Page 1

Installation Manual

fantech

Manuel d'installation

Manual de Instalación

RVF Model

Exterior-Mount Fan

Ventilateur à montage extérieur

Ventilador a mataje exterior

Item #: 401452

Rev Date: 2015-05-19

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Page 2

2

Note Warning /

Information Technical

Important

note

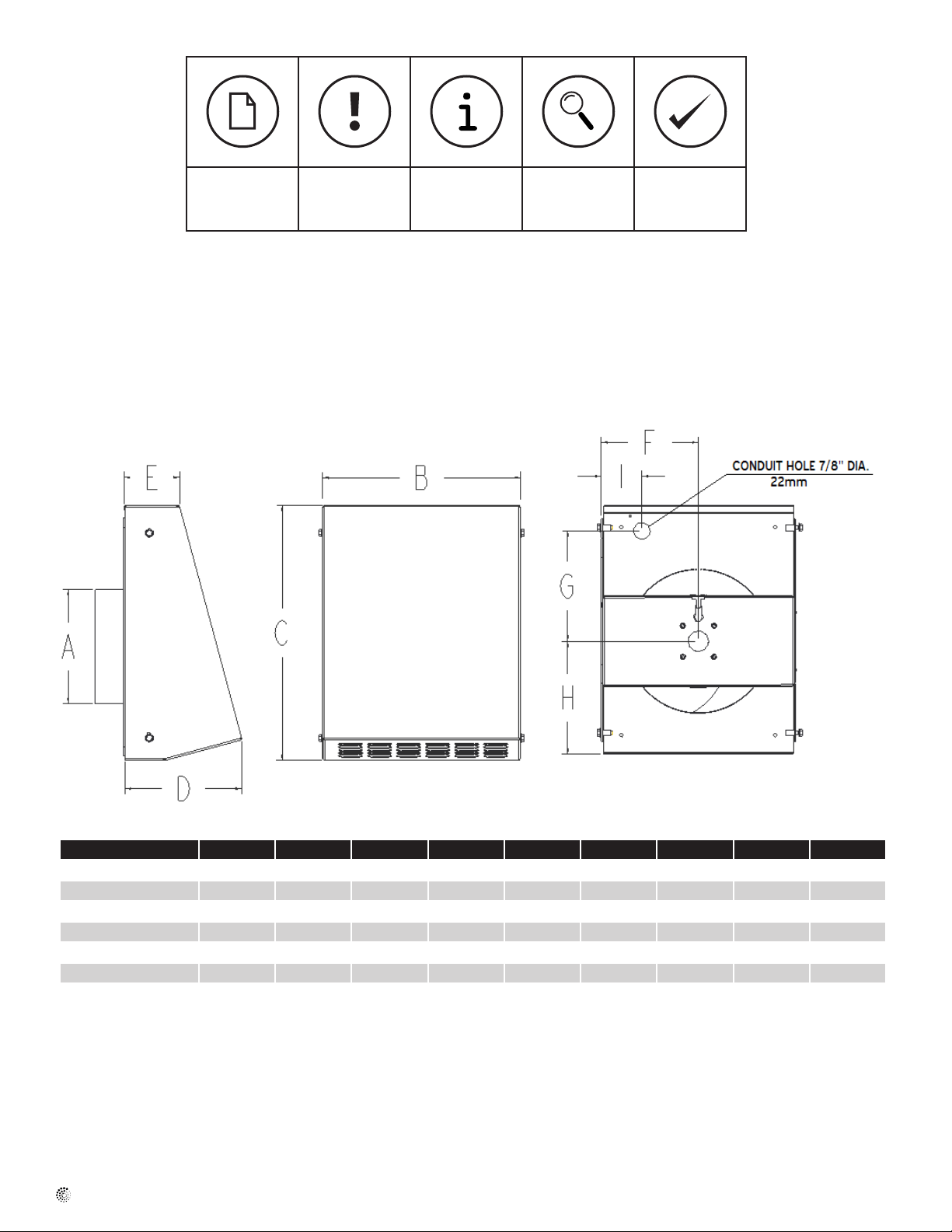

Dimensions - Dimensions- Dimensiones

Practical tip

information

Model/Modèle/Modelo A B C D E F G H I

RVF 4 4 10 1/

RVF 4XL 4 10 1/

RVF 4XL-EC 4 10 1/

RVF 6 6 10 1/

RVF 6XL 6 14 1/

RVF 8XL 8 14 1/

Dimensional information is in inches – Toutes les dimensions sont en pouces – Dimensiones en pulgadas

4

4

4

4

4

4

13 6 2 3/

13 6 2 3/

13 6 2 3/

13 6 2 3/

17 6 2 3/

17 6 2 3/

4

4

4

4

4

4

5 1/

5 1/

5 1/

5 1/

7 1/

7 1/

8

8

8

8

8

8

6 1/

5 1/

5 3/

5 1/

11 3/

11 3/

2

4

4

4

8

8

4 1/

16 1

5 1/

4

5 7/

8

5 9/

32 1

7 1/

16 1

7 1/

16

fantech

1

2 1/

1

8

Page 3

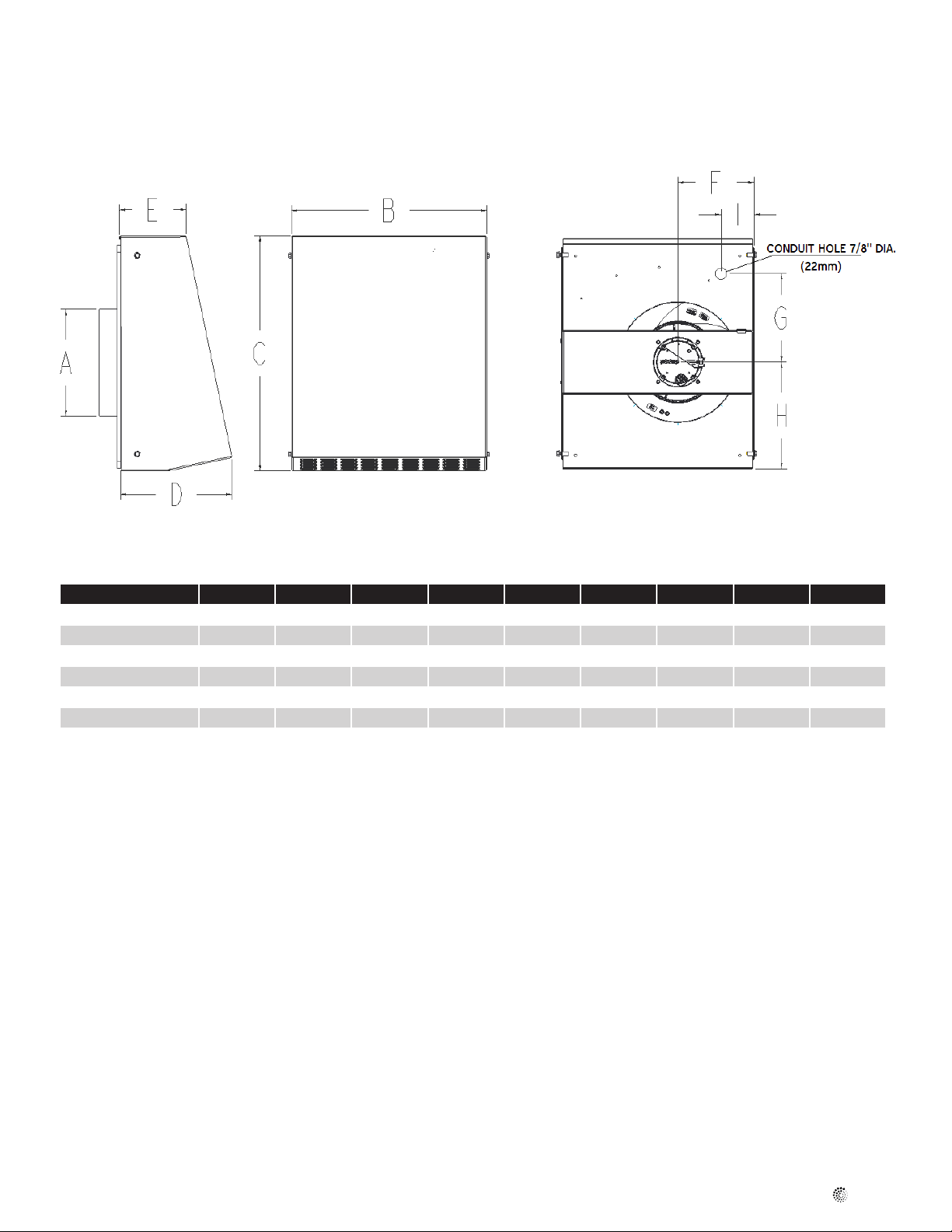

Dimensions - Dimensions- Dimensiones

3

Model/Modèle/Modelo A B C D E F G H I

RVF 6XL-EC 6 14 1/

RVF 8XL-EC 8 14 1/

RVF 10-EC 10 17 7/

RVF 10 10 17 7/

RVF 10L 10 17 7/

RVF 10XL 10 17 7/

Dimensional information is in inches – Toutes les dimensions sont en pouces – Dimensiones en pulgadas

4

4

8

8

8

8

17 8 4 7/

17 8 4 7/

21 1/

21 1/

21 1/

21 1/

4

4

4

4

10 5 7/

10 5 7/

10 5 7/

10 5 7/

8

8

8

8

8

8

5 5/

5 5/

8 1/

8 1/

8 1/

8 1/

8

8

8

8

8

8

6 1/

6 1/

8 1/

8 1/

8 1/

8 1/

2

2

16

16

16

16

7 13/

7 13/

9 1/

9 1/

9 1/

9 1/

16

16

8

8

8

8

2 1/

2 1/

2 3/

2 3/

2 3/

2 3/

2

2

4

4

4

4

fantech

Page 4

4

WARNINGS

Do not connect power supply until fan is completely

installed. Make sure electrical service to the fan is

locked in “off” position.

1. Remove unit from packaging and inspect within 15

days after receipt. If damaged, report damage to

carrier. Do NOT operate this unit with visible

damage to the blower or impeller assembly

2. All products with A/C motors installed are

suitable for use with solid state speed control.

(example: RVF4, RVF4XL, RVF6, RVF6XL,

RVF8XL, RVF10, RVF10L, & RVF10XL).

3. All products with EC motors installed can be

speed controlled via 0-10V or PWM signal

(potentiometer provided)

4. This unit has rotating parts and safety

precautions should be exercised during

installation, operation and maintenance.

5. CAUTION: “For General Ventilation Use Only. Do

Not Use To Exhaust Hazardous Or Explosive

Materials and Vapors.”

6. WARNING! To reduce the risk of fire, electric

shock, or injury to persons- observe the following:

a. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

b. Before servicing or cleaning, switch power off at

the service panel and lock service panel to prevent

fan from being switched on accidentally.

c. Installation work and electrical wiring must be

done by qualified person(s) in accordance with all

applicable codes and standards, including firerated construction.

d. Sufficient air flow is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment

manufacturer’s guidelines and safety standards

such as those published by the National Fire

Protection Association (NFPA), the American

Society of Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE) and the local

code authorities.

e. When cutting or drilling into a wall or ceiling, do

not damage electrical wires or other hidden

utilities.

f. Ducted fans must always be vented to the

outdoors.

g. Install fan at least five feet above the floor.

h. NEVER place a switch where it can be reached

from a tub or shower.

7. WARNING! Check voltage at the fan to see if it

corresponds to the motor nameplate.

8. Guards must be installed when this fan is within

reach of personnel or within seven (7) feet of

working level or when deemed advisable for safety.

fantech

AVERTISSEMENTS

Ne pas brancher la source d'énergie avant que

l'installation du ventilateur soit complète. S'assurer

que le courant électrique au ventilateur soit

interrompue (en position "off")

1. Retirer l'appareil de l'emballage et inspecter dans

les 15 jours après la réception. Sìl est

endommagé, rapporter les dommages au

transporteur. Ne pas utiliser cet appareil avec des

dommages visible au ventilateur ou à l'ensemble

de rotor.

2. Tous les produits avec des moteurs AC installés

sont adaptés pour une utilisation avec commande

de vitesse à semi-conducteur.

3. La vitesse de tous les produits avec des moteurs

C.E installés peut être contrôlée via 0-10V ou

signal PWM

4. Cet appareil contient des pièces rotatives et des

précautions doivent être prises durant

l'installation, l'opération et l'entretien.

5. ATTENTION: "Pour ventilation générale seulement.

Ne pas utiliser pour l'évacuation de matériaux ou

de vapeurs dangereux ou explosifs.

6. AVERTISSEMENT! Afin de réduire les risque

d'incendie, de choc électrique ou de blessures

corporelles, observer ce que suit:

a. Utiliser seulement l'appareil tel que prévu par le

fabricant. Communiquer avec le manufacturier

pour toute question.

b. Avant de procéder à l'entretien ou au nettoyage

de l'appareil, interrompre le courant au panneau

central et refermer la porte pour ne pas que l'on

remette le courant de façon accidentelle.

c. Les travaux d'installation et de raccordement

électrique doivent être effectués par des

personnes qualifiées conformément aux codes et

normes applicables, y compris les codes de

protection contre les incendies.

d. L'apport d'air de combustion requis pour le

fonctionnement sécuritaire d'équipement à

combustion pourrait être affecté par le

fonctionnement de cet appareil. Respecter le

guide du fabricant pour équipement de chauffage

ainsi que les normes de sécurité telles que celles

qui sont publiées par la National Fire Protection

Association (NFPA), l'American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), ainsi que les autorités

locales.

e. En taillant ou en perforant les murs et les

plafonds, attention de ne pas endommager les fils

électriques ou autres appareils dissimulés.

f. Les ventilateurs à conduits doivent toujours être

ventilés vers l'extérieur.

g. Installer le ventilateur à au moins cinq pieds du

plancher.

h. NE JAMAIS installer un interrupteur où il pourrait

être accessible d'un bain ou d'une douche.

7. AVERTISSEMENT! Vérifier le voltage au ventilateur

afin de voir s'il correspond à l'indication sur la

plaque du moteur.

8. Des barrures de sécurité doivent être installés

lorsque le ventilateur sera accessible par du

personnel, s'il est situé dans un rayon d'au moins

sept pieds de l'aire de travail, ou lorsque

considéré nécessaire aux fins de sécurité.

ADVERTENCIAS

No conecta la alimentación eléctrica hasta tanto

quede el ventilador totalmente instalado. Compruebe

que la alimentación eléctrica del ventilador este

asegurada en la posición "off" (desactivado).

1. Remueva la unidad del empaque e inspecciónela

dentro de los 15 días de su recibo. Si está

dañada, reporte el daño al transportador. NO

opere esta unidad con daños visibles al conjunto

del ventilador o del impulsor.

2. Todos los productos con motores A/C instalados

son adecuados para su uso con control de

velocidad de estado sólido. (por ejemplo, RVF4,

RVF4XL, RVF6, RVF6XL, RVF8XL, RVF10,

RVF10L, & RVF10XL).

3. Todos los productos con motores EC instalados

pueden ser de velocidad controlada vía 0-10V o

señal PWM (potenciómetro provisto)2. Todas las

unidades son adecuadas para su uso con control

de velocidad de estado sólido

4. Esta unidad tiene piezas rotativas; se deben

tomar precauciones de seguridad durante la

instalación, operación y mantenimiento.

5. PRECAUCIÓN: "Sólo para Uso General de

Ventilación. No Utilizar para Extraer Materiales y

Vapores Peligrosos o Explosivos".

6. ADVERTENCIA! Para reducir el riesgo de incendio,

conmoción eléctrica o lesiones personales,

observe lo siguiente:

a. Sólo utilice esta unidad en al forma contemplada

por el fabricantes. Si tiene cualquier pregunta,

diríjase a la fábrica.

b. Antes de hacerle ningún mantenimiento o limpieza

a la unidad, desconecte la alimentación en el

tablero de control y ciérrelo con ilave para impedir

que se active accidentalmente.

c. Los trabajos de instalación y cableado deben ser

realizados por personal calificado conforme todos

los códigos y normas del caso incluso

construcción contra incendios.

d. Hay que proveer un caudal suficiente de aire para

la debida combustión y desalojo de gases a través

de la chimenea de los equipos quemadores de

combustible para evitar la contracorriente. Guíese

por las indicaciones y normas de seguridad del

fabricante, tales como las publicadas por la

National Fire Protection Association (NFPAAsociación Nacional de Incendios) y la American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE-Sociedad

Americana de Ingenieros de Calefacción,

Refrigeratión y Aire Acondicionado), así como las

autoridades competentes de la localidad.

e. Al cortar o perforar paredes y techos, tena

cuidado de no dañar el cableado eléctrico y demás

servicios ocultos.

f. Los ventiladores con conducto siempre deben

tener salida al exterior.

g. Instálese por lo menos a 152 cm por encima del

piso.

h. JAMAS coloque un interruptor donde pueda

alcanzarse desde una bañera o ducha.

7. ADVERTENCIA! Compruebe la tension de línea a la

entrada del ventilador, para verificar que

corresponda al voltaje de placa del motor.

8. Hay que instalar guardas donde quiera que se

instale el ventilador al alcance del personal, si se

encuentra a menos de 213 cm del piso de

trabajo, o bien cuando se considere necesario por

motivos de seguridad.

Page 5

5

Fan installation

5

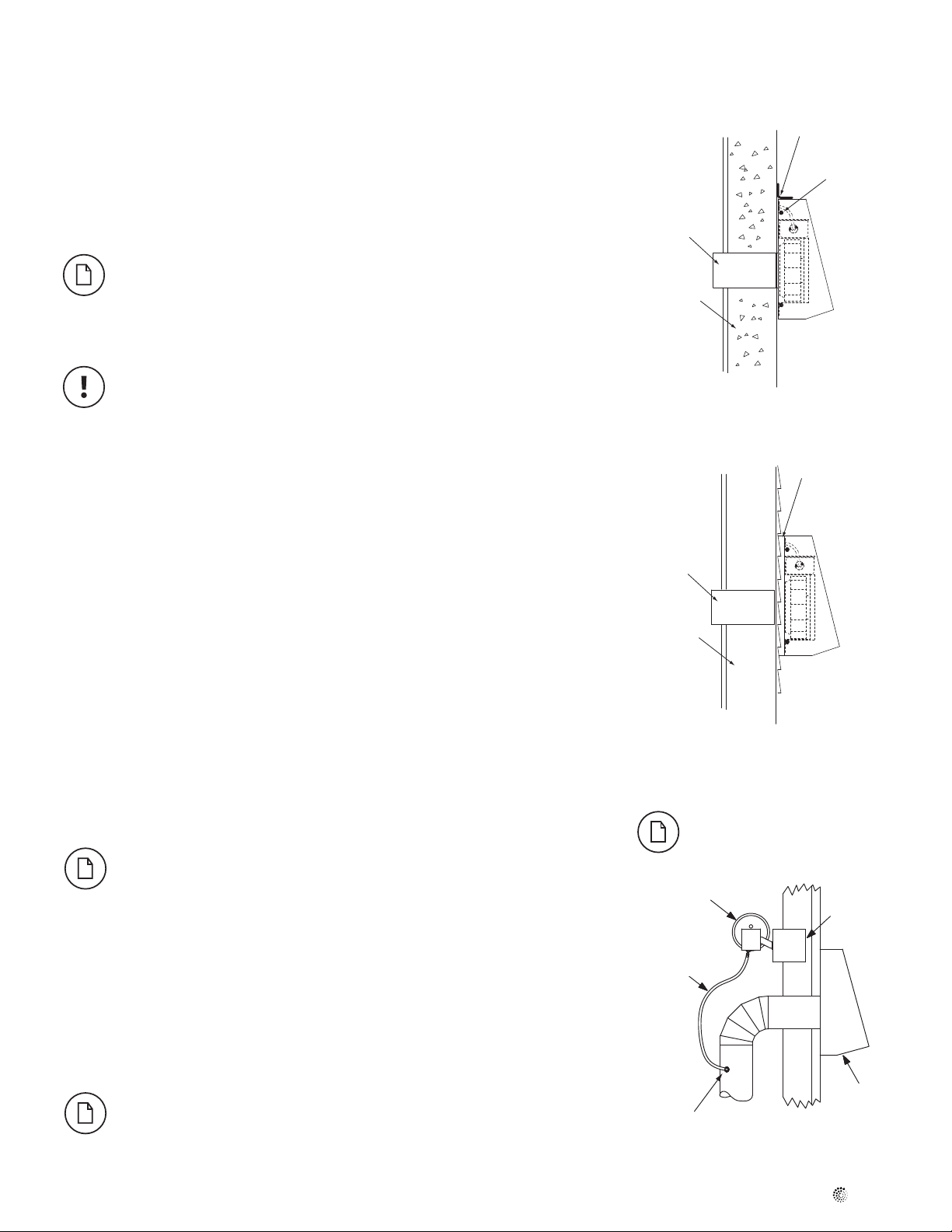

Step 1

When selecting the fan mounting location, the following criteria should be considered: a) type of

application; b) proximity to fresh air intakes; c) sound created by fan operation.

a) For dryer boosting applications, fan must be mounted a minimum of 12 linear feet from the

dryer outlet. If the fan is mounted closer than the recommended 12 feet, it will develop enough

pressure to pull wet lint through the duct system causing buildup on the impeller and clogging

of the vents in the discharge cover.

To prevent the possibility of fire hazards when using a booster fan in conjunction with a

gas fired dryer, booster fan flow must not exceed the dryer fan capacity. Typical

resident dryer fans produce 160 cfm.

For range venting applications, sufficient access for periodic cleaning of exhausted grease from

the wall and fan discharge cover should be provided.

In order to minimize operational noise, only the RVF4 should be used for direct,

through-the-wall, systems. The larger units (RVF4XL,RVF8XL) should only be used in

conjunction with ducted systems.

b) With any exhaust system, the fan should be located a minimum of 6 feet horizontally and 8 feet

vertically from any fresh air intakes for HVAC systems, heat recovery systems, etc. to prevent

re-entrainment of exhaust air streams. Windows that are frequently opened during moderate

seasons may also be considered fresh air intakes.

c) Although system noise at the point of exhaust will be virtually silent, windows and other

structural openings may be sources for noise entry during fan operation. Proximity to windows

and openings should be considered.

Select the location on the exterior wall where the fan is to be mounted. Make a hole through the

wall that is 1/2” larger than the diameter of the fan duct connection collar. A short piece of rigid

duct (not included) approximately 2” longer than the wall thickness is recommended for use as an

extension through the wall.

Extension Collar

through wall

Masonry Wall

Extension Collar

Lapped Siding

Wall

Optional Standard Fange

Discharge

Cover

Mounting

Screws

Figure 1

Mounting

Frame

Step 2

Remove the four screws securing the white fan discharge cover and remove the cover. Place the

fan against the wall, as centered as possible on the wall opening, then mark the location of the

four backplate mounting holes and the electrical knockout. Drill a hole for the electrical service

that is 1/8” larger than the size of conduit to be used. A 1” diameter electrical service opening is

provided on the fan backplate (see dimensional drawing on Page 1). When mounting the fan on a

masonry wall, drill 7/32” holes for the four anchors and mounting screws (provided). Tap the

anchors flush into the holes. When mounting the fan on a wood surface, wood screws should be

used.

If the fan is to be mounted on a wall surface which is Lapped Siding, a mounting frame

made from 1x1 board may be necessary for a flush fit (see I-2).

Step 3

Before mounting the fan, bring the electrical supply through the wall. Attach the extension collar

to the fan duct connection collar. The connection should be as air tight as possible to prevent

leakage from the wall cavity. Apply a generous amount of polyurethane caulk to the exterior side of

the fan housing backplate (except the bottom so that water that leaked in can drain back out).

This will ensure an airtight/waterproof connection between the fan and the wall surface. If a

mounting frame is used in conjunction with lapped siding, be certain to apply a generous amount

of caulk between the frame and the wall as well as the fan backplate and the frame. Mount the fan

to the wall.

Be certain to make an airtight seal around all interior wall penetrations before

attaching duct work.

Figure 2

For use with DB10 Pressure Switch

See DB10 Pressure Switch

installation manual for complete

installation instructions

DB10

Pressure Tube

Pressure tube inserted 1/4"

into drilled hole in dryer duct before elbow

tube must be sealed with grommet to

prevent leakage

Figure 3

Electrical Box

(Not included)

RVF4XL

Exterior Fan

fantech

Page 6

6

Wiring Instructions

Step 1.

Remove the screws securing the terminal box

cover plate. Depending on the model, the

wiring compartment is either located on the

motor mounting bracket (gure4) or will be

located out of the air stream on the back side

of the scroll (gure 5 & gure 6). The RVF

series is factory wired to the terminal block.

Except for the supply power installation, no

additional eld wiring is necessary.

Figure 4 – Models: RVF4, RVF4XL, RVF6, RVF6XL, RVF8XL

Wiring Compartment

Capacitor

Step 2.

A 3/8-inch romex cable clamp (not supplied) is

needed to secure the incoming power supply

to the exhaust fan (see illustration on gure

4, 5 & 6). Begin by installing the romex cable

clamp through either the electrical box (gure

4) or through the conduit hole as shown on

gure 5 & 6. Thread the nut on the connector

until rmly tight. Route the power supply cable

through the romex clamp. The eld wiring

locations are indicated below and are labeled

‘L’ for line voltage (black wire), ‘N’ for neutral

(white wire), and GND for ground (green wire).

Firmly secure each incoming wire to the proper

terminal post using a small at head screw

driver. CAUTION- maximum terminal block

screw torque is 7lb-in (0.79 Nm).

Step 3.

Secure the power cable by tightening the romex

clamp and replace the fan terminal box cover.

3/8 - inch romex wire clamp

Figure 5 – Models: RVF10, RVF10L, RVF10XL

Ground

115V

Supply

BROWN WIRE (CAP.)

BLACK WIREL

N

FIELD WIRE

GRD

Note: Capacitor wires are non-directional

GRD

L

FIELD WIRE

N

BLUE WIRE

GRN/YELLOW

(GROUND)

GRN/YELLOW

(GROUND)

BLUE WIRE

BLACK WIRE

fantech

BROWN WIRE (CAP.)

Note: Capacitor wires are non-directional

Page 7

Figure 6 – Models: RVF4XL-EC, RVF6XL-EC, RVF8XL-EC, RVF10-EC

0 10

7

BLUE (LOW

VOLTAGE - GND)

5

YEL (LOW

VOLATAGE 0 -10 V

RED (LOW

VOLTAGE +10V)

WHITE (LOW

VOLTAGE - TACH)

Alternate Control Options: Products Containing EC Motors

Connection to Building Management System

External Motor Speed Controller

Green

Black

White

GRD

L

FIELD WIRE

N

MTP10 - Potentiometer

Aux. switch 24V

1 2 3 4 5

U - Supply

GRN/YELLOW

(GROUND)

BLACK WIRE

BLUE WIRE

120V Supply

Figure 7

Red (+) 10VDC

Yellow

CTRL 0-10V/PWM

Control

Blue(-) GRD

White TACH OUT

Motor

Green

Black or Brown

BlueBlue

Power

Figure 8

Red (+) 10VDC

Yellow

CTRL 0-10V/PWM

Control

Blue(-) GRD

White TACH OUT

Motor

Green

Green

Black

White

Black or Brown

BlueBlue

Power

fantech

Page 8

8

For applications such as multi bathroom exhaust where multi location switching is desired, refer to gure 8 for proper wiring.

Neutral

(White)

115V Supply

Line

(Black)

Figure 9

SPST Switch

SPST Switch

SPST Switch

Motor

Troubleshooting

If fan fails to operate, please check the following:

1. Consult wiring diagrams (page four of these instructions) to insure proper connection.

2. Check motor lead wiring, capacitor leads and incoming supply leads to insure denite contact.

3. If possible, use a meter to test for continuity across the fan motor leads. In order to do this, the capacitor must be disconnected (do not test the

capacitor it will not meter continuity). If motor leads show continuity, consult manufacturer for a replacement capacitor.

Maintenance

1. Since fan bearings are sealed and provided with an internal lubricating material, no additional lubrication is necessary.

2. When using in a dryer boosting application, DISCONNECT POWER SUPPLY and check impeller periodically for lint buildup.

No other maintenance is necessary.

fantech

Page 9

Installation du ventilateur

9

Étape 1

Pour choisir l’emplacement du ventilateur, considérer les points suivants: a) le type d’application;

b) la proximité des sources d’air frais; c) la propagation du bruit.

a) Pour agir comme appoint d’une sécheuse, le ventilateur DOIT être installé à au moins 12 pieds

de la sortie de la sécheuse. Si le ventilateur est installé à moins des douze pieds

recommandés, il produira suffisamment de pression pour retirer la charpie à travers le

système de conduits causant ainsi une accumulation sur l’impulseur et l’obstruction des évents

dans le couvercle de la bouche d’évacuation.

Afin d’éviter tout danger d’incendie lors de l’utilisation d’un ventilateur d’appoint avec

une sécheuse à gaz, le débit du ventilateur d’appoint ne doit pas excéder la capacité du

ventilateur de la sécheuse. Les ventilateurs de sécheuses résidentielles produisent

habituellement 160 PCM.

Pour la ventilation d’une cuisinière, il convient de laisser suffisamment d’accès pour un nettoyage

périodique de la graisse sur le mur et sur le couvercle de la bouche d’évacuation.

Afin de minimiser le bruit d’opération, seul le RVF4 devrait être utilisé comme système

trans-mural direct. Les plus gros modèles (RVF4XL-RVF8XL) devraient seulement être

utilisés conjointement à des systèmes de conduits.

b) Avec tout système d’évacuation, le ventilateur devrait être situé à au moins six pieds

horizontalement et 8 pieds verticalement de toute entrée d’air frais pour systèmes HVAC, à

récupération de chaleur, etc. afin de prévenir la réintroduction de l’air évacué. Des fenêtres que

l’on ouvre souvent peuvent aussi être considérées comme des entrées d’air frais.

c) Quoique le bruit du système au point d’évacuation sera pratiquement nul. La proximité aux

fenêtres et autres ouvertures doit être prise en considération dans certains cas où la

conduction du bruit doit être nulle.

Choisir l’emplacement sur le mur extérieur où le ventilateur va être placé. Faire un trou dans le

mur d’un demi-pouce de plus que le diamètre du collet de raccord du conduit du ventilateur. Un

bout de conduit rigide (non-inclus) d’environ 2” supérieur à l’épaisseur du mur est recommandé

pour servir de rallonge à travers le mur.

Étape 2

Enlever les quatre vis qui retiennent le couvercle blanc de la bouche d’évacuation et enlever le

couvercle. Placer le ventilateur contre le mur en le centrant autant que possible sur l’ouverture du

mur, puis indiquer l’emplacement des quatre trous pour monter la plaque arrière, ainsi que le trou

d’entrée électrique (ELECTRICAL KNOCKOUT). Pour le service électrique, percer un trou de 1/8"

supérieur à la grosseur de fil utilisée. Une ouverture d'un pouce de diamètre est prévue sur la

plaque arrière du ventilateur pour le service électrique (voir le dessin dimensionnel à la page 1).

Lorsque le ventilateur est monté sur un mur en béton, perforer des ouvertures de 7/32" pour les

quatre ancrages et vis de montage (inclus). Enfoncez les ancrages complètement dans le trou.

Pour placer le ventilateur dans un mur en bois, utiliser des vis pour le bois.

Si le ventilateur doit être placé sur une surface où le revêtement est gradué, un cadre

en bois de 1"x1" pourrait s'avérer nécessaire pour assurer un ajustement uni. (voir

figure 2).

Étape 3

Avant de placer le ventilateur, introduire la source électrique dans le mur. Rattacher le collet de

rallonge au collet de raccord du conduit du ventilateur. Le raccord devrait être aussi hermétique

que possible afin d'éviter tout écoulement de la cavité murale. Appliquer une quantité considérable

de calfeutrage en polyuréthanne au côté extérieur de la plaque renfermant le ventilateur. Il y aura

ainsi une joint étanche entre le ventilateur et la surface murale. Si un cadre en bois est utilisé

conjointement avec du revêtement gradué, il faut s'assurer de bien calfeutrer l'endroit entre le

support et le mur, ainsi qu'entre la plaque arrière du ventilateur et le support. Placer le ventilateur

sur le mur.

S'assurer d'obtenir un scellement hermétique tout autour des ouvertures dans les

murs intérieurs avant de procéder à l'installation des conduits.

Bride standard en option

Vis de montage

Collet de

rallonge à

travers le mur

Mur en béton

Figure 1

Collet de

rallonge

Mur avec

revêtement

gradué

Figure 2

Pour ns d'utilisation avec le pressostat DB10

Voir manuel d'installation du

Pressostat DB10 pour les

instructions d'installation complètes.

DB10

Tube de pression

Tube de pression inséré 1/4po dans l'ouverture

percée dans le conduit de la sécheuse avant

le coude. Tube doit être scellé avec œillet an

d'éviter les fuites

Figure 3

de la bouche

d'évacuation

Cadre en bois

Ventilateur

extérieur

RVF4XL

fantech

Page 10

10

Instructions pour le raccordement

Étape 1:

Retirer les vis de xation de la plaque de

couvercle de la boîte à bornes. Selon le modèle,

le compartiment de câblage est soit situé

sur le support de montage du moteur (gure

4) ou se trouvera sur le ux d'air à l'arrière

de la spirale (gure 5 et gure 6). La série

RVF est câblé en usine au bornier. Sauf pour

l'installation d'alimentation en énergie, sans

câblage supplémentaire ne est nécessaire.

Figure 4 – Modèles: RVF4, RVF4XL, RVF6, RVF6XL, RVF8XL

Compartiment de raccordement

Condensateur

Étape 2.

Une pince à câble de 3/8 pouce romex

(non fourni) est nécessaire pour garantir

l'alimentation entrant au ventilateur

d'évacuation. (voir gure 4, 5 et 6).

Commencez par installer la pince à c^pable

romex soit par la boîte électrique (gure 4)

ou à travers le trou de conduit comme indiqué

sur la gure 5 et 6. Visser l'écrou sur le

connecteur jusqu'à fermement serré. Faites

passer le câble d'alimentation à travers la pince

romex. Les emplacements de câblage sont

indiqués ci-dessous et sont étiquetés «L» pour

la tension de ligne (l noir), «N» pour neutre (l

blanc) et GND pour la terre (l vert). Attachez

fermement chaque l entrant au poste terminal

appropriée en utilisant un petit tournevis à tête

plate. ATTENTION - maximum bornier couple

de vis est 7lb-in (0.79 Nm).

Étape 3.

Fixez le câble d'alimentation en serrant la

pince romex et replacez le couvercle de boîte à

bornes du ventilateur.

3/8 - pouce connecteur romex

Figure 5 – Modèles: RVF10, RVF10L, RVF10XL

115V

Fil neutre

Haute tension –

Côté de raccordement du moteur

Condensateur

BRUN (CAP.)

NOIRL

N

GRD

FIL DE CHAMP

Note: Les ls de condensateur sont non-directionnelle

GRD

L

FIL DE CHAMP

N

BLEU

VERT/JAUNE

(GROUND)

VERT/JAUNE

(GROUND)

BLEU

NOIR

fantech

BRUN (CAP.)

Compartiment de

raccordement

Note: Les ls de condensateur sont non-directionnelle

3/8 - pouce connecteur romex

Page 11

Figure 6 – Modèles: RVF4XL-EC, RVF6XL-EC, RVF8XL-EC, RVF10-EC

0 10

Basse tension –

Côté de raccordement du moteur

Haute tension –

Côté de raccordement du moteur

11

BLEU (BASSE

TENSION - GND)

5

JAUNE (BASSE

TENSION 0 -10 V

ROUGE (BASSE

TENSION +10V)

BLANC (BASSE

TENSION - TACH)

Compartiment de

raccordement

3/8 - pouce connecteur romex

FIL DE CHAMP

Autres option de contrôle: Les produit contenant un moteur EC

Connexion au système de gestion du bâtiment

Rédulateur de vitesse du moteur externe

Contact Auxiliaire 24V

Vert

Noir

Blanc

GRD

L

N

MTP10 - Potentiometer

1 2 3 4 5

U - Approvisionnement

VERT/JAUNE

(GROUND)

NOIRE

BLEU

120V Approvisionnement

Figure 7

Rouge (+) 10VDC

Jaune

CTRL 0-10V/PWM

Contrôle

Bleu(-) GRD

Blanc TACH OUT

Moteur

Vert

Noir ou Brun

Bleu

Pouvoir

Figure 8

Rouge (+) 10VDC

Jaune

CTRL 0-10V/PWM

Contrôle

Bleu(-) GRD

Blanc TACH OUT

Moteur

Vert

Vert

Noir

Blanc

Noir ou Brun

Bleu

Pouvoir

fantech

Page 12

12

Pour des applications telles l'évacuation de plusieurs salles de bain ou à avec interrupteur dans multiples emplacement est désirée, reportez-vous à la

gure 8 pour le raccordement approprié.

Neutre

(Blanc)

115V Approvisionnement

Ligne

(Noir)

Figure 9

Interrupteur SPST

Interrupteur SPST

Interrupteur SPST

Moteur

Dépannage

Si le ventilateur cesse de fonctionner, vérier ce que suit:

1. Consulter le diagramme de raccordement électrique inclus an d'assurer les bons raccords.

2. Pour assurer un contact approprié, vérier le l principal du moteur, les ls d'approvisionnement et les raccords du condensateur.

3. Si possible, utiliser un compteur pour vérier la continuité entre les ls conducteurs du ventilateur. Pour ce faire, le condensateur doit être

débranché (ne pas vérier le condensateur n'indiquera pas la continuité). Si les ls conducteurs indiquent la continuité, consulter le manufacturer/

distributeur pour un nouveau condensateur.

Entretien

1. Puisque les coussinets du ventilateur sont scellés et qu'ils comportent déjà un lubriant interne, aucune lubrication n'est nécessaire.

2. Pour utiliser comme appoint d'une sécheuse, DÉBRANCHER LE COURANT et vérier l'impulseur de façon périodique pour vérier sil y a

accumulation de charpie.

Aucun autre entretien n'est nécessaire.

fantech

Page 13

Instalacion del ventilador

13

Paso 1

Al seleccionar la ubicación del ventilador, se debe considerar lo siguiente: a) tipo de aplicación,

b) proximidad a entradas de aire fresco; c) el ruido del ventilador.

a)Para aumentar el rendimiento de una secadora, hay que montar el ventilador a un minimo de

366 cm de la salida de la secadora. De montarse más cerca, el ventilador levanta suficiente

presión para halar la hilacha húmeda a través del conducto, causando cúmulos en el impulsor y

atascando los respiraderos en la caperuza de descarga..

Aviso Importante: Para evitar el posible riesgo de incendio, si se trata de un ventilador

auxiliar para una secadora quemadora de gas, el caudal del ventilador auxiliar no

puede superar el des ventilador propio de la secadora. Los ventiladores típicos de

secadoras caseras mueven 4, 53 m3 de aire por minuto.

Para ventilación de cocinas se debe disponer un acceso adecuado para la limpieza periódica de

grasas en la pared y en la caperuza de descarga.

Para minimizar el ruido del funcionamiento, sólo se debe emplear el RVF-4 para

sistemas directos a través de la pared. Las unidades mayores (RVF-4XL-RVF8XL) sólo

deben instalarse en conductos.

b) En cualquier sistema extractor, el ventilador se debe situar por lo menos a 183cm de distancia

lateral y 244 cm de distancia vertical de cualquier toma de aire fresco de sistemas HVAC,

sistemas de recuperación de calor, etc., para impedir la reintroducción de aire extraído.

Cualquier ventana que se abra con frecuenia durante temporadas moderadas se pueden

considerar también como entradas de aire fresco.

c) Aucque el ruido propio del sistema a la salida es prácticamente silensioso, puede haber otras

fuentes de ruido a través de ventanas y otras aperturas estructurales que se escuchen

durante la operación del ventilador. Se debe tomar en consideración la proximidad a ventanas y

otras aperturas.

Seleccione el sitio en la pared exterior donde corresponde montar el ventilador. Abrale a la pared

un hueco que mida 12 mm más de diámetro que el collarín adaptador del ventilador al conducto.

Para la extensión a través de la pared recomendamos un tramo corto de conducto rígido (no

incluido) que tenga aproximadamente 50 mm más de longitud que el ancho de la pared.

Paso 2

Desenrosque los cuatro tornillos que sostienen la caperuza blanca de descarga del ventilador y

desmonte la caperuza. Coloque el ventilador contra la pared lo más centrado posible al hueco de

la pared, y marque la ubicación de los cuatro agujeros de montaje de la placa de soporte trasero

del ventilador, y del bocado pasacables. Perfore un agujero pasacables que mida 3mm más de

diámetro que el conducto a instalar. La placa de soporte trasero del ventilador incorpora una

abertura pasacables de 25 mm (ver el diagrama acotado en la Página 1). Al montar el ventilador

en una pared de mamposteriá, perfore agujeros de 5,5 mm para los cuatro tornillos con sus

tapones de encaje (suministrados). Inserte los tapones hasta donde queden al ras. Si se trata de

montar el ventilador en una superficie de madera, se deben usar tornillos tirafondo para madera.

Si hay que montar el ventilador en una pared de tablas solapadas en el exterior, tal vez

haya que construirie un marco de montaje con listones de 25x25 mm para que el

montaje quede asegurado (ver figura 2).

Paso 3

Antes de montar el ventilador, pase la acometida eléctrica a través de al pared. Fije el collarín de

extensión al collarín de conexión del ventilador al conducto. La conexión debe quedar lo más

hermética posible, a fin de evitar fugas desde la cavidad en la pared. Aplique una cantidad

sustancial de calafateo de poliuretano a la parte exterior de la placa de soporte del ventilador. De

esta manera se asegura una conexión hermética e impermeable entre el ventilador y la superficie

de la pared. Si se ha usado un marco adaptador de listones para acomodar el exterior solapado,

no deje de aplicar una cantidad sustancial de calafateo entre el marco y la pared así como entre

la placa de soporte del ventilador y el marco. Monte el ventilador en la pared.

Antes de conectar el conducto, asegúrese de que haya un sello hermético alrededor de

toda perforación de la pared interior.

Optional: Pestana estandar

Collarin de

extension a

través de la

pared

Pared

Figura 1

Collarin de

extension

Pared

recubieta de

traslapos

Figura 2

Para su uso con el interruptor de presión DB10

Ver la manual de instrucciones del

interruptor de presión DB10 para

las instrucciones completas de

instalación.

DB10

Tubo de presión

Tubo de presión añade 1/4" agujero perforrado en el

ducto de la secadora antes de codo. Tube debe ser

sellado con ojal para evitar refuas.

Figura 3

Tornillos de

montaje caeruza de

descarga

Soporte

adaptador

Caja eléctrica

(no incluido)

Ventilador

exterior

RVF4XL

fantech

Page 14

14

Instrucciones de cableado

Paso 1:

Remueva los tornillos que sujetan la tapa de

la caja terminal. Dependiendo del modelo, el

compartimiento del cableado está ubicado o en

el soporte de montaje del motor (gura 4) o

estará localizado fuera de la corriente de aire

en la parte posterior del desplazamiento (gura

5 y gura 6). La serie RVF viene alambrada

de fábrica al bloque terminal. Excepto para la

instalación del de suministro de energía, no es

necesario ningún cableado de campo adicional.

Figura 4 – Modelos: RVF4, RVF4XL, RVF6, RVF6XL, RVF8XL

Compartimiento de Cableado

Capacitor

Paso 2.

Una abrazadera de cable romex de 3/8

pulgadas (no incluida) es necesaria para

asegurar la alimentación entrante al ventilador

de escape (ver ilustración en guras 4, 5 y 6).

Comience instalando la abrazadera de cable

romex a través o de la caja eléctrica (gura

4) o a través del oricio del conducto como

se muestra en las guras 5 y 6. Enrosque

la tuerca al conector hasta que esté bien

apretada. Pase el cable de la fuente de

alimentación a través de la abrazadera romex.

Las ubicaciones de cableado de campo están

indicadas y etiquetadas a continuación. L para

línea de voltaje (cable negro). N para neutro

(cable blanco) y GND para tierra (cable verde).

Asegure rmemente cada cable entrante

al terminal apropiado utilizando un pequeño

destornillador cabeza plana. PRECAUCION

torsión del tonillo bloque terminal máxima es de

7lb (0.79 Nm)

Paso 3.

Paso 3. Asegure el cable de alimentación

apretando la abrazadera romex y reemplace la

tapa de la caja terminal del ventilador.

115V

MARRÓN (CAP.)

Abrazadera de cable romex de

3/8 pulgadas

Figure 5 – Modèles: RVF10, RVF10L, RVF10XL

Fil neutre

Alto voltaje –

lado de conexión del motor

Condensador

NEGROL

N

CAMPO

ALAMBRE DE

Nota: Alambres de condensador no son direccionales

ALAMBRE DE

GRD

GRD

L

CAMPO

N

AZUL

VERDE/AMARILLO

(GROUND)

VERDE/AMARILLO

(GROUND)

AZUL

NEGRO

MARRÓN (CAP.)

fantech

Compartimiento de

Cableado

Nota: Alambres de condensador no son direccionales

Abrazadera de cable romex de

3/8 pulgadas

Page 15

Figura 6 – Modelos: RVF4XL-EC, RVF6XL-EC, RVF8XL-EC, RVF10-EC

0 10

Bajo voltaje –

lado de conexión del motor

Alto voltaje –

lado de conexión del motor

15

AZUL (BAJO

VOLTAJE - GND)

5

AMARILLO (BAJO

VOLTAJE 0 -10 V

ROJO (BAJO

VOLTAJE +10V)

BLANCO (BAJO

VOLATJE- TACH)

GRD

Abrazadera de cable romex de

3/8 pulgadas

L

Abrazadera de cable romex de

3/8 pulgadas

ALAMBRE DE CAMPO

N

Suplentes Opciones de control: Productos que contienen la EC Motors

Conexión al Sistema de Gestión de Edicios

Controlador de Velocidad de Motor Externo

Potenciómetro – MTP10

Interruptor auxiliar 24V

1 2 3 4 5

Verde

Negro

Blanco

Suministro

U

VERDE/AMARILLO

(GROUND)

NEGRO

AZUL

120V Suministro

Figura 7

Rojo (+) 10VDC

Amarillo

CTRL 0-10V/PWM

Control

Azul(-) GRD

TACOMETRO HACIA

Motor

Verde

FUERA Blanco

Negro o marrón

Azul

Energía

Figura 8

Rojo (+) 10VDC

Amarillo

CTRL 0-10V/PWM

Control

Azul(-) GRD

TACOMETRO HACIA

Motor

Verde

Verde

FUERA Blanco

Negro

Blanco

Negro o marrón

Azul

Energía

fantech

Page 16

16

Para aplicaciones como multi extractor de baño donde se desea una conmutación de multi posición, reérase a la gura 8 para el cableado apropiado.

Neutro

(Blanco)

115V

Lignea

(Negro)

Figure 9

Conmutador SPST

Conmutador SPST

Motor

Análisi de Fallas

Si el ventilador deja de funcionar, favor comprobar lo siguiente:

1. Consulte los diagramas de cableadi (Página 4 de estas instruccuibes) para comprobar las conexiones correctas.

2. Para asegurar el buen contacto compruebe los cables del motor, la alimentación y las conexiones del capacitor.

3. Si es possible, use un ohmiómetro para comprobar la continuidad entre contactos del ventilador. Para ello, hay que desconectar el capacitor (no

trate de comprobar el capacitor: no indica continuidad). Si los cables del motor no indican falta de continuidad, pídale un capacitor de repuesto a la

fábrica.

Instrucciones de Mantenimiento

1. No hay necesidad de lubricación, ya que los rodamientos del ventilador están sellados y vienen cargados de lubricante.

2. Si el ventilador se emplea para reforzar la capacidad de una secadora, DESCONECTE LA ALIMENTACION ELECTRICA y revise el impulsor regularmente por si acumula hilacha.

No hace falta ningún otro mantenimiento.

fantech

Page 17

Warranty

Five (5) Year Warranty

This warranty supersedes all prior warranties

17

DURING ENTIRE WARRANTY PERIOD:

Fantech will repair or replace any part which has a factory defect in

workmanship or material. Product may need to be returned to the

Fantech factory, together with a copy of the bill of sale and identified

with RMA number.

FOR FACTORY RETURN YOU MUST:

• Have a Return Materials Authorization (RMA) number. This may be

obtained by calling Fantech either in the USA at 1.800.747.1762 or

in CANADA at 1.800.565.3548. Please have bill of sale available.

• The RMA number must be clearly written on the outside of the

carton, or the carton will be refused.

• All parts and/or product will be repaired/replaced and shipped back to

buyer; no credit will be issued.

OR

The Distributor may place an order for the warranty part and/or product

and is invoiced. The Distributor will receive a credit equal to the invoice

only after product is returned prepaid and verified to be defective.

FANTECH WARRANTY TERMS DO NOT PROVIDE FOR REPLACEMENT

WITHOUT CHARGE PRIOR TO INSPECTION FOR A DEFECT.

REPLACEMENTS ISSUED IN ADVANCE OF DEFECT INSPECTION ARE

INVOICED, AND CREDIT IS PENDING INSPECTION OF RETURNED

MATERIAL. DEFECTIVE MATERIAL RETURNED BY END USERS SHOULD

NOT BE REPLACED BY THE DISTRIBUTOR WITHOUT CHARGE TO THE

END USER, AS CREDIT TO DISTRIBUTOR’S ACCOUNT WILL BE

PENDING INSPECTION AND VERIFICATION OF ACTUAL DEFECT BY

FANTECH.

THE FOLLOWING WARRANTIES DO NOT APPLY:

• Damages from shipping, either concealed or visible. Claim must be

filed with freight company.

• Damages resulting from improper wiring or installation.

• Damages or failure caused by acts of God, or resulting from improper

consumer procedures, such as:

1. Improper maintenance

2. Misuse, abuse, abnormal use, or accident, and

3. Incorrect electrical voltage or current.

• Removal or any alteration made on the Fantech label control number

or date of manufacture.

• Any other warranty, expressed, implied or written, and to any

consequential or incidental damages, loss or property, revenues, or

profit, or costs of removal, installation or reinstallation, for any breach

of warranty.

WARRANTY VALIDATION

• The user must keep a copy of the bill of sale to verify purchase date.

• These warranties give you specific legal rights, and are subject to an

applicable consumer protection legislation. You may have additional

rights which vary from state to state.

Limitation of Warranty and Liability

This warranty does not apply to any Fantech product or part which has

failed as a result of faulty installation or abuse, incorrect electrical

connections or alterations made by others, or use under abnormal

operating conditions or misapplication of the product or parts. We will

not approve for payment any repair not made by us or our authorized

agent without prior written consent. The foregoing shall constitute our

sole and exclusive warranty and our sole exclusive liability, and is in lieu

of any other warranties, whether written, oral, implied or statutory.

There are no warranties which extend beyond the description on the

page hereof. In no event, whether as a result of breach of contract, or

Warning

Fantech products are designed and manufactured to provide reliable

performance, but they are not guaranteed to be 100% free from

defects. Even reliable products will experience occasional failures and

this possibility should be recognized by the user. If these products are

warranty or alleged negligence, defect incorrect advice or other causes,

shall Fantech be liable for special or consequential damages, including,

but not limited to, loss of profits or revenue, loss of use of equipment or

any other associated equipment, cost of capital, cost of substitute

equipment, facilities or services, downtime costs, or claims of

customers of purchase for such damages. Fantech neither assumes or

authorizes any person to assume for it any other liability in connection

with the sale of product(s) or part(s). Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages so the

above limitations and exclusions may not apply to you.

used in a life support ventilation system where failure could result in loss

or injury, the user should provide adequate backup ventilation,

supplementary natural ventilation, failure alarm system, or acknowledge

willingness to accept the risk of such loss or injury.

fantech

Page 18

18

Garantie

Garantie de 5 ans

Cette garantie remplace toutes les garanties précédentes.

DURANT TOUTE LA PÉRIODE DE GARANTIE:

Fantech s'engage à réparer ou à remplacer toute pièce présentant un

défaut d'usine en matière de qualité d'exécution ou de matériau. Il sera

peut être nécessaire de retourner le produit à l'usine Fantech, accompagné d'une copie du contrat de vente et du numéro d'autorisation de

retour.

POUR RETOURNER UN PRODUIT À L'USINE, VOUS DEVEZ:

• Obtenir un numéro d'autorisation de retour; pour ce faire, communiquer avec Fantech aux États-Unis au numéro 1.800.747.1762, ou au

Canada, au numéro 1.800.565.3548. Veuillez avoir votre contrat de

vente à portée de la main.

• S'assurer que le numéro d'autorisation de retour est lisible sur

l'extérieur de la boîte, sinon la boîte sera refusée.

• Toutes les pièces et/ou le produit seront réparés ou remplacés puis

retournés à l'acheteur. Aucun crédit ne sera accordé.

OU

Le Distributeur peut commander une pièce ou un produit couvert par la

garantie; la facture lui sera envoyée. Le distributeur ne sera crédité du

montant de sa facture qu'après que le produit a été retourné port payé

et qu'il a été trouvé défectueux.

LES TERMES DE LA GARANTIE DE Fantech NE PRÉVOIENT PAS DE

REMPLACEMENT SANS FRAIS AVANT QUE LA PIÈCE OU LE PRODUIT

DÉFECTUEUX AIT ÉTÉ INSPECTÉ. LES PRODUITS OU PIÈCES

REMPLACÉS AVANT L'INSPECTION DE LA DÉFECTUOSITÉ SERONT

FACTURÉS ET LE MONTANT DU CRÉDIT EST FONCTION DE

L'INSPECTION DE LA PIÈCE OU DU PRODUIT RETOURNÉ. LE

DISTRIBUTEUR NE DOIT PAS REMPLACER SANS FRAIS POUR

L'UTILISATEUR FINAL L'ÉQUIPEMENT DÉFECTUEUX RETOURNÉ PAR

L'UTILISATEUR FINAL, CAR LE COMPTE DU DISTRIBUTEUR NE SERA

CRÉDITÉ QU'APRÈS L'INSPECTION ET LA VÉRIFICATION PAR FANTECH

DE LA DÉFECTUOSITÉ.

LES GARANTIES NE S'APPLIQUENT PAS DANS LES CAS SUIVANTS:

• Dommages dus au transport (dissimulés ou visibles). Les

réclamations doivent être faites à la compagnie de fret.

• Dommages dus au mauvais câblage ou à l'installation inappropriée.

• Dommages ou défectuosité causés par une calamité naturelle ou

résultant d'une procédure irrégulière de l'acheteur, notamment :

1. Entretien irrégulier

2. Mauvais usage, usage abusif, usage anormal ou accident

3. Tension ou courant électrique incorrect

• Enlèvement ou toute modification du numéro de contrôle ou de la date

de fabrication de l'étiquette Fantech

• Toute autre garantie expresse, écrite ou implicite, pour les dommages

accidentels ou indirects, perte de biens, de recettes, manque à

gagner ou coûts relatifs à la dépose, à l'installation ou à la

réinstallation, en cas de violation de garantie.

CERTIFICATION DE LA GARANTIE:

• L'utilisateur doit conserver une copie du contrat de vente pour

confirmer la date d'achat.

• Les présentes garanties vous donnent des droits spécifiques reconnus

par la loi et sont régies par les lois sur la protection du

consommateur appropriées. Il est possible que différents états offrent

d'autres droits.

Limites de garanties et de responsabilités

Cette garantie ne s’applique à aucun produit de Fantech ou à aucune

pièce détachée dont la défectuosité relève d’une erreur d’installation ou

d’abus ou de mauvaise installation électrique ou dut à des modifications

extérieures ou utilisées dans des conditions anormales ou encore une

mauvaise installation du produit ou des pièces détachées. Nous

n’approuverons aucun remboursement pour des réparations qui ne sont

pas effectuées par un agent américain ou un agent autorisé sans un

accord écrit. Ce dernier constituera notre seule et exclusive garantie et

notre seule exclusive responsabilité et tient lieu de toute autre garantie

ou bien écrite ou orale implicite ou statuaire. Aucune garantie ne

s’appliquera au-delà des descriptions faites de la page ci-dessus. En

aucun cas, que ce soit pour une rupture de contrat ou de garanties ou

Avertissement

Les produits de Fantech sont conçus et fabriqués pour produire des

performances fiables, mais il n’y a aucune garantie qu’ils soient 100%

sans défaut. Les plus produits les plus fiables ont occasionnellement des

défectuosités et cette possibilité devraient être reconnu par les usagers.

Si ces produits sont utilisés comme une source de ventilation ou leur

fantech

des dommages dut à la négligence ou a des conseils incorrects ou

autres causes, Fantech ne pourra être tenu pour responsable des

dommages particuliers ou consécutifs, incluant mais pas limités aux

pertes et profits ou bénéfices perte de matériel ou autres matériels

associés. Coût du capital, coût des équipements de remplacement,

matériels ou services, coût de temps d’arrêt ou les réclamations des

clients pour de tels dommages. Fantech ne délègue ou autorise aucune

personne d’assumer sa responsabilité sur la vente du produit ou des

pièces détachées. Certaines juridictions ne permettent pas l’exclusion de

la limitation des dommages accidentels ou consécutifs ainsi ces

limitations ci-dessus et les exclusions ne s’appliquent pas à vous.

panne risque de mettre en danger des vies humaines ou entraîner des

blessures, les usagers devront avoir une source de ventilation de

secours en addition à une ventilation naturelle, le défaut de système

d’alarme ou la connaissance de ces conditions entraînent sa

responsabilité envers de telles pertes ou blessures.

Page 19

Garantia

Garantia de Cinco (5) Años

Esta garantia de sin efecto cualquier otra garantia anterior

19

DURANTE EL PERÍODO INTEGRO DE LA GARANTÍA:

Fantech reparará o reemplazará toda parte que presente un defecto en

el material o en la mano de obra. Es posible que el producto deba ser

devuelto a la fabrica Fantech, juntamente con una copia de la constancia

de compraventa e identificado con el número de RMA.

PARA DEVOLUCIÓN A FÁBRICA USTED DEBE:

• Tener un número de Autorización de Devolución de Material (RMA).

Esto se puede obtener llamando a Fantech ya sea en los Estados

Unidos al 1.800.747.1762

• en Canadá al 1.800.565.3548. Tenga a mano la constancia de

compraventa.

• El número de RMA deberá estar claramente escrito en la parte

exterior de la caja, de lo contrario la caja será rechazada.

• Todas las partes y/o el producto serán reparados/reemplazados y

devueltos al comprador; no se otorgará crédito.

O BIEN

El Distribuidor puede colocar una orden por la parte y/o producto en

garantía y facturarla/o. El Distribuidor recibirá un crédito igual a la

factura sólo después de que se haya devuelto el producto con pago

previo y con verificación de defecto.

LAS CONDICIONES DE LA GARANTÍA DE FANTECH NO CONTEMPLAN

EL REEMPLAZO SIN CARGO ANTES DE REALIZAR LA INSPECCIÓN

PARA DETECTAR DEFECTOS. LOS REEMPLAZOS EMITIDOS ANTES DE

INSPECCIONAR POR DEFECTOS SON FACTURADOS, Y EL CRÉDITO

ESTÁ A LA ESPERA DE INSPECCIÓN DEL MATERIAL DEVUELTO. EL

MATERIAL DEFECTUOSO DEVUELTO POR LOS USUARIOS FINALES NO

DEBERÁ SER REEMPLAZADO POR EL DISTRIBUIDOR SIN CARGO PARA

EL USUARIO FINAL, YA QUE EL CRÉDITO DE LA CUENTA DEL

DISTRIBUIDOR ESTARÁ A LA ESPERA DE INSPECCIÓN Y VERIFICACIÓN

DEL DEFECTO REAL POR FANTECH.

LAS SIGUIENTES GARANTÍAS NO SE APLICAN:

• Daños durante el envío, ya sean encubiertos o visibles. Se deberá

presentar el reclamo a la compañía transportadora.

• Daños ocasionados por cableado o instalación indebidos.

• Daños o fallas causados por hechos fortuitos, u ocasionados por

procedimientos impropios por parte del usuario, tales como:

1. Mantenimiento indebido

2. Uso indebido, abuso, uso anormal o accidente y

3. Tensión o corriente eléctrica incorrecta.

• Remoción o modificación realizada al número de control del rótulo de

Fantech o de la fecha de fabricación.

• Toda otra garantía, expresa, implícita o escrita, daños y perjuicios,

pérdida de propiedad, de ingresos, o de beneficios, o costo de

remoción, instalación o reinstalación por incumplimiento de la

garantía.

VALIDACIÓN DE LA GARANTÍA

• El usuario debe conservar una copia de la constancia de compraventa

para verificar la fecha de compra.

• Estas garantías le otorgan derechos legales específicos, y están

sujetas a una legislación aplicable para protección del consumidor.

Usted puede tener derechos adicionales que varían de estado en

estado.

Limitacion de Garantia y Responsabilidad Civil

Esta garantía no cubre ningún producto o pieza de Fantech que haya

fallado por mala instalación, abuso, conexión eléctrica incorrecta o por

alteraciones hechas por terceros, o por utilización bajo condiciones

anormales de operación, o por aplicación incorrecta del producto o de

las piezas. Nosotros no aprobamos el pago de ninguna reparación que

no se haya realizado por nosotros o por nuestro agente autorizado previo

consentimiento por escrito. Lo que antecede constituirá nuestra única y

exclusiva garantía y nuestra única y exclusiva responsabilidad; y obra en

lugar de cualquier otra garantía, ya sea escrita, verbal, tácita o

estatutaria. No hay ninguna garantía que vaya más allá de lo que está

descrito en esta página. Bajo ninguna circunstancia responderá Fantech,

ya sea por incumplimiento de contrato o garantía ni por alegada

Advertencia

Aunque los productos de Fantech están diseñados y son fabricados para

un rendimiento seguro, no garantizamos que estén libres de defectos al

100%. Hasta productos confiables a veces fallan; y el usuario debe

reconocer esta posibilidad. Si estos productos se utilizan en un sistema

negligencia, defecto, consejos incorrectos u otra causa, por daños

especiales o consiguientes, incluso, pero no de manera única, pérdida de

ganancias o ingresos, equipo cesante o cualquier otra pérdida relativa a

equipos asociados; el costo del capital, costo de equipos, instalaciones o

servicios sustitutos, tiempo ocioso o reclamos de clientes por compras

incurridas por tales daños. Fantech ni asume ni autoriza a ninguna

persona a que asuma a su nombre ninguna otra responsabilidad relativa

a la venta de productos o piezas. Debido a que algunos distritos

jurisdiccionales no permiten la exclusión o limitación por daños

incidentales o consiguientes, puede que las limitaciones y limitaciones

antes descritas no lo afe cten a Ud.

de ventilación vital en donde una falla pudiera dar lugar a pérdidas o

lesiones, el usuario debe disponer de una ventilación adecuada de

reserva, ventilación natural suplemental, sistema de alarma de fallas, o

expresar su voluntad de aceptar el riesgo de tales pérdidas o lesiones.

fantech

Page 20

fantech

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

Fantech®

Fantech se réserve le droit de faire des changements

techniques. Pour de la documentation à jour, s'il vous plaît se

référer au www.fantech.net

Fantech se reserva el derecho de hacer modicaciones

técnicas en cualquier momento. Para obtener la documentación actualizada, por favor consulte www.fantech.net

Loading...

Loading...