Owner’s Manual

GM ALDL MG2000™

Tachometer

IS0195

rev. A ecr#5576 8/2005

IS0195 x7 w/ corrections

Mark ups 12/20/05

Index

Figure 1 Default screens page 1

Description page 1

Normal Mode page 2

Contrast and Lighting page 2

Displayed Functions page 3

Default screen 1 page 3

Default screen 2 page 3

Default screen 3 page 3

Default screen 4 page 4

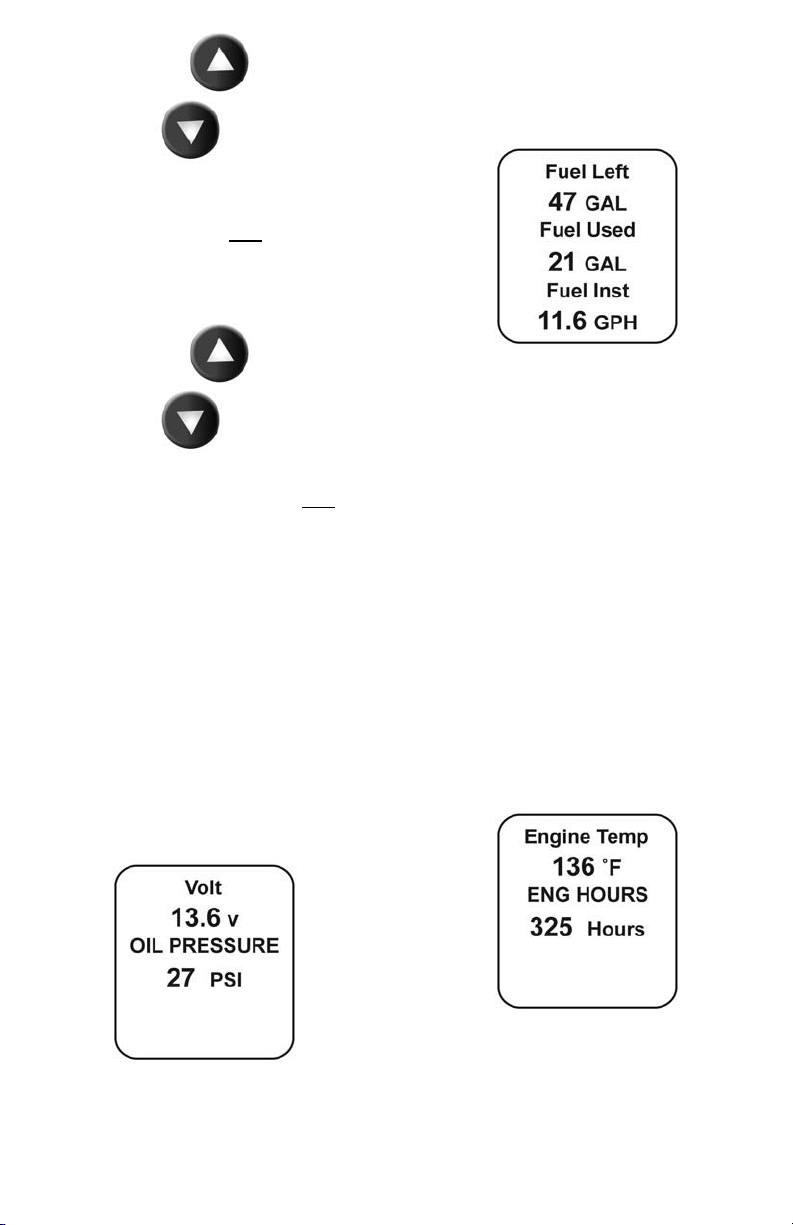

Figure 2 Screen Sequence page 4

Figure 3 LCD Display Screens page 5

Edit Mode page 7

Functions that are adjusted in Edit Mode. page 7

Select Default Screen page 7

Reset Fuel Used page 8

Set Fuel Tank Full page 8

Set Amount of Fuel page 9

Organize User Screens page 9

Select Gauge Range page 10

Select Oil Pressure Dial page 10

Select Coolant Temp Dial page 11

Select Voltmeter page 11

Select Water Press Dial page 12

Select Boost Press Dial page 12

Select Fuel Sender page 12

Select Oil Pressure Sender page 13

Select Display Units page 13

Select Pressure Units page 13

Select Volume Units page 14

Select Temperature Units page 14

Select Distance Units page 14

Select Depth Units page 15

Select Fuel Tank Size page 15

Select Other Fuel Tank Size page 15

Fuel Tank Calibration page 16

Low Fuel Alarm page 17

Software ID and Revision page 17

Select Self Test page 17

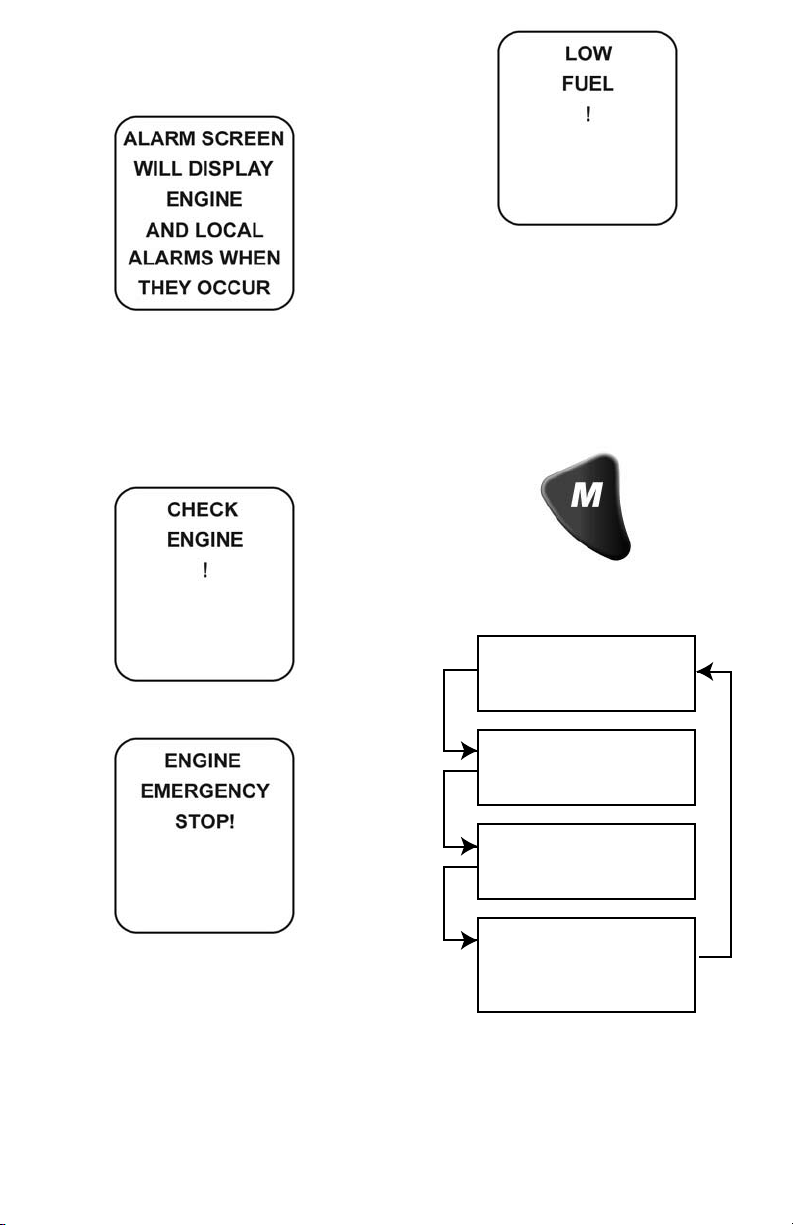

Alarm Mode page 19

Low Fuel page 19

Engine Warnings page 19

Alarm Messages From ECU page 20

Alarm Clear Mode page 21

Harness HN0390 page 22/23

Harness HN0401 GPS NMEA0183 Cable page 24

Harness Two inch Gauge connection page 25

This page left blank intentionally.

The FARIA MG2000 Tachometer

combines the features of an ECU serial

bus gateway and several instruments

into one unit:

• The tachometer is analog in

appearance but driven by a stepper

motor for digital accuracy.

• The high resolution LCD screen

displays information for many other

functions and the various “screens”

can be configured as the user

wishes. As received, the screens

are configured as shown in Fig. 1.

The MG2000 receives digital engine data

from the Engine Control Unit (ECU) via

the GM ALDL bus and can receive GPS

information via a NMEA 0183 connection

to a suitable GPS unit. GPS information

is displayed in the MG2000 speedometer.

Analog inputs are provided for two nonengine sensors such as fuel level and oil

pressure.

The MG2000 provides a Faria Bus output

to allow use of various other 5, 4, and 2

inch instruments with the MG2000.

The Faria MG2000 Tachometer will turn

on when the ignition key is turned on and

will turn off when the ignition key is turned

off. The unit will power up showing the

default screen selected by the user.

Figure 1

The instrument has three push buttons;

“M” “Mode”, “Down”, and “Up”; that

control the functions available. The “M”

“Mode” button is used to change the

function of the LCD display and to access

submenus and adjustable settings. The

“Down” and “Up” buttons are used to

modify the settings.

Default Screens

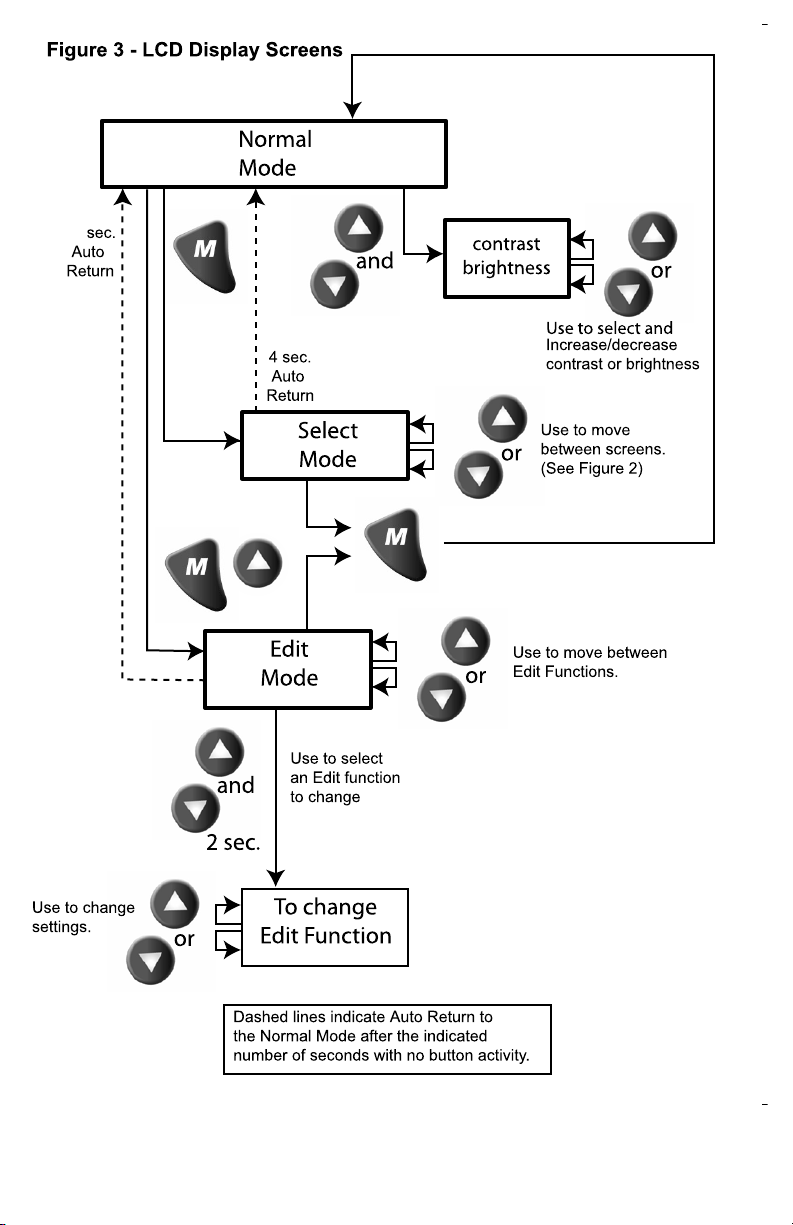

In the “Normal” operation mode, pressing

the “Mode” button and then pressing

“Down” or “Up” button causes the display

to cycle between the available screens

Page 1

(see Figure 2). Press the “Mode” button

to exit the “screen selection mode” and

return to “Normal” mode or do not push

any buttons for 4 seconds and the current

screen will stay selected and the unit will

return to “Normal” mode (see Figure 3).

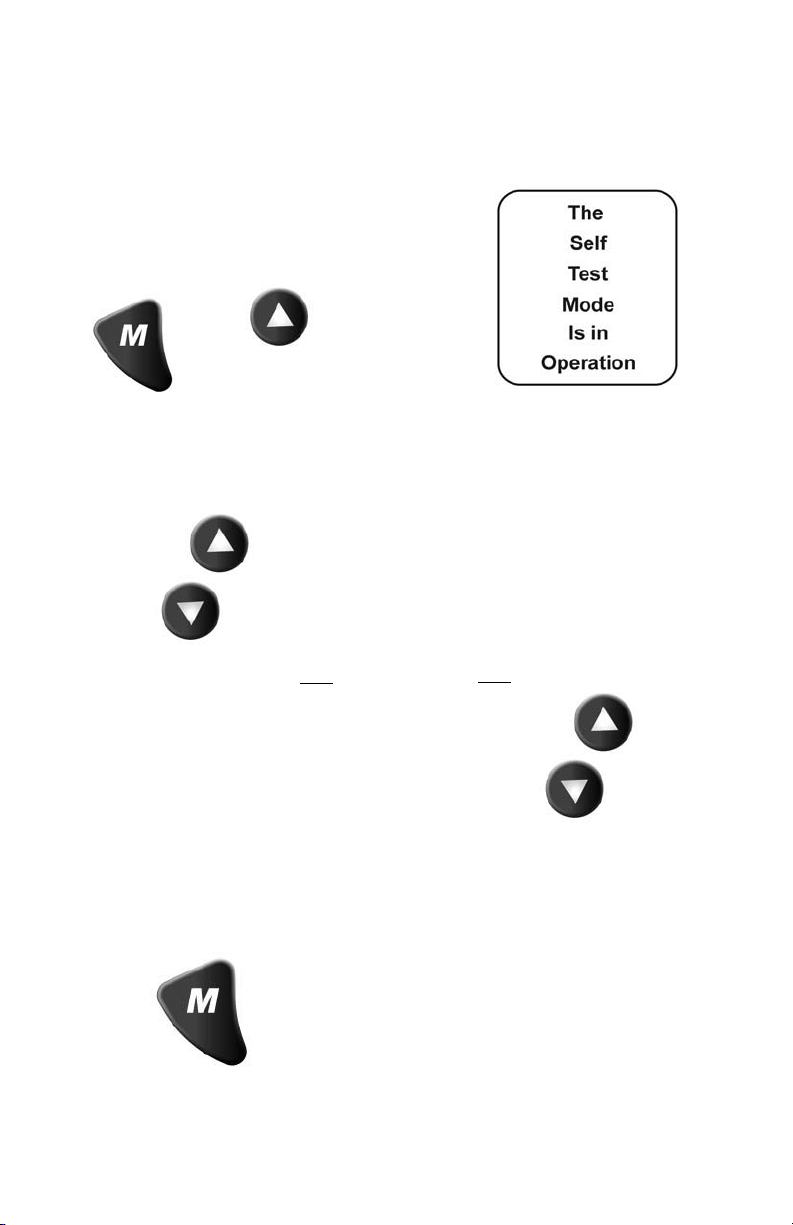

In the “Normal” operation mode, press

the “Mode” and “Up” buttons to change to

the “Edit” menus (see Figure 3 and “Edit”

mode below).

Press the “Down” or “Up” buttons to cycle

between the available “Edit” functions.

Press and hold the “Down” and “Up”

buttons for two (2) secs to select an

“Edit” function to change. Within each

“Editing” function the “Down” or “Up”

buttons select settings or sub-functions.

Follow the instructions in the “Edit” mode

section of this manual to save the new

settings after you select / adjust them.

To exit the “Edit” mode after the edit is

completed, press the “Mode” button to

return to “Normal” mode.

Normal Mode

When the MG2000 is turned on the unit

will “beep” once, flash once and then the

unit enters “Self Test” mode. The screen

will display “The Self Test Mode Is In

Operation” for 10 seconds.

The horn will sound three times and the

warning lights and back lights will flash

three times. When this is complete, the

software ID and revision screen will show

for two seconds, then the user selected

“Default” screen will appear.

Contrast and Lighting

In the “Normal“ operating mode the

instrument display contrast and display

mode can be adjusted by pressing the

“Down” and “Up” buttons.

With the display in “Positive” mode, black

on white, pressing the “Down” button

decreases the contrast. Pressing the

“Up” button increases contrast.

Page 2

Continuing to press the “Up” button

causes the display to reverse to the

“Negative” mode, white on black. The

contrast in this mode is controlled the

same way as the “Positive” mode.

To return to “Positive” mode, continue to

press the “Down” button until the display

reverses.

To adjust the lighting intensity of all of

the instruments in the system, press and

hold both the “Down” and “Up” buttons

for 2 seconds. The lighting intensity may

now be adjusted by using the “Down” or

“Up” buttons.

Return to the “Normal” mode by pressing

and holding both the “Down” and “Up”

buttons for 2 seconds.

Displayed Functions

Tachometer

The tachometer is a digital instrument with

the appearance of an analog instrument.

The tachometer receives data directly

from the ECU so no settings are required

for the dial range. A microprocessor

controlled stepper motor moves the

pointer to display engine revolutions per

minute.

Default Screen “1”

OIL PRESSURE

Analog input. Displays information from

the analog oil pressure sender.

Default Screen “2”

Fuel Left

Displays the quantity of fuel remaining

in the fuel tank based on the original

quantity of fuel in the tank when full and

the amount of fuel used based on the

GPH from the engine ECU and the time

spent at each GPH. Fuel tank size and

reset are available in the “Edit” mode.

Fuel Used

Displays the amount of fuel used since

reset based on the GPH from the engine

ECU and the time spent at each GPH.

Fuel Inst

Displays the current, instantaneous, fuel

flow in GPH.

Default Screen “3”

Volts

Displays system voltage as received

from the ECU (Engine Control Unit).

Engine Temp

Displays the coolant temperature

received from the ECU. Dial range can

be selected in the “Edit” function.

Engine Hours

Page 3

Displays the Engine Hours data received

Screen “1”

Screen “2”

Screen “3”

Screen “4”

Alarms (ONLY IF

ALARMS ACTIVE)

from the engine ECU.

Default screen “4”

This screen displays fault conditions

based on engine data received from the

ECU or alarms based on internally set

alarm points. Engine alarms from the

ECU will be displayed as “Check Engine

!”

LCD Display Screens:

In “Normal” mode, press “Mode” once to

enter screen “Select” mode, press “Up”

or “Down” to move between screens.

Press “Mode” once to return to “Normal”

mode.

or “Engine Emergency Stop !”.

Accessing the “View“ mode when the

Alarm screen appears will allow more

information to be displayed about the

alarm if provided by the engine.

Internal alarm values can be set for “Low

Fuel” and other functions. Alarms for

these settings will appear as required.

Page 4

Figure 2

1. Select Default Screen

2. Reset Fuel Used

3. Set Fuel Tank Full

4. Set Amount of Fuel

5. Organize User Screens

6. Select Gauge Range

7. Select Fuel Sender

8. Select Oil Pressure Sender

9. Select Display Units

10. Select Fuel Tank Size

11. Fuel Tank Calibrate

12. Low Fuel Alarm

13. Software ID and Revision

14. Select Self Test

40

Figure 3

Page 5

This page left blank intentionally.

Page 6

Edit Mode

The “Edit” mode is used to adjust or set

the values of numerous functions and

options in the MG2000. The procedure

below specifies the steps to be taken

in the “Edit” mode to adjust / set each

option.

To enter “Edit” mode, press the “Mode”

and “Up” buttons while in “Normal” mode

To return to “Normal” mode, press “Mode”

button once while in “Edit” mode.

Functions that are set or adjusted in the

“Edit” mode:

1. Select Default Screen

2. Reset Fuel Used

3. Set Fuel Tank Full

4. Set Amount of Fuel

5. Organize User Screens

6. Select Gauge Range

7. Select Fuel Sender

8. Select Oil Pressure Sender

9. Select Display Units

10. Select Fuel Tank Size

11. Fuel Tank Calibrate

12. Low Fuel Alarm

13. Software ID and Revision

14. Select Self Test

Instructions – Function LINE

Select “Default Screen.”

Press and hold the “Up” and “Down” buttons for 2

seconds to select the “Default Screen.”

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

(Display Screen 1 is the “Default” at first turn on.)

Press and hold the “Up” and “Down” buttons for 2

seconds to select screen 1 as the “Default Screen” and

exit.

Press “Up” or “Down” to select another screen.

DISPLAY

1

2

3

1

2

3

Select

Default

Screen

Display

Screen

1

Page 7

1

Display

Press and hold the “Up” and “Down” buttons for 2

seconds to select this screen as the “default screen” and

exit.

Press “Up” or “Down” to select another screen.

Repeat until desired “Default Screen” is selected.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Reset “Fuel Used”

Press and hold the “Up” and “Down” buttons for 2

seconds to reset “Fuel Used” to zero (0).

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Set “Fuel Tank Full”

2

3

1

2

3

1

2

Next

Screen

Reset

Fuel

Used

Set

Fuel Tank

NOTE: In order to use the “Fuel Left” function, the owner

must set this function when the fuel tank is filled or use

the set current amount of fuel below. In addition, if “Set

Fuel Tank Full” function is used, the “Fuel Tank Size”

must be set correctly to the size of the fuel tank in this

application. The computer will monitor fuel usage and

calculate the fuel left in the tank. This function does not

replace the fuel level function provided by the fuel sender

and should be used with caution.

Press and hold the “Up” and “Down” buttons for 2

seconds to set “Fuel Tank Full.”

Automatically sets the fuel available to the tank size

selected by the user and returns to “Edit” mode.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Page 8

3

Full

1

Set

Set “Amount of Fuel”

NOTE: If a known amount of fuel is in the fuel tank but

it is not full, this function can be used to indicate the

amount of fuel available. The “Fuel Left” function will

then use the amount of fuel entered to calculate the “Fuel

Left.”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Current Amount of Fuel.”

Press “Up” or “Down” to set the amount of fuel known

to be in the fuel tank. Adjust until the displayed volume

matches the known amount of fuel in the tank.

When the volume is correctly set, Press and hold the “Up”

and “Down” buttons for 2 seconds to save and exit.

Organize User Screens

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Organize User Screens.”

2

3

Amount

Of Fuel

1

2

Fuel

Amount

3

1

2

3

XXX G

Organize

User

Screens

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Organize Screen 1

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Organize Screen 1.”

Press “Up” or “Down” to select another screen or “Mode”

to return to “Edit” mode.

Refer to the list of available functions in the ownerʼs

manual. Press and hold “Up” or “Down” to select the

number of the function to be displayed in screen 1, line 1.

1

2

3

1

2

3

Set up

Screen

1

Screen 1

Line 1

Item XX

Page 9

Press and hold the “Up” and “Down” buttons for 2

seconds to save selection for Screen 1, line 1 and advance

to Screen 1, line 2.

Press “Mode” to exit with no change made.

Refer to the list of available functions in the ownerʼs

manual. Press and hold “Up” or “Down” to select the

number of the function to be displayed in screen 1, line 2.

Press and hold the “Up” and “Down” buttons for 2

seconds to save selection for Screen 1, line 2 and advance

to Screen 1, line 3.

Press “Mode” to exit with no change made.

Refer to the list of available functions in the ownerʼs

manual. Press and hold “Up” or “Down” to select the

number of the function to be displayed in screen 1, line 3.

Press and hold the “Up” and “Down” buttons for 2

seconds to save selection for Screen 1, line 3 and advance

to view new screen 1.

Press “Mode” to exit with no change made.

Press and hold the “Up” and “Down” buttons for 2

seconds to save new Screen 1.

Press “Mode” to exit with no change made.

1

2

3

1

2

3

1

2

3

Screen 1

Line 2

Item XX

Screen 1

Line 3

Item XX

Display

Customer’s

New screen 1

Repeat for remaining screens (2, 3, etc).

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Select “Gauge Range” (dial reading range)

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Gauge Range.”

Press “Up” or “Down” to select another function.

Select “Oil Pressure Dial”

Page 10

1

2

3

1

2

3

Select

Gauge

Range

Select

Oil Pressure

Dial

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Oil Pressure Dial.”

Press “Up” or “Down” to select another “Gauge Range.”

Press “Mode” to return to the “Edit” mode.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to “Gauge

Range” selection

1

2

3

1

> 60 psi

80 psi

100 psi

Select

Select “Coolant Temperature Dial”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Coolant Temp Dial.”

Press “Up” or “Down” to select another “Gauge Range.”

Press “Mode” to return to the “Edit” mode.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to “Gauge

Range” selection.

Select “Voltmeter Dial”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Voltmeter Dial.”

Press “Up” or “Down” to select another “Gauge Range.”

Press “Mode” to return to the “Edit” mode.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to “Gauge

Range” selection.

2

3

1

Coolant Temp

Dial

> 60 –220 f

100 – 250 f

2

3

1

2

3

1

Select

Voltmeter

Dial

> 16 v

32 v

2

3

Page 11

1

Select

Select “Water Press Dial”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Water Press Dial.”

Press “Up” or “Down” to select another “Gauge Range.”

Press “Mode” to return to the “Edit” mode.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to “Gauge

Range” selection.

Select “Boost Press Dial”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Boost Press Dial.”

Press “Up” or “Down” to select another “Gauge Range.”

Press “Mode” to return to the “Edit” mode.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to “Gauge

Range” selection.

2

3

Water Press

Dial

1

> 30 PSI

2

3

1

2

3

1

2

3

4

1

45 PSI

60 PSI

Select

Boost Press

Dial

20 PSI

> 30 PSI

50 PSI

70 PSI

Select

Select “Fuel Sender”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Fuel Sender.”

Press “Up” or “Down” to select another function.

Page 12

2

3

Fuel

Sender

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to the “Edit”

mode.

Press “Up” or “Down” to select another function or

“Mode” to return to the “Normal” mode.

1

2

3

4

5

> USA

240 – 33 ohm

EU

10 – 180 ohm

Centroid

6

1

Select

Select “Oil Pressure Sender”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Oil Pressure Sender.”

Press “Up” or “Down” to select another function.

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to the “Edit”

mode.

Press “Up” or “Down” to select another function or

“Mode” to return to the “Normal” mode.

Select “Display Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Units.”

Press “Up” or “Down” to select another function.

2

3

Oil Pressure

Sender

1

60 PSI

2

3

1

2

3

1

80 PSI

100 PSI

Select

Display

Units

Select

Select “Pressure Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Pressure Units.”

Press “Up” or “Down” to select another choice of

“Units.”

2

3

Pressure

Units

Page 13

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units.”

Select “Volume Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “volume units”

Press “Up” or “Down” to select another choice of “Units”

1

2

> PSI

BAR

3

1

2

3

Select

Volume

Units

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units”

Select “Temperature Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Temperature Units.”

Press “Up” or “Down” to select another choice of

“Units.”

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units.”

Select “Distance Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Distance Units.”

1

2

> GAL

LITERS

3

1

2

3

1

2

Select

Temperature

Units

> F

C

3

1

2

3

Select

Distance

Units

Press “Up” or “Down” to select another choice of

“Units.”

Page 14

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units.”

1

2

3

1

> Miles

kM

NM

Select

Select “Depth Units”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Depth Units”

Press “Up” or “Down” to select another choice of

“Units.”

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units.”

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Select “Fuel Tank Size”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Fuel Tank Size”

Press “Up” or “Down” to select another function

Press “Up” or “Down” to scroll through the selections.

When the correct choice is next to the selection arrow,

Press and hold the “Up” and “Down” buttons for 2

seconds to save the selection and return to select “Units”

2

3

1

2

3

1

2

3

1

2

3

4

1

2

3

Depth

Units

> Feet

Meters

Fathoms

Select

Fuel Tank

Size

Select

Standard

Fuel Tank

Size

> 25 G

36 G

40 G

50 G

55 G

80 G

120 G

Page 15

1

Select

If there is no tank size available in the list that matches

your tank size, scroll to the next screen.

Press “Up” or “Down” to set the fuel tank size displayed

on the screen to match your fuel tank size. Line 4 value

will adjust.

When set, Press and hold the “Up” and “Down” buttons

for 2 seconds to save and exit.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Select “Fuel Tank Calibration”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Fuel Tank Calibration.”

Press “Up” or “Down” to select another function.

Ensure that fuel tank is as empty as possible.

2

3

4

1

2

3

4

1

2

3

1

2

Other

Fuel Tank

Size

Select

Other

Fuel Tank

XXX G

Calibrate

Fuel

Tank

Calibrate

Fuel Tank

Press and hold the “Up” and “Down” buttons for 2

seconds to save “Empty” calibration and press “Down” to

go to “Half” tank calibration.

Fill fuel tank half full.

Press and hold the “Up” and “Down” buttons for 2

seconds to save “1/2 tank” calibration and press “Down”

to go to “Full” tank calibration.

Fill fuel tank completely full.

Page 16

3

1

2

3

1

2

3

Empty

Calibrate

Fuel Tank

Half

Calibrate

Fuel Tank

Full

Press and hold the “Up” and “Down” buttons for 2

seconds to save “Full Tank” calibration and exit.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

1

Low

Select “Low Fuel Alarm” setting

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Low Fuel Alarm.”

Press “Up” or “Down” to select another function.

Adjust low fuel alarm setting.

Press “Up” or “Down” to set desired “Low Fuel Alarm”

setting. Line 3 value will adjust.

Press and hold the “Up” and “Down” buttons for 2

seconds to save “Low Fuel Alarm” and exit.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Select “Software ID and Revision”

2

3

1

2

3

1

2

3

Fuel

Alarm

Low

Fuel

XX.X

Software Id

and

Revision

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Select “Self Test”

Press and hold the “Up” and “Down” buttons for 2

seconds to select “Self Test.”

Press “Up” or “Down” to select another function.

4

5

1

2

3

Minigateway

- Rev -

Select

Self

Test

Page 17

1

The

This screen will display for 10 seconds.

The horn will sound three times.

The warning lights will flash three times.

The backlights will flash three times.

2

3

4

5

6

Self

Test

Mode

Is in

Operation

When “Self Test” is complete the unit will return to the

“Edit” mode.

Press “Up” or “Down” to select another function or

“Mode” to return to “Normal” mode.

Available Functions for Display in MG2000 ALDL Tachometer Screens

The functions listed below can be displayed in the user configurable screens. All of

the functions may not be available in your installation. If a function is selected for

display and that function does not appear on the screen, the function does not exist

in this installation.

A function is selected for display by selecting “Organize User Screens” in “Edit”

mode.

1. System voltage

2. Oil Pressure

3. Coolant temperature (Engine Temp)

4. Engine hours

5. Fuel remaining based on usage and tank volume when filled (Fuel Left)

6. Fuel used since last reset (Fuel Used)

7. Fuel consumption rate (Fuel Inst)

Page 18

Alarm Mode

The “Alarm” screen appears only if

an alarm condition exists. The alarm

alarm will re-occur after a period of time

to ensure that the user remembers the

alarm condition.

condition may be a warning sent from

the engine ECU or a “Local” alarm such

as “Low Fuel”. When an alarm condition

occurs, the “Alarm Screen” will appear

and the screens described below will be

displayed.

Once an alarm condition has been

corrected, the alarm screen, horn,

and warning lights will no longer be

displayed.

The descriptions below also explain how

to temporarily override the alarm screen

and audible / visual warnings and return

to “Normal” mode. In all cases, the

Alarm Mode LINE DISPLAY

The “Alarm” screen will appear if a local alarm or an

engine alarm occurs.

The local alarm is “Low Fuel”.

Only two engine alarms appear automatically, “Check

Engine” and “Engine Emergency Stop”. Follow the

instructions provided to view more information about

engine alarms.

LOW FUEL

Displays “Low Fuel” warning.

Red LED blinks.

Horn “Beeps”.

1

2

3

Low

Fuel

!

Press “Mode” to turn off LED, silence alarm horn, and

return to “Run” mode. Alarm will reactivate in 15 minutes

but can continue to be deactivated as required.

ENGINE WARNINGS

Any engine alarm except “Engine Emergency Stop”

Red LED blinks.

Horn “Beeps.”

“Engine Emergency Stop” alarm.

Red LED on continuously.

Horn on continuously.

1

2

3

1

2

3

CHECK

ENGINE

!

ENGINE

EMERGENCY

STOP !

Page 19

Press and hold “Up” and “Down” for 2 seconds to view

alarm messages.

Press “Mode” to silence alarm horn and return to “Run”

mode. LED will continue to function as stated until engine

alarm(s) is no longer sent by ECU.

Alarm Messages

From the Engine ECU

OVER TEMPERATURE

LOW OIL PRESSURE

LOW OIL LEVEL

LOW FUEL PRESSURE

LOW SYSTEM VOLTAGE

RPM REDUCTION

RPM LIMIT EXCEEDED

KNOCK SENSOR

IGNITION FAULT

MAGNETIC SENSOR

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

HIGH

ENGINE

TEMP

LOW

OIL

PRESSURE

LOW

OIL

LEVEL

LOW

FUEL

PRESSURE

LOW

SYSTEM

VOLTAGE

RPM

REDUCTION

SEE DEALER

RPM

LIMIT

EXCEEDED

KNOCK

SENSOR

SEE DEALER

IGNITION

FAULT

SEE DEALER

MAG

SENSOR

SEE DEALER

Page 20

MANIFOLD AIR SENSOR

THROTTLE POSITION SENSOR

COOLANT SENSOR

ENGINE ECU CABLE NOT CONNECTED OR NO

DATA

ENGINE EMERGENCY STOP

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

MAN AIR

SENSOR

SEE DEALER

TPS

FAULT

SEE DEALER

COOLANT

SENSOR

SEE DEALER

NO

ENGINE

FOUND

ENGINE

EMERGENCY

STOP !

Alarm Clear Mode LINE DISPLAY

When an alarm condition is corrected or

clears, the “Alarms Clear !” screen will appear

for approximately one second. The original

screen will then reappear. This ensures that

the operator is aware that the condition has

been corrected.

1

Alarms

2

Clear

!

3

Page 21

Harness HN0390

ALDL

Ta

chometer Cable

ALDL

MG2000 Tachometer

12- pin connector

Red

Pin 1

Pin 2 White

Pin 3 Green

Pin 4 Black

Pin 5 Violet

Pin 6 Pink

Pin 7 Blue/ Whit

Pin 8 Not Used

Pin 9 Not Used

Pin 10 Green/ Black

Black

Pin 11

Pin 12 Tan/ Blue

e

4- pin connector

Pin A Red

Pin B White

Green

Pin C

Pin D Black & Sheild

Heat

Shrink

Tubing

654

123

1

1 2 3 4 5 6 7 8 9 10 11 12

d

Not Used

Not Use

Green/ Black

Black

101112

Tan/ Blue

65432

789

Page 22

Heat

Shrink

Tu

bing

Black

Violet

Pink

Blue/White

Blue/White

Pink

Violet

Black

ALDL Data

ALDL Ground

ALDL (Shield)

Oil Press Sender

Fuel Sender

Ignition +14 Vdc

Ground

Wire Jacket

MG2000 Speedometer

Harness HN0390

Speedometer Cable

1 2 3 4 5 6 7 8 9 10 11 12

Wire Jacket

654

123

1

65432

101112

789

12- pin connector

Pin 1 Red

Pin 2 White

Pin 3 Green

Pin 4 Black

Pin 5 Not Used

Pin 6 Tan/ Black

n

Pin 7 Ta

Pin 8 Not Used

Pin 9 Not Used

Pin 10 Not Used

Not Used

Pin 11

Pin 12 Not Used

Not Used

Tan

Tan/Black

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Air Temp/ Paddlewheel sender

Red (+V)

Green (Signal)

Bare (Ground)

White (Thermister)

Brown (Thermister)

Water Temp Sender

White (Sender Signal)

Black & Shield (Ground)

FARIA

Page 23

Harness HN0401

NMEA 0183 Cable

NMEA 2000

MG2000 Tachometer

4 3

Red/ Blue

Red/ White

6- pin connector

Pin 1 Not Used

Pin 2 Not Used

Pin 3 Red/ Whit

Pin 4 Red/ Blue

Pin 5 Not Used

Pin 6 Not Used

NMEA 0183-A

Heat

Shrink

bing

Tu

e

654

123

Red (Ignition)

Green (0183-A)

Shield (Ground)

1

65432

101112

789

GPS100 Antenna

NMEA 0183-B

Not Used

Ground

*Note: 1) Cut off the connector at the end of the antenna cable

2) Cut off the following wires because they are not used: White, Yellow, Brown

3) Cut wires so that they are different lengths. This ensures they do not touch each other.

Page 24

Not Used

Not Used

Brown*

White*

llow*

Ye

Tachometer to 2”

Gauge Connection

From

Tachometer

4- pin connector

Pin A Red

Pin B White

Pin C

Green

Pin D Black & Sheild

HN0503

2" Gauges

PJ0018

Note: To help reduce

moisture

in the gauges, be sure to

install

plug PJ0018 in all open

connectors

Page 25

Notes:

Copyright 2005 by the Thomas G. Faria Corporation, Uncasville CT. All rights reserved.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without

the prior written permission of the company.

Faria® is the trademark of the Thomas G. Faria Corporation

Loading...

Loading...