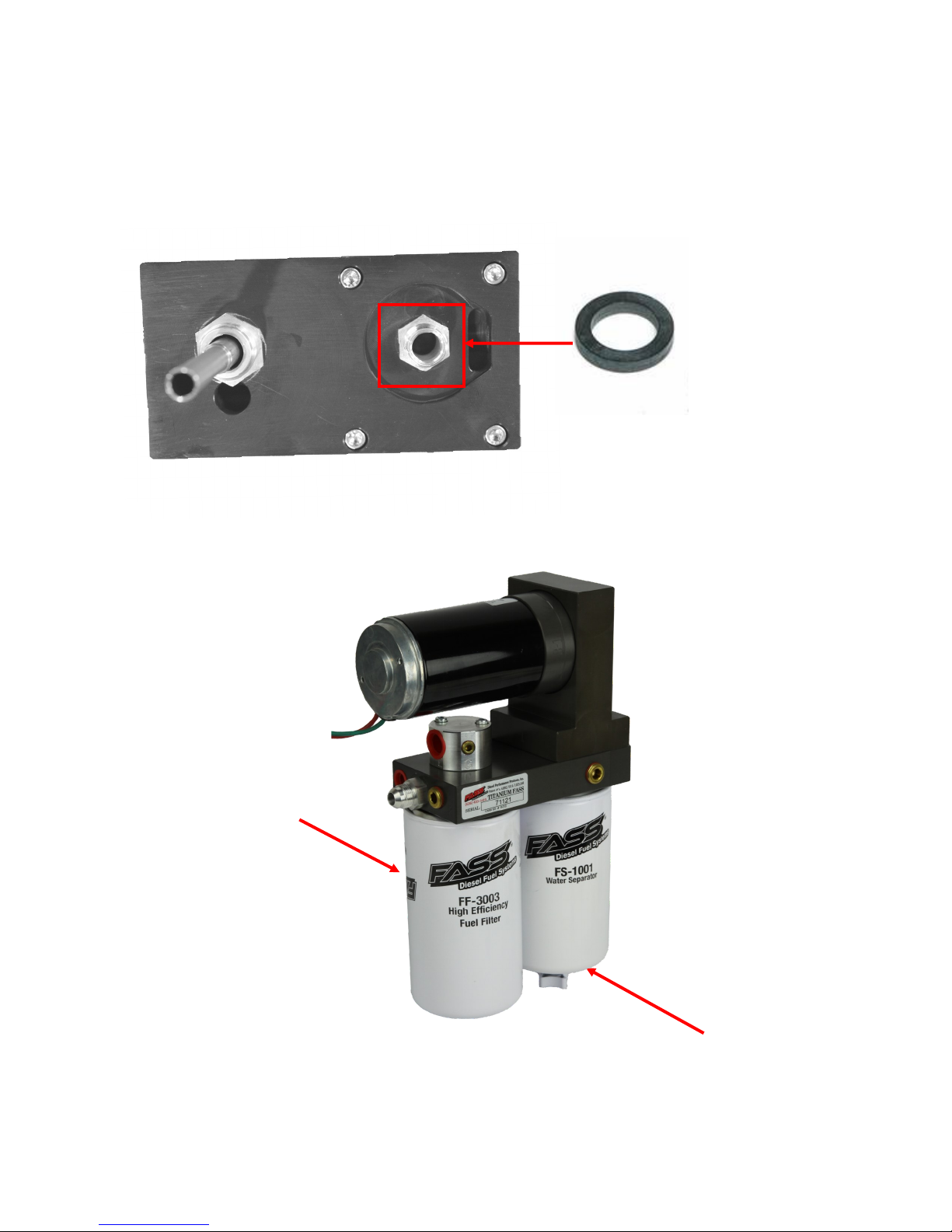

To assist with priming your FASS pump crack the FF-3003. Put power to the FASS pump to

activate the pump. When the tone of the pump changes you can tighten up the fuel filter. If you

need a video of the priming process go to www.FASSride.com.

Note: The Red Plastic Plugs located in the “H” ports can stay in place fuel will not flow

through these ports. Coolant can be plumbed into these ports to heat the fuel in the Winter

months.

Step 7: Review Installation & Secure Connections

Note: O-Ring must be put back on suction side of pump. Failure to do so can result in

priming issues, cavitation, or pressure loses.

Fuel Filter –Install FF-3003

on side of pump with draw

tube in the middle of the

filter nipple.

Water Separator Filter –Install FS-1001 on water

separator nipple without the draw tube. Make sure

to insert O-Ring provided on nipple.

LIMITATION OF 4 Year WARRANTY

Disclaimer: To help insure you receive the proper system and customer support at the local level, FASS has a VIP and

Authorized Dealer network representing FASS products. This is one reason you must purchase through a dealer to comply

with our warranty policies. If you do not, there is no warranty! We recommend you go to www.FASSride.com, click “Find

a Dealer”, put in their ZIP code, select the type of dealer, and see if the company you purchased from is listed. If they are

not, put their phone number in the field below the ZIP code field to see if they are listed. Below these two fields is a list of

“Terminated/Unauthorized” dealers. You may want to review this list. If the company is not listed or is on the

“Terminated/Unauthorized” list, we suggest you return the product immediately to that dealer and call FASS. We’ll recommend you to the nearest dealer.

Diesel Performance Products, Inc. (hereafter “SELLER”) gives Limited Warranty as to description, quality, merchantability, fitness for any product’s purpose, productiveness, or any other matter of SELLER’S product sold herewith. The SELLER shall be in no way responsible for the product’s open use and service and the BUYER hereby waives all rights other

than those expressly written herein. This Warranty shall not be extended or varied except by a written instrument signed by

SELLER and BUYER.

When MANUFACTURER receives the “ORIGINAL” PRODUCT REGISTRATION form with a copy of the “BILL

OF SALE/SALES RECEIPT” within 30 days of the sale, then the following applies! The War ranty will then and

only then be validated to that of which typically accompanies your unit for your specific application from the date of sale or

for recommended service life and limited solely to the original purchaser and/or vehicle and parts contained within the

product’s kit. This warranty does not cover normal wear on consumable items such as but not limited to filters, fuel line,

wire harness & etc. The warranty does not cover seized gears due to lack of filtration. Warranty is voided if used with other

than diesel fuel. Returned items will arrive prepaid to the place of purchase. Diesel Performance Products, Inc. will repair,

without cost, any product found to be defective during the warranty period; parts only, or at its option, will replace such

products in exchange for the product. Repair or replacements are warranted for the remainder of the original warranty period. All Warranty claims are subject to approval by Diesel Performance Products, Inc.

A Return Material Authorization (RMA) number must be obtained before any product is to be returned to Diesel

Performance Products, Inc. for warranty consideration, repair or product return. Requests for product retur ns

must be offset by an equal value order. Return parts must be completed and in resalable condition. No returns after 30 days.

The following information is required to obtain a RMA number before returning product:

Your Name, Address, and Phone Number’s

Model and Serial Number (Not Motor Number) Example: Model HD Series, Serial: 00125966

VIN Number of Vehicle

Date of Purchase

Nature of Problem

RMA and Product Serial Number must be on all paperwork and correspondence. Failure to obtain the required information

or paperwork will result in $25.00/item penalty and delay or denial of any warranty claim.

Under no circumstances shall the SELLER and/or MANUFACTURER be liable for any labor charged or travel time incurred in diagnosis for defects, removal, or reinstallation of this product, or any other contingent expenses.

Under no circumstances shall the SELLER and/or MANUFACTURER be liable for any damage or expenses insured by

reason of the use or sale of any such equipment. This warranty does not apply to products which Diesel Performance Products, Inc. has determined to have been misused or abused, improperly maintained by the user, or where the malfunction or

defect can be attributed to the use of non-genuine Diesel Performance Products, Inc. parts.

IN THE EVENT THAT THE BUYER DOES NOT AGREE WITH THIS AGREEMENT: THE BUYER MAY PROMPLY

RETURN THIS PRODUCT, IN A NEW AND UNUSED CONDITION, WITH A DATED PROOF OF PURCHASE, TO

THE PLACE OF PURCHASE WITHIN THIRTY (30) DAYS FROM DATE OF PURCHASE FOR A FULL REFUND

LESS SHIPPING.

THE INSTALLATION OF THIS PRODUCT INDICATES THAT THE BUYER HAS READ AND UNDER-

STANDS THIS AGREEMENT AND ACCEPTS ITS TERMS AND CONDITIONS.

Technical Support:

Diesel Performance Products, Inc.

16240 State Hwy O Suite B

Marthasville, MO 63357

636-433-5410

Filter Cross References

(Currently in use)

Fuel (FWS-3003)

Water (FS-1001)

Fuel Filter (Micron Rang) Water Separator (Micron Rang)

Thread Size (1-14) Thread Size (1-14)

Baldwin BF7633 (2M) Baldwin BF 1258 (10M)

Carquest 86528 (2M) Baldwin BF1214

CAT 1P2299 (6M) Baldwin BF7546 (10M)

CAT 1R0750 (2M) Donaldson P558000 (20M)

Donaldson P551025(4M) Donaldson P551000 (10M)

Donaldson P551311 (3M) Donaldson P551001(10M)

Donaldson P551313 (3M) Fleetguard FS1282 (14M)

Donaldson P553203(3M) Fleetguard FS-1000 (10M)

Donaldson P557440 (6M) Fleetguard FS-1001 (10M)

Fleetguard FF5320(2M) Fleetguard FS-1009(14M)

Fram P8334 (2M) Fleetguard FS-1212(14M)

Hasngs FF1079 (2M) LuberFiner LFF8011

Wix 33352 (6M) LuberFiner LFF8000

Wix 33528 (2M) Motorcra FD818 (14M)

Wix 33674 (2M) Wix 33405(14M)

Wix 33522 (10M)

NOTES

Loading...

Loading...