Page 1

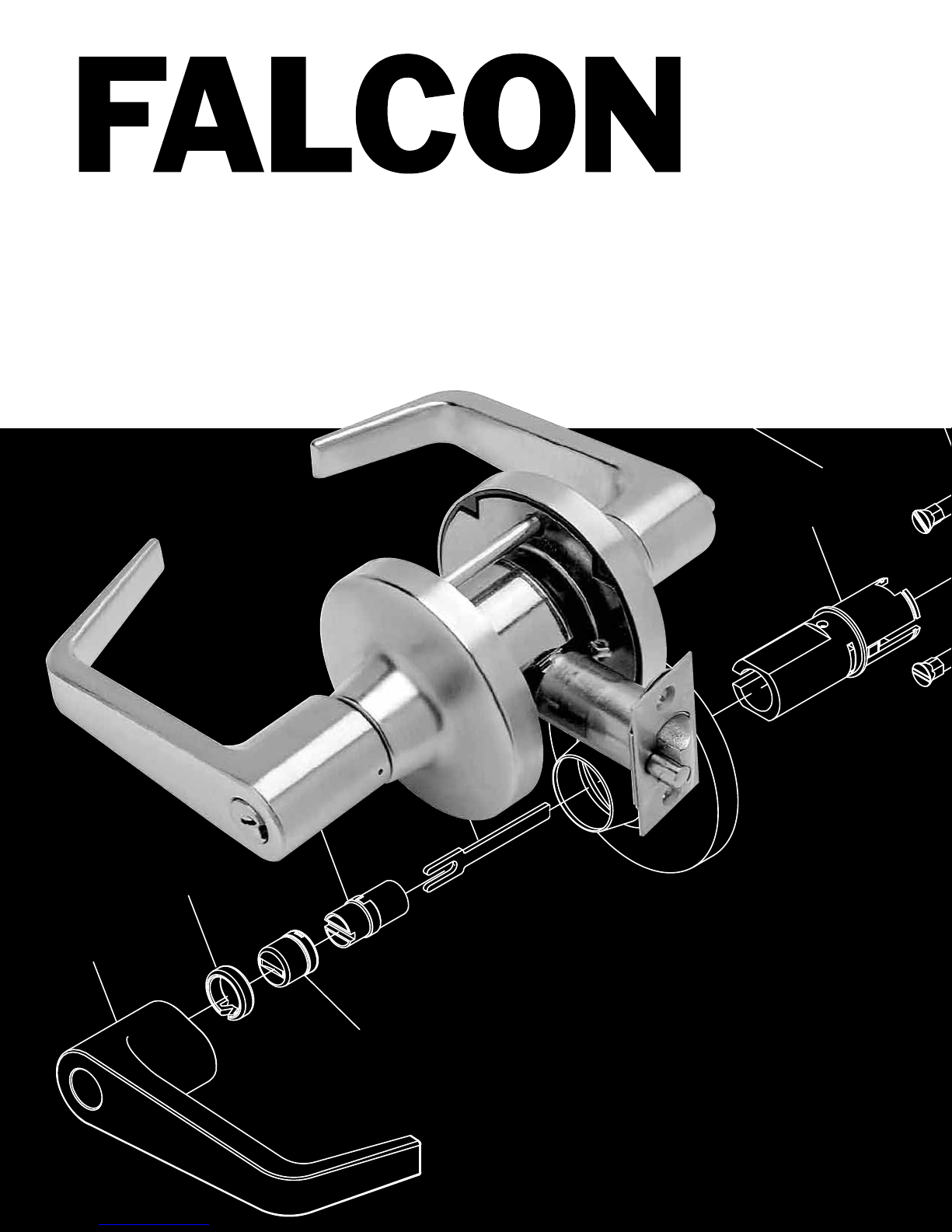

T Series Service Manual

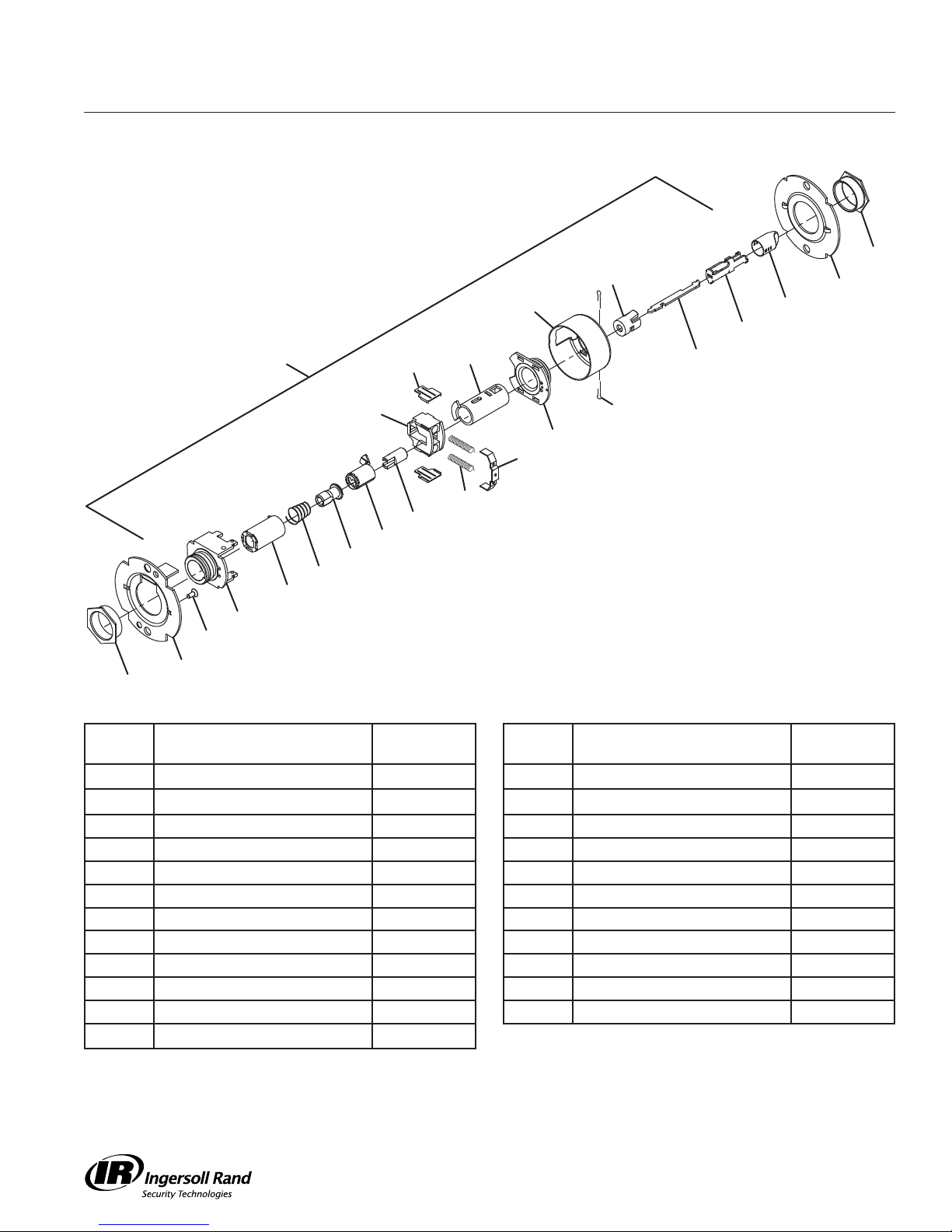

Extra Heavy Duty, Grade 1 Cylindrical Lever Lock

H

T

V

S

Q

B

R

Page 2

Table of Contents

Table of Contents

Introduction ............................................................... iii

Lock Assembly Index ................................................. 1

Chassis Assemblies ................................................... 3

Trim Assemblies ....................................................... 27

Standard Cylinders .................................................. 41

Falcon Complete Standard Cylinders ..................... 41

Standard Cylinder Options ...................................... 41

Standard Cylinder Tailpieces ................................... 41

Cylinders ................................................................... 41

Competitor Keyway Compatibility ............................ 42

IC Cylinders .............................................................. 42

Falcon Complete IC Cylinders ................................ 42

IC Cylinder Options ................................................. 43

IC Cylinder Tailpieces .............................................. 43

Competitor IC Compatibility .................................... 43

Inserts and Spindles ................................................ 44

Inside Inserts and Spindles ..................................... 44

Outside Inserts and Spindles .................................. 45

Levers ........................................................................ 46

Closed Levers ......................................................... 46

Open Levers ............................................................ 46

SFIC/IC Levers ........................................................ 47

Spring Cage Replacement Kits ............................... 47

Latches and Accessories ........................................ 48

Levers ........................................................................ 48

Grade 1 Latches...................................................... 48

Grade 2 Latches...................................................... 48

Accessories ............................................................. 49

Strikes and Dust Boxes ........................................... 50

Strikes ..................................................................... 50

Dust Boxes .............................................................. 50

Preparation and Installation .................................... 51

Installation Template ............................................... 51

Tailpiece Installation ................................................ 51

Installation Instructions ........................................... 52

Spring Cage Replacement Installation .................... 58

Warranty .................................................................... 59

T-Series Service Manual

ii

Page 3

Introduction

Introduction

This manual contains a complete listing of T-Series (Grade 1) cylindrical lock parts and assemblies manufactured by

the Falcon Lock Company. This edition lists components of T-Series locks manufactured after July 2007.

Exploded views of each lock chassis and trim assemblies are provided with an accompanying chart to identify parts

for replacement purposes. In addition, this manual provides general cylinder information, many auxiliary components

of the T-Series cylindrical locks and installation instructions.

Standard Features*

Certifications ANSI A156 .2, Series 4000, Grade 1, UL Listed for 3-hour fire door.

Latch

Strike

Backset

Cylinder 6-Pin solid brass, keyed 5-pin, Falcon G keyway, keyed different (KD)

Door Range

Keys Two nickel silver cut keys per lock, keyed 5-pin, Falcon G keyway

* Locks are furnished with standard features unless otherwise specified.

156” x 256M”, Square corner faceplate, 1” housing diameter, 56O” throw.

56M” x 4(6”, ANSI, Square corner, no box.

26M”

16M” – 256” standard

Lock Assembly Drawing Index

The Lock Assembly Drawing Index provides visual representations and textual descriptions of available functions.

Page numbers for full trim and chassis drawings are referenced.

Outside Inside

Deadlatch

Key

Electrified

Knurled Knob

Springlatch

Push button

Fixed Lever

Turn/push button

iii

T-Series Service Manual

Page 4

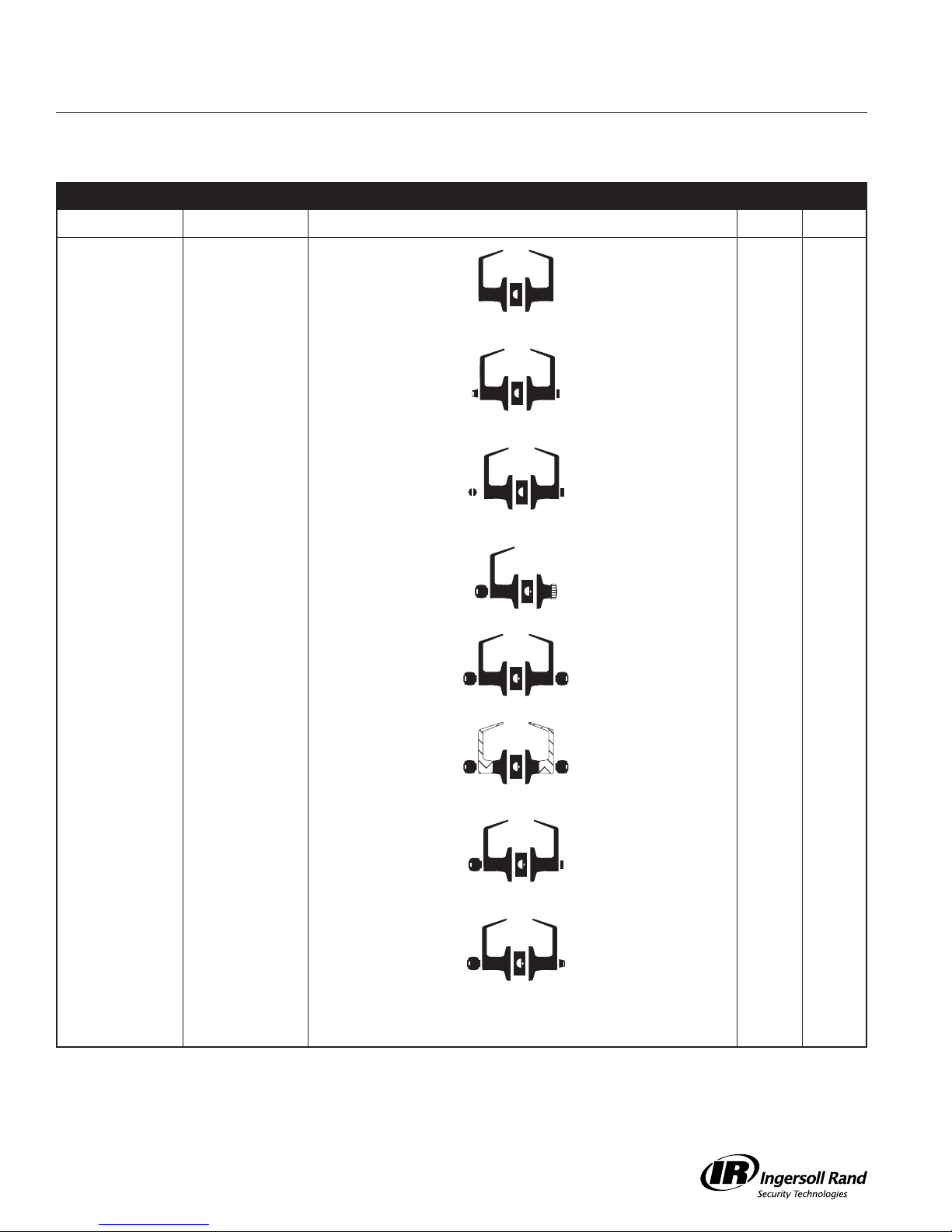

Lock Assembly Index

Lock Assembly Index

Function ANSI A156.2, 1996, Series 4000, Grade 1 Trim Chassis

FALCON ANSI DESCRIPTION OUTSIDE FUNCTION INSIDE FUNCTION

T101 F75 Passage/Closet

Latch

T291 Privacy Hospital

Lock

T301 F76 Privacy Lock

T351 Closet Lock

T381 F88 Classroom

Security Lock

Lever is always unlocked. Lever is always unlocked

Unlocked from outside

by turning emergency

turn-button.

Can be opened from

outside with small

screwdriver or

emergency release tool.

Can be locked with key. Knurled knob free for

Outside lever locked or

unlocked by key in either

lever.

and is always free for

immediate egress.

Push-button locks

outside lever. Turning

inside lever or closing

door releases button.

Inside lever is always

free for immediate egress.

Push-button locks

outside lever. Turning

inside lever or closing

door releases button.

Inside lever is always

free for immediate egress.

immediate egress unless

outside lever locked with

key.

Key locks or unlocks

outside lever. Inside lever

is always unlocked and is

always free for

immediate egress.

27 3

28 4

29 4

30 5

6 (IC)

31 7

8 (IC)

T411 F87 Asylum Lock

T501 F82 Entry Lock

T511 F109 Entry/Office Lock

NOTE: Any function with deadlatch locks latchbolt when door is closed.

Lever is fixed. Entrance

by key only.

Lever is

unlocked with key

when push-button

is pushed.

Key retracts latch when

button pushed and

turned. Lever is

unlocked with key

when push-button

is pushed.

Lever is fixed. Exit by

key only.

Push-button locks

outside lever. Turning

inside lever releases

button. Inside lever is

always free for immediate

egress.

Turn/push-button: pushing

and turning button locks

outside lever until manually

unlocked. Push-button:

pushing button locks

outside lever until unlocked

by turning inside lever.

Inside always free for

immediate egress.

32 9

10 (IC)

33 11

12 (IC)

34 13

14 (IC)

T-Series Service Manual

1

Page 5

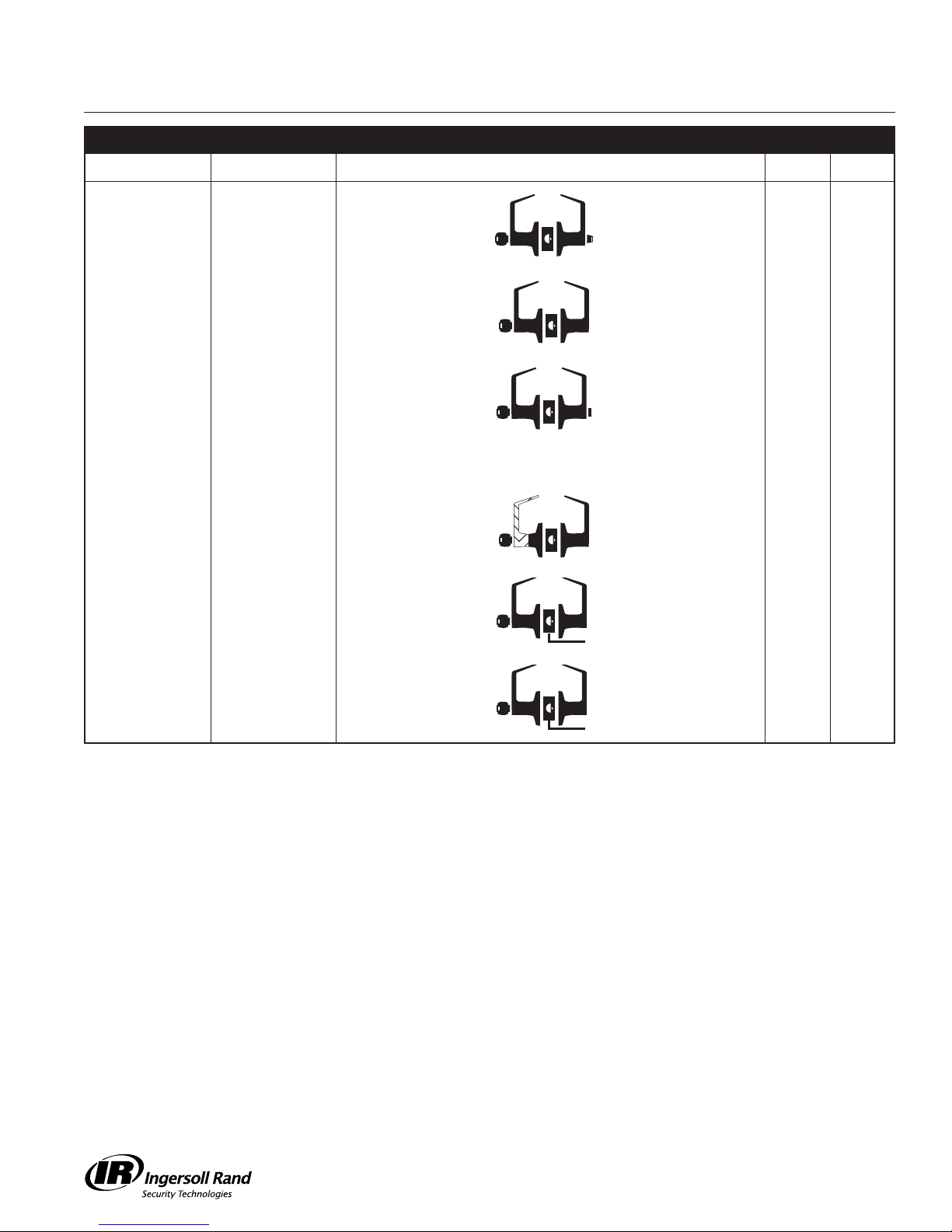

Lock Assembly Index

Function ANSI A156.2, 1996, Series 4000, Grade 1 Trim Chassis

FALCON ANSI DESCRIPTION OUTSIDE FUNCTION INSIDE FUNCTION

T521 F81 Office Lock

T561 F84 Classroom Lock

T571 F90 Dormitory Lock

T581 F86 Storeroom Lock

T851 Storeroom Lock

(Electrified – Fail

Safe)

Key retracts latch when

button turned.

Outside lever locked or

unlocked by key.

Locked or unlocked

by key. When locked

by key it can only be

unlocked by key.

Lever is fixed. Entrance

by key only.

Lever is continuously

locked electrically.

Unlocked by switch or

power failure. When

locked, key retracts latch.

Turning button locks

outside lever until manually

unlocked. Inside always

free for immediate

egress.

Inside lever is always

unlocked and always

free for immediate

egress.

Push-button locks

outside lever. Turning

lever or closing door

releases button.

Inside lever is always

unlocked and is always

free for immediate

egress.

Inside lever is always

unlocked and is always

free for immediate

egress.

Inside lever is always

unlocked and is always

free for immediate

egress.

35 15

16 (IC)

36 17

18 (IC)

37 19

20 (IC)

38 21

22 (IC)

39 23

24 (IC)

T881 Storeroom Lock

(Electrified – Fail

Secure)

NOTE: Any function with deadlatch locks latchbolt when door is closed.

Lever is continuously

locked mechanically until

unlocked by electric

current. When locked,

key retracts latch.

Inside lever is always

unlocked and is always

free for immediate

egress.

40 25

26 (IC)

2

T-Series Service Manual

Page 6

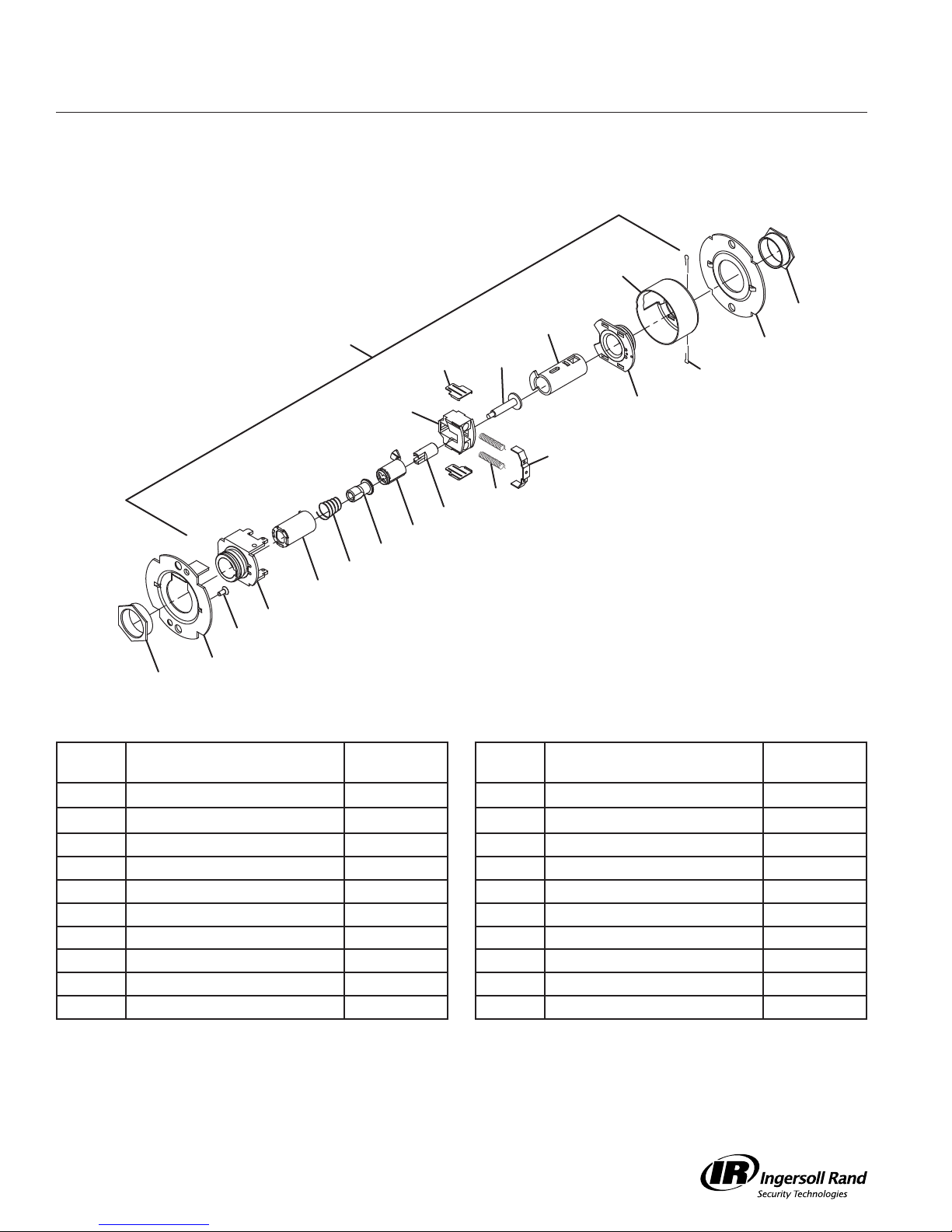

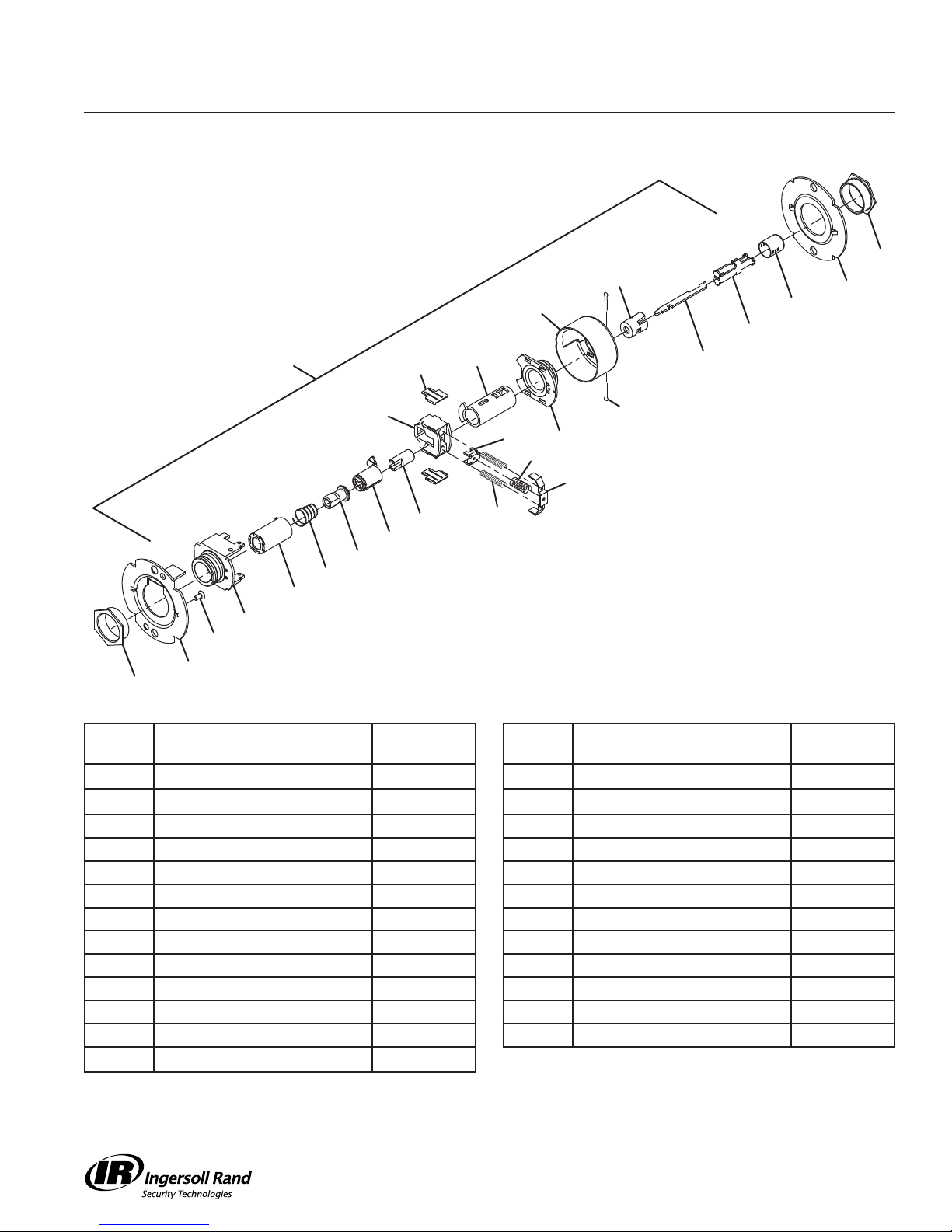

Chassis Assemblies

T101

Passage Latchset

12

1

2

8 (2)

6

14

7

13 (2)

11

10

9 (2)

6

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T101 A30761-000-00 8 Retractor Insert (2) 022986-001-50

2 Flanged Nut (2) 030726-000-30 9 Retractor Spring (2) 022108-001-60

3 Outer Mounting Plate 030712-001-30 10 Retractor Spring Retainer 022112-000-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 12 Housing Case 022114-000-30

6 Spindle 030733-000-55 13 Cotter Pin (2) 002893-000-60

7 Retractor 022106-002-55 14 Inner Mounting Plate 030712-000-30

031533-006-30 11 Hub and Plate Assembly A30747-000-00

Call Out

Number Description Part Number

T-Series Service Manual

3

Page 7

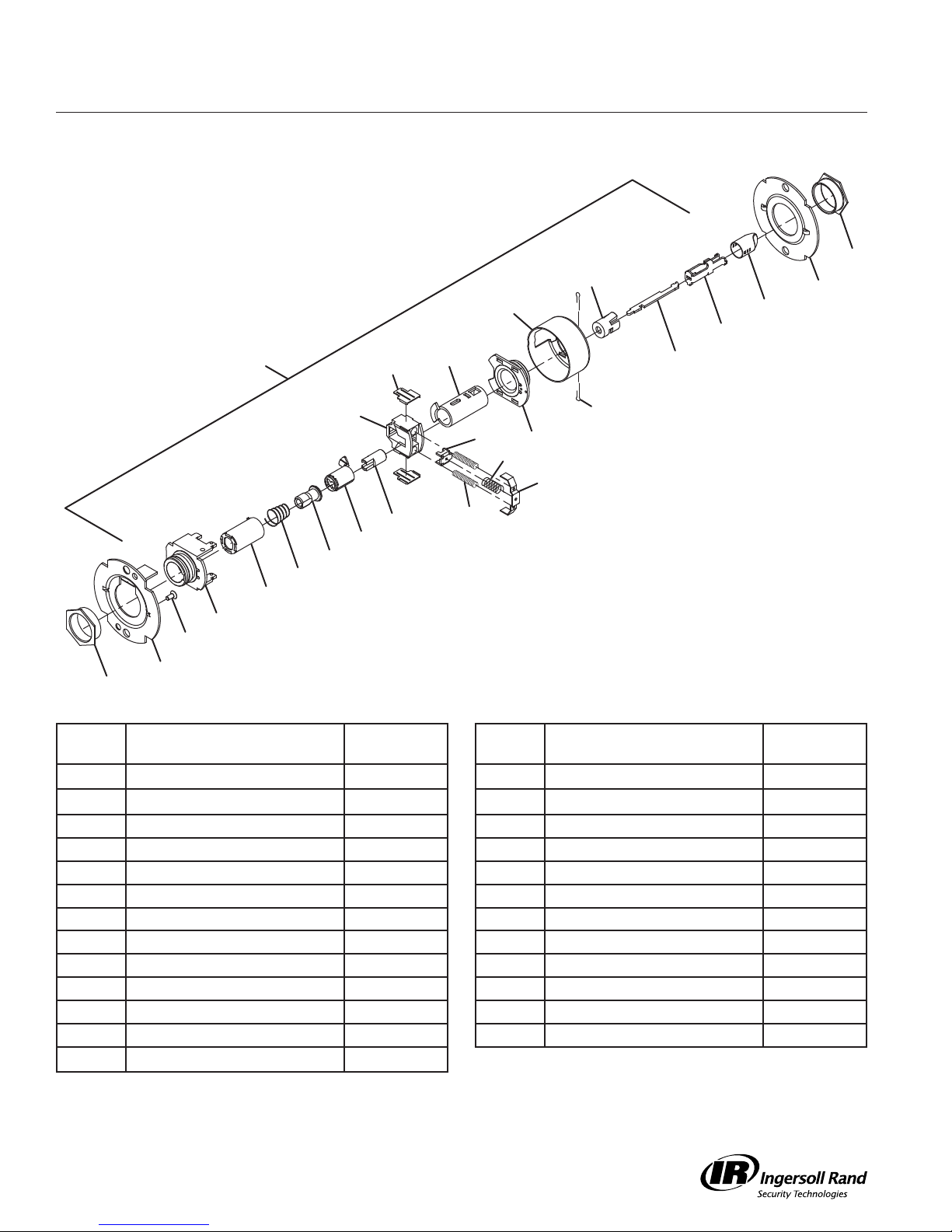

T291/T301

Privacy Hospital Lock

Chassis Assemblies

2

22

12

25

24

1

8 (2)

6

23

14

7

20

11

13 (2)

21

10

19

9 (2)

18

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T291/T301 A30765-000-00 14 Inner Mounting Plate 030712-000-30

2 Flanged Nut (2) 030726-000-30 15 Spindle, 1 Ear, Outer 030732-005-30

3 Outer Mounting Plate 030712-001-30 16 Clutch Spring 030709-000-60

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 18 Key Spindle STD 030718-000-30

6 Spindle 030733-000-55 19 Push Actuator 030711-000-30

7 Retractor 022106-002-55 20 Slide Catch 022105-000-30

8 Retractor Insert (2) 022986-001-50 21 Slide Catch Spring 012107-001-60

9 Retractor Spring (2) 022108-001-60 22 Push Button Sleeve 022134-000-50

10 Retractor Spring Retainer 022112-000-30 23 Dogging Bar 030722-000-30

11 Hub and Plate Assembly A30747-000-00 24 Push/Turn Button Mount 030731-000-30

12 Housing Case 022114-000-30 25 Push Button Cap 030728-000*

13 Cotter Pin (2) 002893-000-60

031533-006-30 17 Clutch Driver 030716-001-30

Call Out

Number Description Part Number

4

T-Series Service Manual

Page 8

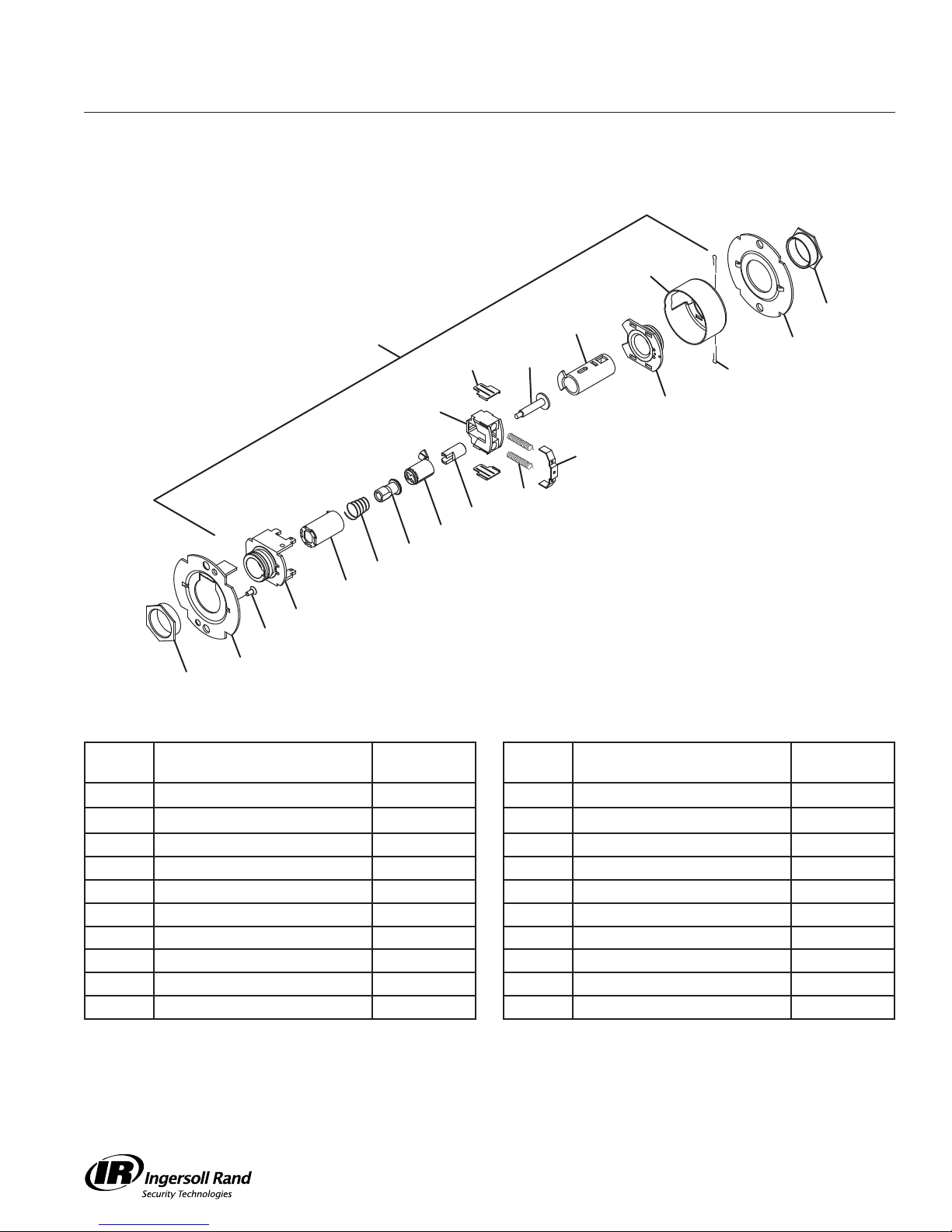

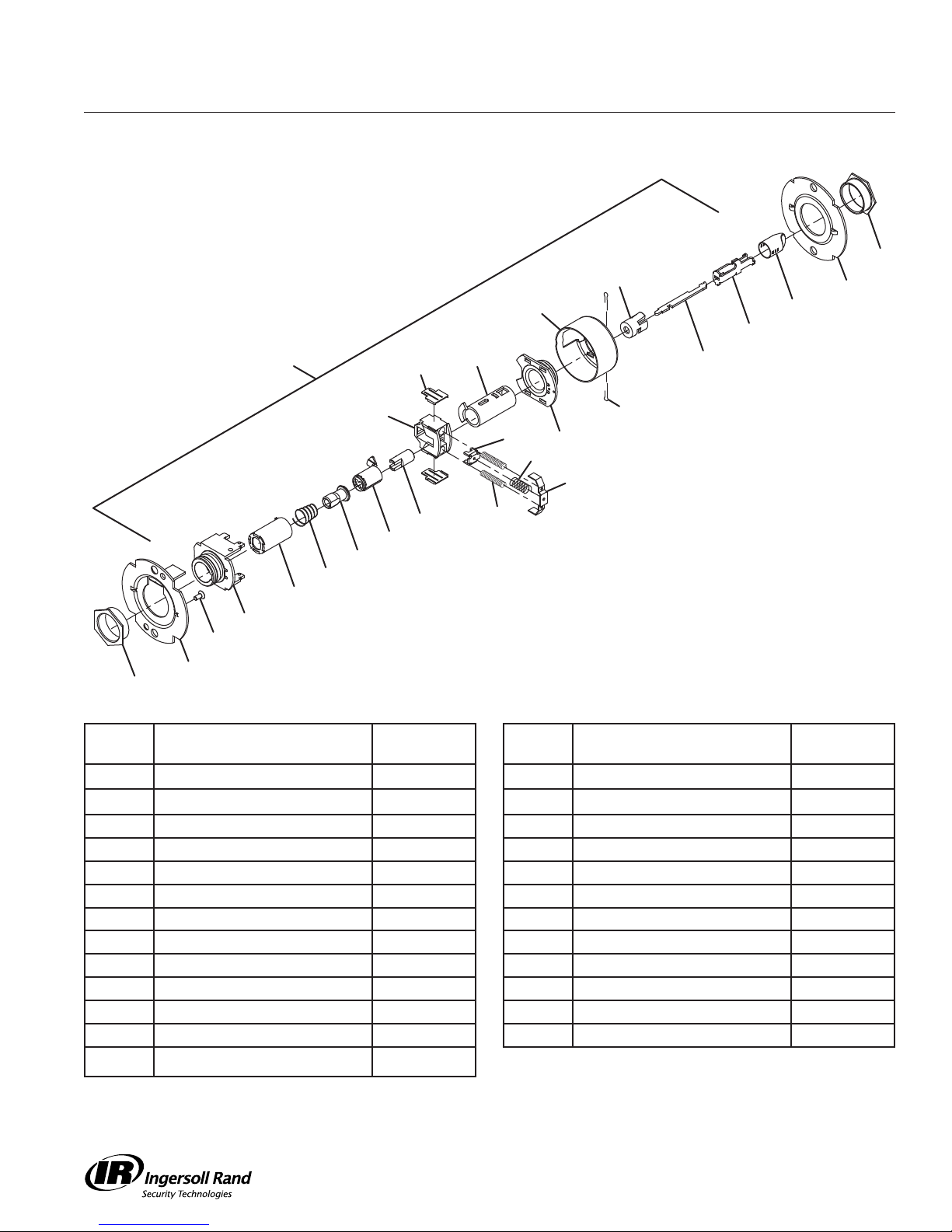

Chassis Assemblies

T351

Closet Lock

12

1

2

8 (2)

6

14

7

13 (2)

11

10

9 (2)

26

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T351/T561 A30758-000-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 26 Key Spindle Assembly, STD A30780-000-30

8 Retractor Insert (2) 022986-001-50

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

T-Series Service Manual

5

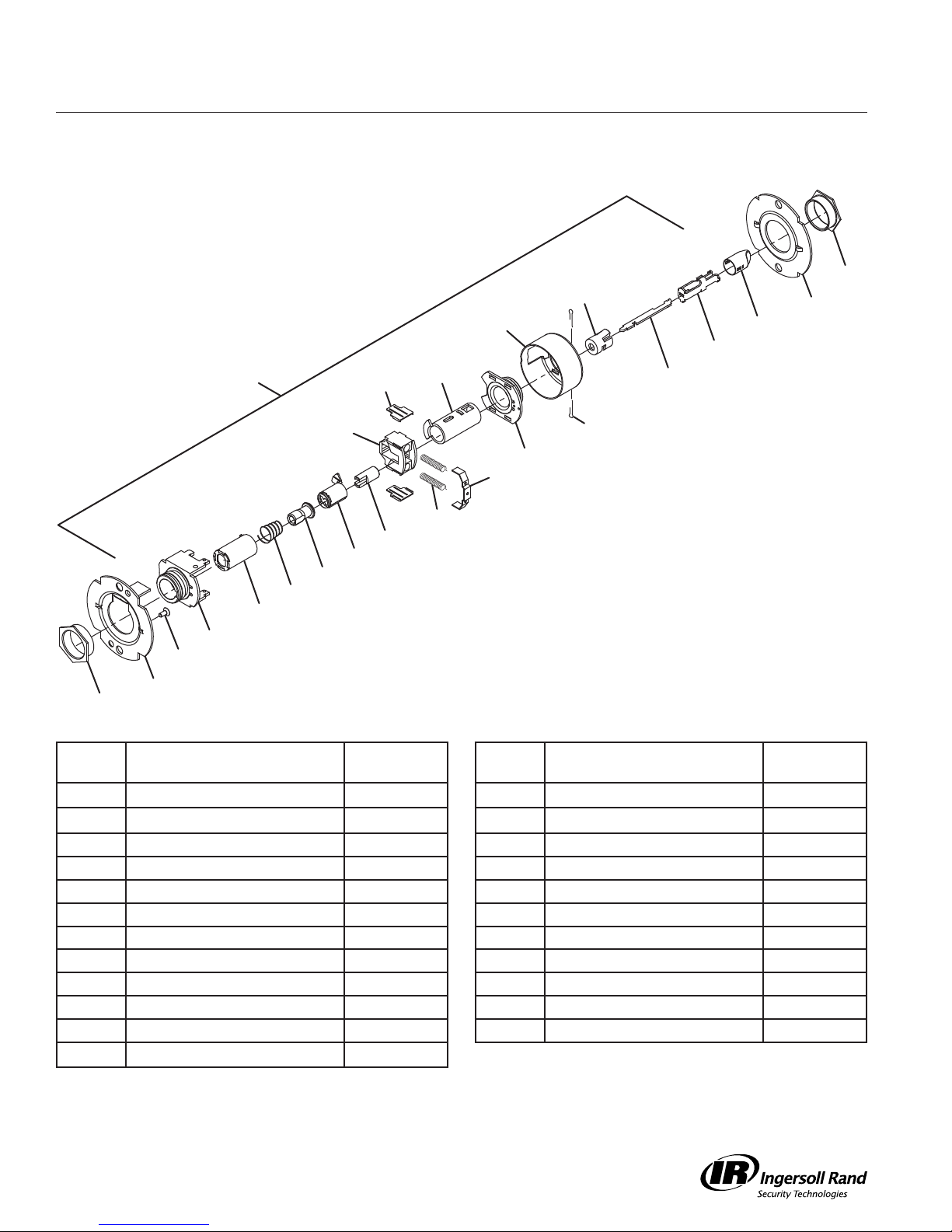

Page 9

T351

Closet Lock – IC

Chassis Assemblies

12

1

2

14

8 (2)

6

7

13 (2)

11

10

9 (2)

27

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T351/T561-ICA30758-001-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 27 Key Spindle Assembly, IC A30780-001-30

8 Retractor Insert (2) 022986-001-50

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

6

T-Series Service Manual

Page 10

Chassis Assemblies

T381

Classroom Security Lock

12

28

2

1

8 (2)

30

14

13 (2)

7

11

10

9 (2)

19

18

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T381 A30767-000-00 12 Housing Case 022114-000-30

2 Flanged Nut (2) 030726-000-30 13 Cotter Pin (2) 002893-000-60

3 Outer Mounting Plate 030712-001-30 14 Inner Mounting Plate 030712-000-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 16 Clutch Spring 030709-000-60

7 Retractor 022106-002-55 17 Clutch Driver 030716-001-30

8 Retractor Insert (2) 022986-001-50 18 Key Spindle STD 030718-000-30

9 Retractor Spring (2) 022108-001-60 19 Push Actuator 030711-000-30

10 Retractor Spring Retainer 022112-000-30 28 IS Key Spindle Assembly, STD A30913-000-00

11 Hub and Plate Assembly A30747-000-00 30 Connecting Rod 030734-000-30

031533-006-30 15 Spindle, 1 Ear, Outer 030732-005-30

Call Out

Number Description Part Number

T-Series Service Manual

7

Page 11

T381

Classroom Security Lock – IC

Chassis Assemblies

12

29

2

1

8 (2)

30

14

13 (2)

7

11

10

9 (2)

19

31

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T381 A30767-001-00 12 Housing Case 022114-000-30

2 Flanged Nut (2) 030726-000-30 13 Cotter Pin (2) 002893-000-60

3 Outer Mounting Plate 030712-001-30 14 Inner Mounting Plate 030712-000-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 16 Clutch Spring 030709-000-60

7 Retractor 022106-002-55 17 Clutch Driver 030716-001-30

8 Retractor Insert (2) 022986-001-50 19 Push Actuator 030711-000-30

9 Retractor Spring (2) 022108-001-60 29 IS Key Spindle Assembly, IC A30913-001-00

10 Retractor Spring Retainer 022112-000-30 30 Connecting Rod 030734-000-30

11 Hub and Plate Assembly A30747-000-00 31 Key Spindle, IC 030718-001-30

031533-006-30 15 Spindle, 1 Ear, Outer 030732-005-30

Call Out

Number Description Part Number

8

T-Series Service Manual

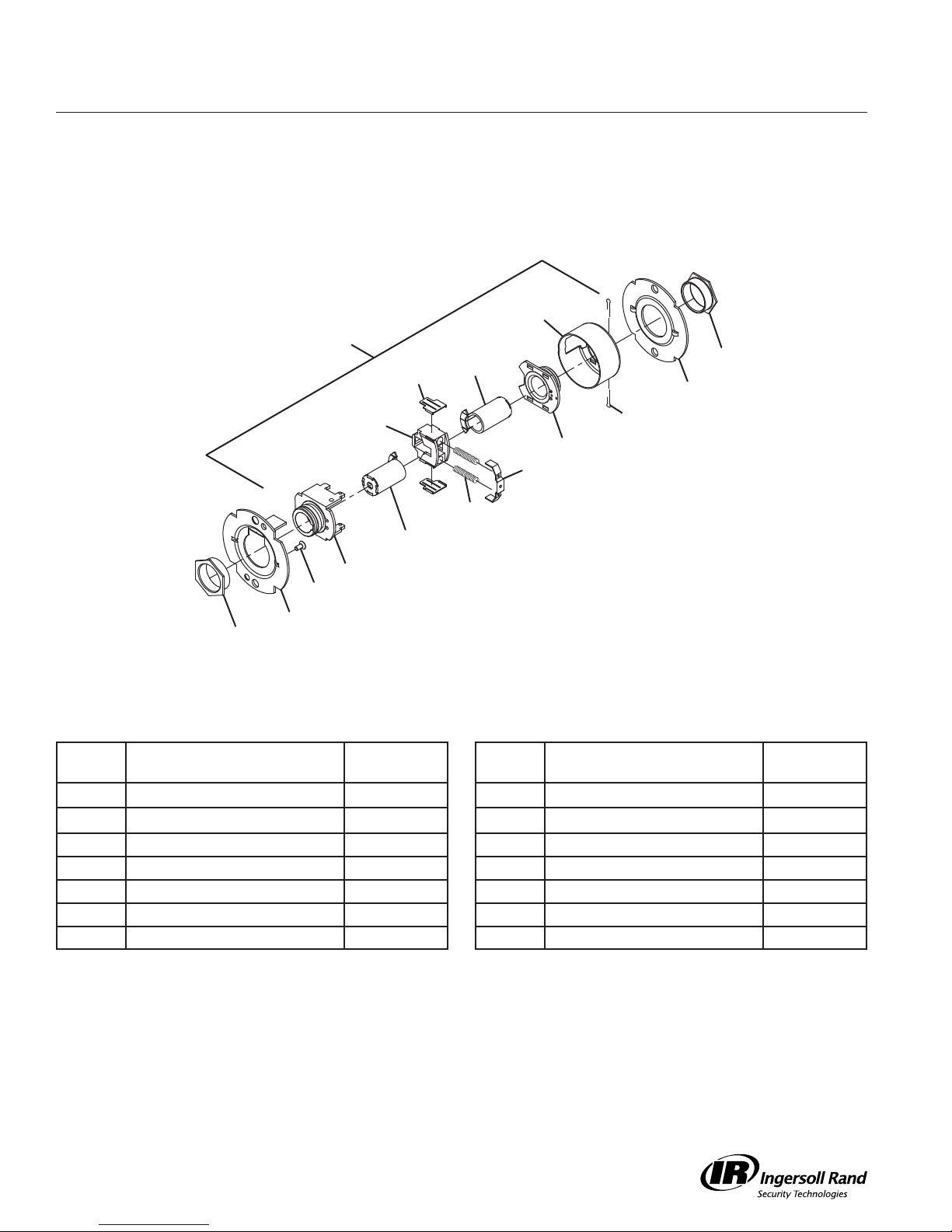

Page 12

Chassis Assemblies

T411

Asylum Lock

12

1

2

8 (2)

32

14

7

13 (2)

11

10

9 (2)

32

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T411 A30769-000-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

7 Retractor 022106-002-55 14 Inner Mounting Plate 030712-000-30

8 Retractor Insert (2) 022986-001-50 32 Spindle, 2 Ear, STD 030732-000-30

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

T-Series Service Manual

9

Page 13

T411

Asylum Lock – IC

Chassis Assemblies

12

1

2

14

8 (2)

33

7

13 (2)

11

10

9 (2)

33

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T411-IC A30769-001-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

7 Retractor 022106-002-55 14 Inner Mounting Plate 030712-000-30

8 Retractor Insert (2) 022986-001-50 33 Spindle, 2 Ear, IC 030732-001-30

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

10

T-Series Service Manual

Page 14

Chassis Assemblies

T501

Entry Lock

2

22

14

12

25

24

1

8 (2)

6

23

7

34

11

13 (2)

21

10

19

9 (2)

18

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T501 A30773-000-00 14 Inner Mounting Plate 030712-000-30

2 Flanged Nut (2) 030726-000-30 15 Spindle, 1 Ear, Outer 030732-005-30

3 Outer Mounting Plate 030712-001-30 16 Clutch Spring 030709-000-60

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 18 Key Spindle STD 030718-000-30

6 Spindle 030733-000-55 19 Push Actuator 030711-000-30

7 Retractor 022106-002-55 21 Slide Catch Spring 012107-001-60

8 Retractor Insert (2) 022986-001-50 22 Push Button Sleeve 022134-000-50

9 Retractor Spring (2) 022108-001-60 23 Dogging Bar 030722-000-30

10 Retractor Spring Retainer 022112-000-30 24 Push/Turn Button Mount 030731-000-30

11 Hub and Plate Assembly A30747-000-00 25 Push Button Cap 030728-000*

12 Housing Case 022114-000-30 34 Short Slide Catch 022104-000-30

13 Cotter Pin (2) 002893-000-60

031533-006-30 17 Clutch Driver 030716-001-30

Call Out

Number Description Part Number

T-Series Service Manual

11

Page 15

T501

Entry Lock – IC

Chassis Assemblies

2

22

12

25

24

1

8 (2)

6

23

14

7

34

11

13 (2)

21

10

19

9 (2)

31

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T501-IC A30773-001-00 14 Inner Mounting Plate 030712-000-30

2 Flanged Nut (2) 030726-000-30 15 Spindle, 1 Ear, Outer 030732-005-30

3 Outer Mounting Plate 030712-001-30 16 Clutch Spring 030709-000-60

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 19 Push Actuator 030711-000-30

6 Spindle 030733-000-55 21 Slide Catch Spring 012107-001-60

7 Retractor 022106-002-55 22 Push Button Sleeve 022134-000-50

8 Retractor Insert (2) 022986-001-50 23 Dogging Bar 030722-000-30

9 Retractor Spring (2) 022108-001-60 24 Push/Turn Button Mount 030731-000-30

10 Retractor Spring Retainer 022112-000-30 25 Push Button Cap 030728-000*

11 Hub and Plate Assembly A30747-000-00 31 Key Spindle, IC 030718-001-30

12 Housing Case 022114-000-30 34 Short Slide Catch 022104-000-30

13 Cotter Pin (2) 002893-000-60

031533-006-30 17 Clutch Driver 030716-001-30

Call Out

Number Description Part Number

12

T-Series Service Manual

Page 16

Chassis Assemblies

T511

Entry/Office Lock

2

35

14

12

36

24

1

8 (2)

6

23

7

34

11

13 (2)

21

10

19

9 (2)

18

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T511 A30756-000-00 14 Inner Mounting Plate 030712-000-30

2 Flanged Nut (2) 030726-000-30 15 Spindle, 1 Ear, Outer 030732-005-30

3 Outer Mounting Plate 030712-001-30 16 Clutch Spring 030709-000-60

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 18 Key Spindle STD 030718-000-30

6 Spindle 030733-000-55 19 Push Actuator 030711-000-30

7 Retractor 022106-002-55 21 Slide Catch Spring 012107-001-60

8 Retractor Insert (2) 022986-001-50 23 Dogging Bar 030722-000-30

9 Retractor Spring (2) 022108-001-60 24 Push/Turn Button Mount 030731-000-30

10 Retractor Spring Retainer 022112-000-30 34 Short Slide Catch 022104-000-30

11 Hub and Plate Assembly A30747-000-00 35 Turn Button Sleeve 022133-000-50

12 Housing Case 022114-000-30 36 Turn Button Cap 030727-000*

13 Cotter Pin (2) 002893-000-60

031533-006-30 17 Clutch Driver 030716-001-30

Call Out

Number Description Part Number

T-Series Service Manual

13

Page 17

T511

Entry/Office Lock – IC

Chassis Assemblies

2

35

12

36

24

1

8 (2)

6

23

14

7

34

11

13 (2)

21

10

19

9 (2)

31

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T511-IC A30756-001-00 14 Inner Mounting Plate 030712-000-30

2 Flanged Nut (2) 030726-000-30 15 Spindle, 1 Ear, Outer 030732-005-30

3 Outer Mounting Plate 030712-001-30 16 Clutch Spring 030709-000-60

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 19 Push Actuator 030711-000-30

6 Spindle 030733-000-55 21 Slide Catch Spring 012107-001-60

7 Retractor 022106-002-55 23 Dogging Bar 030722-000-30

8 Retractor Insert (2) 022986-001-50 24 Push/Turn Button Mount 030731-000-30

9 Retractor Spring (2) 022108-001-60 31 Key Spindle, IC 030718-001-30

10 Retractor Spring Retainer 022112-000-30 34 Short Slide Catch 022104-000-30

11 Hub and Plate Assembly A30747-000-00 35 Turn Button Sleeve 022133-000-50

12 Housing Case 022114-000-30 36 Turn Button Cap 030727-000*

13 Cotter Pin (2) 002893-000-60

031533-006-30 17 Clutch Driver 030716-001-30

Call Out

Number Description Part Number

14

T-Series Service Manual

Page 18

Chassis Assemblies

T521

Office Lock

1

8 (2)

2

35

14

12

36

24

6

23

7

13 (2)

11

10

9 (2)

19

18

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T521 A30748-000-00 13 Cotter Pin (2) 002893-000-60

2 Flanged Nut (2) 030726-000-30 14 Inner Mounting Plate 030712-000-30

3 Outer Mounting Plate 030712-001-30 15 Spindle, 1 Ear, Outer 030732-005-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 17 Clutch Driver 030716-001-30

6 Spindle 030733-000-55 18 Key Spindle, STD 030718-000-30

7 Retractor 022106-002-55 19 Push Actuator 030711-000-30

8 Retractor Insert (2) 022986-001-50 23 Dogging Bar 030722-000-30

9 Retractor Spring (2) 022108-001-60 24 Push/Turn Button Mount 030731-000-30

10 Retractor Spring Retainer 022112-000-30 35 Turn Button Sleeve 022133-000-50

11 Hub and Plate Assembly A30747-000-00 36 Turn Button Cap 030727-000*

12 Housing Case 022114-000-30

031533-006-30 16 Clutch Spring 030709-000-60

Call Out

Number Description Part Number

T-Series Service Manual

15

Page 19

T521

Office Lock – IC

Chassis Assemblies

2

35

12

36

24

1

8 (2)

6

23

14

7

13 (2)

11

10

9 (2)

19

31

17

16

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T521-IC A30748-001-00 13 Cotter Pin (2) 002893-000-60

2 Flanged Nut (2) 030726-000-30 14 Inner Mounting Plate 030712-000-30

3 Outer Mounting Plate 030712-001-30 15 Spindle, 1 Ear, Outer 030732-005-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 17 Clutch Driver 030716-001-30

6 Spindle 030733-000-55 19 Push Actuator 030711-000-30

7 Retractor 022106-002-55 23 Dogging Bar 030722-000-30

8 Retractor Insert (2) 022986-001-50 24 Push/Turn Button Mount 030731-000-30

9 Retractor Spring (2) 022108-001-60 31 Key Spindle, IC 030718-001-30

10 Retractor Spring Retainer 022112-000-30 35 Turn Button Sleeve 022133-000-50

11 Hub and Plate Assembly A30747-000-00 36 Turn Button Cap 030727-000*

12 Housing Case 022114-000-30

031533-006-30 16 Clutch Spring 030709-000-60

Call Out

Number Description Part Number

16

T-Series Service Manual

Page 20

Chassis Assemblies

T561

Classroom Lock

12

1

2

8 (2)

6

14

7

13 (2)

11

10

9 (2)

26

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T351/T561 A30758-000-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 26 Key Spindle Assembly, STD A30780-000-30

8 Retractor Insert (2) 022986-001-50

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

T-Series Service Manual

17

Page 21

T561

Classroom Lock – IC

Chassis Assemblies

12

1

2

14

8 (2)

6

7

13 (2)

11

10

9 (2)

27

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T351/T561-ICA30758-001-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 27 Key Spindle Assembly, IC A30780-001-30

8 Retractor Insert (2) 022986-001-50

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

18

T-Series Service Manual

Page 22

Chassis Assemblies

T571

Dormitory Lock

2

22

14

12

1

8 (2)

6

23

25

24

7

20

11

13 (2)

21

10

9 (2)

37

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T571 A30759-000-00 12 Housing Case 022114-000-30

2 Flanged Nut (2) 030726-000-30 13 Cotter Pin (2) 002893-000-60

3 Outer Mounting Plate 030712-001-30 14 Inner Mounting Plate 030712-000-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 21 Slide Catch Spring 012107-001-60

6 Spindle 030733-000-55 22 Push Button Sleeve 022134-000-50

7 Retractor 022106-002-55 23 Dogging Bar 030722-000-30

8 Retractor Insert (2) 022986-001-50 24 Push/Turn Button Mount 030731-000-30

9 Retractor Spring (2) 022108-001-60 25 Push Button Cap 030728-000*

10 Retractor Spring Retainer 022112-000-30 37 Key Spindle Assembly, T571,

11 Hub and Plate Assembly A30747-000-00

031533-006-30 20 Slide Catch 022105-000-30

Call Out

Number Description Part Number

A30915-000-00

STD

*= Finish or Specify Finish on All

T-Series Service Manual

19

Page 23

T571

Dormitory Lock – IC

Chassis Assemblies

2

22

12

1

8 (2)

6

23

25

24

14

7

20

11

13 (2)

21

10

9 (2)

38

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T571-IC A30759-001-00 12 Housing Case 022114-000-30

2 Flanged Nut (2) 030726-000-30 13 Cotter Pin (2) 002893-000-60

3 Outer Mounting Plate 030712-001-30 14 Inner Mounting Plate 030712-000-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 21 Slide Catch Spring 012107-001-60

6 Spindle 030733-000-55 22 Push Button Sleeve 022134-000-50

7 Retractor 022106-002-55 23 Dogging Bar 030722-000-30

8 Retractor Insert (2) 022986-001-50 24 Push/Turn Button Mount 030731-000-30

9 Retractor Spring (2) 022108-001-60 25 Push Button Cap 030728-000*

10 Retractor Spring Retainer 022112-000-30 38 Key Spindle Assembly, T571, IC A30915-001-00

11 Hub and Plate Assembly A30747-000-00

031533-006-30 20 Slide Catch 022105-000-30

Call Out

Number Description Part Number

20

T-Series Service Manual

Page 24

Chassis Assemblies

T581

Storeroom Lock

1

8 (2)

6

12

2

14

7

13 (2)

11

10

9 (2)

32

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T581 A30760-000-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 32 Spindle, 2 Ear, STD 030732-000-30

8 Retractor Insert (2) 022986-001-50

031533-006-30 12 Housing Case 022114-000-30

Call Out

Number Description Part Number

T-Series Service Manual

21

Page 25

T581

Storeroom Lock – IC

Chassis Assemblies

1

8 (2)

6

12

2

14

7

13 (2)

11

10

9 (2)

33

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T581-IC A30760-001-00 9 Retractor Spring (2) 022108-001-60

2 Flanged Nut (2) 030726-000-30 10 Retractor Spring Retainer 022112-000-30

3 Outer Mounting Plate 030712-001-30 11 Hub and Plate Assembly A30747-000-00

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 13 Cotter Pin (2) 002893-000-60

6 Spindle 030733-000-55 14 Inner Mounting Plate 030712-000-30

7 Retractor 022106-002-55 33 Spindle, 2 Ear, IC 030732-001-00

8 Retractor Insert (2) 022986-001-50

Call Out

Number Description Part Number

031533-006-30 12 Housing Case 022114-000-30

22

T-Series Service Manual

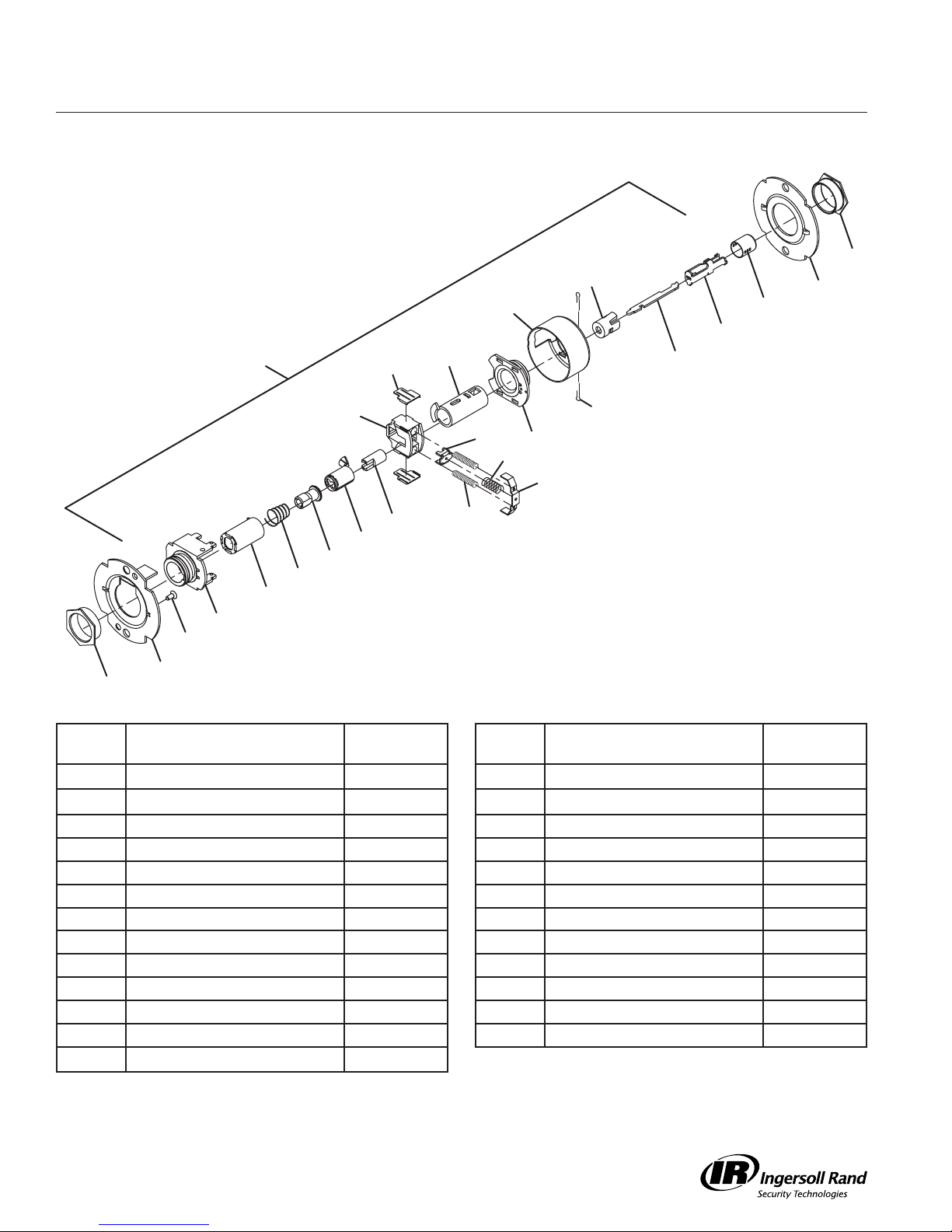

Page 26

Chassis Assemblies

T851

Storeroom Lock (Electrified – Fail Safe)

1

8 (2)

46

12

42

49

47

48

39

50

14

45

44

7

13 (2)

41

10

9 (2)

40

18

17

43

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T851 A31517-000-00 18 Key Spindle, STD 030718-000-30

2 Flanged Nut 030726-000-30 39 Solenoid, Fail Safe 031416-000-70

3 Outer Mounting Plate 030712-001-30 40 Push Acutator, Electrified Lock 030711-001-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 42

7 Retractor 022106-002-55 43 Clutch Spring, Fail Safe 030709-001-30

8 Retractor Insert (2) 022986-001-50 44 Modified Cable Tie Q001-088-70

9 Retractor Spring (2) 022108-001-60 45

10 Retractor Spring Retainer 022112-000-30 46 Spindle, Inside, T851/T881 030733-002-55

12 Housing Case 022114-001-30 47

13 Cotter Pin (2) 002893-000-60 48 Solenoid Mounting 031514-000-30

14 Inner Mounting Plate 030712-000-30 49 Push Rod, Fail Safe 031513-001-60

15 Spindle, 1 Ear, Outer 030732-005-30 50 Flanged Nut, Inside, Electrified 030726-007-30

17 Clutch Driver 030716-001-30

031533-006-30 41 Hub and Plate Assembly,

Call Out

Number Description Part Number

A31538-001-00

Electrified

Special Nut, 56M” x 28

Fillister Head 4-40 x 56M Screw

Fillister Head 4-40 x 56 Screw

031511-000-30

031515-004-30

Q001-087

T-Series Service Manual

23

Page 27

T851

Storeroom Lock (Electrified – Fail Safe) – IC

1

8 (2)

46

12

42

Chassis Assemblies

39

47

48

49

45

44

50

14

7

13 (2)

41

10

9 (2)

40

31

17

43

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T851 A31517-000-00 18 Key Spindle, STD 030718-000-30

2 Flanged Nut 030726-000-30 39 Solenoid, Fail Safe 031416-000-70

3 Outer Mounting Plate 030712-001-30 40 Push Acutator, Electrified Lock 030711-001-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 42

7 Retractor 022106-002-55 43 Clutch Spring, Fail Safe 030709-001-30

8 Retractor Insert (2) 022986-001-50 44 Modified Cable Tie Q001-088-70

9 Retractor Spring (2) 022108-001-60 45

10 Retractor Spring Retainer 022112-000-30 46 Spindle, Inside, T851/T881 030733-002-55

12 Housing Case 022114-001-30 47

13 Cotter Pin (2) 002893-000-60 48 Solenoid Mounting 031514-000-30

14 Inner Mounting Plate 030712-000-30 49 Push Rod, Fail Safe 031513-001-60

15 Spindle, 1 Ear, Outer 030732-005-30 50 Flanged Nut, Inside, Electrified 030726-007-30

17 Clutch Driver 030716-001-30

031533-006-30 41 Hub and Plate Assembly,

Call Out

Number Description Part Number

A31538-001-00

Electrified

Special Nut, 56M” x 28

Fillister Head 4-40 x 56M Screw

Fillister Head 4-40 x 56 Screw

031511-000-30

031515-004-30

Q001-087

24

T-Series Service Manual

Page 28

Chassis Assemblies

T881

Storeroom Lock (Electrified – Fail Secure)

1

8 (2)

46

12

42

53

47

48

52

50

14

45

44

7

13 (2)

41

10

9 (2)

40

18

17

51

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T851 A31517-000-00 18 Key Spindle, STD 030718-000-30

2 Flanged Nut 030726-000-30 39 Solenoid, Fail Safe 031416-000-70

3 Outer Mounting Plate 030712-001-30 40 Push Acutator, Electrified Lock 030711-001-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 42

7 Retractor 022106-002-55 43 Clutch Spring, Fail Safe 030709-001-30

8 Retractor Insert (2) 022986-001-50 44 Modified Cable Tie Q001-088-70

9 Retractor Spring (2) 022108-001-60 45

10 Retractor Spring Retainer 022112-000-30 46 Spindle, Inside, T851/T881 030733-002-55

12 Housing Case 022114-001-30 47

13 Cotter Pin (2) 002893-000-60 48 Solenoid Mounting 031514-000-30

14 Inner Mounting Plate 030712-000-30 49 Push Rod, Fail Safe 031513-001-60

15 Spindle, 1 Ear, Outer 030732-005-30 50 Flanged Nut, Inside, Electrified 030726-007-30

17 Clutch Driver 030716-001-30

031533-006-30 41 Hub and Plate Assembly,

Call Out

Number Description Part Number

A31538-001-00

Electrified

Special Nut, 56M” x 28

Fillister Head 4-40 x 56M Screw

Fillister Head 4-40 x 56 Screw

031511-000-30

031515-004-30

Q001-087

T-Series Service Manual

25

Page 29

T881

Storeroom Lock (Electrified – Fail Secure) – IC

1

8 (2)

46

12

42

Chassis Assemblies

52

47

48

53

45

44

50

14

7

13 (2)

41

10

9 (2)

40

31

17

51

15

5

4

3

2

Call Out

Number Description Part Number

1 Chassis Assembly, T851 A31517-000-00 18 Key Spindle, STD 030718-000-30

2 Flanged Nut 030726-000-30 39 Solenoid, Fail Safe 031416-000-70

3 Outer Mounting Plate 030712-001-30 40 Push Acutator, Electrified Lock 030711-001-30

4

#8-32 x 6” Self Tap Screw

5 Hub and Housing Assembly A30746-000-00 42

7 Retractor 022106-002-55 43 Clutch Spring, Fail Safe 030709-001-30

8 Retractor Insert (2) 022986-001-50 44 Modified Cable Tie Q001-088-70

9 Retractor Spring (2) 022108-001-60 45

10 Retractor Spring Retainer 022112-000-30 46 Spindle, Inside, T851/T881 030733-002-55

12 Housing Case 022114-001-30 47

13 Cotter Pin (2) 002893-000-60 48 Solenoid Mounting 031514-000-30

14 Inner Mounting Plate 030712-000-30 49 Push Rod, Fail Safe 031513-001-60

15 Spindle, 1 Ear, Outer 030732-005-30 50 Flanged Nut, Inside, Electrified 030726-007-30

17 Clutch Driver 030716-001-30

031533-006-30 41 Hub and Plate Assembly,

Call Out

Number Description Part Number

A31538-001-00

Electrified

Special Nut, 56M” x 28

Fillister Head 4-40 x 56M Screw

Fillister Head 4-40 x 56 Screw

031511-000-30

031515-004-30

Q001-087

26

T-Series Service Manual

Page 30

Trim Assemblies

T101

Passage Latchset

P

NN

N

L

I

H

A

NN

K

J

O

H

E

F

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

A Closed Lever, Outside See Page 46 K Mounting Post (2) 030715-000-30

E Lever Set Screw 030831-004-30 L Spring Latch A98535-000*

F Closed Lever and Set Screw

Assembly

H Rose 030706-002* O Spindle, Inside, Passage/Button 030703-000-30

I Spring Cage and Spindle,

Outside, Passage

J Spindle, Outside, Passage A30906-000-00 NN Non-Locking Spring Cage Q330-271

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30753-00X* N

A30749-000-00 P Spring Cage and Spindle,

#8-32 x 6M” Combo Screw

Inside, Passage/Button

27

024416-012*

A30750-000-00

Page 31

T291

Privacy Hospital Lock

Trim Assemblies

P

NN

N

L

U

H

T

S

LL

B

NN

K

V

H

O

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46 P Spring Cage and Spindle, Inside,

E Lever Set Screw 030831-004-30 S Outer Button Mount 030729-000-70

G Open Lever and Set Screw

Assembly

H Rose 030706-002* U Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 V Spindle, Outside, Button A30905-000-00

L Spring Latch A98535-000* LL Button, T291, Outside Q033-044*

N

#8-32 x 6M” Combo Screw

O Spindle, Inside, Passage/Button 030703-000-30

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* T Tailpiece, 6-pin IC 030739-000-30

A30796-000-00

Outside, Button

024416-012* NN Non-Locking Spring Cage Q330-271

28

T-Series Service Manual

Page 32

Trim Assemblies

T301

Privacy Lock

P

NN

N

L

U

H

T

S

Q

B

R

NN

K

V

H

O

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46 P Spring Cage and Spindle, Inside,

E Lever Set Screw 030831-004-30 Q Button Spacer 030787-000-70

G Open Lever and Set Screw

Assembly

H Rose 030706-002* S Outer Button Mount 030729-000-70

K Mounting Post (2) 030715-000-30 T Tailpiece, 6-pin IC 030739-000-30

L Spring Latch A98535-000* U Spring Cage and Spindle,

N

#8-32 x 6M” Combo Screw

O Spindle, Inside, Passage/Button 030703-000-30 NN Non-Locking Spring Cage Q330-271

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* R Emergency Release Cap 030654-000*

A30796-000-00

Outside, Button

024416-012* V Spindle, Outside, Button A30905-000-00

29

Page 33

T351

Closet Lock

Trim Assemblies

W

NN

N

M

BB

H

AA

B

MM

K

CC

X

H

Y

E

Z

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 Y Turn Knob, Knurled 030738-000*

E Lever Set Screw 030831-004-30 Z Turn Knob and Set Screw

H Rose 030706-002* AA 6-Pin Cylinder A23161-05*

K Mounting Post (2) 030715-000-30 BB Spring Cage and Spindle,

M Deadlatch A98535-00D* CC Spindle, Outside, 6-Pin Cylinder A30905-060-00

N

#8-32 x 6M” Combo Screw

W Spring Cage and Spindle, Inside,

T351

X Spindle, Inside, T351 030703-001-30

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30788-000*

Assembly

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* MM Locking Spring Cage Q330-270

A30776-001-00 NN Non-Locking Spring Cage Q330-271

30

T-Series Service Manual

Page 34

Trim Assemblies

T381

Classroom Security Lock

B

DD

NN

N

M

BB

H

AA

B

MM

K

CC

EE

H

AA

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 BB Spring Cage and Spindle,

H Rose 030706-002* CC Spindle, Outside, 6-Pin Cylinder A30905-060-00

K Mounting Post (2) 030715-000-30 DD Spring Cage and Spindle, Inside,

M Deadlatch A98535-00D* EE Spindle, Inside, 6-Pin Cylinder A30906-060-00

N

#8-32 x 6M” Combo Screw

AA 6-Pin Cylinder A23161-05* NN Non-Locking Spring Cage Q330-271

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30910-060-00

Outside, 6-Pin Cylinder

A30779-060-00

6-Pin Cylinder

024416-012* MM Locking Spring Cage Q330-270

31

Page 35

T411

Asylum Lock

Trim Assemblies

B

FF

MM

N

M

GG

H

AA

B

MM

K

CC

EE

H

AA

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 CC Spindle, Outside, 6-Pin Cylinder A30905-060-00

H Rose 030706-002* FF Spring Cage and Spindle, Inside,

K Mounting Post (2) 030715-000-30 GG Spring Cage and Spindle,

M Deadlatch A98535-00D* EE Spindle, Inside, 6-Pin Cylinder 030906-060-00

N

#8-32 x 6M” Combo Screw

AA 6-Pin Cylinder A23161-05*

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A31523-060-00

6-Pin Cylinder, T411

A30749-060-00

Outside, 6-Pin Cylinder, T411/

T581

024416-012* MM Locking Spring Cage Q330-270

32

T-Series Service Manual

Page 36

Trim Assemblies

T501

Entry Lock

P

NN

N

M

BB

H

AA

B

MM

K

CC

O

H

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

G Open Lever and Set Screw

Assembly

H Rose 030706-002* BB Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 CC Spindle, 6-Pin Cylinder, Outside A30905-060-00

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* AA 6-Pin Cylinder A23161-05*

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* NN Non-Locking Spring Cage Q330-271

33

Page 37

T511

Entry/Office Lock

Trim Assemblies

P

NN

N

M

BB

H

AA

B

MM

K

CC

H

O

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

G Open Lever and Set Screw

Assembly

H Rose 030706-002* BB Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 CC Spindle, 6-Pin Cylinder, Outside A30905-060-00

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* AA 6-Pin Cylinder A23161-05*

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* NN Non-Locking Spring Cage Q330-271

34

T-Series Service Manual

Page 38

Trim Assemblies

T521

Office Lock

P

NN

N

M

BB

H

AA

B

MM

K

CC

H

O

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

G Open Lever and Set Screw

Assembly

H Rose 030706-002* BB Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 CC Spindle, 6-Pin Cylinder, Outside A30905-060-00

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* AA 6-Pin Cylinder A23161-05*

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* NN Non-Locking Spring Cage Q330-271

35

Page 39

T561

Classroom Lock

Trim Assemblies

P

NN

N

M

BB

H

AA

B

MM

K

CC

O

H

E

F

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

F Closed Lever and Set Screw

Assembly

H Rose 030706-002* BB Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 CC Spindle, 6-Pin Cylinder, Outside A30905-060-00

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-00X* AA 6-Pin Cylinder A23161-05*

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* NN Non-Locking Spring Cage Q330-271

36

T-Series Service Manual

Page 40

Trim Assemblies

T571

Dormitory Lock

P

NN

N

M

BB

H

AA

B

MM

K

CC

O

H

E

G

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

G Open Lever and Set Screw

Assembly

H Rose 030706-002* BB Spring Cage and Spindle,

K Mounting Post (2) 030715-000-30 CC Spindle, 6-Pin Cylinder, Outside A30905-060-00

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-01X* AA 6-Pin Cylinder A23161-05*

A30910-060-00

Outside, 6-Pin Cylinder

024416-012* NN Non-Locking Spring Cage Q330-271

37

Page 41

T581

Storeroom Lock

Trim Assemblies

P

NN

N

M

GG

H

AA

B

MM

K

CC

O

H

E

F

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 O Spindle, Inside, Passage/Button 030703-000-30

E Lever Set Screw 030831-004-30 P Spring Cage and Spindle, Inside,

F Closed Lever and Set Screw

Assembly

H Rose 030706-002* CC Spindle, 6-Pin Cylinder, Outside A30906-060-00

K Mounting Post (2) 030715-000-30 GG Spring Cage, Outside, T411/

M Deadlatch A98535-00D* MM Locking Spring Cage Q330-270

N

#8-32 x 6M” Combo Screw

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30750-000-00

Passage/Button

A30753-00X* AA 6-Pin Cylinder A23161-05*

A30749-060-00

F581

024416-012* NN Non-Locking Spring Cage Q330-271

38

T-Series Service Manual

Page 42

Trim Assemblies

T851

Storeroom Lock (Electrified – Fail Safe)

JJ

NN

N

M

BB

H

AA

B

MM

K

CC

KK

H

E

HH

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 BB Spring Cage and Spindle,

E Lever Set Screw 030831-004-30 CC Spindle, Outside, 6-Pin Cylinder A30905-060-00

H Rose 030706-002* HH T851/T881 Lever and Set Screw

K Mounting Post (2) 030715-000-30 JJ Spring Cage and Spindle, Inside,

M Deadlatch A98535-00D* KK Spindle, Inside, T851/T881 031519-000-30

N

#8-32 x 6M” Combo Screw

AA 6-Pin Cylinder A23161-05* NN Non-Locking Spring Cage Q300-271

*= Finish or Specify Finish on All

T-Series Service Manual

Call Out

Number Description Part Number

A30910-060-00

Outside, 6-Pin Cylinder

A31544-00X*

Assembly

A31638-000-00

T851/T881

024416-012* MM Locking Spring Cage Q330-270

39

Page 43

T881

Storeroom Lock (Electrified – Fail Secure)

Trim Assemblies

JJ

NN

N

M

BB

H

AA

B

MM

K

CC

KK

H

E

HH

Note: Spring Cage components require lubrication. See page 47 for specifications.

Call Out

Number Description Part Number

B Open Lever, Outside See Page 46,47 BB Spring Cage and Spindle,

E Lever Set Screw 030831-004-30 CC Spindle, Outside, 6-Pin Cylinder A30905-060-00

H Rose 030706-002* HH T851/T881 Lever and Set Screw

K Mounting Post (2) 030715-000-30 JJ Spring Cage and Spindle, Inside,

M Deadlatch A98535-00D* KK Spindle, Inside, T851/T881 031519-000-30

N

#8-32 x 6M” Combo Screw

AA 6-Pin Cylinder A23161-05* NN Non-Locking Spring Cage Q300-271

*= Finish or Specify Finish on All

Call Out

Number Description Part Number

A30910-060-00

Outside, 6-Pin Cylinder

A31544-00X

Assembly

A31638-000-00

T851/T881

024416-012* MM Locking Spring Cage Q330-270

40

T-Series Service Manual

Page 44

Cylinders

Standard Cylinders

Falcon Complete Standard Cylinders

Function 5-Pin Cylinder 6-Pin Cylinder 7-Pin Cylinder

A23151-05 A23161-05 A23171-05

All Except T381IS, T571

A23151-06 A23161-06 A23171-06

T381IS

A23151-07 A23161-07 A23171-07

T571

Notes: 1) Finishes 606 and 626 only

2) Specify Keyway

3) Cylinders are funished G keyway, keyed differently unless otherwise specified.

4) Restricted sections require additional fee.

Standard Cylinder Options

Description Specify

5 Pinned Cylinder

6 Pinned Cylinder

7 Pinned Cylinder

Competitor Keyway Cylinders (6 Pin Only)*

*Cylinders are furnished 0-bitted unless otherwise specified. No master keying, except Schlage C.

P suffix

Example: T581PD DAN

P6 suffix

Example: T581PD6 DAN

P7 suffic

Example: T581PD7 DAN

P6 suffix

Example: T581PD6 SCH C

Standard Cylinder Tailpieces

Cylinders Std. Functions T381 Inside T571

Falcon 6-pin* (10 pack) A30730-001-00 A30730-003-00 A30730-002-00

Falcon 7-pin (10 pack) A30730-002-00 A30730-004-00 A30730-006-00

Sargent 6 & 10 Line 030997-001-30 030997-003-30 030997-005-30

Yale 1801, 5801 030917-001-30 030917-003-30 030917-005-30

*Assa 65611 and 65661, Corbin Russwin 2000-034 and Schlage (including Primus) all use Falcon 6-pin tailpiece.

T-Series Service Manual

41

Page 45

Cylinders

Competitor Keyway Compatibility

Falcon T-Series locks are furnished with Falcon’s standard “G” keyway cylinder unless otherwise specified. The

following cylinders manufactured by competitors are acceptable.

Assa (65611 or 65661) 6-pins

Sargent (6,7 and 10 Line) 6-pin s

- Keso not available

Peaks (Kaba) 6-pins

Medeco (20W200V3) 6-pins

-Tailpiece supplied by Medeco

-Falcon/Schlage style

Schlage Standard 6-pins

Schlage Primus 6-pins

Yale (1801) 6-pin s

- Bicentric not available

Corbin Russwin (2000-034/CL3400) 6-pin s

- Master Ring not available

IC Cylinders

Falcon Complete IC Cylinders

Style Combinated 6-Pin Combinated 7-Pin Uncombinated 6-Pin Uncombinated 7-Pin

C606 C607 C646 C647

Standard

Standard with Best-Style Capping

No Logo

No Logo with Best-Style Capping

Notes: 1) Specify core number, keyway and finish when ordering.

CB806 CB807 CB846 CB847

C608 C609 C648 C649

CB808 CB809 CB848 CB849

42

T-Series Service Manual

Page 46

Cylinders

IC Cylinder Options

Description Specify

Small Format Core*

Small Format Construction Core**

Less Small Format Core

Less Full Size Core

Small Format Disposable Core

*Locks are furnished uncombinated with no keys unless otherwise specified.

**Locks are assessed one non-refundable handling charge per core.

IC Cylinder Tailpieces

Cylinders Std. Functions T381 Inside T571

Falcon 6-pin* 030739-000-30 030739-002-30 030739-000-30

Falcon 7-pin* 030739-001-30 030739-003-30 030739-001-30

Corbin Russwin 8000 and Sargent 6300 031468-000-30 031468-002-30 031468-004-30

Corbin Russin 8000-7 (7-Pin) 031468-001-00 031468-003-30 031468-005-30

Medeco 32 Series and ASSA A30988-000-00 A30988-002-00 A30988-004-00

Schlage Full Size (Including Primus) 031467-000-30 031467-002-30 031467-004-30

Yale and Medeco 31 Series, 6-Pin 030917-001-30 030917-003-30 030917-005-30

*Arrow, Best, InstaKey, Kaba Peaks, Keymark, KSP and Schlage small format cores all use the Falcon configuration.

G suffix

Example: T581GD6 DAN

H suffix

Example: T581HD7 DAN

B suffix

Example: T581BD DAN

J suffix

Example: T581JD SCH DAN

BDC suffix

Example: T581BDC DAN

Competitor IC Compatibility

Locksets with the standard Falcon interchangeable core option can also accept Schlage SFIC, Arrow (including Flex

Core), Best (including PKS and Peaks), InstaKey, Kaba Peaks, Keymark and KSP cores.

In addition, the following larger format interchangeable cores will work when lockset is so specified.

Assa

Old & new style

Specify IC-AS

T-Series Service Manual

Corbin

Russwin

Corbin Russwin

8000 or 8000-7

Specify IC-CR6

or IC-CR7

32 Series 6-Pin

Specify IC-ME

Medeco

32

Medeco

Medeco

31

Medeco

31 Series 6-Pin

Specify IC-YA6

43

Sargent

6300

Sargent

6300

Specify IC-SA

Schlage Yale

Schlage 6-Pin

including Primus

Specify IC-SC

Yale 6-Pin

Specify IC-YA6

Page 47

Inside Inserts and Spindles

Inserts and Spindles

Description Part Number

Insert and Spindle A30750-000-00 ssssss

Insert and Spindle A30776-001-00 s

Falcon 6-Pin and 7-Pin IC A30779-001-00 s

Falcon and Mono 6-Pin Standard A30779-060-00 s

Falcon 7-Pin Standard A30779-070-00 s

Medeco IC A30981-001-00 s

Schlage IC A30982-001-00 s

Corbin-Russwin 6-Pin IC A30983-001-00 s

Corbin-Russwin 7-Pin IC A30983-002-00 s

Yale IC A30984-001-00 s

Sargent IC A30985-001-00 s

Sargent 6-Pin Standard A31491-060-00 s

Yale 6-Pin Standard A31492-060-00 s

Yale 7-Pin Standard A31492-070-00 s

Falcon 6-Pin and 7-Pin IC A31523-001-00 s

Falcon and Mono 6-Pin Standard A31523-060-00 s

Falcon 7-Pin Standard A31523-070-00 s

Medeco IC A31524-001-00 s

Schlage IC A31525-001-00 s

Corbin-Russwin 6-Pin IC A31526-001-00 s

Corbin-Russwin 7-Pin IC A31526-002-00 s

Yale IC A31527-001-00 s

Sargent IC A31528-001-00 s

Sargent 6-Pin Standard A31529-060-00 s

Insert and Spindle A31638-000-00 ss

ASSA IC A31643-001-00 s

ASSA IC A31644-001-00 s

T351 T381 T411 T501 T511 T521 T561 T571 T581 T851 T881

44

T-Series Service Manual

Page 48

Inserts and Spindles

Outside Inserts and Spindles

Description Part Number

Falcon 6-Pin and 7-Pin IC A30749-001-00 ss

Falcon and Mono 6-Pin Standard A30749-060-00 ss

Falcon 7-Pin Standard A30749-070-00 ss

Falcon IC A30910-001-00 ss sssss ss

Falcon and Mono 6-Pin Standard A30910-060-00 ss sssss ss

Falcon 7-Pin Standard A30910-070-00 ss sssss ss

Medeco IC A30941-001-00 ss sssss ss

Schlage IC A30942-001-00 ss sssss ss

Corbin-Russwin 6-Pin IC A30943-001-00 ss sssss ss

Corbin-Russwin 7-Pin IC A30943-002-00 ss sssss ss

Yale IC A30944-001-00 ss sssss ss

Sargent IC A30945-001-00 ss sssss ss

Medeco IC A30971-001-00 ss

Schlage IC A30972-001-00 ss

Corbin-Russwin IC A30973-001-00 ss

Corbin-Russwin 7-Pin IC A30973-002-00 ss

Yale IC A30974-001-00 ss

Sargent IC A30975-001-00 ss

Sargent 6-Pin Standard A31485-060-00 s sssss ss

Yale 6-Pin Standard A31486-060-00 ss sssss ss

Yale 7-Pin Standard A31486-070-00 ss sssss ss

Sargent 6-Pin Standard A31487-060-00 ss

Yale 6-Pin Standard A31488-060-00 s

Yale 7-Pin Standard A31488-070-00 s

ASSA IC A31641-001-00 ss

ASSA IC A31642-001-00 ss sssss ss

T351 T381 T411 T501 T511 T521 T561 T571 T581 T851 T881

T-Series Service Manual

45

Page 49

Closed Levers

Style Part Number Description

030740-000-xxx Standard Closed Lever

A30753-00A-xxx Inside Lever with Set Screw

Levers

Avalon

Dane

Quantum

Notes: 1) Specify finish on end of part number (ex. 030740-000-626)

A31544-00A-xxx Inside Lever with Set Screw for T851/T881 Functions

030742-000-xxx Standard Closed Lever

A30753-00D-xxx Inside Lever with Set Screw

A31544-00D-xxx Inside Lever with Set Screw for T851/T881 Functions

030744-000-xxx Standard Closed Lever

A30753-00Q-xxx Inside Lever with Set Screw

A31544-00Q-xxx Inside Lever with Set Screw for T851/T881 Functions

Open Levers

Style Part Number Description

030740-001-xxx Standard Open Lever

030929-001-xxx Corbin Russwin, Medeco, Yale unit Open Lever

030996-001-xxx Sargent 6, 7 and 10 Line, Yale Open Lever

Avalon

Dane

Quantum

Notes: 1) Specify finish on end of part number (ex. 030740-000-626)

A30753-01A-xxx Inside Lever with Set Screw

030742-001-xxx Standard Open Lever

030929-002-xxx Corbin Russwin, Medeco, Yale unit Open Lever

030996-002-xxx Sargent 6, 7 and 10 Line, Yale Open Lever

A30753-01D-xxx Inside Lever with Set Screw

030744-001-xxx Standard Open Lever

030929-003-xxx Corbin Russwin, Medeco, Yale unit Open Lever

030996-003-xxx Sargent 6, 7 and 10 Line, Yale Open Lever

A30753-01Q-xxx Inside Lever with Set Screw

46

T-Series Service Manual

Page 50

Levers

SFIC/IC Levers

Style Part Number Description

030740-002-xxx Standard SFIC Lever

030926-001-xxx Assa, Medeco, Yale IC Lever

030927-001-xxx Schlage IC Lever

Avalon

Dane

Quantum

Notes: 1) Specify finish on end of part number (ex. 030740-000-626)

030928-001-xxx Corbin Russwin IC Lever

030930-001-xxx Sargent IC Lever

030742-002-xxx Standard SFIC Lever

030926-002-xxx Assa, Medeco, Yale IC Lever

030927-002-xxx Schlage IC Lever

030928-002-xxx Corbin Russwin IC Lever

030930-002-xxx Sargent IC Lever

030744-002-xxx Standard SFIC Lever

030926-003-xxx Assa, Medeco, Yale IC Lever

030927-003-xxx Schlage IC Lever

030928-003-xxx Corbin Russwin IC Lever

030930-003-xxx Sargent IC Lever

Spring Cage Replacement Kits

Q330-270 - Locking Spring Cage Q330-271 - Non-Locking Spring Cage

Apply light film of M204-250 on surfaces with brush or equivalent.

Barrel or tumble with M204-250 to acheive approximately .015-.040 film thickness

T-Series Service Manual

47

Page 51

Grade 1 Latches

Latches and Accessories

A98535-000

Square Corner Spring Latch,

6QE” Projection

A98538-00D

6QE” Radius Corner Deadlatch,

6QE” Projection

Grade 2 Latches

A98535-00D

Square Corner Deadlatch,

6QE” Projection

A98835-00D

Square Corner Deadlatch,

6M” Projection

A98538-000

6QE” Radius Corner Spring Latch,

6QE” Projection

A98838-000

6QE” Radius Corner Spring Latch,

6M” Projection

A92320-000

Square Corner Spring Latch,

56O” Projection, 26” Backset

A92320-00D

Square Corner Deadlatch,

56O” Projection, 26” Backset

48

A92321-000

56M” Radius Cor ner Spr ing Latch,

56O” Projection, 26” Backset

T-Series Service Manual

Page 52

Latches and Accessories

A92321-00D

56M” Radius Cor ner Deadlatch,

56O” Projection, 26” Backset

A92331-000

56M” Radius Corner Spr ing Latch,

56O” Projection, 26M” Backset

Accessories

A92330-000

Square Corner Spr ing Latch,

56O” Projection, 26M” Backset

A92331-00D

56M” Radius Cor ner Deadlatch,

56O” Projection, 26M” Backset

A92330-00D

Square Corner Deadlatch,

56O” Projection, 26M” Backset

A22161-005-00

Link for 5" Backset

For use with 26M” backset latches

(except 6M” projection)

T-Series Service Manual

A30775-000-00

Thin Door Installation Kit

For door thicknesses 16”–16M”

49

Page 53

Strikes

Strike and Dust Boxes

Full Lip Square Corner Strike

Dust Boxes

005164-000

ANSI Strike

Q001-049

A05185-000

Square Corner T-Strike

Q001-048

Full Lip 56M” Radius Corner Strike

A05185-004

6QE” Radius Corner T-Strike,

K510-066-PLA 012191-003-70 Q001-059

50

T-Series Service Manual

Page 54

Preparation and Installation

Installation Template

For reference only. DO NOT place on door for drilling.

FOLD HERE &

PLACE ON HIGH

EDGE OF DOOR BEVEL

Mark Centerline of Latch for

Correct Door Thickness.

Drill 1"(25mm) diameter hole.

17N"(45mm)

2"(51mm)

267N"(57mm)

Tailpiece Installation

T–Series

Lever Lock

Template

Mark Center for

Latch

High Edge

267"(54mm) Hole

27N"(70mm) BACKSET

IMPORTANT:

Check lock for proper backset

BEFORE drilling

Mark Center for

7RF"(8mm) Holes

Use of Drill Fixture

030736-000-50

recommended to

ensure proper

alignment of

thru-bolt holes.

7;P"(4mm)

7;P"(4mm) x 67"(3mm) deep

(800) 266-4456

©

2008 Schlage Lock Company

Printed in Country

030793-000-70 Rev. 04/08-b

Door Centering Adjustment

267N"(57mm) Door

17N"(44mm) Door

2"(51mm) Door

T-Series Tailpiece Installation

For proper function of the lock, the right tailpiece must be used and installed correctly.

All T-locks with standard cylinders must have the tailpiece installed

VERTICALLY on the cylinder as shown.

NOTE: The cap must be properly adjusted.

If too loose, excessive plug end play will prevent the key from being withdrawn.

If too tight, the plug will drag and be difficult to rotate with the key.

Cylinder

Spring

Pin

Tailpiece

800-266-4456

©

2008 Schlage Lock Company

Printed in Country

030102-000-70 Rev. 04/08-b

Cap

T-Series Service Manual

51

Page 55

03079400070

INSTALLATION INSTRUCTIONS FOR INSTALLING

T-SERIES

EXTRA HEAVY DUTY LEVER LOCKSET

IMPORTANT: THIS LOCK IS NON-HANDED. LOCK IS FACTORY PACKED PREADJUSTED FOR 17N" (45mm)

THICK DOORS. TO ADJUST LOCK FOR OTHER DOOR THICKNESS, SEE STEP 8, 9 & 10. SPACERS MUST

BE USED FOR DOORS THINNER THAN 17N" (45mm) THICK. FOR FUNCTIONS

SEE STEPS 17 (STANDARD CYLINDER) OR 18 (IC CORE) FOR TIMING INSTRUCTIONS.

& T571

Set Screw

67N-20 x 67N"

Mounting Screws

#10-32 x 1"

Outer Trim Assembly

Interchangeable Core Cylinder

Flange Nut

Inner Mounting Plate

*Spacer

Spacer required for all

doors under 17N" thick.

Attaching Screws

#8 Combination

Latch Assembly

INSIDE

Chassis Assembly

Outer Trim Assembly

Standard Cylinder

*Spacer

Spacer required for all

door under 17N" thick.

OUTSIDE

T341, T351, T371, T381, T391, T561

Inner Lever

Rose

Inner Trim Assembly

INSIDE

RIGHT HAND

LEFT HAND

LEFT HAND REVERSE

RIGHT HAND REVERSE

OUTSIDE

LEFT HAND REVERSE SHOWN

STEP 1

MARK DOOR

Fold template on line indicated.

Place on HIGH EDGE of door bevel.

Position centerline of template on heightline (suggested

height is 38" (965mm) from floor).

A. Locate and mark center for 267" (54mm) hole.

B. Locate and mark positions for notches.

Caution: Notches must be horizontal.

C. Locate and mark center for two (2)7RF" (8mm)

thru-bolt holes.

D. Locate and mark center for 1" (25mm) latch bolt hole

in door edge.

Note: If steel frames are used, the latch centerline must

be in line with the center of the strike preparation.

Hint: For retrofitting of existing 267" (54mm) holes, fold template in half to locate position for the two (2) 7RF" (8mm) holes.

"(45mm) DR

/

4

3

2"(51mm) DR

1

B) Mark Notches

A) Mark 267" Hole

C) Mark Thru-Bolt Holes

52

"(57mm) DR

/

4

1

2

DOOR CENTERING ADJUSTMENT

x1/8"(3mm) DEEP

5/32"(4mm)

5/32"(4mm)

HOLES.

THRU-BOLT

ALIGNMENT OF

ENSURE PROPER

High Edge Of Bevel Door

RECOMMENDED TO

030736-000-50 IS

USING DRILL FIXTURE

5/16"(8mm) HOLES

MARK CENTER FOR

2 1/8"(54mm) HOLE

MARK CENTER FOR

DOOR HANDS DETERMINED FROM OUTSIDE

2 1/4"(57mm)

BACKSET BEFORE DRILLING

CHECK LOCK FOR PROPER

2"(51mm)

IMPORTANT:

(45mm)

1 3/4"

2 3/4"(70mm) BACKSET

HIGH EDGE

LATCH

LOCKS

T–SERIES LEVER

INSTALLING

D) Mark Latch Hole

DRILL 1"(25mm) DIA HOLE.

FOR CORRECT DOOR THICKNESS.

MARK CENTERLINE OF LATCH

EDGE OF DOOR

PLACE ON HIGH

FOLD HERE &

TEMPLATE FOR

T-Series Service Manual

Page 56

STEP 2

BORE HOLES: INSTALL LATCH

When drilling through door, be careful not to damage door finish.

A) 5/16" (8mm)

Thru hole

A. Bore a 267" (54mm) hole and two (2) 7RF" (8mm) holes

from both sides of door to avoid splintering wood.

C) File Notches

B. Bore a 1" (25mm) hole into door edge. Using latch faceplate

as pattern, trace outline and mortise door edge so latch is flush

with door. If 7N projection latch is to be installed see Step 20.

Note: For wood jambs, close door and using a strike-locating tool

A) 2-1/8" (54mm)

Thru hole

A) 5/16" (8mm)

Thru hole

or other pointed object mark position of hole in jamb. Open door

and drill 1" (25mm) hole in jamb minimum 7N" (19mm) deep.

C. File two (2) 7;P" (4mm) x 7;P" (4mm) x 67" (3mm) deep notches

into both sides of door.

D. Insert latch unit in door, making certain that latch bolt bevel faces

direction of closing door. Attach with two #8 combination screws

provided.

Note: Use of a drill guide is recommended to ensure

straight and level holes.

IF USING THE FALCON OPTIONAL DRILL GUIDE

Install Drill Guide (030736-000-70) into door. Make certain correct backset

locators are even with door edge. Drill two (2) 7RF" (8mm) holes from both

sides to center.

B) 1" (25mm) Hole

Latch Unit

Use faceplate as pattern for mortise.

Backset

Locator

5/32"

Latch

Bolt Bevel

Note: Drill guide replacement is recommended after 10 door preparations.

STEP 3

INSTALL CHASSIS AND OUTER TRIM ASSEMBLY

Note: For ease of installation, lock should be in

the unlocked position.

Slide chassis assembly into door from outside

making sure that lock housing engages latch

prongs. Retractor must also engage latch tail.

Important: Chassis assembly must be positioned

in center of door for proper operation.

STEP 4

INSTALL INNER MOUNTING PLATE

A. Place inner mounting plate onto chassis assembly

making sure that plate tabs engage horizontal

notches in door.

B. Position flanged nut over chassis assembly and

tighten securely with hex wrench provided.

Lock Housing

Chassis Assembly

Latch Prong

Latch Tail

Retractor

Latch Case

Outside of Door

Notches

Tab

Flanged Nut

Black Hex Wrench Chassis Assembly

Tab

T-Series Service Manual

Inner Mounting Plate

53

Page 57

STEP 5

INSTALL INNER TRIM ASSEMBLY

Thru Post

Slide inner trim assembly over chassis spindle. Thru-posts will

engage inner trim asembly on 17N" (45mm) thick doors.

Secure to door with two #10-32 x 1" machine screws provided.

STEP 6

INSTALL INNER LEVER

A. Position rose over inner trim assembly making sure rose

detent engages groove in spindle assembly.

B. Install lever handle and tighten set screw with hex key

provided.

Stop! Test operation to be sure latch bolt moves freely. Do not force.

If lockset does not operate properly, remove lockset from door and

check door preparation and door thickness adjustment. See Step 4

to re-install chassis.

Thru Post

Chassis Spindle

Inner Trim Assembly

Groove

Rose

Inner Trim Asssembly

Rose Detent

67N-20 x 67N"

Set Screw

Mounting Screws

#10-32 x 1"

Inner Lever

STEP 7

LOCATE AND INSTALL STRIKE

A. For wood jambs center strike latch opening over 1" (25mm)

hole in jamb. Trace outline around the strike on door jamb.

B. Mortise door jamb to accommodate strike box and strike.

C. Insert strike box if required and fasten strike to jamb with

combination screws provided.

Caution: Deadlocking plunger of latch bolt must not enter

opening in strike plate.

Note: When strike box is not used, recess in jamb must be

a minimum of 7RF" (14mm) deep to allow latch bolt to extend

to its full projection.

STEP 8

INSTRUCTIONS FOR REMOVING OUTSIDE TRIM

A. Remove the outside trim retaining screw (A).

B. Slide the outside trim (B) from the chassis assembly.

C. See Step 9 for chassis adjustment procedure,

or Step 10 for spacer installation.

Mortise for

dust box

and strike

Mortise for

dust box

and strike

Jamb

ANSI Dust Box

ANSI Strike

#12 Combination Screw

Jamb

Dust Box

T-Strike

#8 Combination

Screw

B

A

D. Slide the outside trim (B) onto the chassis.

E. Replace the outside trim retaining screw (A).

54

T-Series Service Manual

Page 58

STEP 9

ADJUST LOCK FOR DOOR THICKNESS

Lock is factory packed preadjusted for 17N" (45mm) doors unless

ordered special.

A. Place template provided against retractor housing to find

marking for door thickness.

1 3/4"(45mm) DR

2"(51mm) DR

5/32"(4mm)

5/32"(4mm)

2 1/4"(57mm) DR

DOOR CENTERING ADJUSTMENT

x1/8"(3mm) DEEP

ALIGNMENT

PROPER

ENSURE

MENDED TO

RECOM-

030736-000-50 IS

FIXTURE

USING DRILL

5/16"(8mm) HOLES

MARK CENTER FOR

2 1/8"(54mm) HOLE

MARK CENTER FOR

BACKSET BEFORE DRILLING

CHECK LOCK FOR PROPER

IMPORTANT:

(45mm)

1 3/4"

2 3/4"(70mm) BACKSET

HIGH EDGE

LATCH

LOCKS

T–SERIES LEVER

INSTALLING

TEMPLATE FOR

2 1/4"(57mm)

2"(51mm)

THICKNESS.

FOR CORRECT DOOR

MARK CENTERLINE OF LATCH

PLACE ON HIGH

FOLD HERE &

B. If adjustment is necessary, use hex wrench provided

and rotate flanged nut counterclockwise to adjust.

Again, use template markings to measure adjustment

before installing lock on door.

Hint: Three full turns of nut equals (=) 67" (3mm) adjustment.

C. Pinch button mount legs together and

move cap to desired position.

STEP 10

INSTALLING SPACER FOR DOORS THINNER

THAN 17N" (45mm)

A. Remove flanged nut with blakc hex wrench

pro-vided along with outer mounting plate.

B. Place on spacer over outer chassis spindle

as shown.

C. Re-install outer mounting plate and flanged nut.

Using adjusting gage provided adjust flanged nut

for proper door thickness as shown.

D. See Step 4 for chassis installation.

E. Place second spacer over inner chassis spindle

before installing inner mounting plate and

flanged nut. Continue at Step 5.

Flanged Nut

Chassis Assembly

DOOR CENTERING

ADJUSTMENT GAGE