Page 1

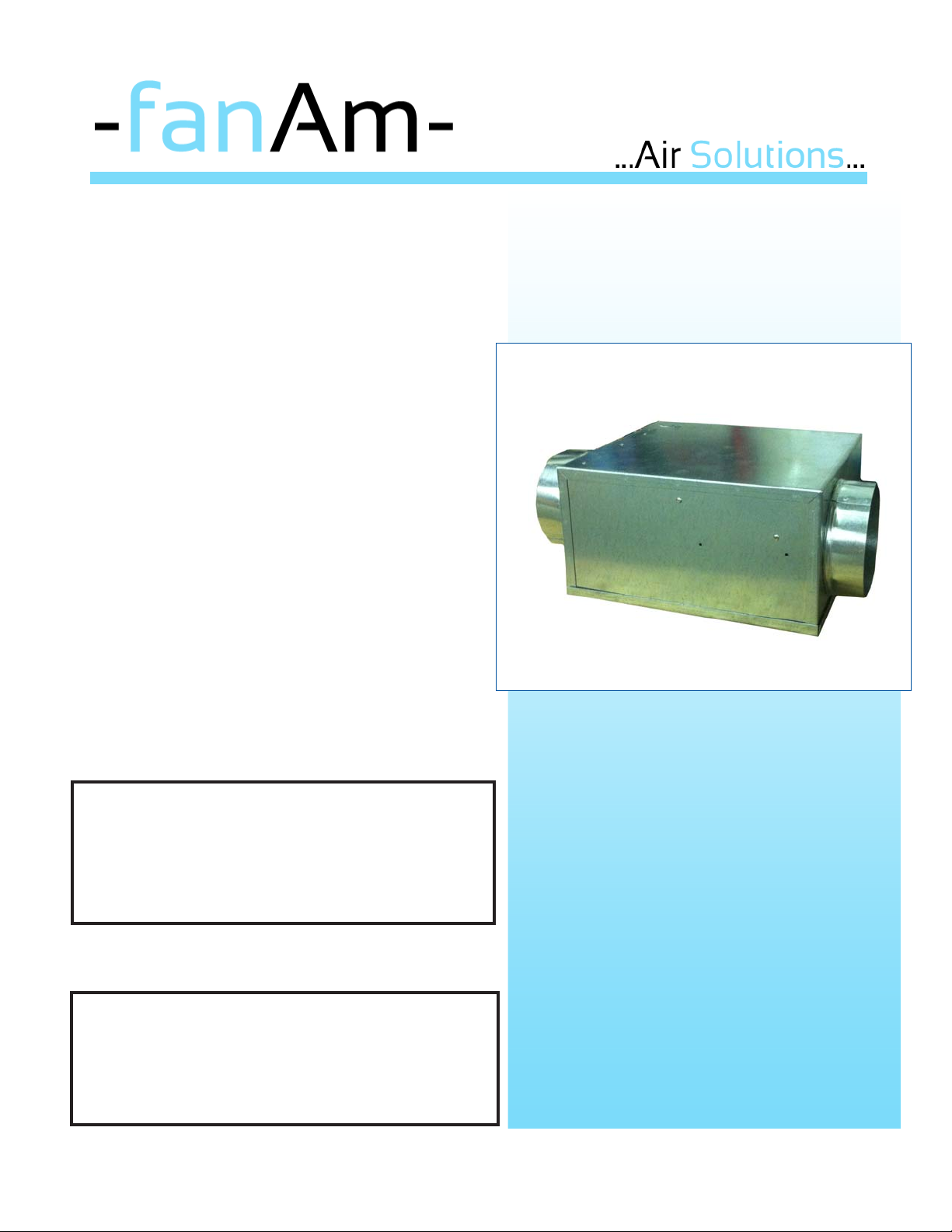

DQC Series Inline Fans

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation

and maintenance procedures for standard units of

the DQC Series Fans

Carefully read this publication prior to installation.

Receiving and Inspection

Carefully inspect the fan and accessories for any

damage and shortage immediately upon receipt of the

fan.

• Turn the wheel by hand to ensure it turns freely and

does not bind.

• Inspect dampers (if included) for free operation of all

moving parts.

• Remove shipping tape.

• Record on the Delivery Receipt any visible sign of

damage.

Handling

Lift fan by the outside housing (box) or by the blower

mounting brace.

Storage

If the fan is stored for any length of time prior to

installation, store it in its original shipping crate and

protect it from dust, debris and weather.

Low Profile DQC-Series

Removable Bottom Access

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

ALWAYS disconnect power prior to working on fan.

PERSONAL SAFETY

Disconnect switches are recommended. Place the

disconnect switch near the fan in order that the

power can be swiftly cut off in case of an emergency,

and in order that maintenance personnel are provided

complete control of the power

Page 2

Installation

Motor Installation

All DQC units are shipped with motors mounted at

the factory.

Fan Installation

1. DQC Series fans are compact, versatile and may

be mounted in any position. The recommended

mounting location of the fan is a minimum of 15

linear feet from the dryer exhaust port in order to

avoid moist or wet lint to gather in the fan. If a

lint trap is being used between the fan and the

dryer, the fan can be mounted closer than the

recommended 15 feet. The DQC fan warranty is

increased from three(3) to five(5) years if F anAm’s

2100 Series lint trap is used in conjuction with the

fan.

2. Because this unit has rotating parts, safety

precautions should be excercised during

installation, operation and maintenance procedures.

3. WARNING! Unless specifically built for hazardous

environments, do not use the fans where the electrical system could ignite combustible or flammable

material.

4. Remove unit from package and inspect within 15

days after receipt. If damaged, report damage to

carrier . Do NO T operate this unit with visible damage

to the blower or impeller assembly . Turn centrifugal

impeller by hand to assure free rotation.

5. CAUTION: Before proceeding with installation, make

sure there is no electrical connection. All wiring should

be in accordance with local ordinances and the

National Electric Code.

WARNING: Check voltage to the fan to assure it

corresponds with the motor name plate.

6. CAUTION: Always vent this unit to the outside,

NOT into spaces within ceilings or walls, attics, crawl

spaces, garages, etc.

7. Keep drywall spray, construction dust, etc., off

and out of the impeller assembly to avoid motor bearing damage, noise, or unbalanced impellers.

DQC

Page 3

Detailed Installation Instructions

P

120 VA C

All dimensions in inches

12

1. Provide a solid frame against which the unit will

be mounted (see dimensional data for proper frame

sizing). Make sure that the housing will be flush with

the finished ceiling, once the unit has been fixed into

the frame.

2. Bend mounting bracket and fasten it in desired

location in the ceiling.

3. Mount brackets with self-drilling tap screws in

desired position on the unit housing. Fan mounting

brackets are adjustable vertically on the fan housing.

4. Hang unit. Tighten mounting screws as firmly as possible to assure secure support and lowest possible

sound levels. Note: A secure solid frame will also help

sound levels to remain at a minimal.

11

5

Inlet

Wiring Diagrams

Using Current Sensor

Outlet

6.5

NEUTRAL/WHITE

4 7/8

5. Wire unit.

Turn power off at circuit breaker or fuse panel

a) Remove desired knockout and open fan

terminal box from inside the fan.

Connect incoming electric supply per wiring

diagram.

b) Use appropriate electrical connector and strain

relief to secure the incoming electric cable.

6. Connect ductwork to the collars 4 and 5 inch.

Tape joints with duct tape.

7.Reattach lid with screws.

COMPAX FAN

OWER TO DRYER

DRYER JUNCTION BOX

Hot (Black lead)

L1

120 VAC

Supply Voltage

Neutral (White lead)

Neutral (white lead) from dryer

N1

L2

N2

CURRENT

SENSOR

WITH TIMER

Hot (Gray lead)

Supply

Voltage

For Fan

Neutral (White lead)

Page 4

Wiring Diagrams cont.

SPECIAL WIRING PRECAUTIONS

All installations should be wired according to the following diagrams.

Failure to comply will cause the motor to “hum” or not work.

1. Turn off power at service entrance before wiring this fan.

2. Read the fan serial number to determine the current draw. Check

that available supply is suitable.

3. Be certain to use proper connector type for securing conduit cable.

4. Connect electrical supply per diagrams supplied here.

Troubleshooting

1. If fan fails to operate, please check the following:

a) Fan has power.

b) Consult wiring diagrams included to assure proper connection.

c) To assure proper contact, check motor lead wiring, incoming supply wiring and capacitor connections.

d) If possible, use a meter to test for continuity between fan leads. Please note that capacitor will show no

reading if tested with meter.

2. If fan still fails to operate, consult FanAm Distributor for return/replacement instructions.

Maintenance

1. Since fan bearings are sealed and have been provided with an internal lubricating material, no lubrication is

necessary.

2. At least once a year, clean any particles accumulated in the fan.

CAUTION: Never attempt to open the fan without the electrical service to the fan locked in the “OFF” position.

Limitation of W arranty and Liability

This warranty does not apply to any FanAm product or part which has failed as a result of faulty installation or abuse, incorrect electrical connections or alterations made by others, or use under abnormal

operating conditions or misapplication of the products or parts. We will not approve for payment any repairs not made by us or our authorized agent without prior written consent. The foregoing shall constitute

our sole and exclusive warranty and our sole and exclusive liability, and is in lieu of all other warranties, whether written, oral, implied or statutory . There are no warranties which extend beyond the description

on the page hereof. We do not warranty that said goods and articles are of merchantable quality nor that they are fit for a particular purpose. Our liability on any claim of any kind, including negligence, for any

loss or damage arising from or connected with, or resulting from, the sale and purchase of the products and parts covered by this proposal, acknowledgement, order or from the performance or breach of any

contract pertaining to such sale of purchase, or from the design, manufacture, sale, delivery, resale, inst allation, technical direction in installation, inspection, repair , operation or use of any product or part

covered by the proposal, acknowledgement, order or furnished by FanAm shall, in no case, exceed the price allocable to the products or parts thereof which give rise to the claim and shall terminate at the end

of the applicable warranty period of said product or part. In no event whether as a result of breach of contract, or warranty or alleged negligence, defect, incorrect advice or other causes, shall FanAm be liable

for special or consequential damages, including but not limited to loss of profits or revenue, loss of use of equipment or any associated equipment, cost of capital, cost of substitute equipment, facilities or

services, downtime cost, or claims of customers of purchases for such damages. FanAm neither assumes nor authorizes any person to assume for it any other liability in connection with the sale of its products

or parts. Some jurisdiction do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations and exclusions may not apply to you.

EXTENDED WARRANTY

FanAm warrants its COMP AX Series fan and parts to be free from defects in workmanship and service for period of one (3) years from the date of purchase. If the unit is furnished with FanAm’ s lint trap,

the warranty is extended to (5) years from the date of purchase. Products and parts not specifically designed for use in a corrosive or explosive environment shall have no warranty and the user assumes

full liability for use in such environments. Our obligation under this warranty is limited to the repair or replacement as our option, without cost at our facility, of any p art or parts thereof which shall, within the

warranty period, be returned to us with transportation charges prepaid, and which our examination discloses as being defective. All requests for repair or replacement must be directed to FanAm for

authorization prior to the return of any product or part. This warranty gives you specific legal rights and you may also have other rights in the jurisdiction in which you reside. (It is incumbent upon the claiment

to provide substantiation of purchase of installation dates if such question should arise.)

DISCLAIMER

FanAm Inc. has made a diligent effort to illustrate and describe the products in this literature accurately however, such illustrations and descriptions are for the sole purpose of identification, and do not

express or imply a warranty that the products are merchantable, or fit for a particular purpose, or that the products will necessarily conform to the illustrations.

Loading...

Loading...