Page 1

03079400070

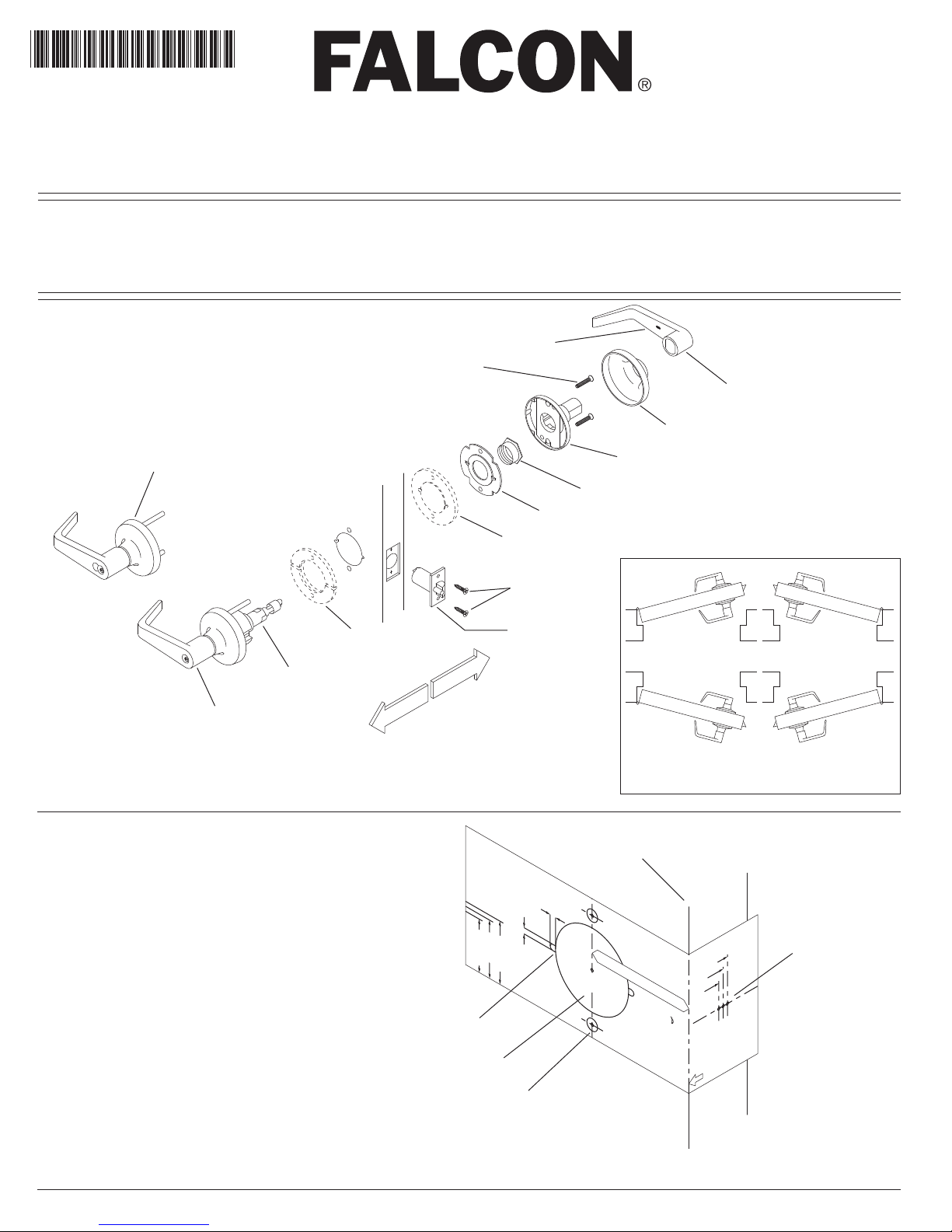

INSTALLATION INSTRUCTIONS FOR INSTALLING

T-SERIES EXTRA HEAVY DUTY LEVER LOCKSET

IMPORTANT: THIS LOCK IS NON-HANDED. LOCK IS FACTORY PACKED PREADJUSTED FOR 1³⁄₄" (45mm)

THICK DOORS. TO ADJUST LOCK FOR OTHER DOOR THICKNESS, SEE STEP 8, 9 & 10. SPACERS MUST BE

USED FOR DOORS THINNER THAN 1³⁄₄ " (45mm) THICK. FOR FUNCTIONS T351, T3 81 , T 561 AND T571,

SEE STEPS 16 (STANDARD CYLINDER) OR 17 (IC CORE) FOR TIMING INSTRUCTIONS.

Set Screw

¹⁄₄-20 x ¹⁄₄"

Mounting Screws

#10-32 x 1"

Rose

Inner Lever

Outer Trim Assembly

Interchangeable Core Cylinder

*Spacer

Chassis Assembly

Outer Trim Assembly

Standard Cylinder

OUTSIDE

LEFT HAND REVERSE SHOWN

STEP 1

MARK THE DOOR

Fold the template on the line indicated.

Place on HIGH EDGE of door bevel.

Position centerline of the template on heightline

(suggested height is 38" (965 mm) from floor).

A. Locate and mark center for 2¹⁄₈" (54 mm) hole.

B. Locate and mark positions for notches.

Caution: Notches must be horizontal.

C. Locate and mark center for two (2) ⁵⁄₁₆" (8 mm)

through-bolt holes.

D. Locate and mark center for 1" (25 mm) latch bolt hole

in the door edge.

Note: If steel frames are used, the latch centerline must

be in line with the center of the strike preparation.

INSIDE

*Spacer required for all

doors less than 1³⁄₄" thick.

RD )mm54

R

D )mm15("2

(

"

/

4

3

1

B) Mark Notches

A) Mark 2¹⁄₈" Hole

C) Mark Thru-Bolt Holes

Inner Mounting Plate

*Spacer

Attaching Screws

#8 Combination

Latch Assembly

x1/8"(3mm) DEEP

5/32"(4mm)

5/32"(4mm)

TNEMT

SUJDA GNIRETNE

R

D )

mm75("

LT

OF

T

/

4

1

2

C

RO

O

D

Flanged Nut

High Edge Of Bevel Door

HOLES.

THRU-BO

ALIGNMEN

ENSURE PROPER

RECOMMENDED TO

FIXTURE

030736-000-50 IS

USING DRILL

5/16"(8mm) HOLES

MARK CENTER FOR

Inner Trim Assembly

INSIDE

LEFT HAND

LEFT HAND REVERSE

OUTSIDE

DOOR HAND DETERMINED FROM OUTSIDE

T:

TAN

2 1/8"(54mm) HOLE

MARK CENTER FOR

TCH

2 3/4"(70mm) BACKSET

LA

LOCKS

2 1/4"(57mm)

BACKSET BEFORE DRILLING

CHECK LOCK FOR PROPER

2"(51mm)

IMPOR

(45mm)

1 3/4"

A

TCH

HOLE.

THICKNESS.

1"(25mm) DIA

IH

G

H

E

EGD

T–SERIES LEVER

INSTALLING

DRIL

L

FOR CORRECT DOOR

MARK CENTERLINE OF L

EDGE OF DOOR

PLACE ON HIGH

FOLD HERE &

TEMPLATE FOR

RIGHT HAND

RIGHT HAND REVERSE

D) Mark Latch Hole

Hint: For retrofitting of existing 2¹⁄₈" (54mm) holes, fold template in half to locate position for the two (2) ⁵⁄₁₆" (8mm) holes.

Page 2

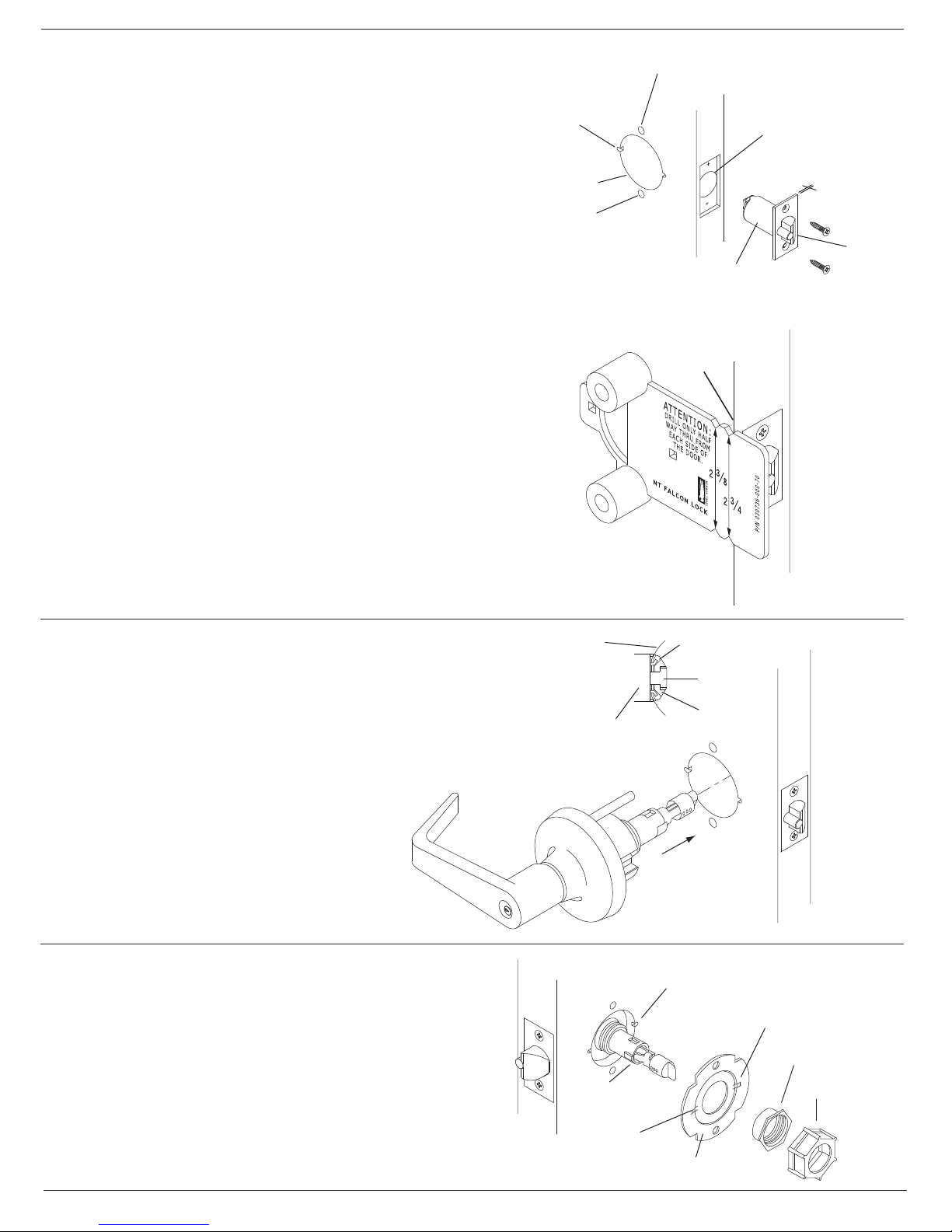

STEP 2

BORE HOLES: INSTALL LATCH

When drilling through the door, be careful not to damage the door finish.

A) 5/16" (8 mm)

Thru hole

A. Bore a 2¹⁄₈" (54 mm) hole and two (2) ⁵⁄₁₆" (8 mm) holes

from both sides of door to avoid splintering wood.

B. Bore a 1" (25 mm) hole into door edge. Using the latch faceplate

as a pattern, trace outline and mortise the door edge so the latch

is flush with door. If ³⁄₄" projection latch is to be installed see Step 19.

Note: For wood jambs, close the door and using a strike-locating tool

or other pointed object, mark the position of the hole in the jamb.

Open the door and drill 1" (25 mm) hole in the jamb a minimum of ³⁄₄"

19 mm) deep.

C. File two (2) ⁵⁄₃₂" (4 mm) x ⁵⁄₃₂" (4 mm) x ¹⁄₈" (3 mm) deep notches

into both sides of the door.

D. Insert the latch unit in the door, making certain that the latch bolt

bevel faces the direction of the closing door. Attach with two (2)

#8 combination screws provided.

Note: Use of a drill guide is recommended to ensure

straight and level holes.

IF USING THE FALCON OPTIONAL DRILL GUIDE

Install Drill Guide (M204-198) into the door. Make certain the

correct backset locators are even with door edge. Drill two (2) ⁵⁄₁₆" (8 mm)

holes from both sides to the center.

C) File Notches

A) 2-1/8" (54 mm)

Thru hole

A) 5/16" (8 mm)

Thru hole

B) 1" (25 mm) Hole

Latch Unit

Use faceplate as pattern for mortise.

Backset

Locator

5/32" (4 mm)

Latch

Bolt Bevel

Note: Drill guide replacement is recommended after ten (10) door preparations.

STEP 3

INSTALL CHASSIS AND OUTER TRIM ASSEMBLY

Note: For ease of installation, the lock should be in

the unlocked position.

Slide the chassis assembly into the door from outside

making sure that the lock housing engages the latc h

Chassis Assembly

prongs. Retractor must also engage the latch tail.

Important: The chassis assembly must be positioned

in the center of the door for proper operation.

See Step 9 for door thickness adjustment.

STEP 4

INSTALL INNER MOUNTING PLATE

A. Place the inner mounting plate onto the chassis assembly

making sure that the plate tabs engage the horizontal

notches in the door.

Lock Housing

Latch Case

Latch Prong

Latch Tail

Retractor

Outside of Door

Notches

Tab

Flanged Nut

B. Position the flanged nut over the chassis assembly and

tighten securely with hex wrench provided.

Black Hex Wrench Chassis Assembly

Tab

Inner Mounting Plate

Page 3

STEP 5

INSTALL INNER TRIM ASSEMBLY

Thru Post

Slide the inner trim assembly over the chassis spindle. Thru-posts will

engage the inner trim asembly on 1³⁄₄ " (45 mm) thick doors.

Secure to the door with two #10-32 x 1" machine screws provided.

STEP 6

INSTALL INNER LEVER

A. Position the rose over the inner trim assembly making

sure the rose detent engages the groove in the

spindle assembly.

B. Install the lever handle and tighten the set screw with

the hex key provided.

STOP! Test operation to be sure the latch bolt moves freely.

DO NOT FORCE. If the lockset does not operate properly, remove the

lockset from the door and check the door preparation and door thickness

adjustment. Go back to Step 3 to re-install the chassis.

Inner Trim Assembly

Thru Post

Chassis Spindle

Groove

Rose

Inner Trim Asssembly

Rose Detent

¹⁄₄-20 x ¹⁄₄"

Set Screw

Mounting Screws

#10-32 x 1"

Inner Lever

STEP 7 LOCATE AND INSTALL THE STRIKE

A. For wood jambs, center the strike latch opening over 1" (25 mm)

hole in jamb. Trace the outline around the strike on the door jamb.

B. Mortise the door jamb to accommodate the strike box

and the strike.

C. Insert the strike box if required and fasten the strike to the

jamb with #12 or #8 combination screws provided.

Caution: Deadlocking plunger of the latch bolt must not enter

opening in the strike plate.

the

Note: When the strike box is not used, the recess in the jamb must

be a minimum of ⁹⁄₁₆" (14 mm) deep to allow the latch bolt to extend

to its full projection.

STEP 8

INSTRUCTIONS FOR REMOVING OUTSIDE TRIM

A. Remove the outside trim retaining screw (A).

B. Slide the outside trim (B) from the chassis assembly.

C. See Step 9 for chassis adjustment procedure,

or Step 10 for spacer installation.

Mortise for

dust box

and strike

Mortise for

dust box

and strike

Jamb

ANSI Dust Box

ANSI Strike

#12 Combination Screw

Jamb

Dust Box

T-Strike

#8 Combination

Screw

B

A

D. Slide the outside trim (B) onto the chassis.

E. Replace the outside trim retaining screw (A).

Page 4

STEP 9

ADJUST LOCK FOR DOOR THICKNESS

The lock is factory packed preadjusted for 1³⁄₄" (45 mm) doors unless

special ordered.

A. Place the template provided against the retractor housing to find

the mark for door thickness.

"(45mm) DR

4

/

3

1

"(57mm) DR

4

/

1

2"(51mm) DR

2

x1/8"(3mm) DEEP

5/32"(4mm)

5/32"(4mm)

ALIGNMENT

PROPER

ENSURE

MENDED TO

RECOM-

DOOR CENTERING ADJUSTMENT

030736-000-50 IS

FIXTURE

USING DRILL

5/16"(8mm) HOLES

MARK CENTER FOR

LATCH

2 1/8"(54mm) HOLE

MARK CENTER FOR

BACKSET BEFORE DRILLING

CHECK LOCK FOR PROPER

IMPORTANT:

2"(51mm)

(45mm)

1 3/4"

2 3/4"(70mm) BACKSET

HIGH EDGE

LOCKS

T–SERIES LEVER

INSTALLING

TEMPLATE FOR

2 1/4"(57mm)

THICKNESS.

FOR CORRECT DOOR

MARK CENTERLINE OF LATCH

PLACE ON HIGH

FOLD HERE &

B. If adjustment is necessary, use hex wrench provided

and rotate flanged nut counterclockwise to adjust.

Again, use the template markings to measure adjustment

before installing lock on door.

Hint: Three full turns of the nut equals (=) ¹⁄₈" (3 mm) adjustment.

C. Pinch the button mount legs together and

move the cap to the desired position.

STEP 10 INSTALLING SPACER FOR DOORS THINNER

THAN 1³⁄₄ " (45 mm)

A. Remove the flanged nut with the black hex wrench

provided, and remove the outer mounting plate.

B. Place the spacer on over the outer chassis spindle

as shown.

C. Re-install the outer mounting plate and flanged nut.

Using the adjusting gage provided, adjust the flanged nut

for proper door thickness as shown.

D. Go back to Step 3 for chassis installation.

E. Place the second spacer over the inner chassis

spindle before installing the inner mounting plate

and flanged nut. Continue at Step 5.

Flanged Nut

Chassis Assembly

Black Hex Wrench

DOOR CENTERING

ADJUSTMENT GAGE

NT FALCON T-SERIES LEVER

LOCKS FOR DOORS LESS THAN

1 3/4 (45mm) THICK

NT FALCON LOCK

1 3/4 (45mm)

1 1/4 (32mm)

1 1/2 (38mm)

P/N 030793-001-70

PRINTED IN U.S.A.

Spacer

Outer Mounting Plate

Outer Mounting Plate

Gage

Spacer

Flanged Nut

Chassis Assembly

Button Mount Legs

2¹⁄₄"

(57 mm)

Inner Mounting Plate

Inside

Outside

Cap

2"

(51 mm)

(45 mm)

Flanged Nut

Spacer

1³⁄₄"

STEP 11

TO REMOVE ALL LEVERS WITH INTERCHANGEABLE CORE CYLINDERS

A. Insert the control key into the core and rotate 15 degrees clockwise.

Pull the key to remove the core.

B. Insert a screwdriver into the “figure 8” core hole and into the

lever retainer.

C. Depress the retainer and slide the lever off the spindle.

TO RE-INSTALL THE LEVER

D. Slide the lever over the spindle and push on over the retainer.

E. Pull on the lever to be sure the retainer is engaged with the lever.

F. Re-install the core with the tailpiece pushed into the core.

Control Key

A

B

Push

Retainer

Page 5

STEP 12

IC CORE AND TAILPIECE

Be certain to use the correct tailpiece with the core.

Six pin cores should only use the "6P" tailpiece.

Seven pin cores should only use the "7P" tailpiece.

STEP 13

TO REMOVE ALL CYLINDER LEVERS

(Except Interchangeable Core)

A. Insert the key and rotate clockwise

approximately 60 degrees.

B. Depress lever retainer with tool provided.

C. Slide lever off spindle.

TO RE-INSTALL THE LEVER

D. Insert cylinder into spindle.

E. Slide lever onto spindle.

F. Insert key into cylinder and rotate clockwise approximately

60 degrees and push lever over retainer.

G. Pull on lever to be sure the retainer is engaged with the lever.

FALCON

6 Pin Core

C

FALCON

7 Pin Core

B

A

STEP 14 TAILPIECE INSTALLATION

For proper function of the lock, the tailpiece must be

installed correctly.

All T-Series tailpieces should be installed

VERTICALLY in the cylinder.

STEP 15

SINGLE DUMMY TRIM, T12

A. Using the template described in Step 1,

locate and mark the center for

two (2) mounting holes.

B. For Wood Door - Drill two (2) pilot holes

⁵⁄₃₂" (4 mm) x ⁷⁄₈" (22 mm) deep for #12 wood screws.

For Metal Door - Drill and tap two (2) holes

for #12-24 machine screws.

C. Position the spindle assembly over the

mounting holes and secure to the door

with the screws provided.

D. See Step 6 for lever installation.

Cylinder

Spring

Inside of Door

Pin

Screws for Metal Doors

#12-24 x ³⁄₄"

Screws for Wood Doors

#12 x 1¹⁄₂"

Tailpiece

Cap

Inner Trim Assembly

Groove

Page 6

STEP 16

TIMING INSTRUCTIONS FOR STANDARD CYLINDER LOCKS

T351, T381, T561, T571

A. If the cylinder and lever are installed, refer to Step 13 for

lever removal instructions.

B. Using a thin flat screw driver, turn the action bar slot clockwise

(cw) until it stops at about 2:00.

FOR THE FOLLOWING FUNCTIONS:

RH Shown

Action

bar

slot

C. Then turn the action bar counterclockwise (ccw) to the 9:00

position. NOTE: There is no physical stop at this location.

D. With the key out, install the standard cylinder into the spindle.

E. Refer to Step 13 for lever re-installation.

F. Operate the key to test for proper operation.

STEP 17 TIMING INSTRUCTIONS FOR IC CORE LOCKS

T351, T381, T561, T571

FOR THE FOLLOWING FUNCTIONS:

A. If the core is installed, refer to Step 11 for IC core removal instructions.

B. Using a thin flat screw driver, turn the action bar slot clockwise

(cw) until it stops at about 11:00.

C. Then turn the action bar counterclockwise (ccw) to the 7:00

position. NOTE: There is no physical stop is at this location.

D. Using the control key, insert IC core into the lever and spindle.

E. Remove the control key.

F. Operate the key to test for proper operation.

STEP 18 TAILPIECE INSTALLATION INSTRUCTIONS FOR T381 FUNCTION

Door

edge

RH Shown

Action

bar

slot

Door

edge

SEE STEP 14 FOR STANDARD CYLINDER

LONG TAILPIECE SHORT TAILPIECE

TAILPIECE INSTALLATION

OUTER STANDARD CYLINDER ASSEMBLY

CLUTCH

ON

OUTSIDE

SEE STEP 12 FOR IC CORE

LONG TAILPIECE SHORT TAILPIECE

TAILPIECE INSTALLATION

OUTER IC CORE ASSEMBLY INNER IC CORE ASSEMBLY

STEP 19

INSTALLATION INSTRUCTIONS FOR OPTIONAL ³⁄₄" PROJECTION LATCH

A. Determine the hand of the door.

B. On the side closest to the door stop, remove the shaded area as shown.

Use a standard rotary file ³⁄₈" diameter maximum.

C. Try the latch for fit and function.

D. Secure the latch with two (2) #8-32 machine screws provided.

INNER STANDARD CYLINDER ASSEMBLY

Door stop

on this side

1"

MIN

REF

1¹⁄₁₆" MIN REF

800-266-4456©2010 Schlage Lock Company Printed in Country 030794-000-70 Rev. 05/10-d

Loading...

Loading...