RESTRICTED USE ONLY FARGO Electronics, Inc.

DTC500 Series Card Printer/Encoders

Troubleshooting Guide (Rev. 3.0)

P/N: L000315

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

1

RESTRICTED USE ONLY FARGO Electronics, Inc.

TC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0), property of

D

FARGO Electronics, Incorporated

Copyright 2002, 2003, 2004, 2005, 2006 by FARGO Electronics, Incorporated. All rights

reserved. Printed in the United States of America. Exclusive permission is granted to

authorized resellers of FARGO products to reproduce and distribute this copyrighted

document to authorized FARGO customers, who have signed a “no disclosure agreement”

regarding the restricted, proprietary use of said document.

The revision number for this document will be updated to reflect changes, corrections,

updates, and enhancements to this document.

Revision Control

Date Document Title

Number

Revision 3.0 10 March 2003 DTC500 Series Card Printer/Encoders

Troubleshooting Guide (Rev. 3.0)

These reference documents were thoroughly reviewed to provide FARGO with professional

and international standards, requirements, guidelines, and models for our technical, training,

and user documentation. At all times, the Copyright Protection Notice for each document

was adhered to within our FARGO documentation process. This reference to other

documents does not imply that FARGO is an ISO-certified company at this time.

• ANSI/ISO/ASQ Q9001-2000 American National Standard

, (sub-title) Quality Management

Systems - Requirements (published by the American Society of Quality, Quality Press,

P.O. Box 3005, Milwaukee, Wisconsin 53201-3005)

• The ASQ ISO 9000:2000 Handbook

(editors, Charles A. Cianfrani, Joseph J. Tsiakals,

and John E. West; Second Edition; published by the American Society of Quality, Quality

Press, 600 N. Plankinton Avenue, Milwaukee, Wisconsin 53203)

• Juran's Quality Handbook

(editors, Joseph M. Juran and A. Blanton Godfrey; Fifth

Edition, McGraw-Hill)

Any questions regarding changes, corrections, updates, or enhancements to this document

should be forwarded to:

FARGO Electronics, Incorporated

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(952) 941-9470

(800) 459-5636

FAX: (952) 941-7836

www.fargo.com

E-mail: sales@fargo.com

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

2

RESTRICTED USE ONLY FARGO Electronics, Inc.

Table of Contents

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0) _________ 1

Safety Messages (review carefully) _________________________________________ 8

General Troubleshooting__________________________________________________ 9

Reviewing the LCD display and LED light ___________________________________ 9

Troubleshooting the LCD Messages ______________________________________ 9

Communications Errors _________________________________________________ 16

Resolving the Communication Errors ____________________________________ 16

Card Feeding Errors ____________________________________________________ 21

Resolving the Card Feeding Errors ______________________________________ 21

Resolving the Card Jam on the Flipper Table ______________________________ 24

Resolving the Card Hopper Jam Error Message ____________________________ 26

Resolving the Card Hopper Empty Error Message __________________________ 27

Encoding Errors _______________________________________________________ 28

Resolving the No Magnetic Encoder Error Message_________________________ 28

Resolving the No ENC Response Error Message ___________________________ 28

Replacing the Main Board _______________________________________________ 29

Replacing the Main Board (D850426) ___________________________________ 30

Reviewing the DTC500 Board Cable Connections Reference _________________ 33

Replacing the Main Board (D850427) ___________________________________ 35

Replacing the Main Board (D850428) ___________________________________ 37

Replacing the Main Board (D850429) ___________________________________ 39

Resolving the Failed Magnetic Encode Error Message _______________________ 41

Resolving the No Prox Encoder Error Message ____________________________ 41

Resolving the No Smart Encoder Error Message ___________________________ 42

Resolving the Failed Smart Encode Error Message__________________________ 42

Removing the Card Jam in the Printer’s Magnetic Encoding Area______________ 43

Removing the Card Jam in the Printer’s Smart Card Encoding Area ____________ 44

Resolving the Printer not reading Encoded Magnetic Track Data_______________ 45

Resolving the Magnetic Stripe Data being printed on a Card problem ___________ 47

Printing Process Errors__________________________________________________ 48

Resolving the Ribbon Alignment Error Message ___________________________ 48

Replacing the Ribbon Sensor Array Assembly (840108) _____________________ 49

Resolving the Print Ribbon Error Message ________________________________ 50

Resolving the Print Ribbon Out Error Message_____________________________ 50

Resolving the Ribbon Jam / Broke Error Message __________________________ 50

Resolving the Wrong Print Ribbon Error Message __________________________ 51

Resolving the Unknown Ribbon Type Error Message _______________________ 52

Resolving the Headlift Error Message ____________________________________ 53

Replacing the Headlift Motor (A000124) _________________________________ 54

Replacing the Headlift Sensor (A000126) _________________________________ 55

Resolving the Printer pausing between panels error _________________________ 57

Replacing the Printhead Components ______________________________________ 58

Replacing the Printhead Assembly (850102)_______________________________ 58

Removing the Original Printhead Assembly _______________________________ 61

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

3

RESTRICTED USE ONLY FARGO Electronics, Inc.

Installing the New Printhead Assembly___________________________________ 62

Resolving the Printhead Temp Error Message______________________________ 63

Resolving the Flipper Alignment Error Message____________________________ 64

Replacing the Flipper Home Sensor (140407) _____________________________ 65

Firmware Errors _______________________________________________________ 66

Resolving an Upgrade Failed error ______________________________________ 66

Resolving a Program Exception Error ____________________________________ 69

Diagnosing the Image Problems __________________________________________ 70

Resolving the Pixel failure problems _____________________________________ 70

Resolving the Card surface debris problems _______________________________ 73

Resolving the incorrect Image Darkness problems __________________________ 76

Resolving the Ribbon wrinkle problems __________________________________ 79

Resolving the excessive Resin Printing problems ___________________________ 81

Resolving the incomplete Resin Printing problems__________________________ 83

Resolving the cut off or off-center Card Image problems _____________________ 85

Resolving the poor Image Quality problems _______________________________ 86

Printing a Test Image ___________________________________________________ 87

Reviewing the Gray/Align YMC/K Self-Test ______________________________ 87

Reviewing the Color/Resin YMCK Self-Test ______________________________ 88

Reviewing the Color Bars YMC Self-Test ________________________________ 88

Reviewing the Card Count Self-Test _____________________________________ 89

Reviewing the Magnetic Test option _____________________________________ 89

Card Lamination Module ________________________________________________ 90

Safety Messages (review carefully) ________________________________________ 90

Loading the Overlaminate _______________________________________________ 91

Adjusting the Card Lamination Module ____________________________________ 94

Adjusting the Card Flattener ___________________________________________ 94

Adjusting the Card Guide Rail__________________________________________ 96

Adjusting the Internal Card Guide ______________________________________ 100

Attaching the Card Lamination Module _________________________________ 102

Printer Adjustments____________________________________________________ 108

Safety Messages (review carefully) _______________________________________ 108

Adjusting the Internal Card Guide ______________________________________ 109

Printer Driver options__________________________________________________ 111

Using the Device options tab ____________________________________________ 111

Adjusting for the Ribbon Type ________________________________________ 112

Adjusting for the Color matching ______________________________________ 113

Adjusting for the Resin Dither _________________________________________ 114

Using the Print Both Sides option (DTC520 / DTC525 only)_________________ 115

Using the Split 1 Set of Ribbon Panels option (DTC520 / DTC525 only) _______ 116

Using the Print on Back Side Only option (DTC520 / DTC525 only) __________ 117

Using the Rotate Front by 180 Degrees option ____________________________ 118

Using the Rotate Back by 180 Degrees option (DTC520 / DTC525 only) _______ 119

Using the Buffer Single Card option ____________________________________ 120

Using the Link Card to Print Job option _________________________________ 121

Using the Disable Printing option ______________________________________ 122

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

4

RESTRICTED USE ONLY FARGO Electronics, Inc.

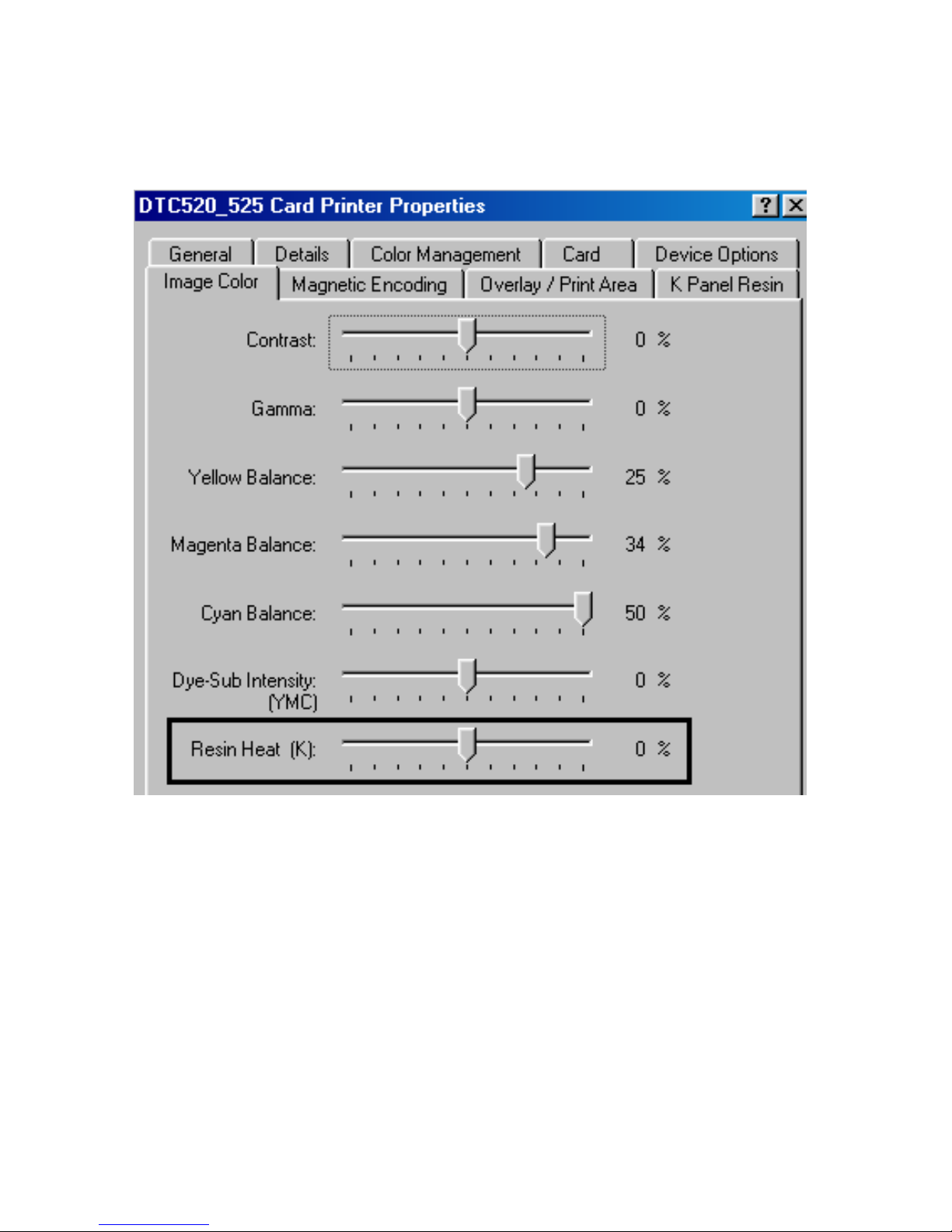

Using the Image Color tab ______________________________________________ 123

Using the K Panel Resin tab_____________________________________________ 127

Selecting the Full Card with the K Panel Resin tab_________________________ 128

Selecting the Defined Area(s) with the K Panel Resin tab ___________________ 129

Selecting the Undefined Area(s) with the K Panel Resin tab _________________ 130

Defining the Area to activate the Card Grid ______________________________ 131

Measuring the Total Card area_________________________________________ 132

Defining the positioning of the area on the Card ___________________________ 134

Selecting the Print YMC under the K and Print K Only options_______________ 136

Using the Magnetic Encoding tab ________________________________________ 138

Using the Encoding Mode option ______________________________________ 139

Encoding the Mode / Coercivity / Magnetic Track Selection _________________ 141

Using the Magnetic Track Selection option_______________________________ 143

Using the Magnetic Track options ______________________________________ 144

Using the Bit Density radio buttons_____________________________________ 145

Using the Character Size radio buttons __________________________________ 145

Using the ASCII Offset ______________________________________________ 146

Using the LRC Generation radio buttons_________________________________ 147

Using the Character Parity radio buttons _________________________________ 147

Using the Verification option__________________________________________ 148

Reviewing the Shift Data Left _________________________________________ 149

Reviewing the ISO Track Locations ____________________________________ 150

Reviewing the Sample String__________________________________________ 150

Sending the Track Information ________________________________________ 151

Reviewing the ASCII Code and Character Table __________________________ 152

Using the Overlay / Print Area tab________________________________________ 153

Using the Overlay / Print Area dropdown menu ___________________________ 154

Using the Overlay / Print Area_________________________________________ 155

Using SmartShield Area dropdown menu ________________________________ 161

Using the Card tab ____________________________________________________ 162

Selecting the Card Size ______________________________________________ 163

Using the Card Hopper Selection (DTC515 / DTC525 only) option ___________ 165

Reviewing the Orientation ____________________________________________ 168

Specifying the Copies _______________________________________________ 168

Using the Test Print button ___________________________________________ 169

Clicking on the About button__________________________________________ 170

Using the Image Position button _______________________________________ 171

Using the Lamination tab (only with Card Lamination Module) ________________ 174

Selecting the Lamination Position ______________________________________ 175

Selecting the Lamination Side _________________________________________ 176

Selecting the Lamination Type ________________________________________ 177

Selecting the Lamination Type ________________________________________ 178

Adjusting the Transfer Dwell Time and Transfer Temperature________________ 179

Selecting the Sensors button and Defaults button __________________________ 179

Calibrating the Card Lamination Module’s Lamination Sensor _______________ 180

Board Level Diagnostics ________________________________________________ 181

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

5

RESTRICTED USE ONLY FARGO Electronics, Inc.

Board Errors_________________________________________________________ 181

Resolving the EE Memory Error _______________________________________ 181

Resolving the EE Checksum Error _____________________________________ 181

Resolving the DRAM Memory Error ___________________________________ 182

Resolving the RAM Memory Error _____________________________________ 182

Resolving the FPGA Error____________________________________________ 183

Resolving the Update Firmware Now ___________________________________ 184

Sensor Testing _______________________________________________________ 184

Reviewing the Sensor Location and Voltages _____________________________ 185

Reviewing the Sensor Layout on Ribbon Sensor array ______________________ 186

LCD On-Line Menu Navigation __________________________________________ 187

Entering the LCD Menu and selecting an Option ____________________________ 187

Using the Softkey and Scroll buttons____________________________________ 188

Accessing the Menu Option Structure Tree_________________________________ 188

Selecting from the Menu Option Structure Tree ___________________________ 189

Using the LCD Menu__________________________________________________ 190

Printing the Self-test_________________________________________________ 190

Reviewing the Gray/Align YMC (DTC510/515) and Gray/Align YMC/K

(DTC520/525) Self-Test _____________________________________________ 191

Reviewing the Color/Resin YMCK Self-Test _____________________________ 191

Reviewing the Card Count YMC Self-Test _______________________________ 192

Reviewing the Standard Resin Self-Test _________________________________ 192

Using the Magnetic Test option (only with Magnetic Encoding Module) _______ 193

Setting up the Printer ________________________________________________ 193

Print TOF and Print EOF Alignment Procedures ____________________________ 194

Preparing to Adjust the Print TOF and Print EOF __________________________ 195

Setting the Print TOF ________________________________________________ 195

Setting the Print EOF ________________________________________________ 196

Adjusting the Ribbon Tension _________________________________________ 198

Setting the Printhead Resistance _______________________________________ 199

Adjusting the Image Darkness _________________________________________ 200

Changing the Encoder Settings ________________________________________ 201

Adjusting the Magnetic TOF __________________________________________ 202

Changing the Hopper Settings _________________________________________ 204

Changing the BAUD Rate Settings _____________________________________ 205

Adjusting the Flipper Offset___________________________________________ 205

Viewing the Report Supplies __________________________________________ 206

Using the Show the Error Count Tool ___________________________________ 206

Showing the Card Count _____________________________________________ 207

Selecting the System Upgrade (Firmware Upgrade) ________________________ 207

Firmware Updates _____________________________________________________ 208

Firmware Updater Application Program ___________________________________ 208

Downloading Firmware Updates _________________________________________ 209

Updating the Printer's Firmware _________________________________________ 209

Updating the Main Firmware__________________________________________ 210

Updating the LCD Firmware __________________________________________ 213

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

6

RESTRICTED USE ONLY FARGO Electronics, Inc.

Index ________________________________________________________________ 215

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

7

RESTRICTED USE ONLY FARGO Electronics, Inc.

Safety Messages (review carefully)

Symbol Critical Instructions for Safety purposes

Danger: Failure to follow these installation guidelines can result in death or

serious injury.

Information that raises potential safety issues is indicated by a warning

symbol (as shown to the below).

• To prevent personal injury, refer to the following safety messages

before performing an operation preceded by this symbol.

• To prevent personal injury, always remove the power cord prior to

performing repair procedures, unless otherwise specified.

• To prevent personal injury, make sure only qualified personnel

perform these procedures.

Caution: This device is electrostatically sensitive. It may be damaged if

exposed to static electricity discharges.

Information that raises potential electrostatic safety issues is indicated

by a warning symbol (as shown to the below).

• To prevent equipment or media damage, refer to the following

safety messages before performing an operation preceded by this

symbol.

• To prevent equipment or media damage, observe all established

Electrostatic Discharge (ESD) procedures while handling cables in

or near the Circuit Board and Printhead Assemblies.

• To prevent equipment or media damage, always wear an

appropriate personal grounding device (e.g., a high quality wrist

strap grounded to avoid potential damage).

• To prevent equipment or media damage, always remove the

Ribbon and Cards from the printer before making any repairs,

unless otherwise specified.

• To prevent equipment or media damage, take jewelry off of

fingers and hands, as well as thoroughly clean hands to remove oil

and debris before working on the printer.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

8

RESTRICTED USE ONLY FARGO Electronics, Inc.

General Troubleshooting

IMPORTANT! FARGO Card Printers require highly specialized print Ribbons to function

properly. To maximize Printer life, reliability, printed card quality and durability, you must use

only FARGO Certified Supplies. For this reason, your FARGO warranty is void, where not

prohibited by law, if you use non-FARGO Certified Supplies. To order additional materials,

please contact your authorized reseller.

Reviewing the LCD display and LED light

The LCD display provides the current status of the Printer. Refer to the following tables for a

complete list and cause of all possible LCD messages. The tables (in this section) display

the LCD messages. If the LCD message is communicating an error or requires an action,

these tables will also offer a solution to what should be done.

The purpose of this section is to provide the User with specific procedures relating to the

LCD/SmartGuard Messages, Communication Errors, Card Feeding Errors, Encoding Errors,

Printing Process Errors, and Diagnosing the Image Problems for the DTC500 series card

Printer.

Troubleshooting the LCD Messages

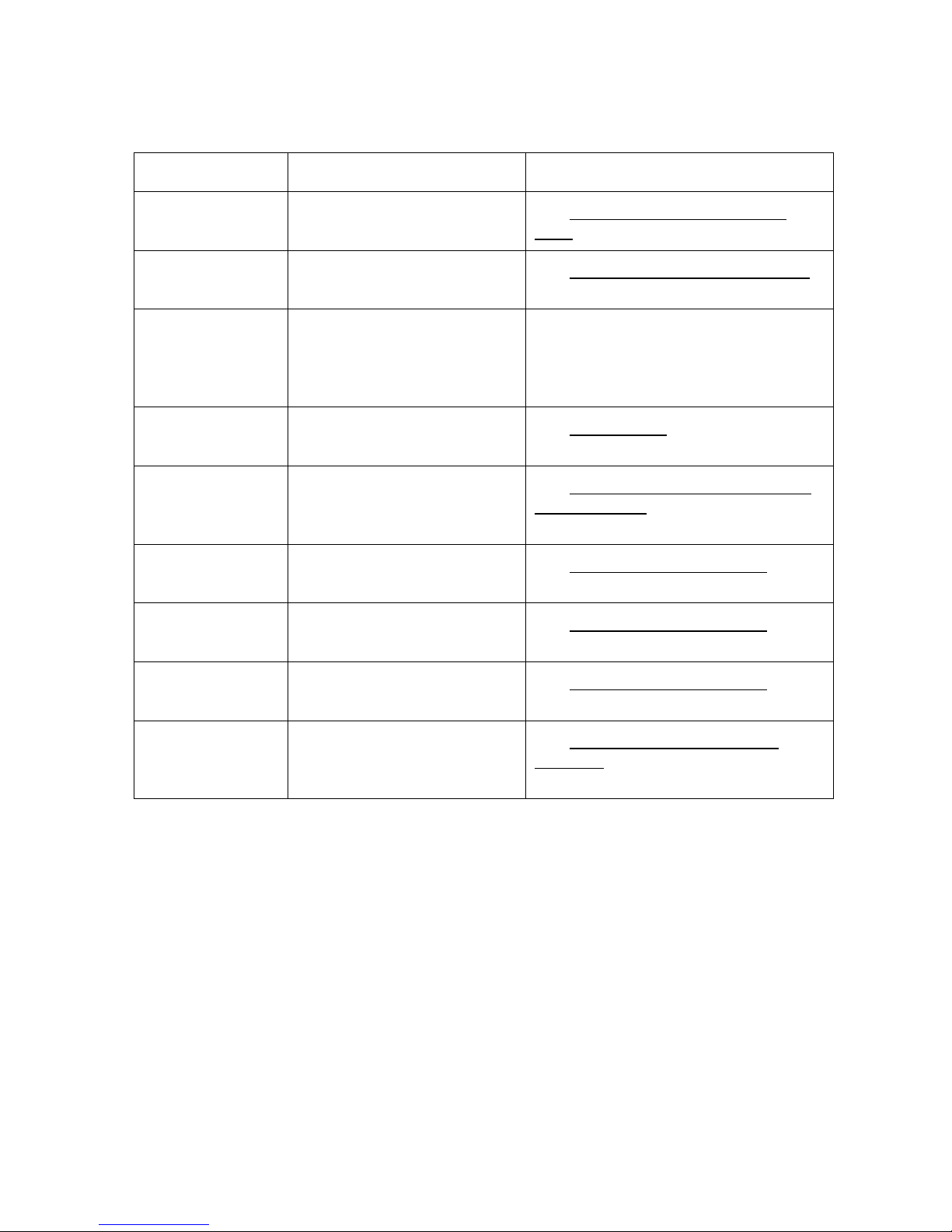

Message Cause Solution

Aligning Ribbon If this appears as a prompt, it

indicates the print Ribbon is

self-aligning to the proper

position for printing.

If this appears as an

ERROR, it indicates the print

Ribbon is not installed

properly or is damaged.

Card Hopper

Empty

Card Hopper Jam Indicates that the Card

Indicates the Printer has run

out of blank cards.

Hopper is unable to move

from one hopper to the next.

See Resolving the Ribbon Alignment

Error Message on page 48.

See the Resolving the Card Hopper

Empty Error Message procedure on

page 27.

Clear any obstructions, and close the

hopper door.

See Resolving the Card Hopper Jam

Error Message on page 26.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

9

RESTRICTED USE ONLY FARGO Electronics, Inc.

e Print Station or

Troubleshooting the LCD Messages (continued)

Message Cause Solution

Card Jam Indicates that a card is

jammed in th

card flipping area of the

Printer.

Card Jam: Flipper Indicates that a card is

jammed in the card flipping

area of the Printer.

Card Jam: Print Indicates that a card is

jammed in the Print Station

of the Printer.

Card Jam: Mag Indicates that a card is

jammed in the magnetic

encoding area of the Printer.

Card Jam: Smart Indicates that a card is

jammed in the Smart Card

encoding area of the Printer.

Data Input Indicates that the print data

sent to the Printer is corrupt

or has been interrupted.

See Card Feeding Errors

on page 21.

See Resolving cards jamming on the

Flipper table on page 24.

See Card Feeding Errors

on page 21.

See Removing the Card jam in the

Printer’s Magnetic Encoding Area on

page 43.

See Removing the Card jam in the

Printer’s Smart Card Encoding Area

on page 44.

See Resolving the Communication

Errors on page 16.

Data Timeout Indicates that the print data

sent to the Printer is corrupt

or has been interrupted.

DRAM Memory

Error

Indicates that the Printer's

Memory Module is bad or is

not installed properly.

See Resolving the Communication

Errors on page 16.

See Resolving the DRAM Memory

Error on page 182.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

10

RESTRICTED USE ONLY FARGO Electronics, Inc.

urred.

hardware error has occurred.

hardware error has occurred.

hardware error has occurred.

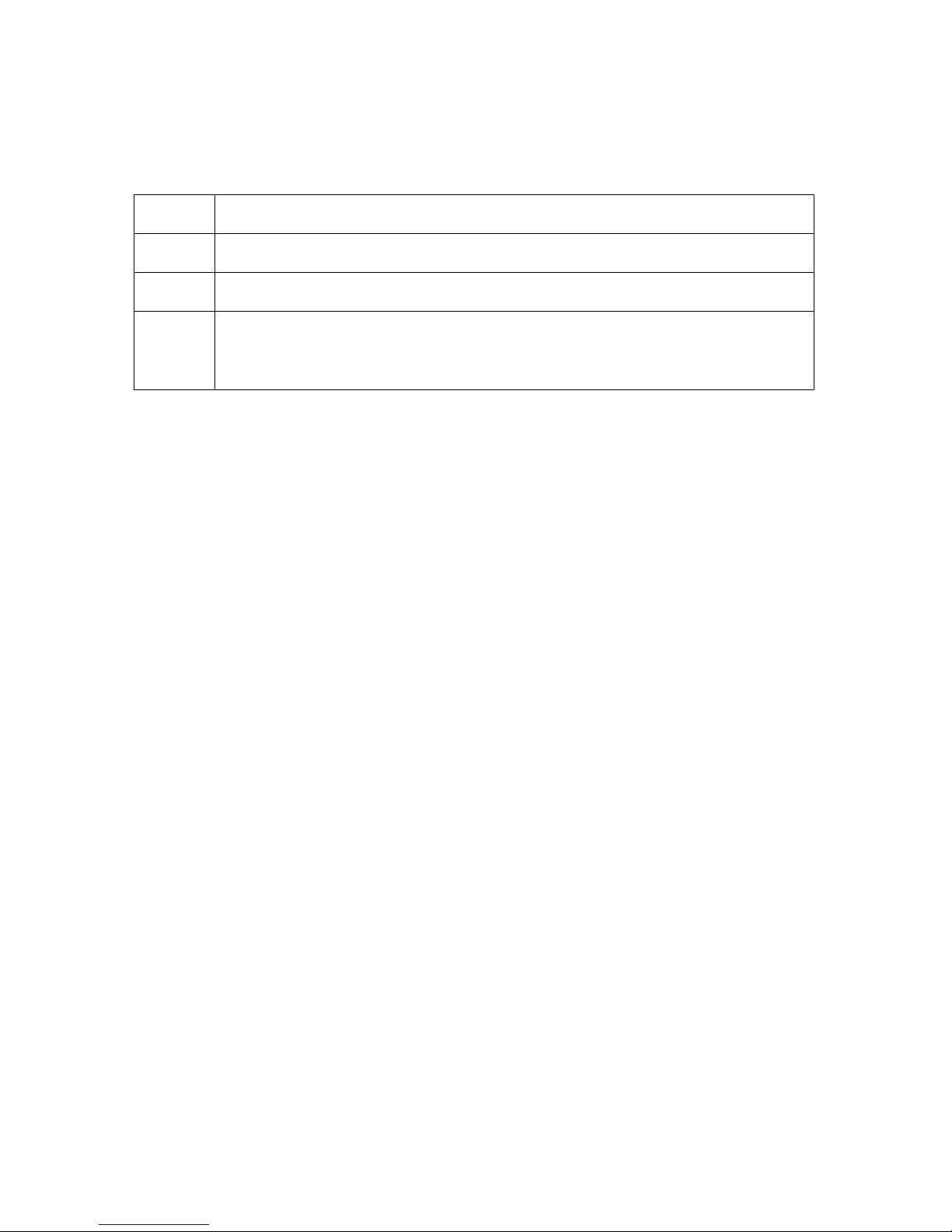

Troubleshooting the LCD Messages (continued)

Message Cause Solution

EE Checksum

Error

Indicates that the permanent

circuit board memory is bad.

EE Memory Error Indicates that the permanent

circuit board memory is bad.

Ejecting Used

Card

Indicates that the system

Firmware has detected a

card already in the Printer.

Failed To

Initialize

Indicates that an unexpected

hardware error has occ

Flipper Alignment Indicates that the Printer is

unable to align the Flipper

table.

FPGA Indicates that an unexpected

FPGA Load Fail Indicates that an unexpected

See Resolving the EE Checksum

Error on page 181.

See Resolving the EE Memory Error

on page 181.

This card has been ejected; however,

it may contain encoded data and

should be disposed of in a proper

manner.

See Board Errors on page 181.

See Resolving the Flipper Alignment

Error Message on page 64.

See Resolving the FPGA Error on

page 183.

See Resolving the FPGA Error on

page 183.

FPGA Timeout Indicates that an unexpected

Head Lift Indicates that the Printer was

unable to raise or lower the

Printhead.

See Resolving the FPGA Error on

page 183.

See Resolving the Headlift Error

Message on page 53.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

11

RESTRICTED USE ONLY FARGO Electronics, Inc.

Troubleshooting the LCD Messages (continued)

Message Cause Solution

Head Resistance

Error

The LCD requires that a

value be input for the Print

Head Resistance.

Head Voltage

Error

A hardware fault has

prevented a correct setting

of the Printhead voltage.

Hopper 1 Empty Card Hopper 1 has run out

of cards. (Note: The Printer

will continue printing from

Hopper 2 if First Available is

set as the Card Hopper

Selection in the Driver.)

Hopper 2 Empty Card Hopper 2 has run out

of cards. (Note: The Printer

will continue printing from

Hopper 1 if First Available is

set as the Card Hopper

Selection in the Driver.)

Enter a value for head resistance in

the LCD's Printer Setup menu.

See Setting the Printhead Resistance

on page 198.

A default value will be used.

See the Resolving the Card Hopper

Empty Error Message procedure on

page 27.

See the Resolving the Card Hopper

Empty Error Message procedure on

page 27.

Invalid Flip

Command

Invalid Print

Ribbon

Indicates that the Printer

received a command to print

both sides of the card, but

this model does not support

dual-sided printing.

Indicates an unauthorized

Ribbon.

Press CANCEL to reset the Printer or

RESUME to print onto two separate

cards.

Install a valid, FARGO-authorized

Ribbon, and press RESUME to

continue.

See Resolving the Unknown Ribbon

Type Error Message on page 52.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

12

RESTRICTED USE ONLY FARGO Electronics, Inc.

Troubleshooting the LCD Messages (continued)

Message Cause Solution

Mag Encode

Failed

Indicates that the card's

Magnetic Stripe was not

encoded properly.

Multiple Cards

Fed

Indicates that two or more

cards were fed from the

Card Hopper.

No ENC

Response

Indicates that there is no

response from the Encoder

control module.

No MAG Encoder Indicates that the Printer has

received encoding data, but

the Printer is not configured

with this Encoder type.

No Ribbon

Installed

Indicates that the Printer is

trying to print with no print

Ribbon installed.

No Smart

Encoder

Indicates that the Printer has

received encoding data, but

the Printer is not configured

with this Encoder type.

See Resolving the Failed Magnetic

Encode Error Message on page 42.

See Resolving the Card Feeding

Errors on page 21.

See Resolving the No ENC Response

Error Message on page 28.

See Resolving the No Magnetic

Encoder Error Message on page 28.

Install the proper print Ribbon, and

press RESUME to continue or

CANCEL to reset the Printer.

See Resolving the No Smart Encoder

Error Message on page 42.

Pause... Indicates the Printer is

paused.

Press the Printer's RESUME button to

continue or CANCEL to clear all

pending print jobs and reset the

Printer.

Please Clean

Printer

This message appears every

3,000 prints to remind you to

See the Cleaning the Printer

procedure on page 174.

perform the recommended

Printer maintenance.

Please Remove

Card

Indicates that the card is

jammed in the Print Station

See Card Feeding Errors

or card flipping area of the

Printer.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

on page 21.

13

RESTRICTED USE ONLY FARGO Electronics, Inc.

Troubleshooting the LCD Messages (continued)

Message Cause Solution

Print Data Indicates that the print data

sent to the Printer is corrupt

or has been interrupted.

Print Ribbon Low Indicates that the print

Ribbon will soon run out.

Print Ribbon Out Indicates that the print

Ribbon has run out.

Print Station

Open

Indicates that the Print

Station is open during

printing.

Print Timeout Indicates that the Printer was

unable to complete the print

process.

Printhead Temp Indicates that the Printhead

Temperature Regulator is

not functioning properly.

See Communications Errors on page

16.

If printing a large number of cards,

replace the Ribbon now or monitor the

Printer until the Ribbon is gone, and

install a new Ribbon.

Install a new Ribbon, and press

RESUME to continue.

Close the Station, and press the

Printer's RESUME button to continue

or CANCEL to reset the Printer.

See Communications Errors on page

16.

See Resolving the Printhead Temp

Error Message on page 58.

Program

Exception

RAM Memory

Error

Ribbon Jam /

Broken

Indicates that the system

Firmware has detected an

error while attempting to

process the current print job.

Indicates that the Printer's

Memory Module is bad or

not installed properly.

The print Ribbon is either

jammed or broken.

See the Updating the Printer’s

Firmware procedure on page 209.

See Resolving the DRAM Memory

Error on page 182.

See Resolving the Ribbon Jam /

Broke Error Message on page 50.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

14

RESTRICTED USE ONLY FARGO Electronics, Inc.

Troubleshooting the LCD Messages (continued)

Message Cause Solution

Smart Encode

Failed

The card's smart chip was

not encoded properly.

Starting Self-test The self-test print is

preparing to print.

Testing Memory The Printer's memory is

being tested.

Top Cover Open A print job was started with

the Top Cover open.

Unable To Feed

Card

The Printer is unable to feed

a card from the Card

Hopper.

Unknown Ribbon

Type

The print Ribbon installed is

not appropriate for your

specific Printer model.

Update Failed The Firmware update was

interrupted or not completed

successfully.

See Resolving the Failed Smart

Encode Error Message on page 42.

See the Printing the Self-test

procedure on page 190.

Upon completion, the Printer will

continue its normal boot up sequence.

Close the Printer, and press RESUME

to continue or CANCEL to reset the

Printer.

See Resolving the Card Feeding

Errors on page 21.

See Resolving the Unknown Ribbon

Type Error Message on page 52.

See Resolving an Upgrade Failed

error on page 66.

Update Firmware

Now

Wrong Print

Ribbon

An error has occurred in

trying to load the Firmware.

The print Ribbon installed in

the Printer does not match

the Ribbon type selected in

the Printer driver.

The system Firmware MUST be

updated.

See Updating the Printer's Firmware

on page 209.

See Resolving the Wrong Print

Ribbon Error Message on page 51.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

15

RESTRICTED USE ONLY FARGO Electronics, Inc.

Communications Errors

Resolving the Communication Errors

Symptom(s): Incorrect output, communications error on PC or Printer, stalling, no response

from Printer, no job printed, “Paper out” error.

Step Procedure

1 Confirm that the system meets the minimum requirements, as shown here:

• IBM-PC or compatible

™

• Windows 95/98/ME/NT/2000/XP Pentium

32 MB of RAM or higher

• 200 MB free hard disk space or higher

• ECP Parallel Port with DMA access

2 Confirm the correct installation of the Printer driver.

class 133 MHz computer with

a. Close the software program and check the Printer driver.

b. Reboot the computer.

c. Be sure the correct setup options within the Printer driver are selected.

d. Confirm that the driver is current by checking at: www.fargo.com

3 Verify the use of an adequate data cable.

a. Use a double-shielded parallel cable (no longer than six feet in length).

(Note: Data transmission failure can be attributed to a long or faulty

parallel cable.)

b. Use an I-EEE 1284 compliant cable to reduce the effect of radio emissions

from computers, monitors, and other equipment that can broadcast Radio

frequency interference (RFI).

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

16

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Communication Errors (continued)

Step Procedure

4 Determine if there is interference from an external device.

a. Do not use an A/B Switch Box or other peripheral in line with the parallel

cable.

b. If using a Switch Box or other peripheral, remove it while testing

communication between the computer and the Printer.

c. If needed, replace the Switch Box or other peripheral (once it is determined

that the cause of the interference is not the Switch Box or the peripheral).

d. Alternative: Add a second Parallel Port into the computer (if a second

Printer is required).

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

17

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Communication Errors (continued)

Step Procedure

5 Determine the nature of the problem with printing from the application.

a. Print a self-test from the Printer to ensure that the Printer (itself) is

functioning properly. See the Printing the Self-test

b. Print the Windows test page that is located in the General tab of the driver.

c. Use WordPad (a Windows 95/ 98/ ME/ NT/ 2000/XP word processing

program in the Accessories Program Group) via Start > Programs >

Accessories > WordPad. Follow this procedure:

• Open the program and type: “This is a Test.”

• Select File > Page Setup and click on the Printer button.

• Ensure that the DTC500 Series Card Printer/Encodersis selected and

click OK.

• Change all the margin settings to zero (0) and click OK.

on page 190.

• Select File > Print on the Menu Bar.

• Go to File on Menu Bar and select Print.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

18

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Communication Errors (continued)

Step Procedure

6 Determine if the Parallel Port mode is set correctly.

a. Ensure that the Parallel Port is set to the Enhanced Communication Port

(ECP) mode. (Note: The port mode can be determined by checking the

Device Manager tab in the System Control Panel.)

b. If the port mode is not set to ECP, it will need to be changed in the

computers BIOS. (Note: Refer to the appropriate computer manual for

instructions on how to change the Parallel Port mode.)

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

19

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Communication Errors (continued)

Step Procedure

7 Determine whether there is an adequate or inadequate hard drive space.

Caution: A large volume of temporary files on the computer can

cause communications errors.

Access the temporary files by following this process:

• Search for all folders called TEMP. Once found, clear out the contents of

the folders.

• Run the System Tool - Disk Defragmenter (found in the Accessories folder

of the Start Menu) if using Windows 95/98/ME/2000/XP,.

• Use a disk cleanup utility (such as Disk Cleanup found in the System

Tools folder of the Start menu) or use a third party application.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

20

RESTRICTED USE ONLY FARGO Electronics, Inc.

Card Feeding Errors

Resolving the Card Feeding Errors

Symptom: Two or more cards feed at the same time, or the cards will not feed at all.

Step Procedure

1 Clean the Input Roller.

a. Open the Printer's top covers, and remove all cards, and print Ribbons from

the Printer.

b. Leave the Printer power ON and the top covers open throughout this

procedure. (Note: The card-cleaning cartridge can also remain within the

Printer during this cleaning process.)

c. Use a cleaning card from the Printer Cleaning Kit, and remove its adhesive

backing paper.

d. Insert the cleaning card into the Exception Card Slot until the card stops.

• Verify that the longest non-adhesive end of the cleaning card enters the

Printer first and that the sticky side is facing DOWNWARD

e. Press the FORWARD button several times to feed the Cleaning Card all

the way through the Printer.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

21

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Card Feeding Errors (continued)

Step Procedure

2 Ensure the Card Thickness Lever is set correctly, as shown below.

a. Press the Card Thickness Lever Lock and then push the Card Thickness

Lever up or down to the appropriate setting.

b. with any of the Card Thickness settings, move the slide slightly toward a

higher setting until the cards begin feeding (if the Printer seems unable to

feed cards at the selected setting).

c. Move the slide slightly toward a lower setting (if the Printer seems to

double-feed cards). (Note: The card thickness slide is adjustable to

accommodate card thickness variations that often occur even within

standard card sizes.)

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

22

RESTRICTED USE ONLY FARGO Electronics, Inc.

Insert cards neatly stacked.

Card Feed Roller

Resolving the Card Feeding Errors (continued)

Step Procedure

3

4 Ensure that the cards are loaded properly in the Input Hopper.

5 Verify that the Hopper Lift (A000124) is operational.

a. Check for static build up between cards. (Note: Occasionally, a static

charge will build up between the surfaces of two or more cards causing

them to stick together.)

b. Reduce or eliminate this static charge by separating the cards manually

before placing them in the input hopper.

a. Load the cards into the Printer by inserting them straight into the hopper

and setting them on the feed Roller.

a. Reset Power to the Printer.

b. Open the Card Hopper Door and watch to verify that the Hopper Cycles

on startup.

c. If the Hopper does not cycle on startup, remove the top cover and verify

that the Hopper Lift Motor is plugged in properly.

d. If the Hopper Lift Motor is plugged in, disconnect it and attach a 9-volt

battery to the leads.

e. If the Motor turns, replace the Main Board (as needed). See the

Replacing the Main Board

procedure on page 29.

Card Hopper

(side view)

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

Cards

23

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Card Jam on the Flipper Table

Symptom: Cards are jamming on or at the Flipper Table, or a Card Jam: Flip error is

displayed on the LCD.

Step Procedure

1 Verify that the Card Feed Roller on the Flipper table is not running

backwards. (Note: Having an Encoder installed in the Printer will determine

the direction that the Card Feed Roller on the Flipper Table will rotate.)

a. Open the Top Cover and remove any cards that are jammed inside the

Printer, as shown below.

b. Reset power on the Printer to clear any error messages that are on the

LCD.

c. Press the MENU button on the LCD.

d. Press the Down Arrow button and select PRINTER SETUP.

e. Scroll through the menu and select ENCODER SETUP.

f. Ensure that the appropriate Encoders settings are set to Installed or

None, based on the options that are installed in the Printer.

g. Press the Save button to save any changes that have been changed.

Continued on the next page.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

24

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving cards jamming on the Flipper Table. (Continued)

Step Procedure

2

Ensure that the Flipper Table is level. (Note: This procedure does not apply

to Printers with a Stationary Flipper Table, such as a DTC510/515 without

any Encoders installed.)

a. Open the Top Cover and remove any cards that are jammed inside the

Printer.

b. Reset power on the Printer to clear any error messages that are on the

LCD.

c. Press the MENU button on the LCD.

d. Press the Down Arrow button and select PRINTER SETUP.

e. Scroll through the menu and select FLIPPER OFFSET.

f. Select Level.

• If the cards are feeding over the feed Rollers on the card path, adjust

the value by +2.

OR

• If the cards are feeding under the Card Feed Path, adjust the value

by –2.

3 Ensure that the Flipper Table Tension Spring is providing appropriate

tension.

a. Open the Top Cover on the Printer.

b. Remove the Ribbon.

c. Rotate the Flipper Table to an angle perpendicular to the Card Feed

Path.

d. Using the Forward button, insert a card onto the Flipper Table.

e. Once fed onto the Flipper Table (D850855), manually pull the card from

the Flipper table. (Note: There should be sufficient resistance to

prevent the card from slipping from the Flipper table.)

f. If there is not sufficient resistance, replace the U-shaped spring on the

back of the Flipper Table.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

25

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Card Hopper Jam Error Message

Step Procedure

1 Clear any obstructions.

a. Open the Input Hopper Door, as shown below.

b. Remove any cards from the Input Hopper.

c. Ensure that there are no cards that are partially fed out of the Card

Hopper.

2 Verify the mechanical operation.

a. Remove the Top Cover.

b. Ensure that the guide belt for the Hopper Travel Assembly (D850253) is

intact and moves smoothly.

c. Verify that the Hopper Travel Motor is properly meshed with the gear

assembly.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

26

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Card Hopper Empty Error Message

Symptom: The Hopper Empty error message is displayed on the LCD.

Step Procedure

1 Refill the hopper when convenient.

2 Be sure to load cards with the mag stripe toward the rear of the Printer.

3 Turn the Card Sensor off if it is determined that the Hopper’s Card Sensor

cannot see these types of cards. (Note: with the Sensor turned on, the

Printer can believe the Card Input Hopper is empty, and cards will not feed.)

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

27

RESTRICTED USE ONLY FARGO Electronics, Inc.

Encoding Errors

Resolving the No Magnetic Encoder Error Message

Symptom: The Printer is receiving encoding data, but the Printer is not configured with this

Encoder type.

Step Procedure

1 Ensure the LCD Setting correct.

a. Press Select on the LCD.

b. Select Setup Printer and Encoder Settings.

c. Change the Mag Setting from None to Installed.

2 If the encoding data was sent in error, check the in-house, software user’s

manual for encoding instructions.

Resolving the No ENC Response Error Message

Symptom: There is no ENC response.

Step Procedure

1 Check the Magnetic Offset Setting.

a. Press Menu on the LCD.

b. Select Setup Printer and Encoder Settings

c. Select Magnetic TOF.

d. Verify that the current value matches the default value listed on the back of

the Printer.

2 Determine if the Main Board is bad.

a. Replace the Main Board. See the Replacing the Main Board

page 29.

b. Determine if the error repeats itself after replacing the Main Board.

procedure on

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

28

RESTRICTED USE ONLY FARGO Electronics, Inc.

J12

J18

J30

J27

J26

J13, J14

J25

J23

J24J8J9

J21J7J16J4J26

J15J6J31

J33

Replacing the Main Board

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

29

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850426)

For Use with DTC510/DTC515 without Embedded Fonts and Barcodes

Tools Required: Phillips-head Screwdriver, Torx T10 Screwdriver, Needle-nose Pliers, Wire

Cutter

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 Use the Phillips-head Screwdriver to remove the two screws (130939) located

near the hinges. Open the Card Hopper Door before raising the cover.

4 Pull back the plastic tabs at each of the four corners of the cover.

5 a. Carefully lift the cover off of the Printer.

b. Remove the LCD interface cable (D850481) at the main circuit board.

c. Disconnect the grounding cable at the power supply casing.

6 a. Completely remove the Card Output Hopper (D850290) from the Printer by

pulling back the release tab at the bottom of the Printer.

b. Remove the two circuit board mounting screws located in the hopper

opening. (Note: See the next page for a photo display.)

7 Remove the Circuit Board mounting screw located below the Printhead lifter arm

pivot.

8 Go to the back of the Printer. Use the Torx T10 Screwdriver to remove the top

three circuit board mounting screws located at the left, middle, and right

sections. (Note: See the next page for a photo display.)

9 Remove the two mounting screws at the middle and lower section (along the left

edge of the circuit board).

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

30

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850426) (Continued)

This is a view of the bottom of the discharge end of the Printer. (Note: This shows the

release tab from Step 6 in the previous procedure in this section.)

This is the discharge end of the Printer. The arrows point to the screws described in Step 8.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

31

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850426) (Continued)

Step Procedure

10 At the bottom mid-section of the circuit board, remove the last mounting screw.

a. Use the Torx T10 Screwdriver to remove the three screws from the

Magnetics Board (if a Magnetics Board is installed on the Main Board).

b. Use the needle-nose pliers to remove the three Standoff screws from the

Main Board (where the Magnetics Board had been installed).

11 Carefully disconnect the cables from the main circuit board. All cables should be

factory-labeled.

Caution: Some nylon tie wraps may need to be cut to remove cables

attached to the main circuit board. Carefully cut these tie wraps using a wire

cutter.

12 Remove the Main Board.

Caution: When replacing the circuit board, be sure all cables are

carefully routed, as not to bind with pulleys, belts and any other moving parts.)

13 Once the new board is installed, the Printer will have to be recalibrated, and

other presets will have to be entered from the front panel display.

• See the LCD On-Line Menu Navigation

instructions on page 187.

• See the Reviewing the DTC500 Board Cable Connections Reference table

on the next page.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

32

RESTRICTED USE ONLY FARGO Electronics, Inc.

Reviewing the DTC500 Board Cable Connections Reference

Purpose Location

Power Supply J1

No Cable Assembly: Parallel Port Connection J11

No Cable Assembly: DRAM Connector J12

Fan J13

Fan J14

Card Detection Sensor and Flipper Table Card Sensor J15

Ribbon Sensor Array J16

Unpopulated J17

LCD J18

Background Mode Debugger Connection, Program Loading J19

Smart/Proximity Card Interface J21

Ribbon Supply Motor, Ribbon Take-up Motor and Headlift Motor J23

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

33

RESTRICTED USE ONLY FARGO Electronics, Inc.

DTC500 Board Cable Connections Reference (continued)

Description Location

Hopper Lift Motor and Hopper Transport Motor J24

RFID Antenna Coil J25

Main Stepper Motor J26

Flipper Table Angle Stepper J27

Unused, Spare Sensor Circuitry J29

Flipper Feed/Encoding Feed Stepper J30

Print TOF Sensor J31

Hopper Position Sensor J32

Unused, SCI Interface J33

P1 = Card Detection Sensor, P3 = Hopper Lift Sensor, P4 =

J4

Hopper Transport Sensor

P1 = Printhead Arm Sensor, P2 = Headlift Sensor, P3 = Ribbon

J6

Encoder Sensor

P1 = Flipper Home Sensor, P2 = Encoding TOF Sensor J7

Printhead: 12-Pin Connector J8

Printhead: 20-Pin Connector J9

Magnetics Board JP1

No Cable Assembly: Serial Port Connection P1

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

34

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850427)

For Use with DTC520/DTC525 without Embedded Fonts and Barcodes

Tools Required: Phillips-head Screwdriver, Torx T10 Screwdriver, Needle-nose Pliers, Wire

Cutter

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 Use the Phillips-head Screwdriver to remove the two screws (130939) located

near the hinges. Open the Card Hopper Door before raising the cover.

4 Pull back the plastic tabs at each of the four corners of the cover.

5 Carefully lift the cover off of the Printer. Remove the LCD interface cable

(D850481) at the main circuit board, and disconnect the grounding cable at the

power supply casing.

6 Completely remove the Card Output Hopper (D850290) from the Printer by

pulling back the release tab at the bottom of the Printer. Remove the two circuit

board mounting screws located in the hopper opening.

7 Remove the circuit board mounting screw located below the Printhead lifter arm

pivot.

8 From the back of the Printer, use the Torx T10 Screwdriver to remove the top

three circuit board mounting screws located at the left, middle and right sections.

9 Along the left edge of the circuit board, remove the two (2) mounting screws at

the middle and lower section.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

35

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850427) (Continued)

Step Procedure

10 At the bottom mid-section of the circuit board, remove the last mounting screw.

a. Use the Torx T10 Screwdriver to remove the three screws from the

Magnetics Board (if a Magnetics Board is installed on the Main Board).

b. Use the needle-nose pliers to remove the three Standoff screws from the

Main Board (where the Magnetics Board had been installed).

11 Carefully disconnect the cables from the main circuit board. All cables should be

factory-labeled.

Caution: Some nylon tie wraps may need to be cut to remove cables

attached to the main circuit board. Carefully cut these tie wraps using a wire

cutter.

12 Remove the Main Board.

Caution: When replacing the circuit board, be sure all cables are

carefully routed, as not to bind with pulleys, belts and any other moving parts.

13 Once the new board is installed, the Printer will have to be recalibrated, and

other presets will have to be entered from the front panel display.

• See the LCD On-Line Menu Navigation

instructions on page 187.

• See the Reviewing the DTC500 Board Cable Connections Reference table

on page 33.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

36

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850428)

For Use with DTC510/DTC515 with Embedded Fonts and Barcodes

Tools Required: Phillips-head Screwdriver, Torx T10 Screwdriver, Needle-nose Pliers, Wire

Cutter

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 Use the Phillips-head Screwdriver to remove the two screws (130939) located

near the hinges. Open the Card Hopper Door before raising the cover.

4 Pull back the plastic tabs at each of the four corners of the cover.

5 a. Carefully lift the cover off of the Printer.

b. Remove the LCD interface cable (D850481) at the Main Circuit Board.

c. Disconnect the grounding cable at the power supply casing.

6 a. Completely remove the Card Output Hopper (D850290) from the Printer by

pulling back the release tab at the bottom of the Printer.

b. Remove the two (2) circuit board mounting screws (located in the hopper

opening).

7 Remove the circuit board mounting screw located below the Printhead lifter arm

pivot.

8 From the back of the Printer, use the Torx T10 Screwdriver to remove the top

three (3) Circuit Board mounting screws (located at the left, middle and right

sections).

9 Along the left edge of the circuit board, remove the two (2) mounting screws at

the middle and lower section.

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

37

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850427) (Continued)

Step Procedure

10 At the bottom mid-section of the circuit board, remove the last mounting screw.

a. Use the Torx T10 Screwdriver to remove the three screws from the

Magnetics Board (if a Magnetics Board is installed on the Main Board).

b. Use the needle-nose pliers to remove the three Standoff screws from the

Main Board where the Magnetics Board had been installed.

11 Carefully disconnect the cables from the main circuit board. All cables should be

factory-labeled.

Caution: Some nylon tie wraps may need to be cut to remove cables

attached to the main circuit board. Carefully cut these tie wraps using a wire

cutter.

12 Remove the Main Board.

Caution: When replacing the circuit board, be sure all cables are

carefully routed, as not to bind with pulleys, belts and any other moving parts.)

13 Once the new board is installed, the Printer will have to be recalibrated, and

other presets will have to be entered from the front panel display.

• See the LCD On-Line Menu Navigation

instructions on page 187.

• See the Reviewing the DTC500 Board Cable Connections Reference table

on page 33.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

38

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850429)

For Use with DTC520/DTC525 with Embedded Fonts and Barcodes

Tools Required: Phillips-head Screwdriver, Torx T10 Screwdriver, Needle-nose Pliers, Wire

Cutter

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 a. Use the Phillips-head Screwdriver to remove the two screws (130939)

located near the hinges.

b. Open the Card Hopper Door before raising the cover.

4 Pull back the plastic tabs at each of the four corners of the cover.

5 a. Carefully lift the cover off of the Printer.

b. Remove the LCD interface cable (D850481) at the main circuit board, and

disconnect the grounding cable at the power supply casing.

6 a. Completely remove the Card Output Hopper (D850290) from the Printer by

pulling back the release tab at the bottom of the Printer.

b. Remove the two circuit board mounting screws located in the hopper

opening.

7 Remove the circuit board mounting screw located below the Printhead lifter arm

pivot.

8 From the back of the Printer, use the Torx T10 Screwdriver to remove the top

three circuit board mounting screws located at the left, middle and right sections.

9 Remove the two mounting screws at the middle and lower section (along the left

edge of the circuit board).

Continued on the next page

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

39

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Main Board (D850429) (Continued)

Step Procedure

10 a. Remove the last mounting screw at the bottom mid-section of the Circuit

Board. (Note: If a Magnetics Board is installed on the Main Board, use the

Torx T10 Screwdriver to remove the three screws from the Magnetics

Board.)

b. Use the needle-nose pliers to remove the three Standoff screws from the

Main Board where the Magnetics Board had been installed.

11 Carefully disconnect the cables from the main circuit board.

Caution: All cables should be factory-labeled. Some nylon tie wraps

may need to be cut to remove cables attached to the main circuit board.

Carefully cut these tie wraps using a wire cutter.

12 Remove the Main Board.

Caution: When replacing the circuit board, be sure all cables are

carefully routed, as not to bind with pulleys, belts and any other moving parts.

13 Once the new board is installed, the Printer will have to be recalibrated, and

other presets will have to be entered from the front panel display.

• See the LCD On-Line Menu Navigation

instructions on page 187.

• See the Reviewing the DTC500 Board Cable Connections Reference table

on page 33.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

40

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Failed Magnetic Encode Error Message

Symptom: The Magnetic Stripe was not encoded properly.

Step Procedure

1 Check to ensure that the cards are loaded with the Magnetic Stripe facing

down and towards the back of the Printer.

2 Verify the Driver Settings.

a. Ensure that the Coercivity setting in the driver corresponds to the type of

cards that are being used.

• High Coercivity = 2750 Oersted

• Low Coercivity = 300 Oersted

(Note: See the Using the Magnetic Encoding tab

procedure on page 138.)

Resolving the No Prox Encoder Error Message

Symptom: The Printer is receiving encoding data, but the Printer is not configured with this

Encoder type.

Step Procedure

1 Ensure the LCD Setting correct.

a. Press Select on the LCD.

b. Select Setup Printer and Encoder Settings.

c. Change the Prox Setting from None to Installed.

2 Check the appropriate software user’s manual for specific encoding

instructions if the encoding data was sent in error.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

41

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the No Smart Encoder Error Message

Symptom: The Printer is receiving encoding data, but the Printer is not configured with this

Encoder type.

Step Procedure

1 Ensure the LCD Setting correct.

a. Press Select on the LCD.

b. Select the Setup Printer and Encoder Settings.

c. Change the Smart Setting from None to Installed.

2 Check the software user’s manual for encoding instructions if the encoding

data was sent in error.

Resolving the Failed Smart Encode Error Message

Symptom: The card's smart chip was not encoded properly.

Step Procedure

1 Check to ensure that the cards are loaded with the smart chip facing up and

are being fed into the Printer first.

2 Verify that the card is entering the E-card Docking Station properly..

a. Send an encoding print job from the computer.

b. Watch the card feed into the Printer and enter the E-card Docking Station.

c. Adjust the Flipper Offset (as needed) if the card is not feeding into the E-

card Docking Station properly. See Resolving the Card Jam on the Flipper

Table in page 24.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

42

RESTRICTED USE ONLY FARGO Electronics, Inc.

Removing the Card Jam in the Printer’s Magnetic Encoding Area

Symptom: A card is jammed in the magnetic encoding area of the Printer.

Step Procedure

1 Clear the jammed card.

a. Open the Top Cover.

b. Use the arrows on the LCD panel to move the card forward or backward to

free the card.

2 Inspect the Card Feed Roller Motor for proper operation.

a. Leave the power ON and open the Top Lid and Printhead Arm.

b. Press the FORWARD button to advance the card or the BACK button to

reverse the card. Use these buttons to move the card through the Printer.

3 Ensure that the cards are feeding into the Encoding Module properly.

a. Reset power on the Printer to clear any error messages.

b. Select the Menu from the LCD.

c. Select the Print Test Image from the menu. See the Printing the Self-test

on page 190.

d. Select the Magnetic Test from the menu. (Note: A card is fed from the

input hopper onto the Flipper table and rotated into the Encoding Module.)

e. If the card appears to jam against the components of the encoding

assembly, adjust the Encoder angle of the Flipper Offset. See the

Resolving the Card Jam on the Flipper Table

4 Adjust the Flipper Offset.

a. Select Menu on the LCD display.

b. Select Setup Printer.

c. Select Flipper Offset.

d. Select Encoder Angle.

e. Change the setting on the small increments. (Note: A negative

adjustment will lower the side of the Flipper Table closest to the Exit

Hopper.)

f. Press Select to save the new value.

procedure on page 24.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

43

RESTRICTED USE ONLY FARGO Electronics, Inc.

Removing the Card Jam in the Printer’s Smart Card Encoding Area

Symptom: A card is jammed in the Smart Card encoding area of the Printer.

Step Procedure

1 Clear the jammed card.

a. Open the Top Cover.

b. Use the arrows on the LCD panel to move the card forward or backward to

free the card.

2 Inspect the Card Feed Roller Motor for proper operation.

a. Leave the power ON and open the Top Lid and Printhead Arm.

b. Press the FORWARD button to advance the card or the BACK button to

reverse the card. (Note: Use these buttons to move the card through the

Printer.)

3 Adjust the Flipper Offset.

a. Select Menu on the LCD display.

b. Select Setup Printer

c. Select Flipper Offset.

d. Select Encoder Angle

e. Change the setting on small increments. (Note: A negative adjustment

will lower the side of the Flipper Table closest to the Exit Hopper.)

f. Press Select to save the new value.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

44

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Printer not reading Encoded Magnetic Track Data

Step Procedure

1 Verify that the cards are loaded properly with the Magnetic Stripe facing down

and towards the back of the Printer.

2 Verify that the card is encoded with magnetic data by using a magnetic imager

or developer solution.

3

Use WordPad (a Windows 95/ 98/ ME/ NT/ 2000/XP word processing program

in the Accessories Program Group), as shown on the next page.

a. Open the program and type in: ~1%JULIEANDERSON^1234567890?

b. Select File > Page Setup and click on the Printer button.

c. Ensure that the DTC500 Series Card Printer/Encodersis selected and click

on OK.

d. Change all the margin settings to zero (0) and click on OK.

e. Go to File on Menu Bar and select Print. (Note: The Printer should then

feed a card into the Encoder and magnetically encode it.)

4

Caution: Ensure that the Coercivity of the cards matches the setting

in the driver.

5 Compare the settings for the card reader to the settings in the driver.

6

Caution: Ensure that the Magnetic Stripe on the card is free of

scratches or voids.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

45

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Printer not reading Encoded Magnetic Track Data (continued)

See the previous procedure in this section.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

46

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Magnetic Stripe Data being printed on a Card

problem

Step Procedure

1 Confirm that the application is formatting the magnetic string correctly. See the

Sending the Track Information

procedure on page 151.

2

Use WordPad (a Windows 95/ 98/ ME/ NT/ 2000/XP word processing program

in the Accessories Program Group). See previous page for display.

a. Open the program and type: “~1%JULIEANDERSON^1234567890?”

b. Select File > Page Setup and click on the Printer button.

c. Ensure that the DTC500 Series Card Printer/Encodersis selected and click

OK.

d. Change all the margin settings to zero (0) and click OK.

e. Go to File on Menu Bar and select Print. (Note: The Printer should then

feed a card into the Encoder and magnetically encode it.)

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

47

RESTRICTED USE ONLY FARGO Electronics, Inc.

Printing Process Errors

Resolving the Ribbon Alignment Error Message

Step Procedure

1 Check that the Ribbon is loaded properly and completely seated on the hubs.

2 Check that the marks on the Ribbon are complete.

3

4 Test the Ribbon Sensor.

5

6 Clear the jam and reboot the Printer if the Ribbon is jammed.

Check the Motor operation to ensure that the Ribbon moves in both Forward

and Backward directions on Power Up.

a. Remove the back cover and locate the connector labeled J16 on the main

board.

b. Check the voltage for each of the five (5) Ribbon Sensors at their

connection to the Main Board.

c. Use a Multimeter to ground the negative lead to the chassis and put the

positive lead on pins 3, 5, 7, 9, and 11 of J16 on the main board.

d. Place a RibbonTraq™ mark over the Ribbon Sensor. (Note: The voltage

should be less than 1 VDC.)

e. Remove the RibbonTraq mark from the Ribbon Sensor. (Note: The

voltage should be greater than 4 VDC.)

f. Replace the Sensor if the voltages are incorrect. See the Replacing the

Ribbon Sensor Array Assembly (840108) procedure on the next page.

Install a new Ribbon and press the Resume button to continue if the Ribbon is

out.

7 Repair the Ribbon.

a. Repair the Ribbon by taping it back on to the take-up core if the Ribbon is

broken.

b. Press the Resume button to continue or Cancel to reset the Printer.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

48

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Ribbon Sensor Array Assembly (840108)

Tools Required: Phillips-head Screwdriver, Torx T10 Screwdriver

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 Use the Phillips-head Screwdriver to remove the two screws (130939) located

near the hinges.

4 Release the plastic tabs in the four corners of the cover.

5 Lift the cover off of the Printer.

6 Use the Torx T10 Screwdriver to remove the screw (F000169) from the front side

of the Ribbon Sensor Array.

7 Remove the Retainer Clip from the end of the shaft just above the Ribbon

Sensor Array.

8 Use the Torx T-10 Screwdriver to remove the screw (F000169) from the front

side of the cross-member to the right of the Ribbon Sensor Array

9 Spread the sides of the Printer apart until there is enough clearance to remove

the Ribbon Sensor Array.

10 Take the Ribbon Sensor Array Assembly from the Printer.

11 Disconnect the two cable connectors from the back of the Sensor board.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

49

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Print Ribbon Error Message

Symptom: The Print Ribbon is not installed properly, or it has run out, jammed, broken, or

been damaged.

Step Procedure

1 See Resolving Ribbon Alignment Errors on page 48, for details.

Resolving the Print Ribbon Out Error Message

Symptom: The Print Ribbon has run out.

Step Procedure

1

Install a new Ribbon, and press Resume to continue.

Resolving the Ribbon Jam / Broke Error Message

Symptom: An error message is displayed on the LCD, and the Ribbon is broken.

Step Procedure

1 Verify that the Print TOF and Print EOF are set correctly.

a. If the break occurs before anything is printed to the card, reduce the Print

TOF by 5.

b. If the break occurs after the yellow panel is transferred to the card, reduce

the Print EOF by 5.

c. Print a self-test to verify operation. See Printing the Self-test

on page 190.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

50

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Wrong Print Ribbon Error Message

Symptom: The Print Ribbon (installed in the Printer) does not match the Ribbon type

(selected in the Printer driver).

Step Procedure

1 Verify that the Ribbon is installed properly by ensuring that:

• The Ribbon is loaded with the supply side closest to the Card Input

Hopper.

• The Ribbon is rolling from the bottom of the spool to the bottom of the take

up spool.

2 Verify if the Driver has been set correctly.

a. Open the Printer control panel from the computer.

• If using Windows 95/98/ME, right click on the DTC500 Series Card

Printer/EncodersIcon and select Properties.

• If using Windows NT 4.0, right click on the DTC500 Series Card

Printer/Encodersand select Document Defaults.

• If using Windows 2000/XP, right click on the DTC500 Series Card

Printer/Encodersand select Printing Preferences.

b. Click on the Device Option tab. See the Using the Device options tab

procedure on page 111.

c. Verify that the Ribbon Type setting that is listed matches the Ribbon that is

installed in the Printer. (Note: It may be possible to have Driver settings

that are different from those found in the Printer control panel within the

application.)

d. Check any page setup functions in the software to verify that the Ribbon

type matches.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

51

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Unknown Ribbon Type Error Message

Symptom: The Printer is unable to determine the type of Ribbon installed.

Step Procedure

1 Verify the Ribbon type.

a. Ensure that the print Ribbon installed in the Printer is a DTC Ribbon.

(Note: Although similar in appearance, an HDP Ribbon installed in a DTC

Printer will produce an Unknown Ribbon Type error message.)

2 Test the Ribbon Sensor (840108).

a. Remove the back cover and locate the connector labeled J16 on the main

board.

b. Check the voltage for each of the five (5) Ribbon Sensors at their

connection to the main board.

c. Use a Multimeter to ground the negative lead to the chassis and put the

positive lead on pins 3, 5, 7, 9, and 11 of J16 on the main board.

d. Place a RibbonTraq™ mark over the Ribbon Sensor. (Note: The voltage

should be less than 1 VDC.)

e. Remove the RibbonTraq mark from the Ribbon Sensor. (Note: The

voltage should be greater than 4 VDC.)

f. Replace the Sensor if the voltages are incorrect. See the Replacing the

Ribbon Sensor Array Assembly (840108)

procedure on page 49.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

52

RESTRICTED USE ONLY FARGO Electronics, Inc.

Resolving the Headlift Error Message

Symptom: The Printer was unable to raise or lower the Printhead.

Step Procedure

1

Press the Resume button to retry.

2 If the Headlift does not rotate, check the Headlift Motor (A000124) to ensure

that it is running.

3 If the Headlift Motor is not running, replace the Headlift Motor. See the

Replacing the Headlift Motor (A000124) procedure in the next two pages.

4 If the head cycles but does not stop at the position every time, check the

Headlift Sensor as described in Sensor Testing

5

If the Headlift Sensor is failing, replace it. See the Replacing the Headlift

on page 184.

Sensor (A000126) in the next two pages.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

53

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Headlift Motor (A000124)

Tools Required: Phillips-head Screwdriver, Torx T-10 Screwdriver

Step Procedure

1

Caution: Turn OFF the Printer and unplug the power cord from the

Printer.

2 Lift up on the bottom edge of the Top Lid (D850289); tilt it back into the fully

open position.

3 Use the Phillips-head Screwdriver to remove the two screws (130939) located

near the hinges.

4 Release the plastic tabs in the four corners of the cover.

5 Lift the cover off of the Printer.

6 Use the Torx T-10 Screwdriver to remove the two screws that secure the Headlift

Motor to the front side plate.

7 Tip the Printer carefully on its back and remove the Headlift Motor through the

bottom access hole.

8 Set the Printer upright carefully.

9 Disconnect the cable connector.

DTC500 Series Card Printer/Encoders Troubleshooting Guide (Rev. 3.0)

54

RESTRICTED USE ONLY FARGO Electronics, Inc.

Replacing the Headlift Sensor (A000126)