FANOX SIA C Series, SIAC116B1011AB Installation & Commissioning Manual

www.fanox.com SIAC116B1011AB_Rev. 05 1 / 32

ISO 9001:2008

INSTALLATION & COMMISSIONING GUIDE

SIA C

Self & Dual Power O/C &

E/F Protection Relay

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 2 / 32

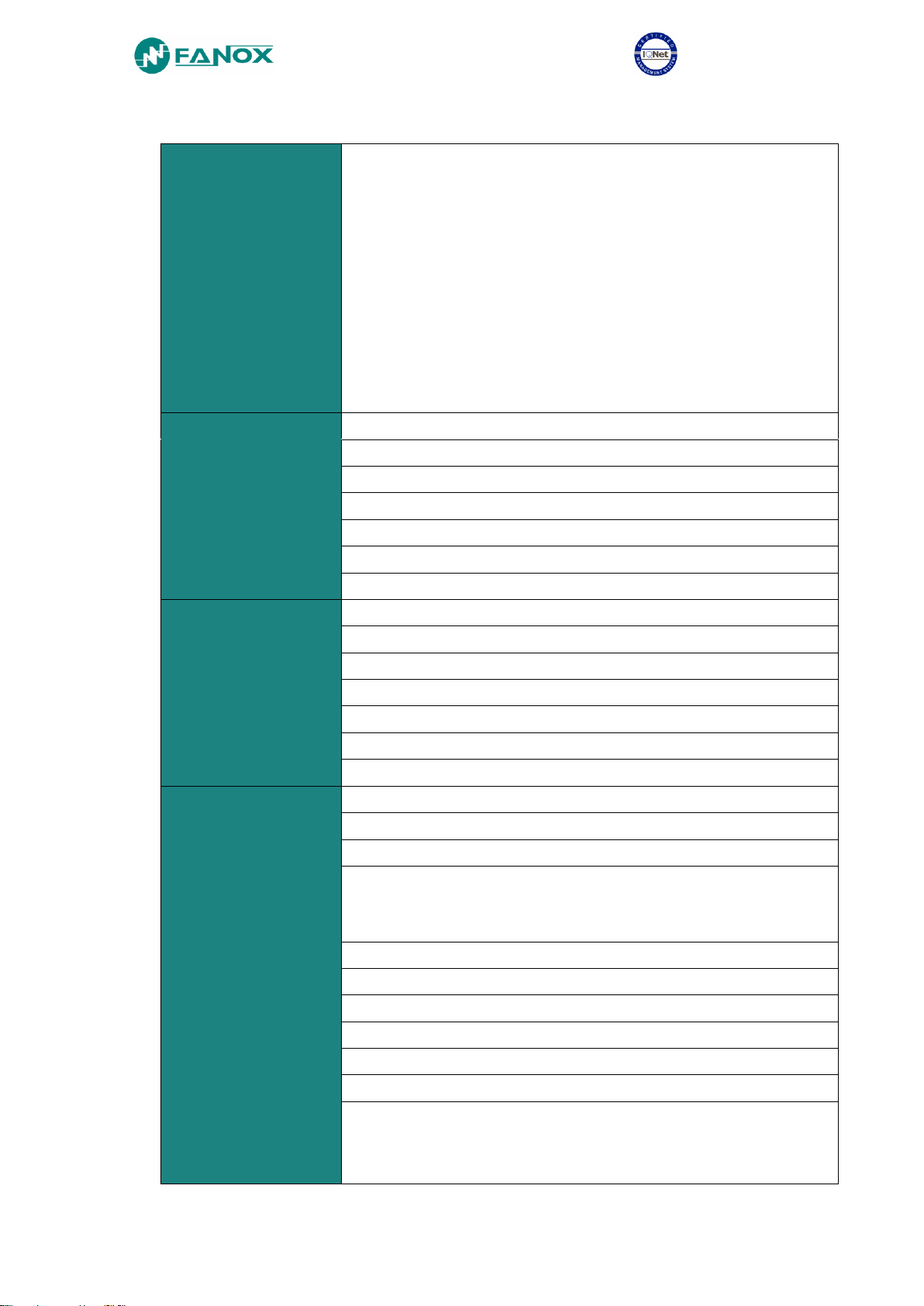

1. ...... RECEPTION & INSTALLATION ......................................................................................................... 3

1.1. Relay unpacking ........................................................................................................................... 3

1.2. Relay verification .......................................................................................................................... 3

1.3. Powering the relay up with kitcom .............................................................................................. 4

1.3.1. Keypad & LCD ........................................................................................................................... 5

1.3.2. Test menu .................................................................................................................................. 5

1.4. Relay installation .......................................................................................................................... 6

1.5. Relay rear part .............................................................................................................................. 7

1.6. Connection diagrams ................................................................................................................... 7

1.6.1. Connection diagram. Three phase CTs and solid neutral. ......................................................... 7

2. ...... USER INTERFACE ............................................................................................................................. 8

2.1. Relay front part ............................................................................................................................. 8

2.2. Bistable magnetic indicator (Flag) .............................................................................................. 8

2.3. LED indicators .............................................................................................................................. 8

2.4. How to install SICOM Software ................................................................................................... 8

2.5. Setting-up the session: Password and access levels ............................................................... 9

3. ...... FUNCTIONAL DIAGRAM ................................................................................................................... 9

4. ...... TECHNICAL SPECIFICATIONS ....................................................................................................... 10

4.1. IEC60255-151 Curves ................................................................................................................. 12

4.2. IEEE Curves ................................................................................................................................ 13

5. ...... OPENING MECHANISM ................................................................................................................... 14

6. ...... PROGRAMMABLE LOGIC CONTROL ............................................................................................ 15

7. ...... FLOWCHART ................................................................................................................................... 16

7.1. Test menu .................................................................................................................................... 16

7.2. Direct Access .............................................................................................................................. 17

7.3. Menus .......................................................................................................................................... 18

7.3.1. Measurements menu ............................................................................................................... 18

7.3.2. States menu ............................................................................................................................. 19

7.3.3. Settings menu .......................................................................................................................... 19

7.3.4. Events menu ............................................................................................................................ 22

7.3.5. Demand menu ......................................................................................................................... 23

7.3.6. Fault reports menu ................................................................................................................... 23

8. ...... COMMISIONING ............................................................................................................................... 24

8.1. Thermal resistance ................................................................ ..................................................... 24

8.2. Self powering .............................................................................................................................. 26

8.2.1. Single phase minimum self-powering checking ....................................................................... 26

8.2.2. Three phase minimum self-powering checking ........................................................................ 26

8.2.3. Verification of Leds/Signalling Outputs/LCD in self-powering conditions ................................. 26

8.3. Measurements ............................................................................................................................ 27

8.4. Protection functions ................................................................................................................... 27

8.4.1. Protection functions testing ...................................................................................................... 27

9. ...... SIAC116B1011AB REGISTRY ......................................................................................................... 30

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 3 / 32

1. RECEPTION & INSTALLATION

1.1. Relay unpacking

Previously to any handling action, confirm that relay carton box is in good conditions, no

broken or damaged due to external manipulation or during storing or moving process. If

packing is correct, proceed to unpack and you should find following element:

• SIAC Electronic protection relay.

• User Guide.

• Testing protocol.

Testing protocol is a certificate that relay has passed all factory testing process with

correct results.

In case some fault is detected, consider to put into quarantine period the relay and contact

Fanox for further instructions.

1.2. Relay verification

When relay is unpacked, please, take your time to confirm following checking list to be

sure that everything is ok:

• Metallic case not damaged and well assembled. No loose screws due to transport or

movement conditions

• LCD and front cover not damaged or scratched.

• Quality sticker and terminal sticker correctly stuck.

• Rear terminals in good state, being able to do a good wiring connection.

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 4 / 32

1.3. Powering the relay up with kitcom

Thanks to the external battery KITCOM the powering and adjusting process of the relay is

very easy and it allows the user to test the relay.

The power comes from two AA batteries (IEC LR06) of 1.5 Volts placed at the bottom of

the kitcom. The equipment has a small Dc/Dc power supply that raises the voltage till the

required 12 volts to operate the equipment and that is plugged into the front RS232

communications port (KITCOM).

Once the KITCom is connected, the relay will be switched on and a led on the right of the

relay (led battery) will blink indicating the relay is powered on through an external battery

(KITCOM).

The relay is totally maintenance free. This is, there is no need of batteries to log events

and fault reports and there is no need of batteries to maintain date and time.

NOTE: Date and time must be correctly set the first time the relay is operative and

energy must be kept at least “1 hour” to maintain the RTC for 72 hours once the energy is

lost.

Besides, the possibility of using external battery power, together with the possibility of

activating the trip contact from the test menu, allows the trip circuit to be tested before the

transformation center is powered up. So, it is clear the KITCOM useful for cases like

commissioning operations, discharges and repairs to the transformation center.

Using battery power does not block the RS232 communications port, as it can be used

simultaneously.

Once the relay is poowerd through the Kitcom, it should be checked:

• Model →Directly, complete model on top line and phases/neutral current measurement

on bottom line are displayed. Once “C” key is pressed the the name of phase and neutral

currents (instead the complete model) is displayed on the top of LCD Standby screen.

• Serial Number → In “General Settings” menu serial number of 8 digits can be checked

(OK - ▼ - ▼ - ◄ - ▼ - ▼)

• Firmware Version → In “Firmware Version” menu (HOLD ▲)

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 5 / 32

1.3.1. Keypad & LCD

• Use the KEYPAD, ensure that all the push-buttons work correctly (no difficulties while

pushing them, check out if the relay reacts by pushing each of the buttons).

• Use the KEYPAD to enter in the relay´s menu and make sure that no text is lost while

going from one menu to another.

• Follow the sequence: Left ◄, Down ▼, Right ►, Up ▲, OK, C and RESET and the

following screen should be displayed:

• If the contrast of the LCD is not the correct one, enter to “CONTRAST” menu by holding

“◄“ for 3 seconds. Then, change it by using up or down buttons to increase or

decrease the contrast.

1.3.2. Test menu

NOTE: When performing test menu, protection won´t be available and it will possible to

open circuit breaker. Only authorized personnel can do this job.

Press ◄,▼,► sequentially and hold OK. The relay will ask for the password “5555” to

enter to the test menu (or customer password if default “5555” has been modified).

It will be checked that the LEDs, Magnetic indicator flags and Outputs are activated if OK

key is pressed and it will be deactivated if OK key is pressed again. LEDs, Magnetic

indicator and outputs will be checked to verify the hardware is OK:

Action

Checking

OK, OK

Led 1

Led Vaux activated

▼, OK

Led 2

Led Self power activated

▼, OK

Led 3

Led Battery activated

▼, OK

Trip output

Trip output activated

▼, OK

Output 2

Output 2 activated

▼, OK

Output 3

Output 3 activated

▼, OK

Trip

Trip bistable activated

C

Skip from test menu

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 6 / 32

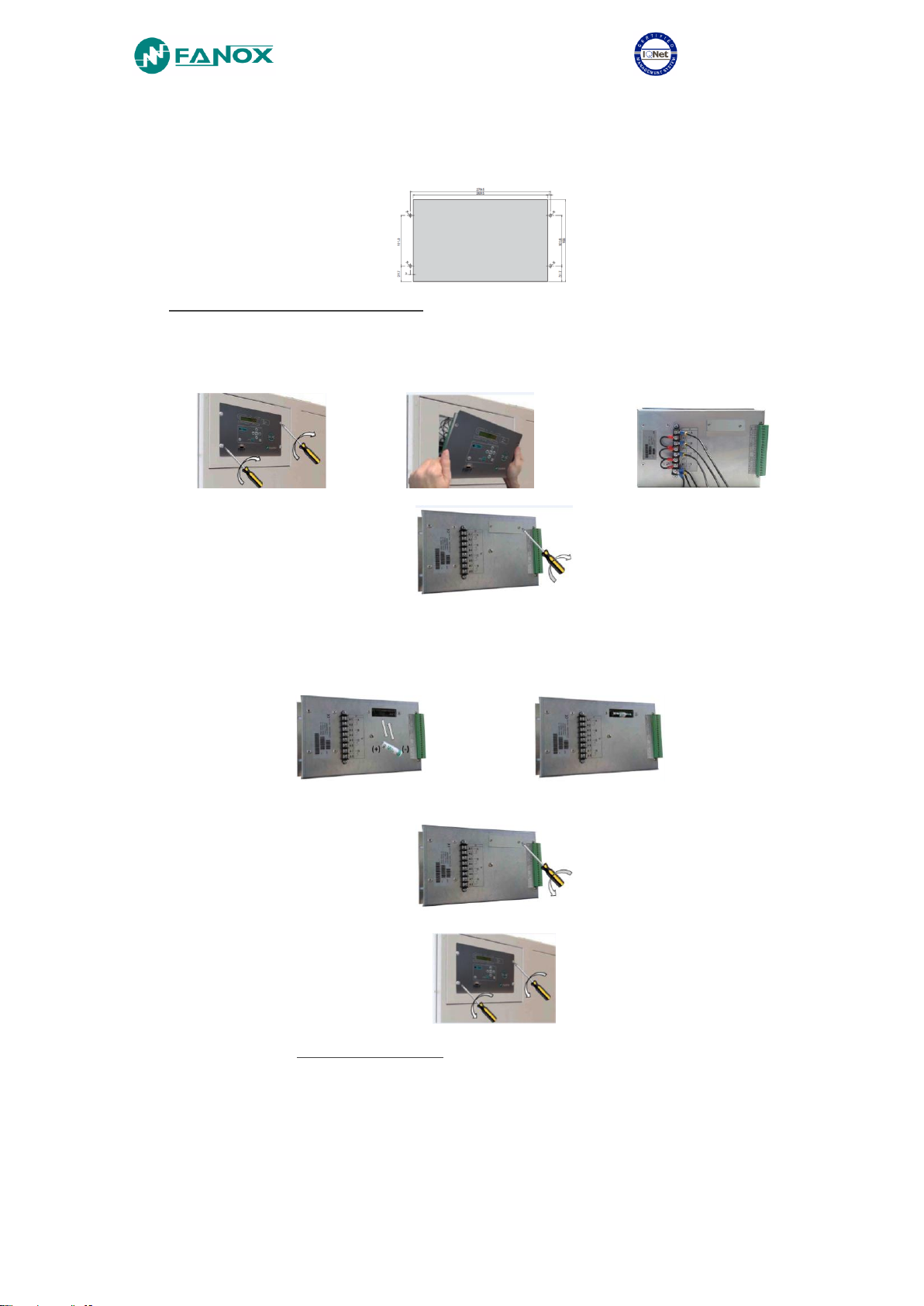

1.4. Relay installation

To fix the relay to the switchgear, use default holes in front of relay with appropriate fixing

system. Do not manipulate relay to fix it on the switchgear.

How to change the internal battery

1. Disconnect the relay. Switch the power supply off to avoid any dangerous situation.

2. Unscrew the 4 screws on the front of the relay to extract it from the RMU and access to

the rear side of the relay.

3. Unscrew the 2 screws to remove the cover from the battery compartment.

4. Remove the battery and replace it respecting polarity (+ facing up):

Battery characteristics:

o AA 3.6V lithium battery

o Model LS14500 from SAFT

o Do not use rechargeable batteries or other types of battery

5. Put on the battery cover and tighten the 2 screws.

6. Put the relay into the RMU again and tighten the 4 screws on the front to fix the relay.

Warning: HAZARD OF EXPLOSION

• Do not recharge the battery.

• Do not short circuit the battery.

• Do not crush the battery.

• Do not disassemble the battery.

• Do not heat the battery above 100ºC (212ºF)

• Do not throw the battery into fire or water.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 7 / 32

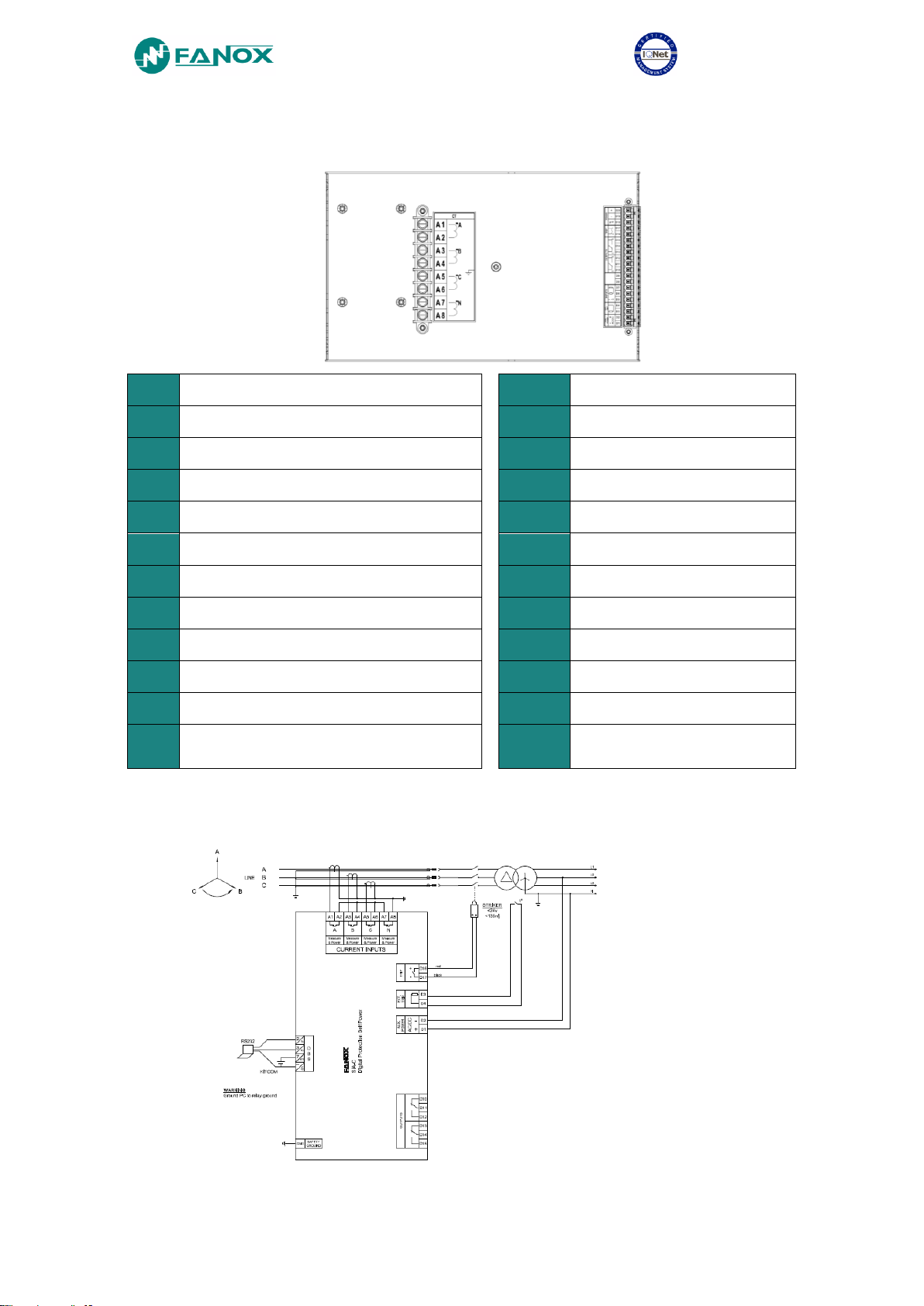

1.5. Relay rear part

Consider the wiring of the switchgear and connect relay properly:

A1

Phase A current input for measurement & power supply

D10

Digital output 1 NC

A2

Phase A current output for measurement & power supply

D11

Digital 1 common output

A3

Phase B current input for measurement & power supply

D12

Digital output 1 NA

A4

Phase B current output for measurement & power supply

D13

Digital output 2 NC

A5

Phase C current input for measurement & power supply

D14

Digital 2 common output

A6

Phase C current output for measurement & power supply

D15

Digital output 2 NA

A7

Neutral current input for measurement & power supply

D16

Trip output positive

A8

Neutral current output for measurement & power supply

D17

Trip output gnd

D1

Auxiliary Voltage -

D18

RS485 gnd (N/A)

D2

Auxiliary Voltage +

D19

RS485 – (N/A)

D3-D4

External trip

D20

RS485 + (N/A)

D5-D6-

D7

Inputs (N/A)

╧ Earthing screw

1.6. Connection diagrams

1.6.1. Connection diagram. Three phase CTs and solid neutral.

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 8 / 32

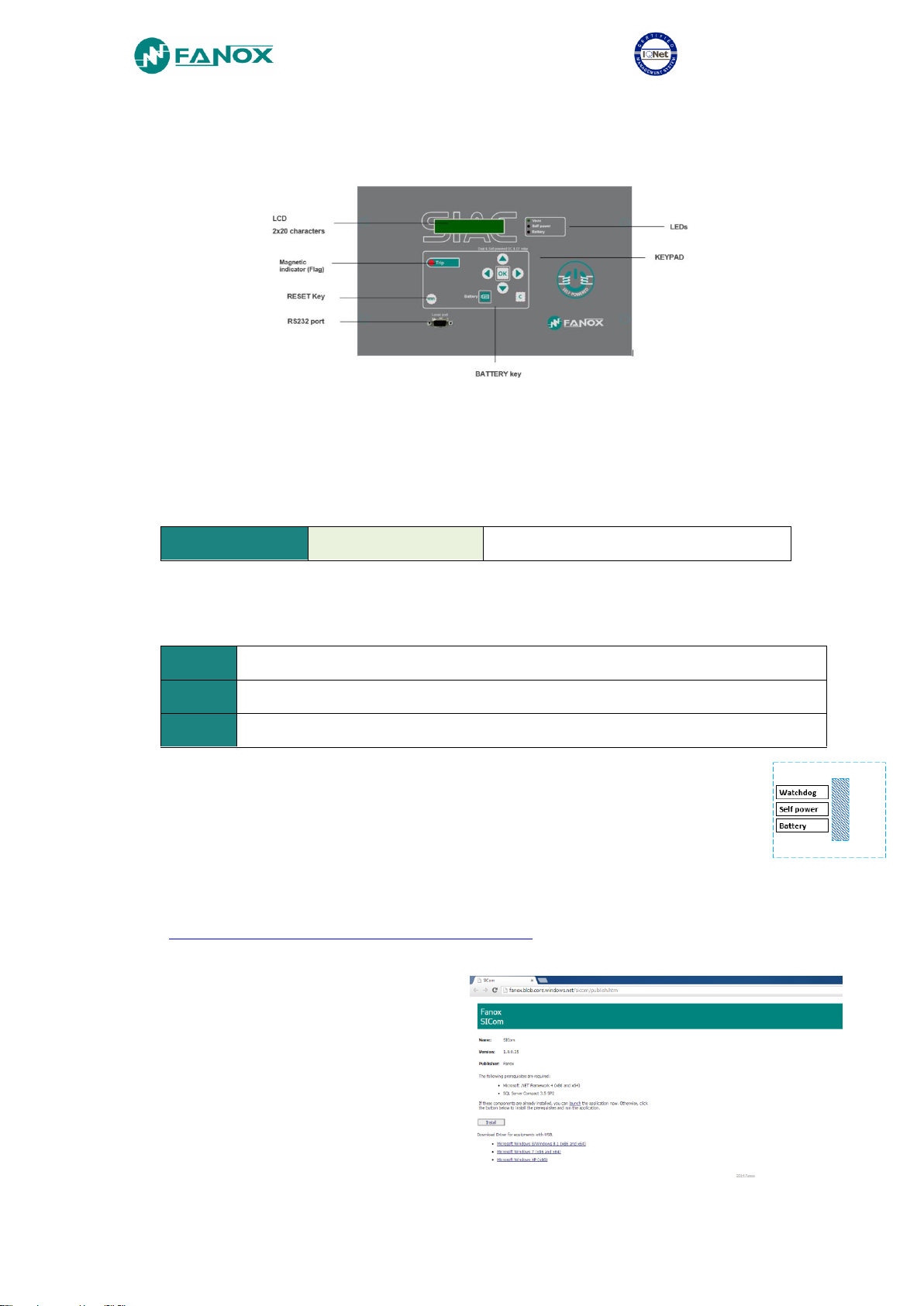

2. USER INTERFACE

2.1. Relay front part

2.2. Bistable magnetic indicator (Flag)

The front panel is equipped with 1 bistable magnetic indicator which indicates the general

trip. The indicator remains in position even when the equipment loses power, so that the

maintenance service can see the trip even through the equipment is not powered.

Once it has been activated, it is necessary to manually reset it by pressing the “RESET”

button. The operation of the magnetic indicator can be checked from the test menu.

1 bistable

Magnetic Indicator “trip”

There is a general trip without indicating the reason.

2.3. LED indicators

The SIA-C front panel has three configurable LEDs. By default, they show: auxiliary

power, self-power or battery.

LED 1

Auxiliary power: Activated (LED blinking) if it detects the auxiliary voltage

LED 2

Self power: Activated (LED blinking) if it detects the self-power current

LED 3

Battery: Activated (LED blinking) if it detects voltage from an external battery

More than one type of power can be used simultaneously, and more than one LED

can be activated as a result. The operation of the LED indicators can be checked

from the test menu.

The user can change the configuration of the LEDs depending on its requirements

and the labels for the LEDs can also be adapted.

2.4. How to install SICOM Software

To install the SICom it is necessary the following link:

http://fanox.blob.core.windows.net/sicom/publish.htm

The link will open the next screen, where key “install” must be pressed:

The necessary drivers depending on

the operative system can be

downloaded from this page. The

update of the software does not

require any user´s action, this is, if

the computer is connected to

Internet, SICom updates itself when

it is started.

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 9 / 32

2.5. Setting-up the session: Password and access levels

Users must identify themselves with a password in order to start communications and to

change the equipment settings or configuration using the HMI. Depending on the access

level, it may or may not be possible to perform the operations shown on the table below.

ACCESS LEVEL

Read-only

permission:

Status and

measurements

Settings

Events

Permission to:

Change settings

Download and Delete

the Events buffer

Permission to:

Execute

Commands

Permission to:

Change Configuration

Permission to Change

Protected Settings

1

YES

YES

NO

NO

YES

2

YES

YES

NO

NO

NO

3

YES

NO

YES

NO

NO

4

YES

YES

YES

NO

NO

5

YES

YES

YES

YES

NO

Four passwords and their associated levels of access are set up when the equipment is

configured using the SIcom program. By default, the equipment is programmed with the

following passwords and their associated levels:

PASSWORD

ACCESS LEVEL

2222

2

3333 3 4444 4 5555

5

3. FUNCTIONAL DIAGRAM

ISO 9001:2008

www.fanox.com SIAC116B1011AB_Rev. 05 10 / 32

4. TECHNICAL SPECIFICATIONS

Complete model

SIAC116B1011AB:

1: Phase measurement→In = 1 A; (0,10 – 30,00 A)

1: Neutral measurement→ In = 1 A; (0,10 – 30,00 A)

6: Net frequency→60 Hz

B: Power supply→Self powered + 230 Vac (Dual) + Commissioning battery

1: Additional functions→striker and external trip (49T)

0: Communications→Local ModBus port (RS 232)

1: Inputs-Outputs→2 outputs to signaling

1: Memory→Non-volatile RAM memory

A: Language→English, Spanish, and German

B: Mechanic→ Horizontal, 1 Flag

Function 50

Permission: yes/no

Operating range: 0.10 to 30 x In (step 0.01 x In)

Operating time: 0.02 to 300 s (step 0.01 s)

Activation level 100%

Deactivation level 95%

Instantaneous deactivation

Timing accuracy: ± 20 ms or ± 0.5% (whichever is greater)

Function 50N/G

Permission: yes/no

Operating range: 0.10 to 30 x In (step 0.01 x In)

Operating time: 0.02 to 300 s (step 0.01 s)

Activation level 100%

Deactivation level 95%

Instantaneous deactivation

Timing accuracy: ± 20 ms or ± 0.5% (whichever is greater)

Function 50/51

Permission: yes/no

Operating range: 0.10 to 7 x In (step 0.01 x In)

Curves: IEC 60255-151 and IEEE

Operating time: IEC Inverse curve, IEC very inverse curve, IEC extremely inverse curve

IEC long time inverse, IEEE Inverse curve, IEEE very inverse curve, IEEE extremely

inverse curve.

Defined time: 0.02 to 300 s (step 0.01 s)

Dial: 0.02 to 1.25 (step 0.01)

Curve, activation level 110%

Curve, deactivation level 100%

Defined time, activation level 100%

Defined time, deactivation level 95%

Instantaneous deactivation

Timing accuracy: ± 5% or ±30 ms (whichever is greater) when the protection works with

inverse time and ± 20 ms or ± 0.5% (whichever is greater) when it works with definite

time

Loading...

Loading...