Page 1

Instructions for Sling Anchors

Warning!

THE USER OF THIS EQUIPMENT, AND THE USER’S EMPLOYER MUST READ AND

COMPLY WITH THESE INSTRUCTIONS. FURTHERMORE, THE USER AND THE

USER’S EMPOLYER MUST READ AND COMPLY WITH ALL INSTRUCTIONS, LABELS

WARNINGS AND MARKINGS INCLUDED WITH EACH COMPONENT OF THE FALL

ARREST SYSTEM OF WHICH THIS PRODUCT IS A PART. FAILURE TO

UNDERSTAND AND COMPLY WITH THESE INSTRUCTIONS CAN RESULT IN

SERIOUS INJURY OR DEATH.

IF THESE INSTRUCTIONS ARE UNCLEAR TO YOU, PLEASE CONSULT A

COMPETENT PERSON. SHOULD THESE INSTRUCTIONS BECOME LOST OR

DAMAGED, OR SHOULD ANY LABELS, INSTRUCTIONS OR MARKINGS BECOME

ILLEGIBLE, PLEASE CONTACT FALLTECH FOR REPLACEMENTS. SHOULD YOU

NEED FURTHER ASSISTANCE WITH UNDERSTANDING THE PROPER

EMPLOYMENT OF THIS PRODUCT, PLEASE CONTACT FALLTECH FOR

ASSISTANCE:

Alexander Andrew, Inc. (dba FallTech)

1306 South Alameda Street

Compton, CA 90221, USA

1-800-719-4619

1-323-752-0066

www.falltech.com

Section 1: Warnings and Advisories

Table of Contents

Section 2: Fall Protection Basics – ABCD’s

Section 3: Use and Limitations

Section 4: Product Selection

Section 5: Anchorage Considerations

Section 6: Employer and User Training

Section 7: Fall Protection Plan

Section 8: Product Inspection

Section 9: Maintenance and Storage

Section 10: Specifications

2.1: Anchorage

2.2: Body wear

2.3: Connectors/Connecting devices

2.4: Deceleration devices

2.5: Fall Arrest

2.6: Fall Restraint

2.7: Work Positioning

2.8: Free-fall

2.9: Clear-fall

2.10: Swing-fall

3.1: General Guidelines

3.2: Sling Anchor types

3.3: Approved applications

3.4: Restricted Applications

3.5: Specialty Applications

3.6: Installation and Use – Chokers

3.7: Installation and Use – Web Pass-Thru Sling Anchors

3.8: Installation and Use – Cable Pass-Thru Sling Anchors

3.9: Installation and Use – Carabiner Sling Anchors

3.10: Installation and Use – Cable Anchor Extenders

6.1: Special notes for the employer

6.2: User training

7.1: The fall protection plan

7.2: Suspension trauma

7.3: Rescue plan

8.1: Issuing

8.2: Daily/Incidental use

8.3: Mandatory semi-annual inspection

10.1: Mandatory disclosures

10.2: Performance specifications

10.3: Labels and markings

10.4: Standards and references

1

2

Page 2

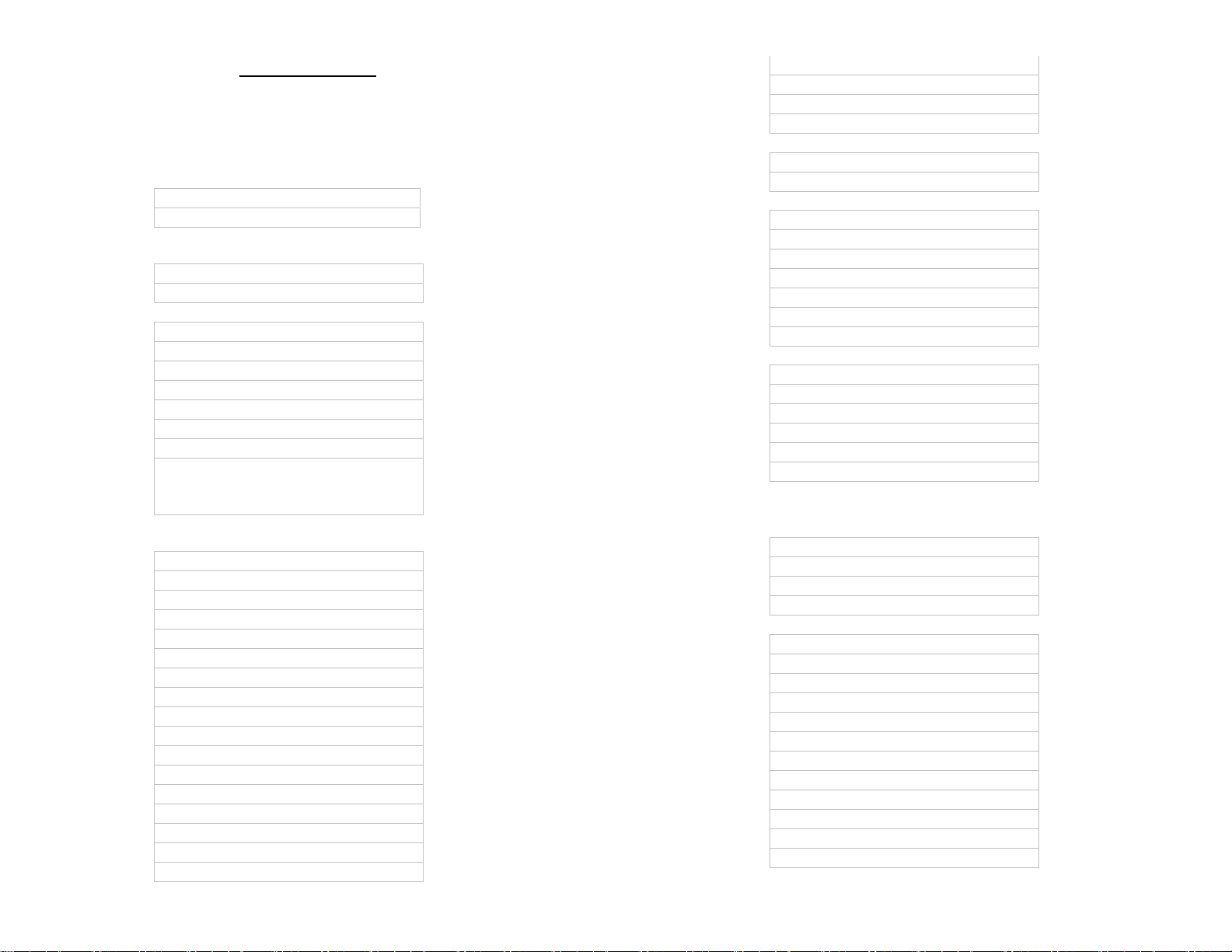

Product Listing

This instruction manual pertains to the use and operation of the

products listed below. Should you have any questions about the product

that you have purchased, please contact FallTech for additional details.

Scaffold Chokers:

Model# Description Standard

7214 17"ChokerAnchor1"webw/D‐Ring A10.32/Z359.1

Choker Sling Anchors:

Model# Description Standard

7218 18"ChokerAnchorStrapWeb A10.32/Z359.1

7224 24"ChokerAnchorStrapWeb A10.32/Z359.1

722448 48"ChokerAnchorStrapWeb A10.32/Z359.1

7236 36"ChokerAnchorStrapWeb A10.32/Z359.1

7244 72"ChokerAnchorKevlar A10.32/Z359.1

7245 36"ChokerAnchorKevlar A10.32/Z359.1

7272 72"ChokerAnchorStrapWeb A10.32/Z359.1

7218LT 18"ChokerAnchorw/O‐Ring A10.32/Z359.1

7224LT 24"ChokerAnchor,LiteDutyWeb A10.32/Z359.1

7236LT 36"ChokerAnchorLiteDutyWeb A10.32/Z359.1

72493FT 36’Choker–Arc/Flash A10.32/Z359.1

72496FT 72”Choker–Arc/Flash A10.32/Z359.1

Web Pass-Thru Sling Anchors:

Model# Description Standard

7324 2'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7336 3'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7336R 3'AnchorPass‐ThruSlingWeb(reinforced) A10.32/Z359.1

A7336 3'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7348 4'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7372 6'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7372R 6'AnchorPass‐ThruSlingWeb(reinforced) A10.32/Z359.1

737210R 10'AnchorPass‐ThruSlingWeb(reinforced) A10.32/Z359.1

737208 8'AnchorPass‐ThruSlingWeb A10.32/Z359.1

737210 10'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7373 12'AnchorPass‐ThruSlingWeb A10.32/Z359.1

7373R 12'AnchorPass‐ThruSlingWeb(reinforced) A10.32/Z359.1

737214 14'AnchorPassThruSlingWeb A10.32/Z359.1

737215 15'AnchorPassThruSlingWeb A10.32/Z359.1

737216 16'AnchorPassThruSlingWeb A10.32/Z359.1

737216R 16'AnchorPass‐ThruSlingWeb(reinforced) A10.32/Z359.1

737218 18'AnchorPassThruSlingWeb A10.32/Z359.1

737220 20'AnchorPassThruSlingWeb A10.32/Z359.1

737224 24'AnchorPassThruSlingWeb A10.32/Z359.1

737230 30'AnchorPassThruSlingWeb A10.32/Z359.1

737240 40'AnchorPassThruSlingWeb A10.32/Z359.1

NS7336 3'AnchorPass‐ThruSlingWeb A10.32/Z359.1

NS7372 6'AnchorPass‐ThruSlingWeb A10.32/Z359.1

Cable Pass-Thru Sling Anchors (PVC Coated):

Model# Description Standard

7427 4'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

7428 6'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

742708 8'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

742808 8'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

742710 10'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

742712 12'AnchorPass‐ThruCableCoatedO+O A10.32/Z359.1

Cable Pass-Thru Sling Anchors (Galvanized):

Model# Description Standard

74373FT 3'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

7437 4'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

7438 6'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

743807 7'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

74388 8'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

743810 10'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

743820 20'AnchorPass‐ThruCableGalvO+O A10.32/Z359.1

Carabiner Sling Anchors (Cable):

Model# Description Standard

74202D3 3'AnchorSlingCable2Ds+7450‐A10 A10.32

84202D3 3'AnchorSlingCable2Ds+8450‐Z359 Z359.1

74202D4 4'AnchorSlingCable2Ds+7450‐A10 A10.32

84202D4 4'AnchorSlingCable2Ds+8450‐Z359 Z359.1

74202D 6'AnchorSlingCable2Ds+7450‐A10 A10.32

84202D 6'AnchorSlingCable2Ds+8450‐Z359 Z359.1

74202D8FT 8'AnchorSlingCable2Ds+7450‐A10 A10.32

84202D8FT 8'AnchorSlingCable2Ds+8450‐Z359 Z359.1

74202D10 10'AnchorSlingCable2Ds+7450‐A10 A10.32

84202D10 10'AnchorSlingCable2Ds+8450‐Z359 Z359.1

74202DC3 3'AnchorSlingCoatedCable2Ds+7450‐A10 A10.32

84202DC3 3'AnchorSlingCoatedCable2Ds+8450‐Z359 Z359.1

74202DC4 4'AnchorSlingCoatedCable2Ds+7450‐A10 A10.32

84202DC4 4'AnchorSlingCoatedCable2Ds+8450‐Z359 Z359.1

74202DC 6'AnchorSlingCoatedCable2Ds+7450‐A10 A10.32

84202DC 6'AnchorSlingCoatedCable2Ds+8450‐Z359 Z359.1

3

4

Page 3

Cable Anchorage Extenders:

Model# Description Standard

8439 6'AnchorExtenderCableGalvSnap+O Z359.1

736707 7'AnchorExtenderCoatedCableSnap+O A10.32

736710 10'AnchorExtenderCoatedCableSnap+O A10.32

Section 1: Warnings and Advisories

This product is to be used as a part of a personal fall arrest system,

and should be used only with compatible components. Please see

Advisory #3 in this section for further details. Failure to use

compatible components can result in a failure of the system to

perform as intended, which may result in serious injury or death.

Throughout the OSHA regulations for safety and health, there are

references to Competent Persons and Qualified Persons. ANSI

Z359.0-2007 goes on to further define the roles and qualifications of

these individuals; as well as Authorized Persons, and their

importance in the workplace. These terms are also used in these

instructions. Below is a brief description of the part these

individuals play in the employment of fall protection equipment:

Authorized Person - a person who is exposed to fall hazards during

the course of their work. This individual requires formal training in

the use of personal fall protection equipment and systems. The

term Authorized Person may be used interchangeably with User

and End-User.

Competent Person – a trained and experienced person who is

designated to supervise, implement and monitor an employer’s

managed fall protection program. This individual is capable of

identifying and addressing fall hazards and is authorized to make

decisions and take corrective action in the workplace.

Qualified Person – a person possessing a degree or professional

certificate and having extensive training, knowledge and experience

with fall protection and who is capable of designing and specifying

fall protection equipment and systems to address fall hazards.

Please read these instructions and be sure that you understand

them prior to utilizing this equipment. Also be sure to read the

instructions included with other components which are being

utilized in your Personal Fall Arrest System (Harnesses,

connectors, anchorage connectors, etc.). Failure to understand and

comply with manufacturer’s instructions may result in serious

injury or death. IF YOU DO NOT UNDERSTAND ANY PART OF

THESE INSTRUCTIONS, PLEASE HAVE THEM EXPLAINED TO YOU

BY A COMPETENT PERSON.

This product is to be used as part of a complete fall arrest system in

accordance with industry-recognized best-practices and your

employer’s fall protection plan, as required by the Occupational

Safety and Health Administration. Be aware of your employer’s fall

protection plan and rescue plan. Be aware of the specific fall

hazards on your jobsite and work deliberately to avoid these

hazards in the course of your work. Also be aware of hazards and

obstructions in your fall path, and work with your employer to

eliminate these hazards where possible. Failure to be aware of and

to address these hazards may result in serious injury or death.

Do’s and Don’ts

Do use this device only with compatible components of a

comprehensive fall arrest system.

Do use this device only in a system which limits free fall distance

to 6 ft or less.

Do use extreme caution when rigging this device.

Do rig this device to avoid the hazards of “swing fall” (see

Section 2.9)

Do use this device only when your clearance distance is a

minimum of 2 ft AFTER you have calculated the total fall

distance (see section 2.10 for details on clear fall distances).

Do make compatible connections (see Advisory #3 at the end of

this Section).

Do avoid sharp or abrasive edges and be sure to employ a pad

or tarp to protect the sling anchor.

Do call FallTech if the device is damaged, does not pass

inspection (see Section 8), or has arrested a fall.

Don’t use this component to hoist materials or equipment.

Don’t use this device if it exhibits signs of corrosion or damage

from exposure to chemicals, excessive heat, flames and

electrical charge or shows signs of any physical damage or

deformation.

Don’t use this equipment if there are signs of excessive wear,

deterioration, deformation of corrosion.

Don’t use this equipment if you are working near high voltage

power lines or other energized electrical equipment.

5

6

Page 4

Don’t use near moving machinery which may entangle any

component of the system.

Don’t use oil to lubricate moving parts. If lubrication is needed,

first be sure to clean all moving parts thoroughly; then use only

100% silicone lubricant.

Don’t use this device if it will expose some element of your

Personal Fall Arrest system (PFAS) to sharp or jagged edges.

Don’t knot any component of this system.

Don’t use this device if you are pregnant, a minor, or have a

reduced tolerance to fall forces by reason of age, physical

medical condition, or other pre-existing disorders.

Don’t use this device if you weigh less than 75 lbs.

Don’t use this device if your total combined weight (body,

clothes, tools, etc) exceeds 425 lbs.

Don’t attempt to modify, repair or alter this device in any way.

Don’t use this equipment if it has been used to arrest a fall.

If it has been used to arrest a fall, this device must

immediately be removed from service and replaced.

Advisory #1: Further Reading

If you have access to the internet, please go to www.osha.gov. This

website is an exceptional resource, and has a great deal of information

which is easy to access. Use the search field to find information on fall

arrest, including standards, news, interpretations and other valuable tools.

The more you know about how this product works and how it is supposed

to be used, the safer you will be during the course of your work.

Advisory #2: Proper product selection

Product selection is an important element of fall protection. Fall Arrest

products are like any other tools that you may use in the course of your

work – there is a proper tool for every application. You may find that while

this product is suitable for some applications, it may not be suitable for

others. Please be sure to pay close attention to sections 2, 3, and 4, for

greater detail on this point.

Advisory #3: Connector Compatibility

Making compatible connections may mean the difference between life

and death. Connectors (snap hooks, rebar hooks and carabin ers), must be

of the locking type and require two distinct actions to open the gate. Your

connectors must be sized and shaped so that the rings or structural

members to which they are attached will not pose a risk of forcing the gate

open, and must fully captivate the connector so that it cannot become

disengaged, slide or shift during use or in the event of a fall.

Certain connections are forbidden and should never be attempted with

this product or any other unless there is a specific allowance in the

manufacturer’s instructions. Forbidden connections include, but are not

limited to:

Two or more connectors to one d-ring are a forbidden connection.

A connection that rests on or loads the gate is a forbidden

connection.

A connection that does not allow the gate to close and lock is a

forbidden connection.

Two or more connectors attached to one another are a forbidden

connection.

Connecting directly to webbing, rope, cable (wire rope) is a

forbidden connection.

Connecting directly to a horizontal lifeline is a forbidden

connection.

Tie-back with your FallTech SAL is a forbidden connection except

for model # 7241, 7241Y, 8241 and 8241Y in the WrapTech series.

Connecting to any ring or structure that does not fully captivate

and completely restrict the movement your connector is a

forbidden connection.

Section 2: ABCD’s

Every Personal Fall Arrest System consists of four basic elements –

Anchorage, Body-wear, Connectors/Connecting Devices and

Deceleration Devices. Each of these four elements is discussed in

greater detail below. If, after reading though this section, you do not fully

understand these items and how they work together to form a compatible

fall arrest system, please be sure to have this explained to you by a

Competent Person.

It is absolutely critical that you be familiar with the proper wear and/or

use of each component of your Personal Fall Arrest System (PFAS).

Failure to read, understand and adhere to instructional materials and

warnings provided with each of these components could lead to a

catastrophic failure of your PFAS, resulting in serious injury or death.

2.1: Anchorage

The selection of an anchor point and anchorage connector is critical

to the successful function of any Personal Fall Arrest System (PFAS).

OSHA 1926.502 (d) (15) states that:

“Anchorages used for attachment of personal fall arrest equipment shall

be independent of any anchorage being used to support or suspend

platforms and capable of supporting at least 5,000 pounds (22.2 kN) per

employee attached, or shall be designed, installed, and used as follows:

7

8

Page 5

as part of a complete personal fall arrest system which maintains a

safety factor of at least two; and under the supervision of a qualified

person.”

Ensure that the structure to which you are attaching your anchorage

connector is capable of meeting the above requirements and that your

anchorage connector is installed in accordance with the manufacturer’s

instructions. Also be sure to check that the anchorage connector is

compatible with your connecting device (lanyard, SRL, vertical lifeline)

and that it securely retains the connecting device without inhibiting its

function. If you are unable to determine whether your connecting device

and your anchorage are compatible, please immediately consult with a

competent person or your immediate supervisor. For more details on

anchorages, please see section 5 of this instruction manual.

2.2: Body-wear

Body wear for any application where this Beam Anchor is to be used

will be defined as a full body harness specifically manufactured for fall

arrest. If being used for restraint applications where the user is restricted

from reaching a fall hazard, a body belt may be used as an alternative.

Be sure to read and follow the manufacturer’s instructions included with

your full body harness or restraint belt at the time of purchase.

2.3: Connectors/Connecting Devices

Connectors and Connecting Devices are terms that are sometimes

used interchangeably. It is important to note the differences between

these two terms in order to help distinguish the parts that these

components play in the rigging of your PFAS. In both cases, these

products/components are required to have a minimum static strength of

5,000 lbs. For additional details on requirements for connectors and

connecting devices, see OSHA 1926.502 at www.osha.gov as

referenced in section 1, advisory #1.

A connector is any metallic, mechanical element such as a

carabiner, snap hook or rebar hook that physically links one or more

elements of a your PFAS together in a manner such that they will remain

engaged to one another unless they are intentionally disengaged.

A connecting device is an element that connects your full body

harness to the anchorage in an effort to ensure that you remain attached

or tethered to the structure upon which you are working. In other words,

the connecting device is that element which secures you to your

anchorage.

2.4: Deceleration Devices

A deceleration device is the element of a Personal Fall Arrest

System (PFAS) which is activated during a fall event and reduces the

forces exerted on the user’s body and on the anchorage during the arrest

of the fall. In the case of Shock-Absorbing Lanyards and Self-Retracting

Lifelines, these products are both a connecting device and a deceleration

device as they will keep you attached to your anchorage and will reduce

the forces on your body in the event of a fall.

2.5: Fall Arrest

Fall Arrest is an area of Fall Protection which focuses on stopping a

fall once it has occurred. Personal Fall Arrest Systems typically consist

of an anchorage, a full body harness and a self-retracting lifeline, shockabsorbing lanyard or other deceleration device designed to bring a falling

user to a stop in the shortest possible distance while limiting the force

imparted to the user’s body.

2.6: Fall Restraint

Fall Restraint is an area of Fall Protection devoted to restraining the

user of the system in a manner which restricts his or her access to the

fall hazard in a manner such that they cannot be subjected to a fall. A

typical Fall Restraint System consists of an anchorage, a full body

harness or a restraint belt and a restraint lanyard. A Shock-Absorbing

Lanyard or a Self-Retracting Lifeline should never be utilized in a

restraint application as it they not capable of restricting a user’s access

to fall hazards.

2.7: Work Positioning

Work Positioning is an area of Fall Protection devoted to allowing a

user to work on a vertical surface by means of a positioning assembly,

and restricting the user’s exposure to a fall of no more than two feet.

Typical positioning assemblies consist of a large rebar hook and a length

of chain, rope, wire rope or webbing with a double locking snap hook on

either end. These snap hooks are attached to d-rings on the hips or on

the waist of the user’s full body harness, with the rebar hook attached to

the structure upon which the user is working. An SAL or an SRL should

never be used for work positioning, nor should they ever be attached to a

side or hip d-ring on a full body harness. However, while rigged for

work positioning, the user should always have an SAL or SRL

attached to the back d-ring of their full body harness and tied-off to

the structure on which they are positioning as a back up device.

9

10

Page 6

2.8: Free-Fall

Free-Fall is the distance that a worker will fall before the connecting

device or deceleration device elements of the PFAS will begin to engage

during a fall event. OSHA allows a maximum Free-Fall Distance of 6’ (6

feet) when rigging a Personal Fall Arrest System (PFAS). In some

cases, exceptions may be allowed when there is no practical way to limit

the Free-Fall Distance to 6’, such as a job-site where no overhead

anchor-point is available. Tying off in a manner that would create a

Free-Fall greater than 6’ should always be a last resort. If you are

rigging a system that allows more than 6’ of Free-Fall, make sure your

Connecting Device/Deceleration Device is rated for this application.

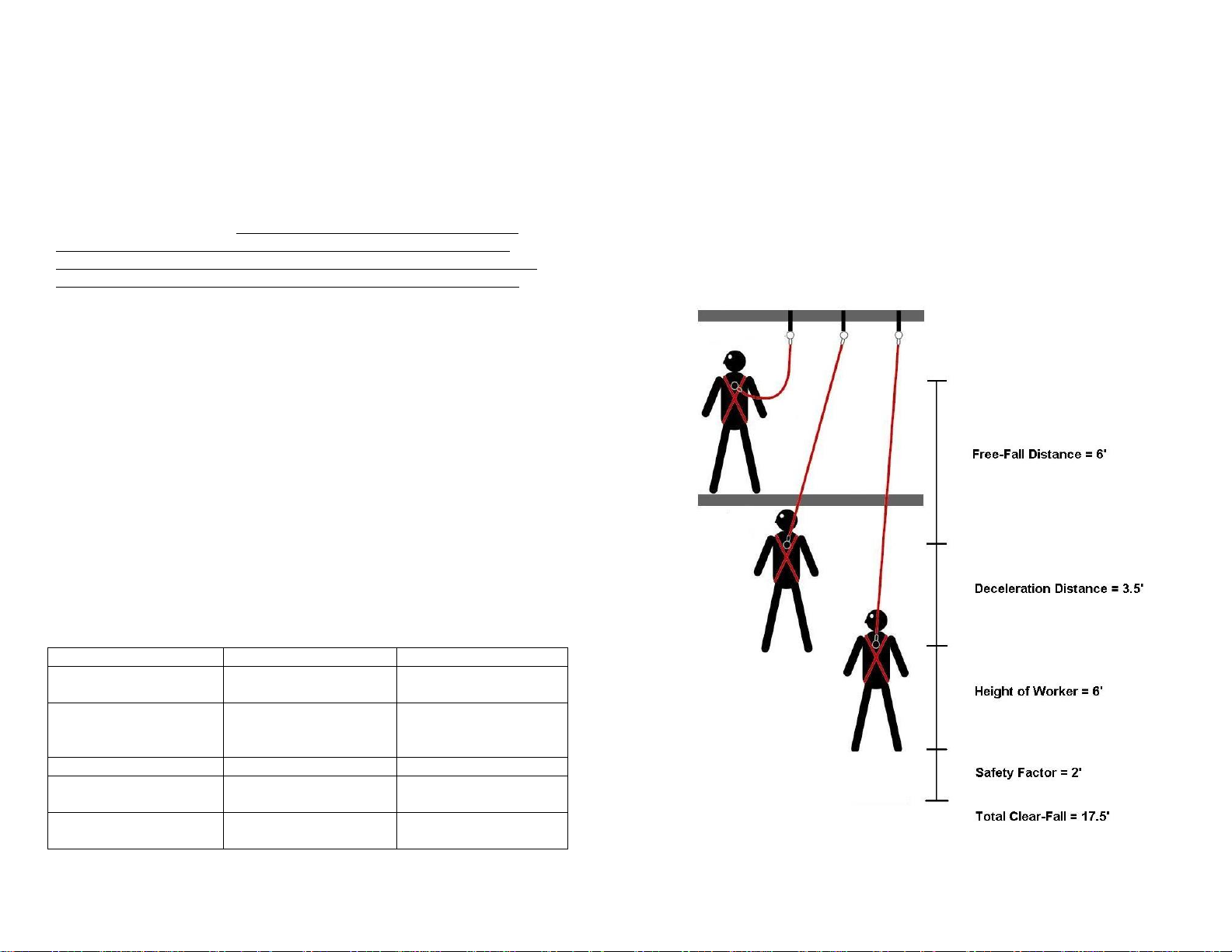

2.9: Clear-Fall

Clear-Fall or Clear-Fall Distance is the distance that is required to

safely arrest the fall of a user. When working at heights and using a

PFAS, it is important to consider the distance between the

walking/working level and the next lower level to ensure that the

components selected are capable of arresting the user’s fall before they

hit the next lower level. The required Clear-Fall Distance can easily be

calculated by adding together the Free-Fall Distance, the Deceleration

Distance, the height of the user plus a safety factor of 2 feet. The

formula for calculating Clear-Fall Distance is shown below:

Free-Fall Distance + Deceleration Distance + Height of Worker + Safety Factor = Clear-Fall

Distance

The matrix below can be used as a guide for calculating Clear-Fall

Distance on your job-site:

Free-Fall Distance

(OSHA allows up to 6’)

Deceleration

Distance

Example Values Actual Values

6’

3.5’

(Typically 3.5’ or less)

Height of Worker 6’

Safety Factor

(Minimum of 2’)

Total

(Sum of all values)

2’

17.5’

See figure 2.1 below for a graphic illustration of Clear-Fall Distance and

the method for calculating. It is also necessary to consider the fall path

when determining the Clear-Fall limitations in your application. Ensure

the fall path is clear of obstructions, protrusions, equipment or materials

that may be a hazard in the event of a fall. Pay special attention to those

items which may present an impalement hazard. Obstructions in the fall

path may be just as hazardous as the fall itself, and your PFAS may not

be able to protect you from these hazards. Failure to clear the fall path

may result in serious injury or death. Rig your PFAS with extreme

caution, and be aware of all of the factors that may come into play in the

event of a fall.

Figure 2.1: Clear-Fall Diagram

11

12

Page 7

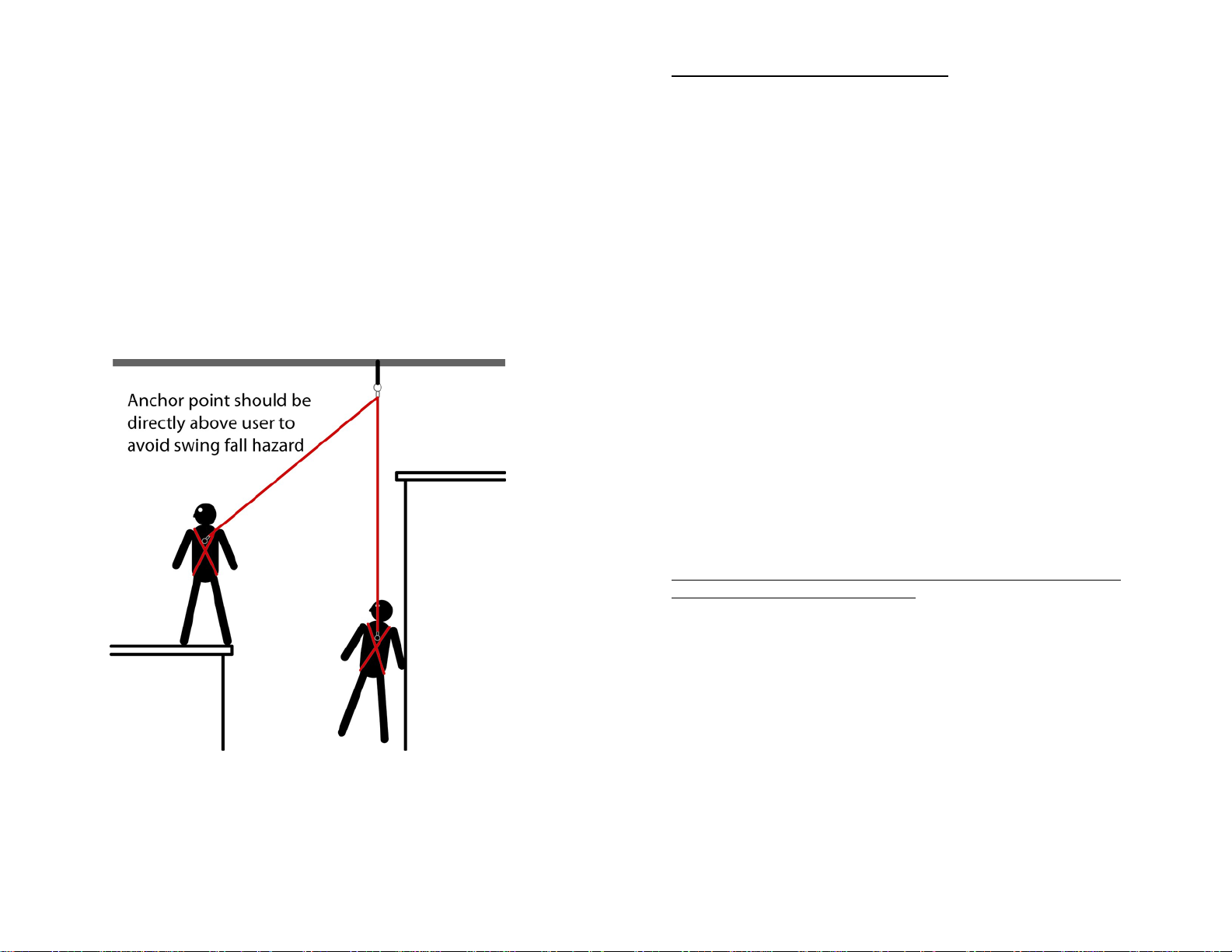

2.10: Swing-Fall

Swing-Fall is the phenomenon that occurs when the user falls from a

location that is not directly adjacent to, or directly below the anchorage

connector. This is also referred to as the “pendulum effect”, and can

result in a situation where the user is not only falling vertically, but is also

swinging on the horizontal as well. This can bring additional hazards into

play, as you may swing into an obstruction or structural element, causing

serious injuries (see figure 2.2). A significant Swing-Fall may also

require increased Clear-Fall distance. As a rule of thumb, you should

ensure work in an area that does not exceed an angle greater than 15

degrees in any direction from your anchorage.

Figure 2.2: Swing-Fall Diagram

Be sure to consider Swing-Fall when calculating your Clear-Fall

requirements and checking the fall path for hazards and instructions.

Failure to do so may result in serious injury or death. Should you have

any questions regarding Free-Fall, Clear-Fall, Swing-Fall or other

hazards in the fall path, be sure to contact FallTech or consult with a

competent person or your direct supervisor on your job-site.

Section 3: Use and Limitations

This section deals with the general use and limitations of FallTech

Sling Anchors. Please read this section and all sections of this manual

thoroughly. If your application is not addressed, or if you have questions

regarding your specific needs, please contact FallTech immediately for

additional guidance.

3.1: General Guidelines

When properly installed and utilized, this FallTech Sling Anchor will

provide a safe anchorage for a single user (the exception to this rule is

the Web Pass-Thru Anchor Slings, which may be included as anchorage

connectors with certain FallTech HLL Kits for multiple users. As the user

is working while tied-off to this Sling Anchor, their Personal Fall Arrest

System (PFAS) will be securely attached to the structure.

Before using this product, the user should be trained in the use of fall

arrest products and should have completed a minimum course of

instruction (4-8 hours) for Authorized Person Training as outlined in ANSI

Z359.2-2007. The user must also read and be familiar with all of the

material contained in this instruction manual as well as all labels and

warnings affixed to the FallTech Sling Anchor. If you have any questions

regarding the use or operation of this product, please contact FallTech, a

competent person, or your immediate supervisor before using.

This product must be inspected before each use. For details on

proper inspection procedures, please refer to section 8 of this manual.

Should this product fail to pass inspection, it must be immediately

removed from service and replaced.

This FallTech Sling Anchor is intended to be used as part of a

Personal Fall Arrest System and will comprise the Anchorage element of

your PFAS (see section 2 of this manual for clarification of these terms).

This product is designed to be attached to a properly rated structural

member meeting the anchorage requirements established in Title 29,

Subpart M (OSHA 1926.502) as well as the ANSI Z359 body of

standards, in order to provide a secure anchorage for your PFAS.

Your Sling Anchor should ideally be mounted to an overhead

structural member, or rigged in a manner such that Free-Fall is restricted

to no more than 6’ (6 feet). In circumstances where there is no way to

limit free fall to 6’, or where there is no access to an overhead structural

member Chokers and Pass-Thru Slings may be used mounted to a rated

structural member provided that the Free-Fall is restricted to a maximum

of 12’, and the Sling Anchor IS NOT exposed to any sharp, jagged or

13

14

Page 8

abrasive edges or surfaces. When rigged for a Free-Fall greater than six

feet, your FallTech Sling Anchor must be used with a FallTech Ironman

series lanyard (7247, 7247Y, 8247, 8247Y, 8248 and 8248Y). Users

weighing more than 310 lbs. (including tools and equipment) may only

use this device if they are utilizing a FallTech Heavyweight Series ShockAbsorbing Lanyards (8248, 82483, 8248Y and 8248Y3) or Heavyweight

Series Self Retracting Lifelines (denoted by “HW” in the model number)

Be sure to review the Clear-Fall diagram and worksheet in section 2.9 of

this manual.

This product meets the requirements of OSHA 1926.502 as well as

ANSI Z359.1-2007 and/or ANSI A10.32-2004. For further details on

these requirements, please go to www.osha.gov to review the OSHA

requirements. Copies of the ANSI standards are available at

www.asse.org in the e-standards store.

3.2: Sling Anchor Types

Chokers

Chokers are Sling Anchors which consist of a webbing loop with a D-

ring or O-ring on one end. Typically, the loop is wrapped around a rated

structural member, and then the D-ring or O-ring is passed through the

loop and cinched down tightly. The D-ring or O-ring is then used as the

attachment point for a connecting device. (See figures 3.1 and 3.2)

Web Pass-Thru Sling Anchors

Web Pass-Thru Sling Anchors are web straps that have a large D-ring

on one end and a smaller D-ring on the opposite end. The strap is

wrapped around a rated structural member and the smaller D-ring is

passed through the larger one, and then the strap is cinched down

tightly. The smaller D-ring is then used as the attachment point for a

connecting device. (See figure 3.3 and 3.4)

Cable Pass-Thru Sling Anchors

Cable Pass-Thru Sling Anchors are web straps that have a large D-

ring or O-ring on one end and a smaller D-ring or O-ring on the opposite

end. The strap is wrapped around a rated structural member and the

smaller D-ring or O-ring is passed through the larger one, and then the

cable is cinched down tightly. The smaller D-ring or O-ring is then used

as the attachment point for a connecting device. (See figure 3.5)

Carabiner Sling Anchors

Carabiner Sling Anchors are made using a length of cable. On one

end is a carabiner, and on the opposite end is a pair of D-rings or Orings. Typically, the cable is wrapped around a rated structural member

and the carabiner is attached to one of the two D-rings or O-rings,

leaving the other to be used as the attachment point for a connecting

device. (See figure 3.6)

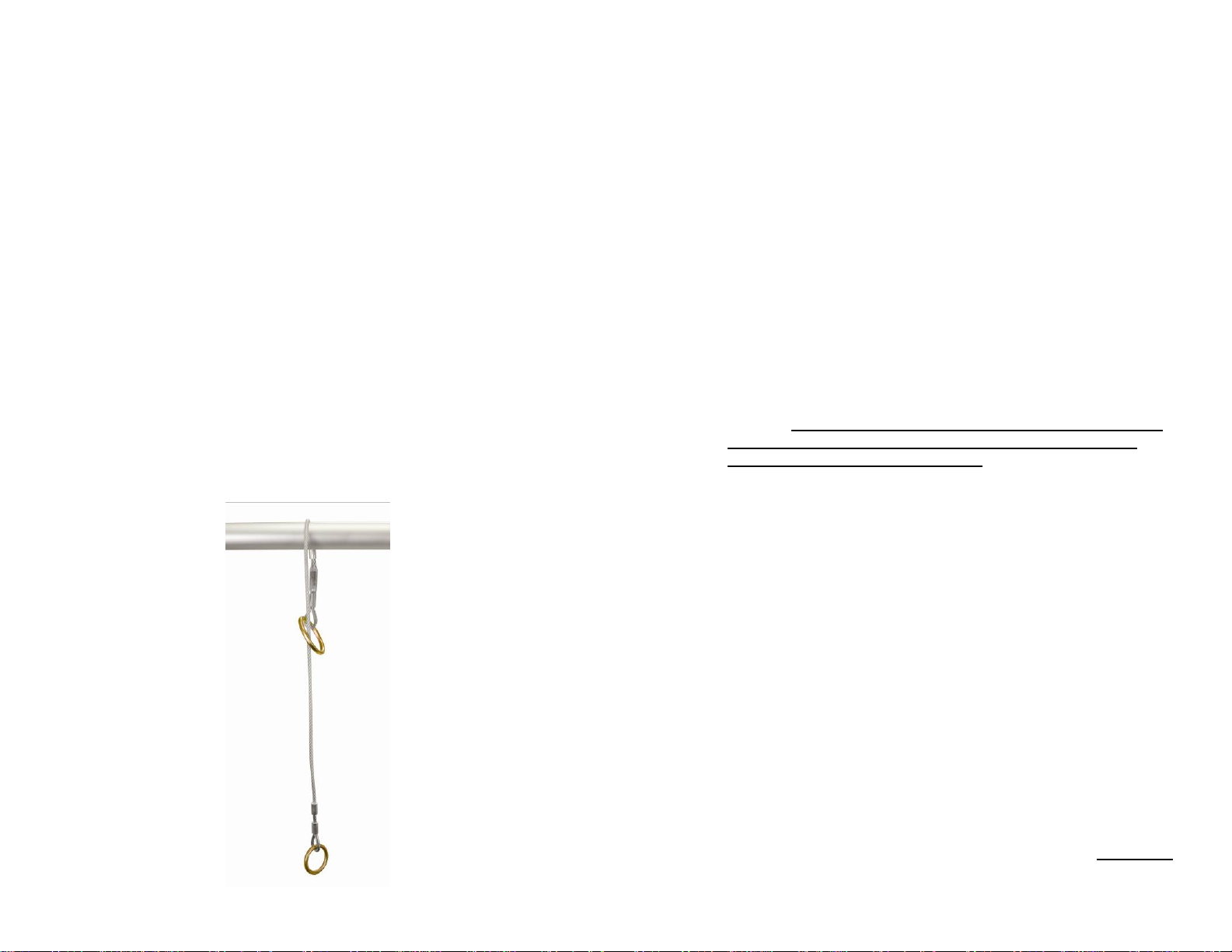

Cable Anchor Extenders

Cable Anchor Extenders are made using a length of cable having a

snap hook or carabiner at one end and a D-ring or O-ring at the opposite

end. These can be attached to an existing anchorage connector in order

to lower the attachment point in order to make it more accessible to the

user.

3.3: Approved Applications

Below are applications for which your FallTech Sling Anchor is

specifically suited. This list is not all-inclusive, but is intended to

anticipate the most common applications in which this product may be

used. If you have questions about whether this product is suitable for

your particular application, please consult a competent person or contact

FallTech for further advice.

Sling Anchors come in various lengths in order to put the attachment

point within proximity of the user and the walking/working surface. Be

sure to rig your sling anchor so that Free Fall is limited to 6’ (six feet) or

less.

The length of some Sling Anchors is such that it may also contribute

to Swing Fall. See Section 2.10 of this manual for additional details, and

be sure to rig your Sling Anchor so as to avoid this hazard.

Be sure to consult Section 5 of this instruction manual for details on

anchorage considerations, as the anchorage and its relationship to the

walking/working surface will be an important factor in determining

suitability and could contribute to the outcome of a fall event. Use of an

anchor point that is not properly rated could lead to a catastrophic failure

of your personal fall arrest system, which may result in serious injury or

death.

Direct Overhead Applications: All FallTech Sling Anchors are suitable for

use in any application where the properly rated anchorage is dire ctly

15

16

Page 9

above the walking/working surface, and allows for a maximum Free-Fall

Distance of 6 feet.

Horizontal Lifelines: Model # 7372R is included with FallTech Checkline

4-User Horizontal Lifeline Kits and with FallTech PSR Horizontal Lifeline

Kits. As components of this kit, a pair of 7372R’s may be used on a

vertical column to provide the anchorage for the multi-user systems.

They may not be used in conjunction with any other Horizontal Lifeline

System. See the instructions for the FallTech Checkline and PSR

Systems for additional details.

Non-Horizontal Structural Members: FallTech Sling Anchors (particula rly

Chokers and Scaffold Chokers) are often used in tower climbing

applications. They may only be attached to vertical or diagonally

oriented members provided that they are rated for fall arrest and that the

Sling Anchor is installed directly above a supporting horizontal member

which will prevent it from sliding in the event of a fall.

If you have any questions regarding the suitability of this product for

your specific application, please consult with a competent person or

contact FallTech before using. Misuse of this product may result in

serious injury or death.

Warning: The structural member to which you are attaching this

product must not be open-ended. If the structural member is open

on either end, and the Sling Anchor is not captivated on the

member, do not attempt to use this device, as there is a serious risk

of accidental disengagement. Serious injury or death may result!

3.4: Restricted Applications

Harsh Chemical Environments: Acids and other caustic chemicals can

cause damage to this Sling Anchor and its component parts. Damage

from chemical exposure can be difficult to detect and FallTech

recommends increased inspection and/or replacement frequency.

Residential Construction: This product is not suitable for certain

applications in residential construction. Consult a competent person

before using this product on a Residential Construction jobsite to ensure

that the anchorage to which you are attaching it meets the requirements

of this manual and applicable fall protection regulations and standards.

Climbing/Fixed Ladders: Do not attempt to affix this product to a fixed

ladder to be used in conjunction with any other equipment for the

purposes of climbing or fall arrest. A Scaffold Choker may be used in a

temporary rigging in this applicaton with a Vertical Lifeline, provided that

the Vertical Lifeline is appropriately counterweighted, and that the

system is installed under the supervision of a Competent Person.

Extended Free Falls: While FallTech Sling Anchors are rated to

withstand the forces associated with extended free falls or foot-level tieoff, they are often exposed to sharp, jagged or abrasive edges in these

applications which may greatly reduce the strength of the Sling Anchor.

In circumstances where Free Fall can’t be limited to 6’ (6 feet), your Sling

Anchor may be used provided the following conditions are met:

Care must be taken to ensure that the structural member does

not make direct contact with the gate or keeper on your

connecting device.

You must use a connecting device that is rated for free falls

greater than six feet (i.e. 7247, 7248, 8247, 8248 or “Y”

versions of these models).

You must protect the Sling Anchor from exposure to sharp,

jagged or abrasive edges by wrapping a tarp or other similar

padding around the structural member prior to installing the

Sling Anchor.

These steps must be done at the discretion of and under the

supervision of a Competent Person.

Welding/Power Transmission: Most FallTech Web Sling Anchors are

manufactured using materials that will not withstand high temperatures.

These models should not be used in situations where they may be

exposed to high temperatures or welding splatter.

3.5: Specialty Applications

Heavyweight: FallTech Sling Anchors have a maximum capacity of 425

lbs. For users weighing between 310 and 425 lbs (with clothing, tools

and equipment), be sure to utilize this product along with body wear and

connecting devices that are rated appropriately (FallTech Heavyweight

SAL’s are black in color and are denoted by model numbers beginning

with 7246 or 8246). Under no circumstances should any user

weighing more than 310 lbs be subjected to more than six feet of

free fall.

Welding/Power Transmission: FallTech Cable Sling Anchors are

manufactured using materials that will withstand high temperatures.

These models should be inspected frequently to ensure that they are

serviceable and have not been damaged by welding splatter or an

electrical arc. Additionally, Model #’s 72493FT and 72496FT are Web

Sling Anchors that have been manufactured using Aramid webbing and

17

18

Page 10

insulated hardware and have been tested in accordance with the

requirements of ASTM F887 for Arc Flash exposure.

3.6: Installation and Use – Chokers (All Types)

1. Select the appropriate FallTech Choker Sling Anchor based on

the work conditions and specific hazards (See Section 3.2 for

recommendations).

2. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Connecting Devices, Anchorage Connectors,

etc.). Be sure to choose components that are compatible with

this Choker Sling Anchor. If you have questions about product

or component compatibility, be sure to contact FallTech for

additional instructions.

3. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your anchorage location.

4. Inspect this Choker Sling Anchor, and all components of your

Personal Fall Arrest System in accordance with Section 8 of this

manual. Be sure to consult, and adhere to the instructional

materials, labels and warnings accompanying the other

components of your PFAS as well.

5. Ensure that the rated structural member to which you are about

to attach your Choker Sling Anchor is free of sharp, jagged or

abrasive edges. If it is not, cover these hazards with a tarp, pad

or moving blanket to protect your Choker Sling Anchor. (See

Section 5 of this manual for details on proper anchorage

strength)

6. Place your Choker Sling Anchor over the top of the structural

member so that the web loop is hanging on one side and the Dring or O-ring is hanging on the other. Pass the D-ring or O-ring

through the web loop, and cinch the Choker Sling Anchor down

tight. (See Figures 3.1 and 3.2)

7. Check your installation to ensure that the Choker Sling Anchor

cannot come off of the structural member at any point along the

intended path of movement or at joints or ends.

8. Ensure your Full Body Harness is properly donned and adjusted

and that your connecting device is securely attached to your

back D-ring. Tie-off to the D-ring on your Choker Sling Anchor

with your connecting device.

9. Proceed cautiously with your work. Do not run, jump or overreach. Any type of sudden movement may cause you to

lose your footing. Move with care and deliberation at all

times while tied-off and working at heights.

10. Do not allow your connecting device to pass under your arm or

between your legs – severe injury or death may result. Also

avoid sharp edges which may damage your connecting device in

the event of a fall.

11. If the structural member that this Choker Sling Anchor is

attached to is sloped or vertical, the Choker Sling Anchor must

be positioned next to a stop which will prevent the Choker Sling

Anchor from sliding or moving in the event of a fall.

12. If you are tied-off at the foot-level, or in a manner that will allow

more than six feet of free fall, ensure that your connecting device

is rated for extended free falls. Also ensure that the gate of your

carabiner or snap hook which is attached to the Choker Sling

Anchor does not make direct contact with the edge of the

structural member or any other obstruction. Such contact could

force a roll-out or accidental disengagement. If in doubt, you

may use a FallTech #7214 Choker to extend your connection.

Attach the 7214 Choker to the D-ring on your Choker Sling

Anchor, and then attach your connecting device to the D-ring on

the 7214. This will help to keep your connector gate away from

any potential hazard.

Note: The 7214 Scaffold Choker makes an excellent anchorage

extender when there are concerns about compatibility or rollout.

Consult a Competent Person on your jobsite if you have questions

or contact FallTech for additional details.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements! When using this

device, care must be taken to be aware of the work environment and any

hazards, obstructions or obstacles that may exist. Be careful of any and

all fall hazards and also be aware of slipping and tripping hazards as

well.

19

20

Page 11

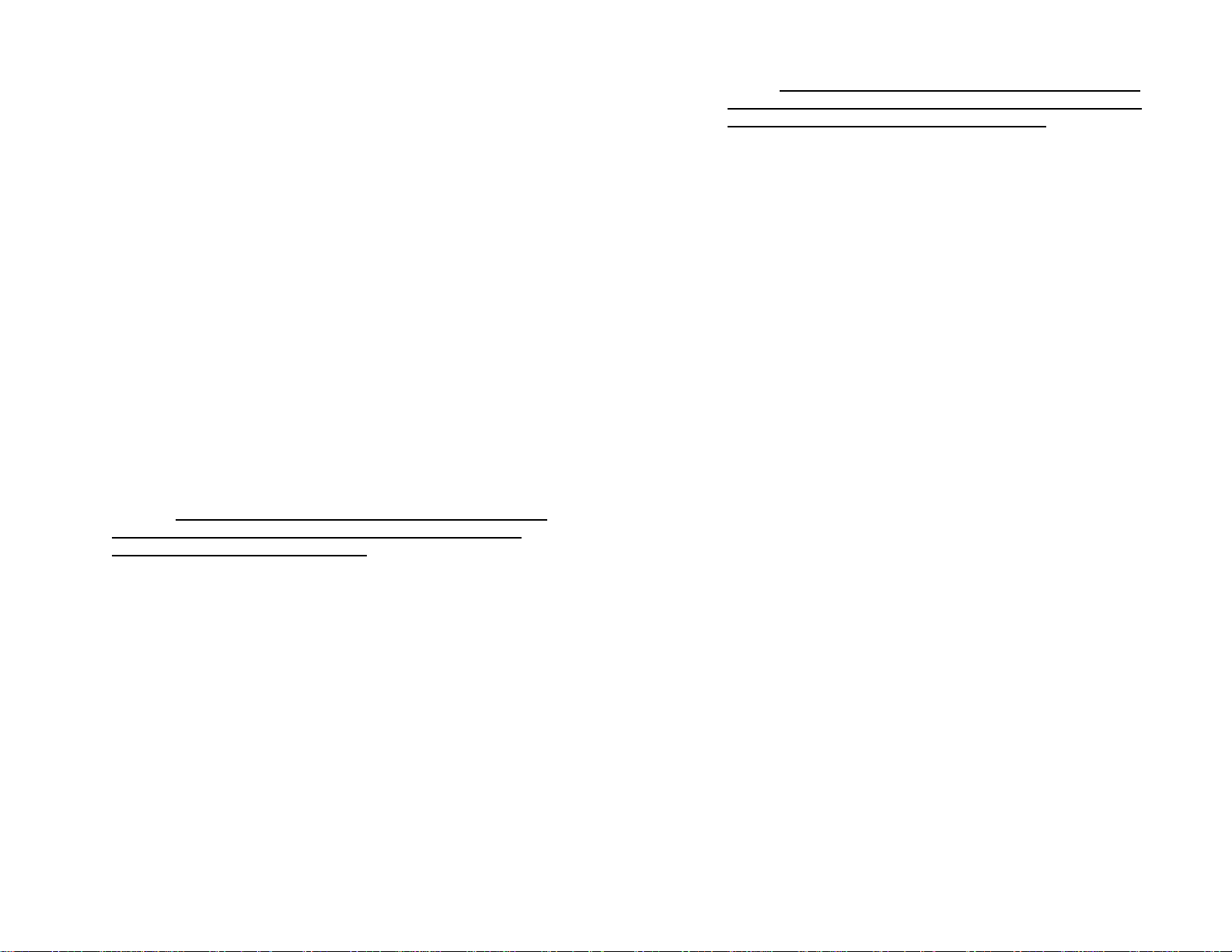

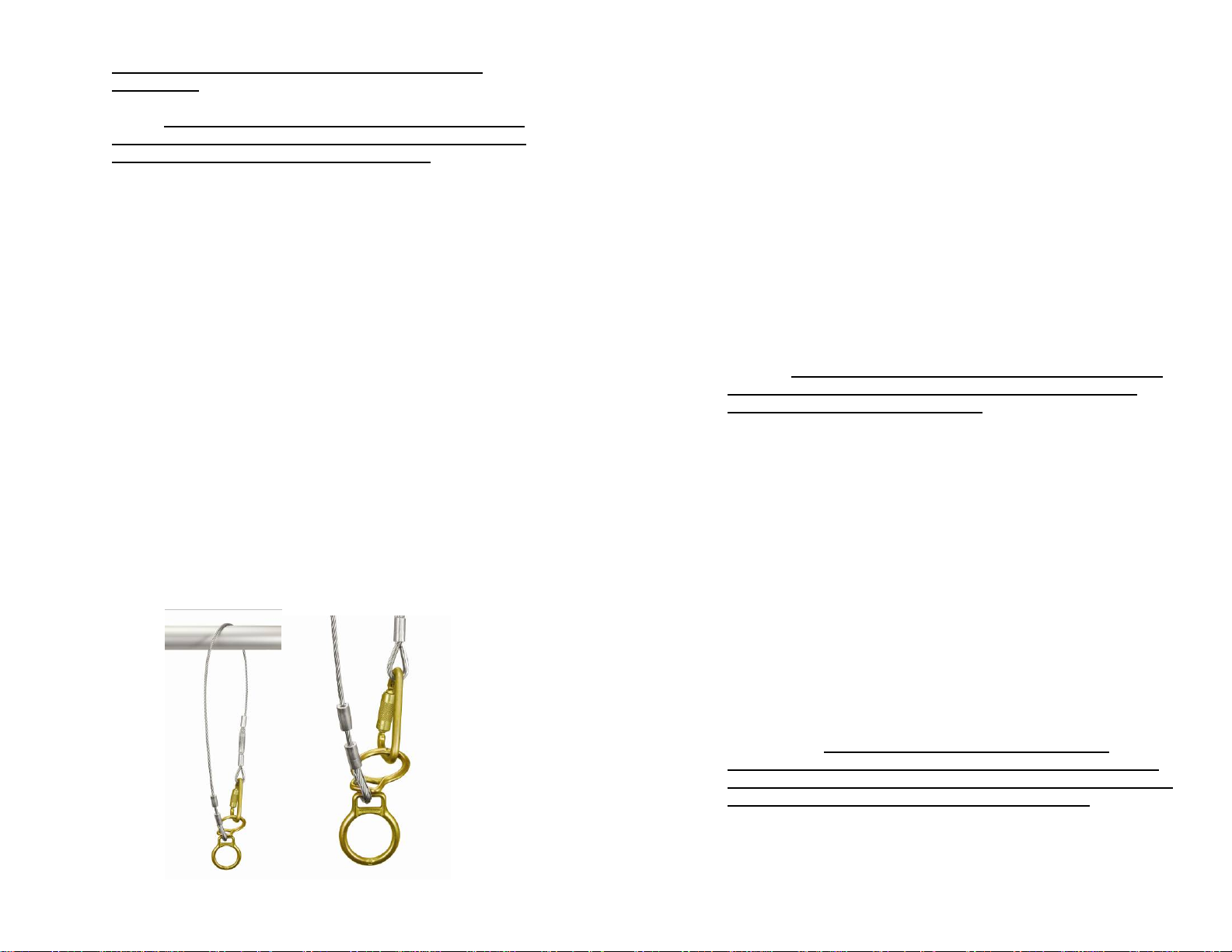

Fig. 3.1

Installation Method for Choker Sling Anchors

Fig. 3.2

Correct Installation of Choker Sling Anchors

Scaffold Choker Choker Sling Anchor

3.7: Installation and Use – Web Pass-Thru Sling Anchors

1. Select the appropriate FallTech Web Pass-Thru Sling Anchor

based on the work conditions and specific hazards (See Section

3.2 for recommendations).

2. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Connecting Devices, Anchorage Connectors,

etc.). Be sure to choose components that are compatible with

this Web Pass-Thru Sling Anchor. If you have questions about

product or component compatibility, be sure to contact FallTech

for additional instructions.

3. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your anchorage location.

4. Inspect this Web Pass-Thru Sling Anchor, and all components of

your Personal Fall Arrest System in accordance with Section 8 of

this manual. Be sure to consult, and adhere to the

instructional materials, labels and warnings accompanying

the other components of your PFAS as well.

5. Ensure that the rated structural member to which you are about

to attach your Web Pass-Thru Sling Anchor is free of sharp,

jagged or abrasive edges. If it is not, cover these hazards with a

tarp, pad or moving blanket to protect your Web Pass-Thru Sling

Anchor. (See Section 5 of this manual for details on proper

anchorage strength)

6. Place your Web Pass-Thru Sling Anchor over the top of the

structural member so that the large D-ring is hanging on one side

and the small D-ring is hanging on the other. Pass the small Dring through the large D-ring, and cinch the Web Pass-Thru Sling

Anchor down tight. (See Figures 3.3 and 3.4)

7. Check your installation to ensure that the Web Pass-Thru Sling

Anchor cannot come off of the structural member at any point

along the intended path of movement or at joints or ends.

8. Ensure your Full Body Harness is properly donned and adjusted

and that your connecting device is securely attached to your

back D-ring. Tie-off to the small D-ring on your Web Pass-Thru

Sling Anchor with your connecting device.

9. Proceed cautiously with your work. Do not run, jump or overreach. Any type of sudden movement may cause you to

lose your footing. Move with care and deliberation at all

times while tied-off and working at heights.

10. Do not allow your connecting device to pass under your arm or

between your legs – severe injury or death may result. Also

avoid sharp edges which may damage your connecting device in

the event of a fall.

11. If the structural member that this Web Pass-Thru Sling Anchor is

attached to is sloped or vertical, the Web Pass-Thru Sling

Anchor must be positioned next to a stop which will prevent it

from sliding or moving in the event of a fall.

12. If you are tied-off at the foot-level, or in a manner that will allow

more than six feet of free fall, ensure that your connecting device

is rated for extended free falls. Also ensure that the gate of your

21

22

Page 12

carabiner or snap hook which is attached to the Web Pass-Thru

Sling Anchor does not make direct contact with the edge of the

structural member or any other obstruction. Such contact could

force a roll-out or accidental disengagement.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements! When using this

device, care must be taken to be aware of the work environment and any

hazards, obstructions or obstacles that may exist. Be careful of any and

all fall hazards and also be aware of slipping and tripping hazards as

well.

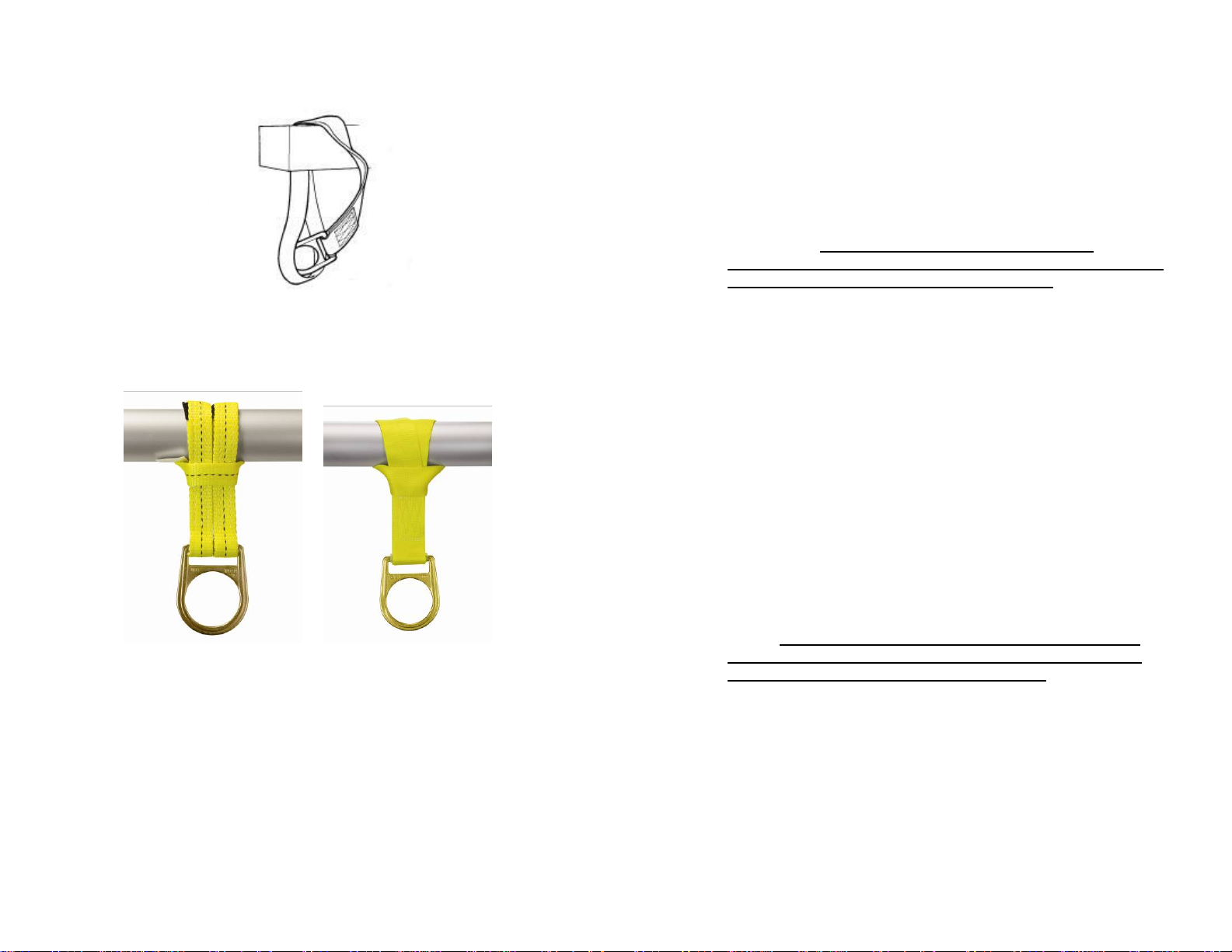

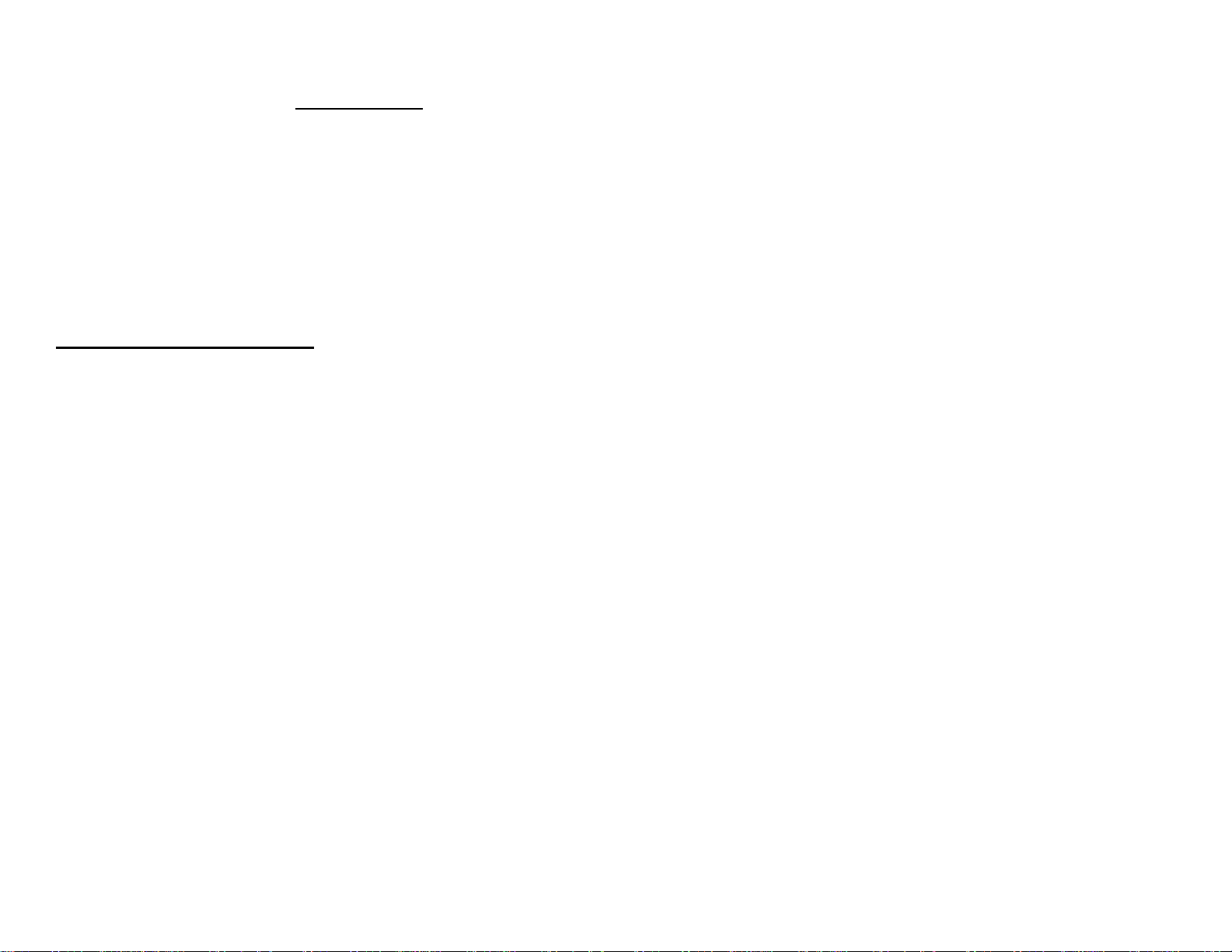

Fig. 3.3

Installation Method for Web Pass-Thru Sling Anchor

Fig. 3.4

Correct Installation of Web Pass-Thru Sling Anchor

3.8: Installation and Use – Cable Pass-Thru Sling Anchors

1. Select the appropriate FallTech Cable Pass-Thru Sling Anchor

based on the work conditions and specific hazards (See Section

3.2 for recommendations).

2. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Connecting Devices, Anchorage Connectors,

etc.). Be sure to choose components that are compatible with

this Cable Pass-Thru Sling Anchor. If you have questions about

product or component compatibility, be sure to contact FallTech

for additional instructions.

3. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your anchorage location.

4. Inspect this Cable Pass-Thru Sling Anchor, and all components

of your Personal Fall Arrest System in accordance with Section 8

of this manual. Be sure to consult, and adhere to the

instructional materials, labels and warnings accompanying

the other components of your PFAS as well.

5. Ensure that the rated structural member to which you are about

to attach your Cable Pass-Thru Sling Anchor is free of sharp,

jagged or abrasive edges. If it is not, cover these hazards with a

tarp, pad or moving blanket to protect your Cable Pass-Thru

Sling Anchor. (See Section 5 of this manual for details on proper

anchorage strength)

6. Place your Cable Pass-Thru Sling Anchor over the top of the

structural member so that the large O-ring is hanging on one

side and the small O-ring is hanging on the other. Pass the

small O-ring through the large O-ring, and cinch the Cable PassThru Sling Anchor down tight. (See Figure 3.5)

7. Check your installation to ensure that the Cable Pass-Thru Sling

Anchor cannot come off of the structural member at any point

along the intended path of movement or at joints or ends.

8. Ensure your Full Body Harness is properly donned and adjusted

and that your connecting device is securely attached to your

back D-ring. Tie-off to the small O-ring on your Cable Pass-Thru

Sling Anchor with your connecting device.

9. Proceed cautiously with your work. Do not run, jump or overreach. Any type of sudden movement may cause you to

lose your footing. Move with care and deliberation at all

times while tied-off and working at heights.

23

24

Page 13

10. Do not allow your connecting device to pass under your arm or

between your legs – severe injury or death may result. Also

avoid sharp edges which may damage your connecting device in

the event of a fall.

11. If the structural member that this Cable Pass-Thru Sling Anchor

is attached to is sloped or vertical, the Cable Pass-Thru Sling

Anchor must be positioned next to a stop which will prevent it

from sliding or moving in the event of a fall.

12. If you are tied-off at the foot-level, or in a manner that will allow

more than six feet of free fall, ensure that your connecting device

is rated for extended free falls. Also ensure that the gate of your

carabiner or snap hook which is attached to the Cable Pass-Thru

Sling Anchor does not make direct contact with the edge of the

structural member or any other obstruction. Such contact could

force a roll-out or accidental disengagement.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements! When using this

device, care must be taken to be aware of the work environment and any

hazards, obstructions or obstacles that may exist. Be careful of any and

all fall hazards and also be aware of slipping and tripping hazards as

well.

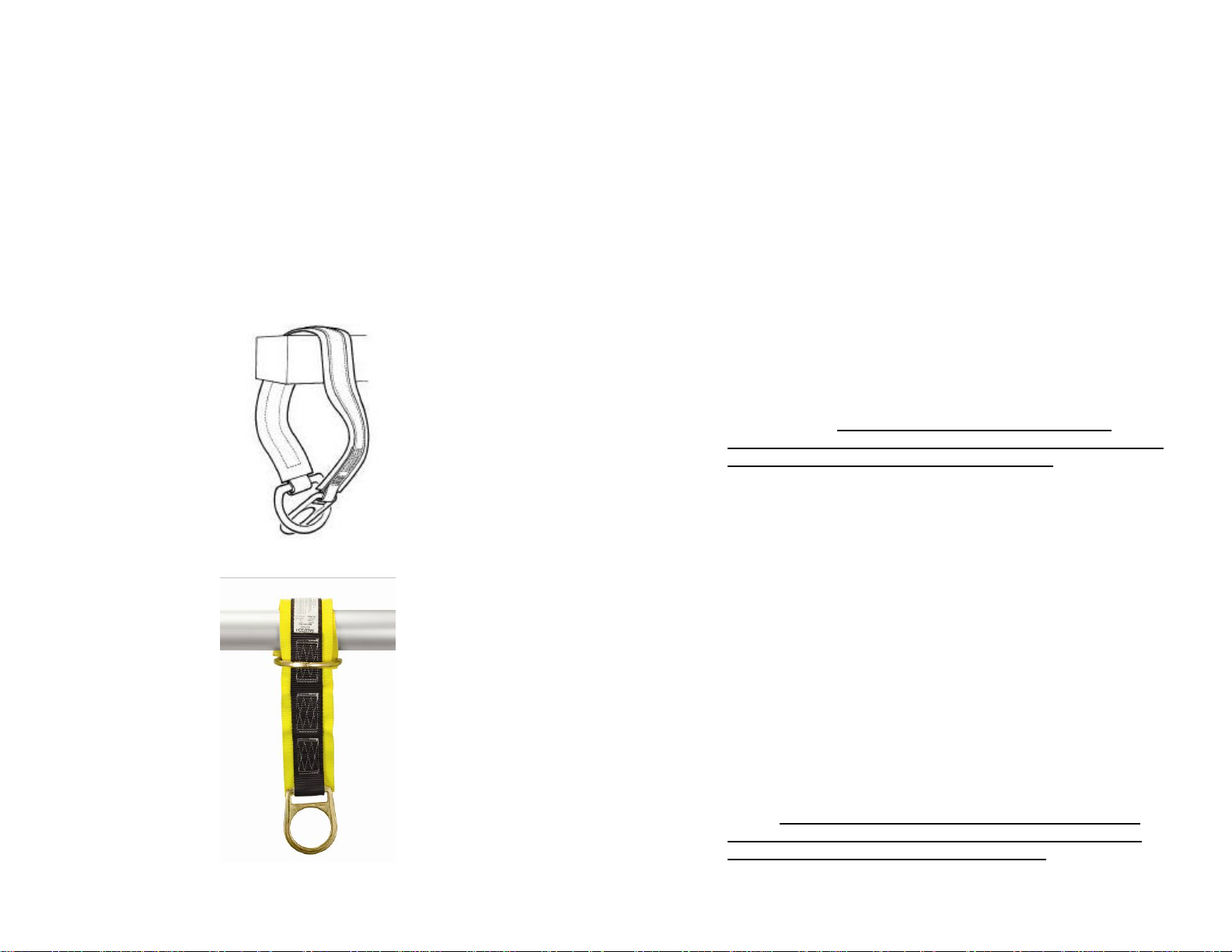

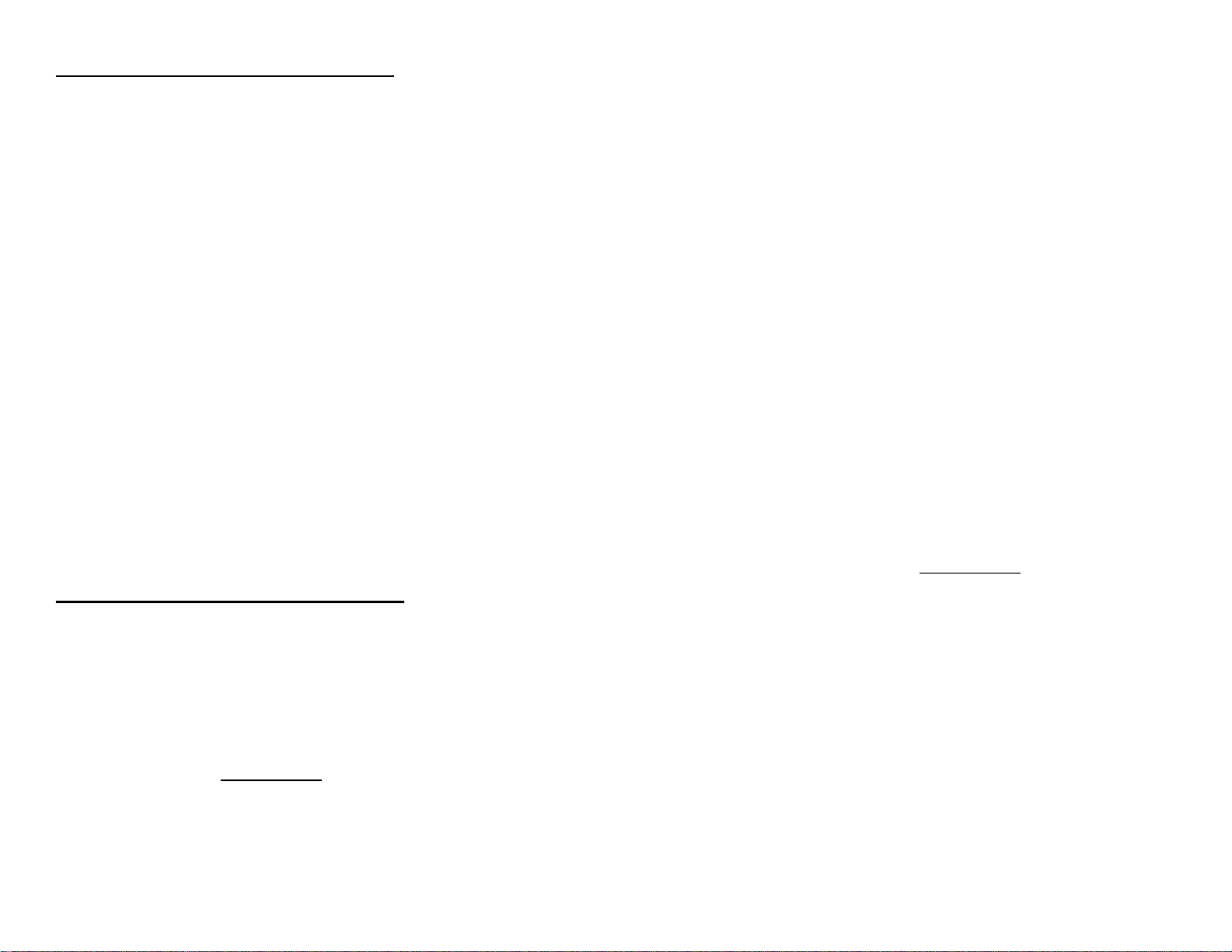

Fig. 3.5

Correct Installation of Cable Pass-Thru Sling Anchor

3.9: Installation and Use – Carabiner Sling Anchors

1. Select the appropriate FallTech Carabiner Sling Anchor based

on the work conditions and specific hazards (See Section 3.2 for

recommendations).

2. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Connecting Devices, Anchorage Connectors,

etc.). Be sure to choose components that are compatible with

this Carabiner Sling Anchor. If you have questions about

product or component compatibility, be sure to contact FallTech

for additional instructions.

3. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your anchorage location.

4. Inspect this Carabiner Sling Anchor, and all components of your

Personal Fall Arrest System in accordance with Section 8 of this

manual. Be sure to consult, and adhere to the instructional

materials, labels and warnings accompanying the other

components of your PFAS as well.

5. Ensure that the rated structural member to which you are about

to attach your Carabiner Sling Anchor is free of sharp, jagged or

abrasive edges. If it is not, cover these hazards with a tarp, pad

or moving blanket to protect your Carabiner Sling Anchor. (See

Section 5 of this manual for details on proper anchorage

strength)

6. Place your Carabiner Sling Anchor over the top of the structural

member so that the carabiner is hanging on one side and the two

O-rings or D-rings are hanging on the other. Connect the

carabiner to one of the two O-rings or D-rings, leaving the other

to hang free – this free O-ring or D-ring will be your attachment

point. (See Figure 3.6)

7. Check your installation and make sure that the gate of the

carabiner will not be forced open by the structural member or

any other object or obstruction in the event of a fall.

8. Check your installation to ensure that the Carabiner Sling Anchor

cannot come off of the structural member at any point along the

intended path of movement or at joints or ends.

9. Ensure your Full Body Harness is properly donned and adjusted

and that your connecting device is securely attached to your

back D-ring. Tie-off to the free D-ring or O-ring on your

Carabiner Sling Anchor with your connecting device. Make sure

25

26

Page 14

that each D-ring or O-ring is used for only a single

connection.

10. Proceed cautiously with your work. Do not run, jump or overreach. Any type of sudden movement may cause you to

lose your footing. Move with care and deliberation at all

times while tied-off and working at heights.

11. Do not allow your connecting device to pass under your arm or

between your legs – severe injury or death may result. Also

avoid sharp edges which may damage your connecting device in

the event of a fall.

12. If the structural member that this Carabiner Sling Anchor is

attached to is sloped or vertical, the Carabiner Sling Anchor must

be positioned next to a stop which will prevent it from sliding or

moving in the event of a fall.

13. If you are tied-off at the foot-level, or in a manner that will allow

more than six feet of free fall, ensure that your connecting device

is rated for extended free falls. Also ensure that the gate of your

carabiner or snap hook which is attached to the Carabiner Sling

Anchor does not make direct contact with the edge of the

structural member or any other obstruction. Such contact could

force a roll-out or accidental disengagement.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements! When using this

device, care must be taken to be aware of the work environment and any

hazards, obstructions or obstacles that may exist. Be careful of any and

all fall hazards and also be aware of slipping and tripping hazards as

well.

Fig. 3.6

Correct Installation of Carabiner Sling Anchor

3.10: Installation and Use – Cable Anchor Extenders

1. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Connecting Devices, Anchorage Connectors,

etc.). Be sure to choose components that are compatible with

this Cable Anchor Extender. If you have questions about

product or component compatibility, be sure to contact FallTech

for additional instructions.

2. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your anchorage location.

3. Inspect this Cable Anchor Extender, and all components of your

Personal Fall Arrest System in accordance with Section 8 of this

manual. Be sure to consult, and adhere to the instructional

materials, labels and warnings accompanying the other

components of your PFAS as well.

4. Check the installation of the anchorage connector to which you

intend to attach this Cable Anchor Extender. Ensure that it has

been inspected and installed according to the manufacturer’s

instructions and that it is firmly attached to the anchorage.

5. Attach the snap hook at the end of this Cable Anchor Extender to

the attachment connector on your anchorage connector. Ensure

that the gate closes and locks automatically, and that the

connection is compatible.

6. Ensure your Full Body Harness is properly donned and adjusted

and that your connecting device is securely attached to your

back D-ring. Tie-off to the Cable Anchor Extender with your

connecting device.

7. Proceed cautiously with your work. Do not run, jump or overreach. While moving, the Ratcheting/Sliding Beam Anchor

should glide on the beam, allowing you greater mobility. If it

does not glide smoothly, then check to ensure the D-ring on the

Beam Anchor is centered on the beam. Also check for jagged

edges, fasteners, paint build-up welding spatter or other

obstructions. Any type of obstruction or any sudden

movement may cause the Beam Anchor to seize-up on the

beam, causing you to lose your footing. Move with care and

deliberation at all times while working at heights.

8. Do not allow your connecting device to pass under your arm or

between your legs – severe injury or death may result. Also

avoid sharp edges which may damage your connecting device in

the event of a fall.

27

28

Page 15

9. The FallTech Cable Anchor Extender should never be used

for foot-level tie-off, nor should it ever be rigged for more

than six feet of free fall: NO EXCEPTIONS. Such a

connection will create Swing Fall and will increase Free Fall

Distance and may lead to serious injury or death.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements! When using this

device, care must be taken to be aware of the work environment and any

hazards, obstructions or obstacles that may exist. Be careful of any and

all fall hazards and also be aware of slipping and tripping hazards as

well.

Section 4: Product Selection

Product selection is as important as the proper use of the product

itself. Poor judgment in product selection can have catastrophic results –

therefore be sure to consult a competent person to ensure that the

product that is issued is appropriate for the application and the specific

location for which it is intended.

ANSI Z359.1-2007, Section 7 describes in detail the steps that should

be taken with regard to the selection of fall arrest equipment. FallTech

strongly encourages the use of this guide by those who employ users of

fall arrest products. The ANSI standard recommends the following steps

be taken:

A workplace assessment by a competent person taking into

account the presence of sources of extreme heat, chemicals,

electrical hazards, environmental contaminants, sharp objects,

abrasive surfaces; moving equipment and materials, unstable,

uneven and slippery walking/working surfaces; unguarded

openings; climatic/weather factors and foreseeable changes to

these conditions. Care must be taken to ensure that the

equipment that is selected is suitable for use where any of these

conditions may exist.

The workplace assessment must identify all paths of movement

and the fall hazards along these paths. Care must be taken to

ensure that there are proper anchorages at appropriate intervals

along these paths to protect the users from these hazards

without exposure to swing-fall conditions. The PFAS selected

must limit the fall distance in order to avoid contact with the next

lower level in the event of a fall.

Anchorage connectors should be selected on the basis of their

suitability for attachment to the anchor point to ensure a

compatible and secure connection.

The exposure of the anchorage connector to sharp edges,

abrasive surfaces and other physical/structural hazards should

be considered when evaluating compatibility.

The competent person shall calculate the weight of all authorized

persons when fully equipped to ensure that they are within the

maximum capacity of the PFAS.

A full body harness meeting the requirements of Z359 shall be

selected, and it shall be sized to fit the user as per the

manufacturer’s instructions.

Connectors that are selected shall be suitably sized and shaped

so as to be compatible with the devices to which they will be

attached.

The competent person shall select the method of protecting the

equipment from damage by workplace conditions, in accordance

with the manufacturer’s instructions.

The competent person shall check the equipment instructions

and markings to ensure compliance with the appropriate

standards and will ensure that manufacturer’s instructions;

markings and warnings are read and followed.

If the PFAS that is selected is made up of components from

different manufacturers, the competent person will ensure that

these components are compatible.

FallTech strongly encourages that the following points also be

considered in the course of product selection, in addition to the points

above:

Select the anchorage connector that is most appropriate for your

application and for the anchor point to which it will be attached.

While sling-style anchors are popular because of their versatility,

they are not always the best choice where sharp or angular

edges are present on the structure to which they are attached.

Select a full body harness of appropriate durability for your

workplace which contains all of the attachment elements that you

will require. Never attach any SRL to anything other than the

back/dorsal d-ring or the front/chest d-ring of your full body

harness.

Depending on workplace conditions and hazards, you may need

to employ multiple systems or different combinations of

components. Do not try and force the system to fit the

application. Use of the correct equipment is the best policy.

29

30

Page 16

Section 5: Anchorage Considerations

OSHA 1910.66 and 1926.502 state that anchorages used for

attachment of a PFAS must be independent of any anchorage being

used to support or suspend platforms, and must support at least 5,000

lbs. per user attached, or be designed, installed and used as part of a

complete PFAS which maintains a safety factor of at least two, and is

supervised by a qualified person (architect, structural engineer, etc.).

The anchor-point to which this Beam Anchor is attached must

capable of sustaining static loads in directions applied by the personal

fall arrest system of at least 3,600 lbs (or at least twice the expected

dynamic load) with certification of a qualified person (architect, structural

engineer, etc.), or 5,000 lbs in the absence of certification. If multiple

personal fall arrest systems are being attached to the same anchorage,

the minimum values stated above must be multiplied by the number of

users.

Ensure that this Sling Anchor is compatible with the anchor point to

which you are attaching it. Be sure that this Beam Anchor is compatible

with other elements of your Personal Fall Arrest System (PFAS) by

checking the manufacturer’s instructions for these compone nts.

Be sure that your anchorage is mounted overhead or above the level

of the back d-ring of your full body harness if at all possible (check for

specific restrictions in sections 3.3 – 3.10). Be sure to calculate your

clear-fall (as discussed in section 2.9) and to avoid swing fall hazards.

Ensure the fall path is clear of obstructions and impalement hazards.

Section 6: Employer and User Training

6.1: Special notes for the Employer

As an employer, you may be obliged to provide Personal Protective

Equipment (to include Personal Fall Arrest and Fall Protection

Equipment) along with an appropriate amount of training to your

employees so that they will be adequately prepared to use this

equipment in the course of their work. If you are unsure about your duty

to provide fall protection, consult Title 29 CFR, section 1926.501 which

can easily be viewed at www.osha.gov. Another important resource for

employers is the Consensus standard on Managed Fall Protection:

ANSI Z359.2-2007.

Equally important is the subject of product/equipment selection. If

you are obliged to provide fall protection equipment for your employees,

be sure to consult with or appoint a competent or qualified person to

select and prescribe equipment that is suitable to address the specific

hazards which may be present on your job-site or in your facility. There

are different products for different applications, and under many

circumstances these products are not interchangeable. If you have

questions as to whether this product is suitable for your application,

please contact FallTech for assistance.

It is important to note that improper use of fall arrest equipment can

be just as dangerous as not using it at all. Failure to adequately train

and supervise your employees may result in serious injury or death. It is

critical to have a training program supported by documentation,

refresher/remedial training and to establish best practices where the

employment of all PPE is concerned.

6.2: User Training

It is the responsibility of the user of this equipment to read and fully

understand these instructions before employing this product as part of a

Personal Fall Arrest System (PFAS). Every user of fall protection should

be provided a four to eight hour course of instruction for the Authorized

User. Training must also be provided in the use of each component of

the user’s PFAS and in the recognition of fall hazards. During the course

of this training, the user may not be exposed to a fall hazard.

In the absence of a formal training program, FallTech has designed

these instructional materials to act as an abbreviated course of

instruction in an effort to give the user an over-view of fall arrest. This

manual does not constitute a comprehensive training program, and it is

not all-inclusive. Be sure to consult www.osha.gov for details on OSHA

requirements for training. FallTech has additional services available to

assist with end-user training – contact a FallTech sales professional for

additional details.

As a minimum, training should address the following points:

ABCD’s of Fall Arrest (as discussed in Section 2).

Recognition of fall hazards.

Fall hazard elimination and control methods.

Applicable fall protection regulations and standards.

The responsibilities of designated persons (Authori zed,

Competent, Qualified).

How to use written fall protection procedures.

Inspection of equipment components and systems before use.

Fall protection rescue procedures.

Installation and use of products common to your duties, job-site

or facility.

31

32

Page 17

It is important to note that improper use of this equipment can be just

as dangerous as not using it at all. Failure to read, understand and

follow these instructions may result in serious injury or death.

Section 7: Fall Protection Plan

Title 29 CFR, section 1926.500 – 503 requires that an employer have

a written fall protection plan where fall hazards exist. The best way to

address a fall hazard is to eliminate it entirely or to employ a passive

system to restrict access to the hazard (i.e. guardrails, netting, covers,

etc.) Fall arrest products are the last line of defense in the hierarchy of

fall protection, and should be used as a last resort by employees who

have been thoroughly trained. The accepted fall protection hierarchy is

as follows:

Eliminate the fall hazard.

Passive fall protection (guardrails, safety nets, barriers, etc.).

Fall Restraint (prevent the worker from having access to the fall

hazard by using a fixed lanyard which is short enough to restrict

access to the hazard).

Fall Arrest (utilizing Personal Fall Arrest Systems).

Administrative Controls (use of warning lines, controlled access

zones or monitors).

Two exceptional resources for developing a written fall protection

plan are OSHA 1926 Subpart M, Appendix E and ANSI Z359.2-2007. All

ANSI standards are available for purchase at www.ansi.org in the estandards store.

7.1: The Fall Protection Plan

As a minimum, a fall protection plan should identify and/or address

the following points:

Any and all fall hazards which may exist on your job-site

or in your facility.

Steps that have been taken to eliminate each fall hazard.

Equipment that has been or will be employed to address

each fall hazard.

Provisions for 100% continuous fall protection in the

vicinity of all fall hazards.

Training procedures for all authorized persons.

Identification of acceptable anchorages for positioning,

restraint and fall arrest.

Clear-fall requirements.

Use and egress from the system.

Limitations on use of the system (maximum Free-fall,

arrest force and maximum number and permitted

locations of authorized persons who may use the system).

Procedures for installation, use and removal of the

system.

Detailed instructions for inspection of systems and system

components to include rejection criteria and replacement

procedures.

A detailed plan and procedures for the rescue of a worker

who may be involved in a fall event.

7.2: Rescue Plan

In the event of a fall, OSHA requires that a prompt rescue be

provided. In order to facilitate a prompt and effective rescue, it is

important to have a Rescue Plan as part of your overall Fall Protection

Plan.

The rescue plan should include detailed procedures for summoning a

professional rescue agency (such as the local fire department) and/or for

performing self-rescue or in-house rescue.

For detailed assistance in formulating and maintaining an effective

rescue plan, see ANSI Z359.2-2007.

7.3: Suspension Trauma

Suspension Trauma (also referred to as orthostatic intolerance) is a

condition that can arise from being suspended in a full-body harness for

a prolonged period of time while awaiting rescue after a fall. Under these

circumstances, blood circulation can be restricted allowing a large

volume of blood to accumulate or pool in the veins of the workers legs.

This condition can result in a variety of symptoms, some of which include

light-headedness, loss of consciousness, difficulty concentrating and

palpitations.

Following a rescue, Suspension Trauma can be so acute as to cause

cardiac arrest when the large volume of un-oxygenated blood

overwhelms the heart. This severity of this condition can be greatly

reduced by using any one of a variety of devices offered to alleviate

Suspension Trauma, such as FallTech’s ReliefPak and by providing a

prompt rescue in the event of a fall.

33

34

Page 18

For additional details on Suspension Trauma, refer to OSHA’s Safety

and Health Information Bulletin SHIB 03-24-2004 at www.osha.gov.

Section 8: Product Inspection

Inspection is a critical element in the employment of any fall

protection equipment. In order to protect Authorized Persons who are

using this Sling Anchor, it is important that the employer establishes

procedures that has layers of inspection to ensure that any mechanical

or functional deficiencies are recognized before the produ ct is put into

use.

8.1: Issuing

If the Sling Anchor is to be kept in a locker or tool crib between

periods of use, the person responsible should inspect the product upon

issuing and receipt to ensure that it is in proper working order. If any

deficiency is noted, this should be logged on the inspection record and

the product should be removed from service and handled in accordance

with the employer’s lock-out/tag-out policy. If this Sling Anchor exhibits a

deficiency, it should be immediately removed from service and replaced.

8.2: Daily/Incidental Use

OSHA 1910.66 and OSHA 1926.502 (as well as ANSI Z359.1-2007

and ANSI A10.32-2004) specifically require that the user inspect all

fall protection equipment prior to each use to ensure proper

function and to ensure that the equipment is in serviceable

condition. Failure to do so may result in serious injury or death.

FallTech requires that the following steps be taken during each

inspection prior to use of this Sling Anchor:

1. Check for any damage to the Sling Anchor. Inspect all metal

parts for cracking, bending, dents, burrs or deformation of any

kind. Ensure that there are no missing parts. If any of these

conditions exist, remove from service immediately and replace.

2. Inspect all metal surfaces for evidence of excessive corrosion.

Light surface corrosion should be removed with steel wool. If

excessive corrosion exists, remove from service immediately and

replace.

3. Inspect the Sling Anchor for build-up of any surface

contamination such as paint, grease, oil, dirt or any other foreign

substance which may inhibit the operation of any mechanical

parts or which may conceal damage or inhibit the performance of

the product.

4. Check the function of any and all mechanical parts such as

carabiners or snap hooks. Any of these elements should be

capable of being operated and should close and lock

automatically. If there is any mechanical deficiency, immediately

remove this Sling Anchor from service and have it replaced.

5. Inspect any webbing components for cuts, tears, holes, burns,

fraying or damage from abrasion. If any of these conditions

exist, remove this Sling Anchor from service immediately and

have it replaced.

6. For Web Sling Anchors, check the stitching for any missing

stitching, tears or damage.

7. For Web Sling Anchors, check wear pads or plastic rollers for

excessive wear. If these elements are damaged or missing,

remove this product from service immediately and have it

replaced.

8. Inspect any cable components and connecting elements for

fraying, damage from abrasion, cuts, kinks, burrs or loose wire.

Check for burns or evidence of damage from an electric arc.

Check for damage from corrosion.

9. Inspect the labels and ensure that they are present or legible.

Re-familiarize yourself with any warnings or instruction on the

labels. If the labels are missing or illegible, remove the Sling

Anchor from service and have it replaced.

10. The results of semi-annual Competent Person inspections

should be recorded in section 8.3 of this manual.

11. If this Beam Anchor fails any part of this inspection or if it has

been used to arrest a fall, be sure to remove it from service

immediately and have it replaced.

8.3: Mandatory Semi-Annual Inspection

ANSI Z359.1-2007 requires that all fall protection equipment be

inspected by a competent person other than the user at least once each

year. FallTech strongly encourages that all fall protection equipment be

inspected by a competent person other than the user at least once every

six months.

This inspection should be noted in the inspection log below, along

with any deficiencies. This inspection should also be used as an

opportunity to counsel any authorized persons with respect to any

deficiencies that they may have failed to note in their daily inspections.

35

36

Page 19

Inspection Log

FallTech Sling Anchor

Model #:_______________

Serial #:_______________

Mfg. Date:_____________

Inspection

Date

Inspector Comments Pass/Fail Corrective

Action to be

Taken

Approved

By

Inspection Log

FallTech Sling Anchor

Model #:_______________

Serial #:_______________

Mfg. Date:_____________

Inspection

Date