Page 1

“

Automatic Truck Tyre Changer

Machine

INSTRUCTIONS BOOKLET

English

,

RGU300.ECO

Page 2

4

WARNINGS

**The presents instructions booklet is an integral part of the product.

** Carefully study the warnings and instructions contained in it.

**This information is important for safe use and maintenance.

**Conserve this booklet carefully for further consultation.

THİS MACHİNE (RGU300.ECO TYPE)

Is a tyre changing machine designed and constructed to be used for mounting and demounting tyres on the whell

rims of trucks and light industrial vehicles.

The machine has been designed to operate within the limits described in this booklet and in accordance with the

maker’s instructions.

The machine must be used only for the functions for which it was expressly designed.Any other use is considered

wrong and therefore unacceptable.

The maker cannot be held responsible for eventual damage casued by improper,erroneous or unacceptable use.

IMPORTANT

CLAUSE 1 - General Warnings...............................................................................................4

CLAUSE 2 - Technıcal Characterıstıcs................................................……………….……....4

CLAUSE 3 - Parts Of The Machine..........................................................................................5

CLAUSE 4- Introduction, safety instructions and packaging, transport, storage …….....6

CLAUSE 5 - Safety warnings and electrical systems,...........................................................7

CLAUSE 6 - Machine safety warning signs........................................................................... 8

CLAUSE 7- İnstallatıon………………………………………………………………………….…9

CLAUSE 8- The location of the machine and problems-causes-remedies …………..…..10

CLAUSE 9 - Operations And Use …………………................................................................11-12

CLAUSE 10 - Lubrication Maintenance and standard parts ………………………………..…13

CLAUSE 11 - Perıodıc Maıntenance ……………………………………………………..….…….14

CLAUSE 12- Technical assistance and warranty …………………………….…………….…....15

CLAUSE 13 - Electric Curcuıt Plan …………………………….…..……………………………….16

CLAUSE 14- Demontage Plan..................................................................................................17-18-19

CLAUSE 15 - Spare Parts List....................................................................................................20-21-22-23

BOYUTLAR

Yükseklik (min./max.).................... 781 - 1084 mm

Derinlik........................................... 1129 - 1375 mm

Genişlik (min./max.)...................... 1082 - 1994 mm

AĞIRLIK

Net Ağırlık ........................... 505 kg

Gürültü Seviyesi ................ 75 db

TECHNICAL CHARACTERISTICS

CONTENTS

CLAUSE 1

CLAUSE 2

RGU300.ECO TYPE may be operated only by suitably trained personnel.

Any work on the electrical , hydraulic , pneumatic systems must be conducted only by profesionally qualified

personnel.

10 years in the life of the machine.

Page 3

5

PARTS OF THE MACHINE

Fig.1 – FOUR-JAW UNIVERSAL CHUCK

With two rotation speeds in boot directions.

Pressure adjustable hydraulic opening and

closing.

Fig.2 – LOCKING JAW

The Jaw was designed to give different

gnopping possibilites.

Fig. 4 – REDUCTOR GROUP

Fig.5 – MOBIL CONTROL UNIT

The controls are combined on a remote

mobile control unit with which the operations

are coordinated.

Fig.6 – HYDRAULIC UNIT

By regulating the operating

pressure of the chuck,the unit

allows safe working conditions

even on the various types of

alloy rim.

Fig.7 – WORKING ARM

A guick rotation system helps changes

in operation dunng the various stages

of bead breaking tool-assisted

extration of tyre etc.

5

6

3

2

1

4

Capable of rotary motion variable gear system

enables movement of mirror groups.

Chuck Arm

Control Unıt

CLAUSE 3

Fig.3 –RGU300.ECOTYPE 14” – 30”

Page 4

6

WARNING !

It is absolutely prohibited to carry out tyre inflation procedures while the wheel is still on the machine!

At least two people are required for the movement of particularly heavy wheels!

WHEEL LOCKING SYSTEM

The self-centering chuck operates by means of a high pressure hydraulic circuit adjustable from 20 to 110 bar. The handle

is turned and the pressure read on the manometer. Standart working pressure is 110 bar, but for weak or particularly thin

rim it is necessary to reduce this pressure.

INTRODUCTION

This manual is designed for service personnel, skilled in the use of these machines and the staff who makes the routine maintenance of the

machine.

Before every operation of this machine, must be read the operating instructions.

This guide;

SAFETY OF EMPLOYEES

It contains information about MACHINE SAFETY.

PRESERVATION OF USER MANUAL

Users and maintenance personnel must keep a place in reach of this manual at the time it is needed.

Handling, transport, Start, Settings, testing, additional maintenance and repair should be performed by the manufacturer authorized specialists.

The manufacturer is not responsible for problems and accidents That Occur in the event of incorrect use of the work done by unskilled people and

machines Mentioned above.

This manual is intended for the machine operators and maintenance personnel, for safe and correct use.

SAFETY

THIS MACHINE IS DESIGNED ONLY FOR 14

ıı

– 30 ıı RIMS.

THIS MACHINE SHOULD BE USED ONLY FOR TYRE REPLACEMENT.

PAY ATTENTION TO THE WARNING SIGNS ON THE MACHINE.

If the operator hears unusual noises or vibrations or something that may be dangerous , he must immediately

press the emergency button and switch off the main switch and check the section “Malfuctions causes and

possible remedies” in the instructions manual.If the problem is still call the service.

Wear protection glasses and gloves during the operation.

Stand straigth during operation.

Work in an insulated and clean area.

Switch off the main switch when there is no electricity.

Work in the safe distance.

The machine must be fixed onto smooth place.

PACKING, TRANSPORT, STORAGE

Packaging, picking up, extraction from shipping and packing must be carried out by experienced personnel at tire assembly

process, and who know the contents of this brochure.

PACKING

Tyre assembly machines, on wooden packaging and boxes were wrapped with stretch film.

LIFTING AND HANDLING

The Pallets Must Be Moved Wıth A Lıft Truck.The Equıpment Chosen Must Be Suıtable For Safe Lıftıng And Movıng,

Bearıng In Mınd The Dımensıons , Weıght , Barycentre , Justs And Fragıle Parts Not To Be Damaged.

STORAGE

Packed machine must be kept in a closed and protected place - between 40% C and 10% C. The machine should be protected

from direct sunlight. Pull the plug if the machine is not used for a long time.

OPENING CRATES

When The Crates Arrıve, Check That The Machıne Has Not Been Damaged Durıng Transport And That All The Lısted

Parts Are Present. The Crates Must Be Opened Usıng All Possıble Precautıonary Measures To Avoıd Damagıng The

Machıne Or Its Parts. Make Sure That Parts Do Not Fall From The Crate Durıng Openıng.

DISPOSAL OF CRATES

Wood pallets and wrapped in stretch film can be reused. Although not harmful Keep out of the reach of children.

CLAUSE 4

Page 5

7

ALL WORK ON THE ELECTRICAL SYSTEM, INCLUDING MINOR OPERATIONS , MUST

BE CARRIED OUT BY PROFESSIONALLY QUALIFIED PERSONNEL

Check that the mains supply is the same as that shown on the registration plate.

Connect the cable to a plug that conforms with European norms or to the norms of

the country in which the machine used.

The plug must have an earth terminal.

Check that the earth connection is effective.

The machine must be connected to the mains through a multipole isolating switch

which conforms with European norms and with contact openings of at least 3 mm.

Check that the multipole connector on the electrical board is correctly connected.

When the machine is connected switch it on and check the correct direction of rotation;this should be as shown by the arrow on

the motor unit.

If the rotation is reversed,reserve the two wires in the connection plug.

If the machine behaves abnormally,immediately press the emergency button and switch off the main switch and check the

section “Malfunctions:causes and possible remedies” in the instructions Manual.

THE MANUFACTURER DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE FAILURE TO OBSERVE THE ABOVE

MENTIONED INSTRUCTIONS.

SAFETY

WARNING!

Do not press on the cable of

the remote control system

may fall,

cable ıs protected by spıral

and sprıng ıncase of droppıng

and smashıng parts.

The direction of movement of the mirror

group

a) The direction of movement of the mirror foot

b) Gear and direction of movement of the rail

system

c) Emergency stop button

Fig.8

Fig.9

Fig.10

CLAUSE 5

Page 6

8

ROTATION

MOVEMENT

KEEP YOUR HAND BACK, DURING

THE WORK OF MIRROR

OPERATING SYSTEM.

KEEP YOUR FOOT BACK, DURING

THE WORK OF MIRROR

OPERATING SYSTEM.

DO NOT STAND BETWEEN

REDUCTOR SYSTEM, DURING IT

WORKS.

DO NOT STAND ON THE FRONT,

DURING THE TYRE CHANGE.

NOT BE UNDER THE REDUCTOR

SYSTEM DURING IT WORKS.

DURING THE WORK OF ARM ASSEMBLY

OPERATING, STAND BACK FROM THE

BACK SIDE.

DO NOT WORK WITHOUT

GLASSES AND GLOVES.

Only trained operators should use this machine.

Failure to read and observe all warnings and instructions should cause injury or death

Before operating read and understand all warnings and the instruction manual provided with this truck tyre

changer.

Follow all warnings and instructions during use.

Dont use the tyre changer if label and / or instruction manual are unreadable or missing.

SAFETY

Fig.11

WHEN YOU USE THE

MACHINE, READ YOUR

INSTRUCTIONS

CLAUSE 6

Page 7

9

İNSTALLATION

Fix the Machine from its connection holes (it is shown figure :12) on the ground by help of steel

wall plug. This function must be done to machine to Work safely and longevously. If the

connection fumction of the machine is not done, It can causes undesirable results such as the

tire cutting, Rim Scratch, mechanical damages on the machine. Therefore it should not be failed.

Otherwise because of the encountered problems It can not be under warranty.

Fig.12

CLAUSE 7

Page 8

10

Problems

Causes

Remedies

- If you have problems while thegear

box head is going up and down.

- If you have problems during the

locking head movements.

- If you have problems during the

movements of tyre changer table.

- The pressure valve may be blocked.

( Figure 14 / Valve 1 )

- The pressure valve may be blocked.

( Figure 14/ Valve2 )

- The pressure valve may be blocked.

( Figure 14 / Valve 3 )

- Open the valve cover and by using

pim of max 5 mm diameter unblock

the valve.( Figure 14 )

- The engine is working but the

locking head is not turning.

- The engine belt may be untightened.

- Check the engine belt.

- There is not enough pressure in the

hydraulic unit

- The direction of the hydraulic unit may

be reverse.

- There may be lack of oil in the

hydraulic unit.

- Change the cables vice in the

connection.

- Put oil till the level of the insdicator.

- The locking head is not working.

- The o-rings of the locking valve may be

damaged.

- The enter o-ring may be damaged.

- Change the o-rings.

- Call our technical service.

- The locking head is not turnig to the

right or left

- The gear box body is not moving up

and down.

- Tyre carriying table is not moving.

- There may be a problem with the

electrical connections.

- Call our technical service.

LOCATION

SAFE DISTANCE:

For the safe and ergonomic use of the

machine it is advisable to locate it so

as to allow work, in conditions of

complete safety.

When the machıne workıng or the

machıne stopped, anybody except the

operator doesn’t apporoach to the

machıne and the each sıdes of the

machıne must be empty at least 1,5 m.

1– Gearbox Up Down Valve

3 – Changer Table Valve

Fig.14

2 – The Locking Head

Fig.13

CLAUSE 8

Page 9

11

OPERATION AND USE

( DEMONTAGE )

The air of the tires must be taken before it is inserted into the machine. Empty the air in the

tire completely attached to the machine, and after starting the removal.

Connect the rim to the mirror.

Both sides of tire and roller are lubricated

and soaped.

Roller set between rim and tire.

Pressuring to tire with roller to break the

bead, with turning the machine.

The same procedure is done on the other

side of the tire (Figure 15).

There are several methods of separating the tire from the rim;

1)- Inner heel, after leaving the wheel to the

active counter outside enabled.

Simultaneous turning of the tire, with roller

and the tire is further squeezed.

Remove both heels slowly outwards from the

rim (Fig.16).

When roller the tire, outward force applied, and when the heel sits on the inner cheek

of the rim and when the rotation of the tire on the rim prevents the clamp attached to

the rim and continue working.

Fig.15

Fig.16

CLAUSE 9

Page 10

12

Fort he front bead, recommended method is applying with roller.

Inner heel and foot wear reduction system described above generally apply to tractor tires.

After seperating the outer bead of tire from rim, tire gets out from the rim, with the help of moving part.

OPERATION AND USE

2)- After separating the inner and outer heel

from the edge, the foot arrangement is first

coated on the outer heel.

Lever mounted in the top of the foot, and the

tire, so that it can be pushed outwards.

Tires rotated clockwise, and slowly outward leg

assembly is towed

(Figure 17).

This process is continued until the heel totally

separated from the outer rim.

The same procedure is applied in the inner

heel, and completely separated from the tire rim

is provided.

(MOUNTAGE )

The tire is fitted on the rim facing the clamp. Inner

and outer heel of mature oiling or soaping

beautiful.

Removal - insert foot is placed between the rim

and the heel. The installation process is

performed by the turn of the tire clockwise.

When beads fit to the rim completely, assembly

finishes.

Do not inflate mature while it is on the machine,

after installation of the machine should be

removed from the tire, and pump elsewhere.

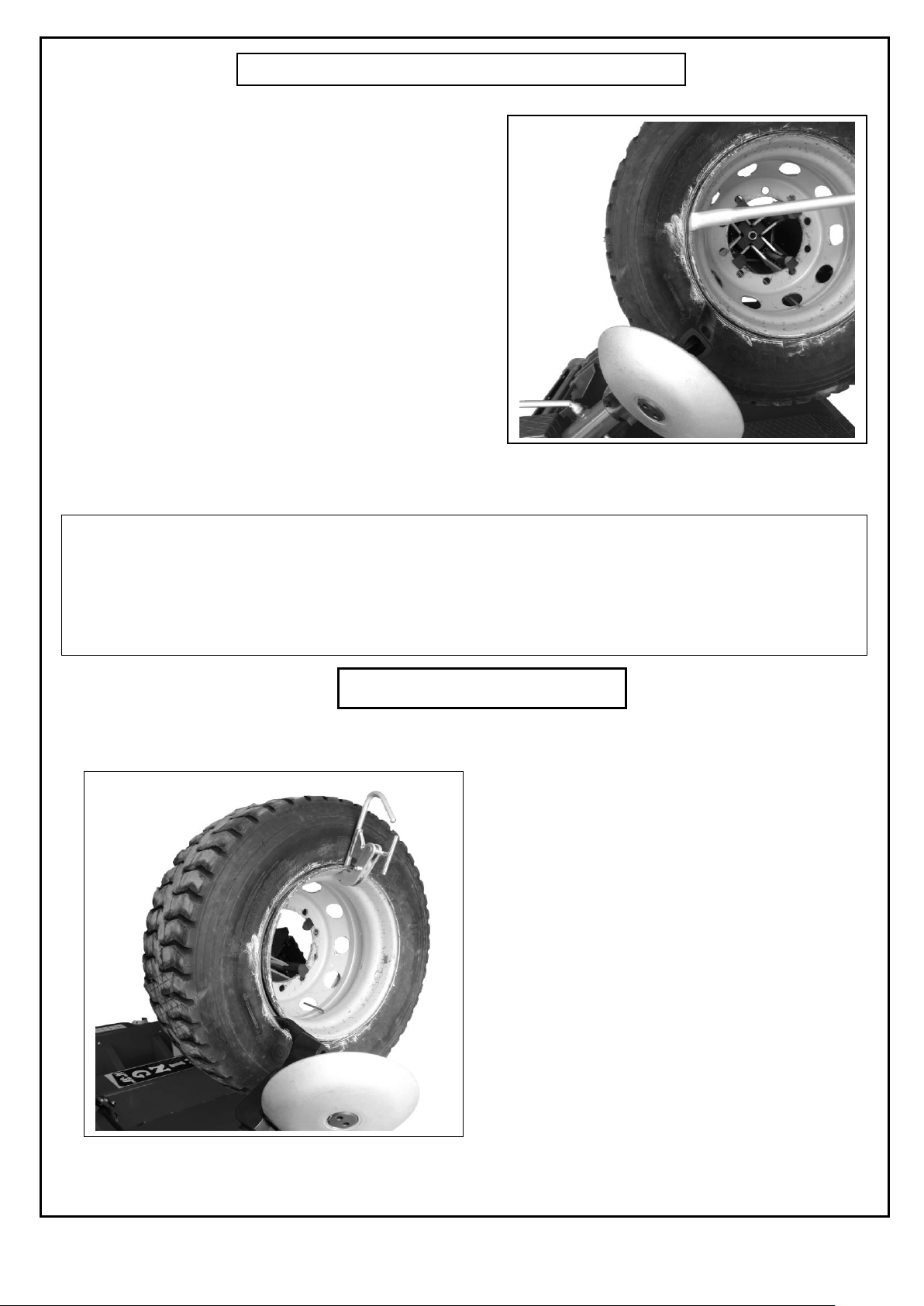

Wheel is connected to the mirror. on the upper part of the rim, pliers (clamp) mount (Fig.18)

For heavy tires, the process of connecting to the machine should be performed by two people.

Fig.17

Fig.18

Page 11

13

Before operating the machine,

lubricate the area shown in the

figure.

OILING PERIODS

ACCESSORIES PROVIDED

BEAD LIFTING LEVER (Fig.20)

A toll necessary for lifting the tyre bead onto the head

dunng demounting.

RIM PINCERS (Fig.21)

These are used when mounting tubeless and

supersingle tyres.

Fig.22

Fig.20

Fig.21

Points to be considered, by Setting the machine, or servicing;

1)Be sure that machine is not working.

2)Wear protection glasses and gloves.

3)After lubrication, do not squeeze your hand on moving parts of machine.

Fig.19

CLAUSE 10

Reductor gear montly

lubricated

Montly lubricated

Weeekly lubricated

Detachable cleaning

weeekly

in arm after the thin with

grease

lubricated

Cleaned on a weekly basis

After the thin with grease

lubricated

Page 12

14

ROUTINE MAINTENANCE

DAILY

1) CHECK THE CABLE OF THE MACHINE BEFORE THE RUNNING.

2) CHECK THE MACHINE IF THE MACHINE IS CLEAN AND MAINTENANCE IS COMPLETED.

3) CHECK THE HYDRAULIC CYLINDER AGAINST THE AIR LEAKAGE.

WEEKLY

1) CHECK IF THE DAILY MAINTENANCE IS DONE SYSTEMATICALLY.

2) CHECK IF THERE IS ANY OIL LEAKAGE ON THE CYLINDEROF THE BEAD LIFTING.

3) CHECK IF THERE IS ANY PROBLEM ON THE SWITCHES AND CONNECTION OF THE MACHINE.

MONTHLY

1) CHECK IF THE DAILY AND WEEKLY MAINTENANCES ARE DONE.

2) CHECK THE MACHINE PEDALS.

3) CHECK THE BELT OF THE MOTOR.

4) CHECK THE CONNECTION OF THE GEARBOX.

5) CHECK THE MOTOR CONNECTION BOLTS.

6 MONTHLY

1) CHECK THE DAILY, WEEKLY AND MONTHLY MAINTENANCE ARE DONE.

2) CHECK IF THERE IS ANY CONNECTION PROBLEMS ON THE CABLES AND SOCKET.

3) CHECK THE EARTH CONNECTION OF THE MACHINE ELECTRIC SYSTEM.

4) CHECK THE ADJUSTMENT OF THE DISMANTLING AND FIXING ARM.

YEARLY

1) CHECK THE DAILY, WEEKLY, MONTHLY AND 6 MONTHLY MAINTENANCE ARE DONE.

2) ARE THERE ANY UBNORMAL NOISES COMING FROM THE MACHINE.

3) ARE THERE ANY UBNORMAL NOISES COMING FROM THE ENGINE.

4) ARE THERE ANY UBNORMAL NOISES FROM THE MACHINE WHEN THE MACHINE IS NOT WORKING BUT

PLUGGED.

5) IS THERE ANY HEATING IN THE CABLES.

6) IS THERE ANY UBNORMALITYIN THE ENGINE DURING THE OPERATION.

IF ANY ANSWERS OF THESE GUESTIONS ARE YES CALL THE TECHNICAL SERVICE IMMEDIATELEY DO NOT

TRY TO SOLVE THE PROBLEMS BY YOURSELF.

CLAUSE 11

Page 13

15

THE MACHINE IS GURANTEED (1 YEARS) ;

FOR ANY MACHINE MAFUNCTIONS CONSULT THE SECTION “MALFUCTIONS: CAUSES AND POSSIBLE REMEDIES”

. ANY OTHER MALFUNCTIONS MUST BE CHECKED BY PROFESSIONALLY QUALIFIED PERSONNEL.

IN ALL CASES CONTACT THE ASSISTANCE SERVICE OF HATCO. FOR PROMPT ASSISTANCE IT IS IMPORTANT AT

THE TIME OF THE CALL TO SPECIFY THE MACHINE MODEL, THE PRODUCTION NO. (FOUND ON THE

REGISTRATION PLATE) AND TYPE OF MALFUNCTION.

hydraulic unit from the oil can that you can find in your accessories box provided with your

machine.

Only Use Shell Tellus 46 And Po Hd 46 Oıl At The System.

Yağ kapasitesi 12 litredir.

Our Guarantee Doesn’t Contaın Electrıc Motor

Control Cables Breaking And Cutting Damage That May Occur İs Outside The Guarantee.

Run The Machine İdle For 10 Minutes During The Winter Months. Start Work Later Please.

TO ORDER SPARE PARTS:

INDICATE THE SERIAL NUMBER OF THE MACHINE AND THE YEAR BUILT.

INDICATE THE CODE OF THE PIECE REQUESTED.

INDICATE THE QUANTITIY REQUIRED.

WARNINGS

USE ONLY ORIGINAL PARTS OF THIS MACHINE

THE MANUFACTURER TAKES NO RESPONSIBILITY OF THE NONORIGINAL

PARTS

THERE IS NO OIL IN THE HYDRAULIC UNIT

WARNING

ANY WORK ON THE ELECTRICAL, HYDRAULIC AND PNEUMATIC SYSTEMS

MUST BE CARRIED OUT ONLY BY PROFESSIONALLY QUALIFIED

PERSONNEL.

CLAUSE 12

Page 14

16

CONTROL BUTON CIRCUIT PLAN ( 3 PHASES )

CONTROL ARM

Up

Mirror Open

Down

MOVEMENT MOTOR

3A 3A

Left

EMERGENCY STOP

Right

HYDRAULIC MOTOR

18

17

MP

18

17

MP

3A

CLAUSE 13

Page 15

17

DEMONTAGE PLAN

CLAUSE 14

Page 16

18

Page 17

19

Page 18

20

CODE NO

DESCRİPTİON

1

83 01 000-EKO

Lower Body Group

2

83 03 000

Reductor Group

3

83 03 001

Reductor Body

4

83 03 013

Reductor Connectıon Group

5

01 0275 18-B14

Engine

6

01 0029 21

Reductor

7

83 03 005

Chaın Bottom Protectıon

8

01 0145 04

Reductor Large Gear

9

83 03 006

Internal Protectıon Plate Chaın

10

83 03 007

Reductor Abs Cover

11

83 03 008

Chaın Protectıon Abs Cover

12

01 0130 035-045-1

Washer

13

01 0074 010

Screw

14

01 0111 008

Washer

15

01 0062 035

Screw

16

01 0063 035

Screw

17

01 0063 025

Screw

18

01 0072 010

Screw

19

01 0112 06

Washer

20

01 0112 08

Washer

21

01 0115 008-04

Nut

22

01 0117 008

Fiber Nut

23

01 0123 050

Setscrew

24

01 0052 50

Fid

25

83 03 009

Connectıon Washer

26

01 0156 19

Two Rows Of Gear Chaın Pulley

27

01 0156 20

Double Roller Chaın Attachment

28

01 0145 05-35

Reductor Small Gear

29

83 03 012

Bearing Bracelet

30

83 03 011

Bearing Bracelet

31

01 0053 6207-FAG

Bearing

32

01 0140 072

Shaft Ring

33

83 03 010

Connectıon Washer

34

01 0084 035

Screw

35

01 0115 008

Nut

36

01 0062 080

Screw

37

83 07 000

Pıston Head Lıftıng Group

38

83 07 001

Cylınder Group

39

83 07 002

Pıston Group

40

53 03 003

Pıston Head

41

01 0117 020

Fiber Nut

42

01 0022 060-044

Compact Set

43

53 03 004

Pıston Nut

44

01 0023 030

Dust Seal

45

01 0021 30-38-6.5

Nutring

46

01 0024 030-3

O-Ring

47

01 0024 055-3

O-Ring

48

01 0024 059-3

O-Ring

49

01 0136 006

Fıttıng

50

01 0024 020-3

O-Ring

51

01 0027 009

Bearıng Bush

52

83 06 000

Slıde Cylınder Group

53

83 06 001

Cylınder Group

54

83 06 002

Pıston Shaft

55

01 0024 060-3

O-Ring

56

83 04 000

Mırror Group

57

83 04 001

Cylınder Body Group

58

01 0021 040-50-10

Nutring

59

01 0024 040-3

O-Ring

60

01 0023 40

Dust Seal

61

53 06 003

Mırror Body

62

53 06 017

Fıxıng Pın

63

53 06 007

Squeezıng Setscrew

64

01 0063 050-10.9

Screw

65

01 0112 10

Washer

66

53 06 010

Spın Rıght Lama

67

53 06 011

Spın Left Lama

SPARE PARTS LIST FOR RGU300.ECO TYPE

CLAUSE 15

Page 19

21

68

01 0130 014-020-1

Washer

69

01 0065 080 10.9

Screw

70

01 0117 014

Fiber Nut

71

53 06 012

Pullıng Lama

72

01 0072 016

Screw”

73

53 06 015

Spın Foot Connectıon Pın

74

01 0139 014

Shaft Rıng

75

53 06 014

Pullıng Lama Pın Connectıon

76

53 06 016

Squeezıng Foot

77

53 06 019

Short Wheel Squeezıng Teeth

78

53 06 020

Long Wheel Squeezıng Teeth

79

01 0111 012

Washer

80

53 06 013

Spıder

81

53 06 008

Remote Control Metal Root

82

53 06 006

Maın Shaft

83

01 0024 020-2.5

O-Ring

84

53 06 004

Rubber Head

85

01 0118 1-14 DİŞ

Nut

86

01 0022 100-075

Compact Set

87

53 06 005

Bracelet

88

83 04 003

Washer

89

53 06 021

Cylınder Cover

90

01 0112 05

Washer

91

01 0060 016

Screw

92

01 0024 007-2

O-Ring

93

01 0024 090-5

O-Ring

94

01 0073 025

Screw

95

01 0111 008

Washer

96

53 06 018

Holdıng Teeth Ofalumınum Wheels

97

01 0074 045

Screw

98

01 0064 040

Screw

99

01 0052 105

Fid

100

01 0159 01

Lockıng Valve

101

01 0150 315-ARKA

Glycerıne Manometer

102

83 11 000

Hydraulıc Unıt Group

103

83 11 001

Oıl Tank Group

104

53 08 001

Upper Cover Group

105

01 0034 21

Tank Top Seal

106

01 0034 01

Motor Seal

107

01 0145 35

Pump

108

01 0147 01

Brake Drum

109

01 0273 09-B5

Engine

110

01 0269 02

Flange

111

53 08 007

Couplıng Group

112

01 0014 21

Record

113

53 08 004

Fılter By-Pass Record

114

53 08 003

Pump Fılter Connectıon Pıpe

115

53 08 005

Pump Outlet Pıpe

116

53 08 006

Tank Return Pıpe

117

01 0149 25

Suctıon Fılter

118

01 0155 01

Tank Cover

119

01 0137 1-2 AL

Level Indıcator

120

01 0135 1-4

Dead End

121

01 0112 10

Washer

122

01 0072 035

Screw

123

01 0117 006

Fiber Nut

124

01 0074 035

Screw

125

01 0060 016

Screw

126

01 0072 020

Screw

127

01 0131 3-8

Copper Washer

128

01 0123 010

Setscrew

129

01 0014 20

Body Fıttıng

130

01 0014 23C

Pıpe Clamp Nut

131

53 09 000

Oıl Support Group

132

01 0072 055

Screw

133

53 00 005

Valve Cover Connectıon Pıpe

134

01 0039 08

Protect Valve Cover

135

53 09 000

Oıl Support Group

136

53 09 001

Body Group

Page 20

22

137

01 0014 176

Body Fıttıng

138

01 0131 1-4

Copper Washer

139

01 0156 02

Valve

140

01 0024 014-3

O-Ring

141

53 09 007

Pressure Regulating Valve Group

142

53 09 002

Pressure Adjustment Screw

143

01 0115 010

Nut

144

01 0024 017-2.5

O-Ring

145

53 09 005

Bottom Transıtıon

146

01 0024 009-2

O-Ring

147

53 09 006

Pressure Adjustment Spındle

148

53 09 004

Sprıng Bottom Had

149

01 0031 04

Pressure Adjustment Sprıng

150

53 09 003

Sprıng Top Had

151

01 0124 030

Setscrew

152

01 0115 010-KS

Nut

153

01 0039 08

Protect Valve Cover

154

83 02 000

Sledge Group

155

83 02 001

Body Group

156

83 02 003

Slıde Changıng Arm Apparatus Shaft Connectıon

157

01 0063 030

Screw

158

01 0063 040

Screw

159

75 02 003

Pressure Washer

160

01 0124 040-D

Setscrew

161

01 0115 010

Nut

162

01 0130 040-50-1

Washer

163

53 01 013

Shaft Washer Connectıon

164

01 0064 030

Screw

165

01 0063 035

Screw

166

33 06 002

Mıle Rubber

167

33 06 003

Slıde Rubber Powder - Prıntıng Plate

168

01 0063 025

Screw

169

83 02 004

Protectıon Cover - Large

170

83 02 005

Protectıon Cover - Small

171

83 02 002

Flat Bed Raıls Of Yellow

172

83 10 000

Accessorıes And Panel Connectıon Group

173

53 17 002

Cabınet Panel Operatıon

174

53 17 003

Panel Inner Metal

175

01 0202 03

Transformer

176

01 0028 64

Raıl Termınal

177

01 0028 27

Dıode Brıdge

178

01 0028 42

Cable Road

179

01 0196 10

Contactor

180

01 0028 28

Grounded Connector

181

01 0028 29

Connector

182

01 0028 30

Fuse Connector

183

01 0028 26

Connector Stopper

184

01 0200 02

Transformer

185

01 0198 16

Plastıc Cable Sleeve

186

01 0198 21

Plastıc Cable Sleeve

187

83 05 000

Removal Installatıon Arm Clamp Group

188

83 05 001

Removal Installatıon Arm Body Group

189

83 05 002

Removal Installatıon Key Group

190

83 05 004

Pressure Pıston

191

53 05 003

Wedge

192

53 05 006

Sprıng Fıxıng Washer

193

01 0112 16

Washer

194

01 0117 016

Fiber Nut

195

01 0066 120

Screw

196

01 0140 034

Hole Rıng

197

01 0139 020

Shaft Rıng

198

01 0031 115

Handle Removal Installatıon Tool Compressıon Sprıngs

199

01 0031 21

Iron Prınt Sprıng

200

01 0053 06004-MOS

Bearıng

201

53 14 000

Removal Installatıon Arm Group

202

53 14 001

Body Group

203

33 17 002

Roller Group

204

33 17 004

Belly Shaft

205

33 17 005

Connecting Shaft

Page 21

23

206

01 0031 52

Changıng Screw Pullıng Sprıng

207

33 17 006

Sprıng Connectıon Plate

208

53 14 003

Washer

209

53 14 002

Changıng Screw

210

01 0115 014

Nut

211

33 17 007

Set Dıstance Screw

212

33 17 003

Changıng Screw

213

53 13 000

Roller Shaft Connectıon Group

214

83 02 000-EKO

Tyre Trolley

215

83 00 001-EKO

Ramp Group

216

01 0073 060

Screw

217

01 0112 08

Washer

218

01 0117 008

Fiber Nut

219

53 21 002

Ramp Wheel

220

53 11 000

Control Group

221

53 11 001

Command Setup

222

53 11 002

Cover Mounting

223

53 11 003

Command Control Group

224

11 12 010A

Plastıc Pedal

225

01 0048 01

Hand Handle

226

01 0060 016

Bolt Screw

227

01 0115 005

Nut Screw

228

01 0071 016

Imbus Bolt Screw

229

01 0122 006

Set Screw

230

01 0107 040

Bolt Wıth Star Head

231

01 0134 02A

Plastic Cable Clamp

232

01 0195 04

Cable End

233

01 0134 02C

Connection Sheet

234

01 0072 020

Imbus Bolt Screw

235

01 0198 15

Plastıc Record

236

53 18 000

Group To Press

237

53 00 004

Lever

Loading...

Loading...