Page 1

Uncasville, CT

INSTRUMENTS

N

U

.

P

R

O

C

A

I

R

A

F

20

10

M

A

T

D

C

E

,

E

L

L

I

V

S

A

C

I

N

U

.

S

30

40

30

20

10

0

Km/h

50

60

70

80

050

MPH

Owner’s Manual

.

A

.

1

6

6

8

-

5

0

-

3

7

A

40

Electronic

Programmable

Speedometer

IS0157

ISO157A ECR#3131 12/02

Page 2

Index

Description

Odometer Page 1

Trip Odometer Page 1

Hour-meter Page 1

Over Speed Condition Page 2

Maximum Saved Speed Page 2

Setting the Speedometer Page 3

Boot menu Page 3

Service Hours Page 3

Service Distance Page 4

Clear Hours Page 4

Clear Distance Page 4

Program High Axle Page 4

Program Low Axle Page 5

Input Level control for the speed pulse input Page 5

Run Menu

Clear Odometer Page 6

Set Speed (Over Speed indicator) Page 6

Calibrate Hi Axle Page 6

Calibrate Low Axle Page 7

Harness P1 6 pin connector Page 8

Harness P2 4 pin connector Page 9

Page 3

COMMERCIAL SPEEDOMETER

Functions available:

1. Odometer display

2. Trip odometer display (resetable)

3. Hour-meter (either rpm or key-on)

4. Service interval for miles or kilometers

(reset, clear and disable features)

5. Service interval for hours (reset, clear

and disable features)

6. Over-speed indicator (microprocessor

output level change at over-speed,

resetable)

7. Two speed axle, selected by input to

microprocessor.

8. Pulses per mile or kilometer input or

change.

A. PPM can be done automatically by

the microprocessor.

B. PPM numbers can be entered using

the push-button.

C. All features available for both high

and low speed axles.

9. Display the highest speed recorded by

the microprocessor (resetable). The

hour-meter and the odometer reading

at the maximum speed time are also

recorded. This information is not

available for display or resetting.

The speedometer must be returned to

the factory for reading.

Detail description

Odometer

The commercial speedometer contains an

odometer to maintain a record of the total

mileage and trip mileage. During normal

operations and after a power on the

odometer display shows;

Trip Odometer

The Trip odometer allows you to keep a

record of the trip miles or kilometers

independent of the Odometer.

The Trip Odometer is fully user resetable.

While in the Trip Odometer display press

the push-button for 4 seconds and the Trip

odometer is reset to zero.

The speedometer is capable of switching

between two different speed axles, selected

by inputting a high or low level on an input

pin.

The pointer travels over a 270-degree dial to

indicate mph (or kph) indicates the speed.

The kph is handled the same as a mph in

the microprocessor. The pulses per mile

will be pulses per kilometer and the self-cal

will be for 1 kilometer instead of 1 mile.

There is no provision to change from miles

to kilometers.

Hour-meter

The speedometer also contains an hourmeter that is always activated by an external

input so that actual engine hours can be

recorded. Quick press the push-button while

in the Trip Odometer function displays the

Hour-meter.

This display cannot be reset. A quick press

of the push-button changes th e display to

the Trip odometer.

Page 1

Page 4

The last digit on the right blinks up and

p

n

d

down indicating the hour-meter function.

The hour-meter cannot be reset.

Grounding P1-E thru an oil low pressure

switch can stop the hour-meter. If P1-E is

not grounded then the hour-meter will run

continuously with the key on. To provide a

true engine running hour-meter an

external low oil pressure switch is

normally used. The low oil pressure switch

is closed connecting the pin to ground.

The hour meter is not running. When the

engine is running the normal high oil

pressure opens the low oil pressure switch

allowing the hour-meter to operate.

pressing the push-button for 4 seconds.

Another feature of the speedometer is to

keep track of and indicate when a service

interval has passed. The interval can be

either or both mileage and hours.

A seven digit display readout displays the

total mileage, the trip mileage, hour-meter

or maximum saved speed (cleared by

pressing and holding the push-button for 4

seconds while in the maximum speed

display), the menu items are scrolled by

pressing and releasing the push-button on

the speedometer.

Over S

eed conditio

An over-speed condition will ground P1-C

(maximum 40 milliamp load) on the

speedometer when a pre-set speed has

been passed. This output can be utilized

by the customer to activate a warning

device.

Maximum Saved Spee

This speedometer will also record the

maximum speed under normal conditions.

The maximum speed is displayed and

changes as t he sp eed is increased over the

current maximum.

The maximum speed can be reset by

Page 2

If a service interval has been passed the

display will show a service message (one

time only).

Service Hours

Service Distance

Pressing the push-button will return the

display to the primary mileage and hour

displays.

The service interval message will also show

once every time the speedometer is

powered up. The display can be cleared by

the push-button. The pulses per mile output

from the sensor to the speedometer can be

Page 5

programmed by hand or done

automatically, for both of the high and low

range axles.

Setting the speedometer

There are two major speedometer setting

routines.

The first is activated during boot-up. If the

push-button is pressed and held on when

power is first turned on the “boot menu”

will be activated.

The second menu, the “run menu”, can be

activated during normal running time by

pressing and holding the push-button for

two seconds.

Boot menu

Pressing and holding the push-button

while power is turned on will activate the

“boot menu”.

If you are in a menu, just do nothing for 32

seconds and the microprocessor will restart

and change nothing.

1. T h e first menu item “SEr HrS” (Service

Hours) is used to set the next service

interval in hours.

When this menu feature is started, the

display will show the actual hours when the

present hour service interval will occur.

The main purpose of this menu feature is to

set the next hour service interval time,

however it can also be used to check when

the present service interval will occur.

Starting at the leftmost digit, the digits will

flash on and off for four seconds.

The display will show “HELLO” and wait

for you to release the push-button.

When the push-button is released the first

item on the menu will be shown. In four

seconds the microprocessor will activate

that menu feature. If you want a different

item from the menu, you must press and

release the push-button before four

seconds have elapsed. The menu items

will scroll continuously. If you want to get

out at this point with no changes, stop a t

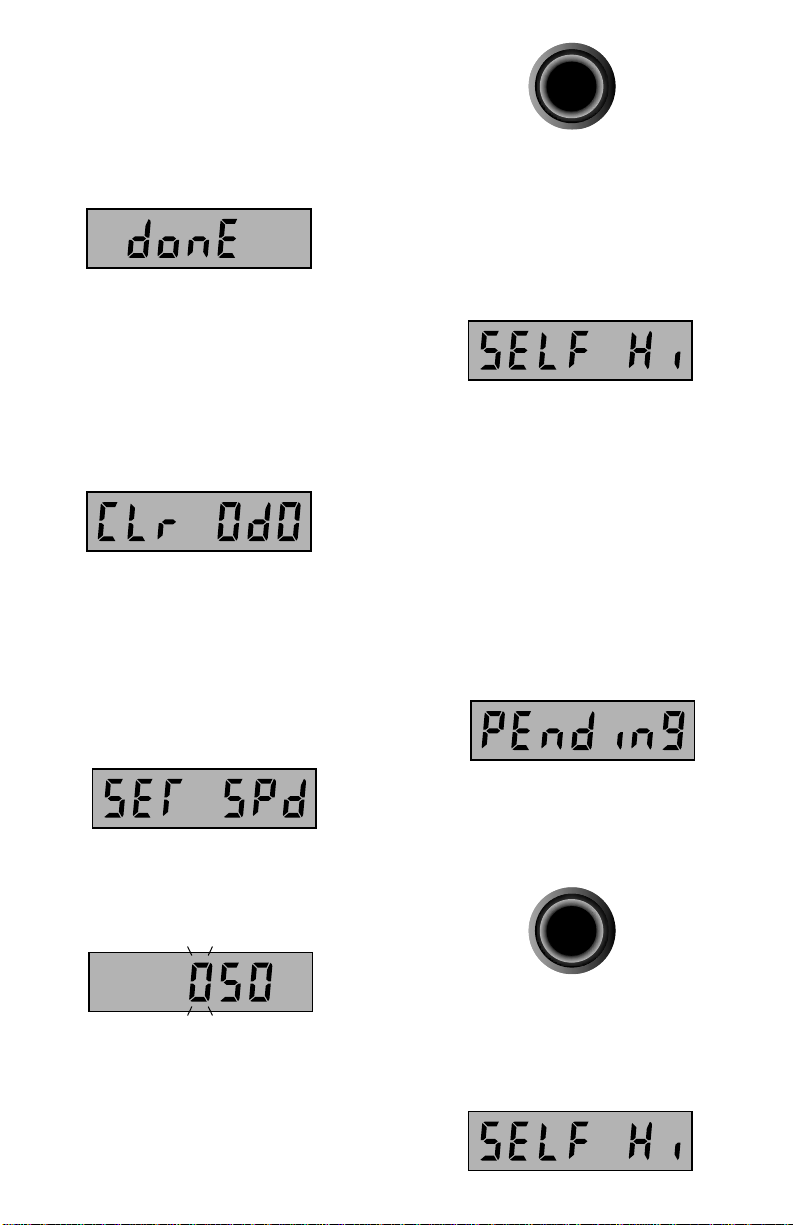

the last menu item “donE”, and in four

seconds the microprocessor will return to

normal with nothing being changed.

During this time you may change the digit

by pressing and releasing the push-button.

Once you have changed the digit once you

may push and hold the push-button to have

that digit count continuously from 0 to 9.

When you have made your digit choice,

don’t touch the push-button for four seconds

and the next digit to the right will now flash

and be accessible for change.

Page 3

Page 6

This will continue for all the digits and

will go back to the first digit and repeat. If

the push-button is not pressed for 32

seconds the microprocessor will return to

normal and will change nothing. This is

useful if you’re only here to check when

the present service interval will occur. The

operator may also turn power off at this

point and nothing will change in the

microprocessor controller.

To save the ch a nges yo u h ave made in the

display, you must press and hold the pushbutton while any digit is flashing.

The digit will stop flashing and four

seconds later the microprocessor will reset

any previous events pertaining to the hour

service interval, and install the new

numbers. When the microprocessor is

finished the display will change to “donE”.

same as number 1 above except the mileage

service interval is changed or observed.

3. The third menu item “Clr HrS” (Clear

Hour Service) allows you to clear the hour

service flag and automatically reset the next

hour service.

The calculation will use the previous

interval value. When the operator stops at

the “Clr HrS” display and waits four

seconds the service interval will be

changed.

4. The fourth menu item “Clr diS” (Clear

distance) allows you to reset the mileage

service interval.

The trip switch must now be released to

return to normal operation. If the present

hour-meter is close to 999,999, your new

number may be past the overflow so wh e n

you examine when the hour service event

will occur, the number shown will be less

then the current hour-meter. This is

because the current hour-meter must

overflow and start at zero before the

service event can occur.

2. The second menu item “Ser

diS”(Service distance) will allow you to

program the mileage service interval.

The description and operation are the

Page 4

The implementation is the same as number

3 above.

5. The fifth menu item “PPgn Hi” (Program

High axle) will allow the operator to enter

the pulses per mile or kilometer for the

high axle.

This number will depend on how your

particular sender is arranged. The

maximum pulses per mile or kilometer are

limited to 150,000. When you stop at the

“PPn HI” display and wait four seconds the

microprocessor will display six digits with

the leftmost digit flashing.

The number displayed will be the present

Page 7

pulses per mile or kilometer rounded off

to the nearest 10 0 th. The rightmost digit

will be a “P” to remind the operator that

they are in the “Programming” mode. The

digit changes and in puts ar e the same as

number 1 (Service Hours) above. Also

present is the same option to do nothing

for 32 seconds and the microprocessor

will reset itself and will change nothing.

will be flashing and every 4 seconds the

next letter will flash.

If the button is pressed when any selection

is flashing, that input signal level will be set

to that level.

Holding the push-button on for four

seconds while a digit is flashing will make

the microprocessor compute the

observation window and will store this

window and the pulses per mile or

kilometer rounded off to the nearest 100

pulses in the EEPROM. The display will

now show “donE” and the operator should

release the push-button to resume normal

operations.

6. The sixth menu feature “PPgn LO”

(Program Low axle) is used to program

the low speed axle pulses per mile or

kilometer.

The implementation and activation are the

same as number 5 (Program High axle)

above.

The choices are low, normal and High. Low

is normally used for magnetic pickups and

normal and high for other types.

8. The last menu item “donE” is used to exit

from this menu.

Leaving the display in “donE” for four

seconds will cause the microprocessor to go

back to normal operations and change

nothing.

Run menu

Pressing and holding the push-button for

two seconds during normal operation will

activate the “run menu”.

The display will show “HELLO” and wait

for you to release the push-button.

7. The next item in the menu is the input

level control for the speed pulse input. The

display will show “ InPuT “.

If nothing is done for 4 seconds then the

display will change to “L n H” and the L

When the push-button is released the first

item on the menu will be shown. In four

seconds the microprocessor will go to the

first menu feature.

Page 5

Page 8

If you want a different item from the

menu, you must press and release the

push-button before four seconds have

passed. The menu items will loop

continuously. If you want to get out at this

point with no changes, stop at the last

menu item “donE”,

and in four seconds the microprocessor

will return to normal with nothing being

changed or if you are in a menu, just do

nothing for 32 seconds and the

microprocessor will restart and change

nothing.

1. T h e first item in the run menu is “Clr

OdO” (Clear trip odometer).

If the operator stops at this display, the

microprocessor will reset the trip

odometer to zero and will return the

microprocessor to its normal operation.

2. The second menu item “SET SPd” (Set

Speed) is used to set the speed at which

the over-speed indicator will activate.

point.

The option to get out with no changes is

available by not making any changes for 32

seconds.

3. The third menu feature “SELF H I” (Self

calibrate high axle) can be activated by

waiting at this display for four seconds.

This is a feature to allow automatic setting

of the high axle pulses per mile or

kilometer that the speedometer will use to

position the pointer and record the correct

mileage. This is accomplished by indicating

to the speedometer microprocessor, the

beginning and end of a measured mile or

kilometer. The microprocessor will actually

count the pulses that occurred during that

mile or kilometer and compute the required

parameters. When this mode is activated the

speedometer will display “PEndInG “.

Stopping at this display and waiting four

seconds will set the display to three digits

corresponding to the last speed that the

over-speed was set to.

The leftmost digit will be flashing and the

change and implementation of the input

numbers are the same as above. When the

push-button is held for four seconds the

microprocessor will set the number in the

display to be the new over-speed trip

Page 6

This means that the microprocessor is

waiting for the push-button to be pressed

indicating the beginning of the measured

mile or kilometer.

When the push-button is pressed and

released the display will change to “SELF

HI” indicating that the microprocessor is

now counting pulses.

Page 9

The speed at this point is not important.

The operator may even stop and wait, as

long as power is not turned off and the

measured mile or kilometer is followed as

straight as possible, the operator may not

turn around and go in the opposite

direction. Also for the maximum accuracy,

the operator should not enter any off road

parking as this would deviate from a

straight mile or kilometer measurement.

At the end of the measured mile or

kilometer the operator must press and

release the push-button one more time,

the display will show “CALCInG”

(Calculating)

4 seconds and the push-button is not

pressed, the microprocessor will return to

normal operation with nothing changed.

while the microprocessor calculates the

numbers it needs and will restart. The

new pulses per mile or kilometer will now

be in effect. This feature may be

abandoned at anytime by pressing and

holding the push-button for two seconds.

The microprocessor will reset itself and

continue normal operations. This menu

item may also be stopped by turning off

power to the speedometer.

4. The forth menu item “SELF L ” (Self

calibrate low axle) is used to automatically

calculate the pulses per mile or kilometer

for the low ratio axle.

The implementation and setting are the

same as number 3 “SELF HI” above.

5. The last feature “donE” is used to exit

from this menu. If this display is left on for

Page 7

Page 10

Shrink Tubing

or Wrap

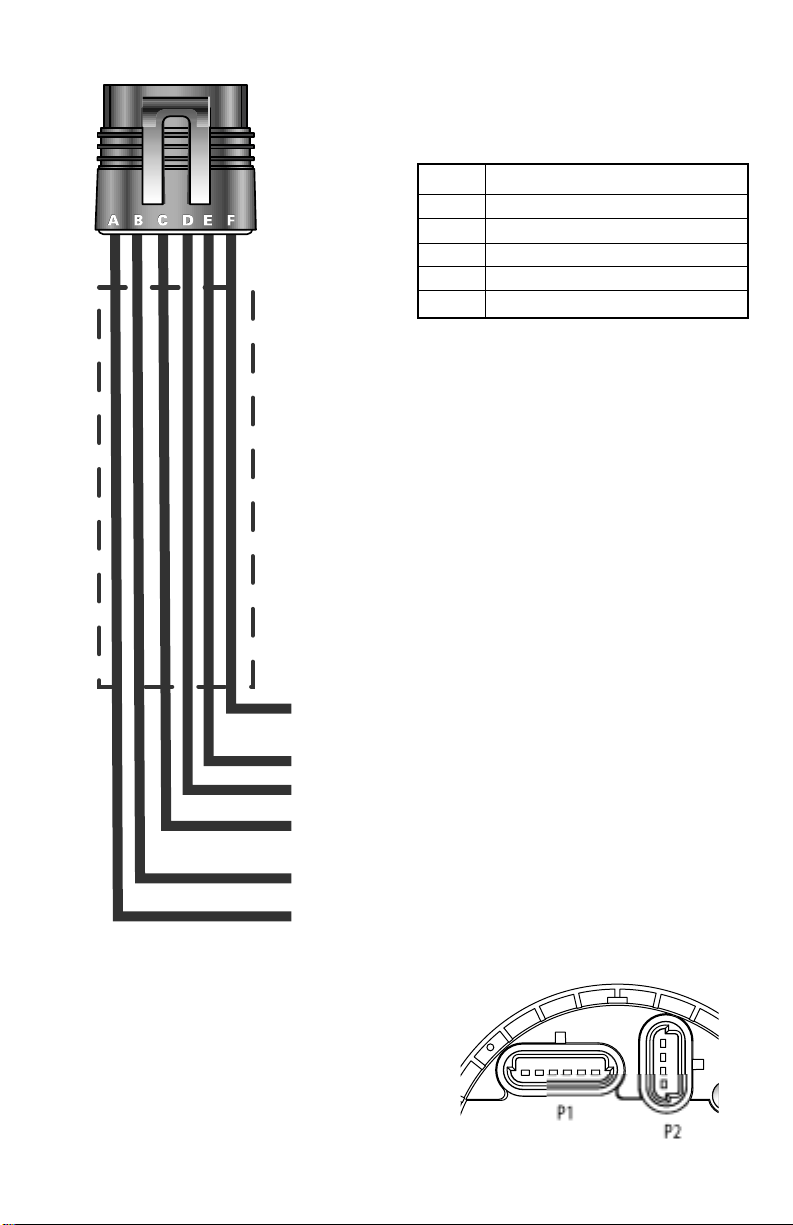

Harness P1

6 - pin connector

Pin A Battery Input

Pin B Ground

Pin C Over speed signal

Pin D External Push-Button grnd

Pin E Hourmeter control

Pin F Speed Axle

Page 8

2 speed axle (ground selects low axle,

open connection selects high axle)

Hourmeter control (ground disables hour-meter)

External push button (ground active)

Over speed output (ground when over set

speed, 20 milliamps max current)

Ground

Battery input

Page 11

Shrink Tubing

or Wrap

Harness P2

4 - pin connector

Pin A +8.4 vDC

Pin B Faria

Pin C Faria

Pin D Ground

®

Bus AY

®

Bus BZ

Dash lights (controls

gauge back lights)

Ground

Speed pulses in from sensor

Power for external sensor

Page 9

Page 12

Notes:

Page 13

Copyright 2002 by the Thomas G. Faria Corporation, Uncasville CT

No part of this publication may by reproduced in any form, in an electronic retrieval system or otherwise, without

the prior written permission of the company.

Loading...

Loading...