Page 1

*941367-00*

941367-00

MEL 24/25 Series

Motorized Electric Latch Retraction

These instructions are for MEL conversion kits or MEL

devices with preinstalled motors.

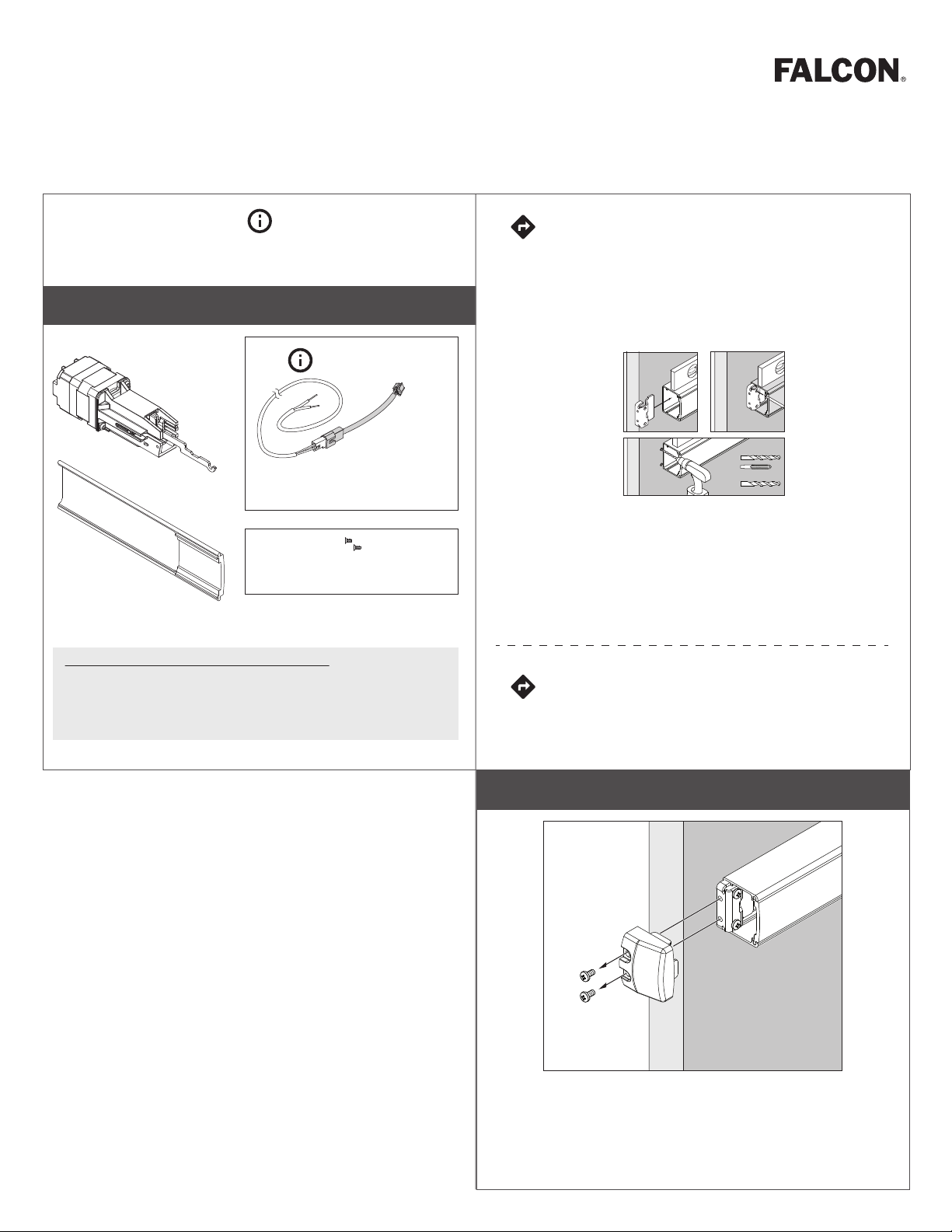

Parts

MEL motor

assembly

MEL 6' cable with motor cable

MEL

cover plate

4-20 x ¹⁄₄" FHP screws (qty 2)

Do not discard

Motor cable

only

(114320)

(47269206)

MEL motor mounting

Installation Instructions

If MEL is preinstalled in the device:

Follow original device instruction up to the point

A.

where this end mounting bracket step has been

completed.

Mark and Prepare 2 Holes

a

c

Complete MEL wiring per steps 15-21 of this

B.

instruction.

Return to original device instruction at point you left

C.

off, and complete installation.

b

Metal/Metal/Métal

#25

#10-24

Wood/Madera/Bois

¹⁄₈" (3 mm) x 1" (25 mm)

Allegion Connect accessories available to order

106198 MEL-CON adapter cable with 8-pin connector

040069 MEL motor cable + MEL-CON adapter cable with 8-pin

connector

If installing the MEL conversion kit, follow

the instruction steps as written.

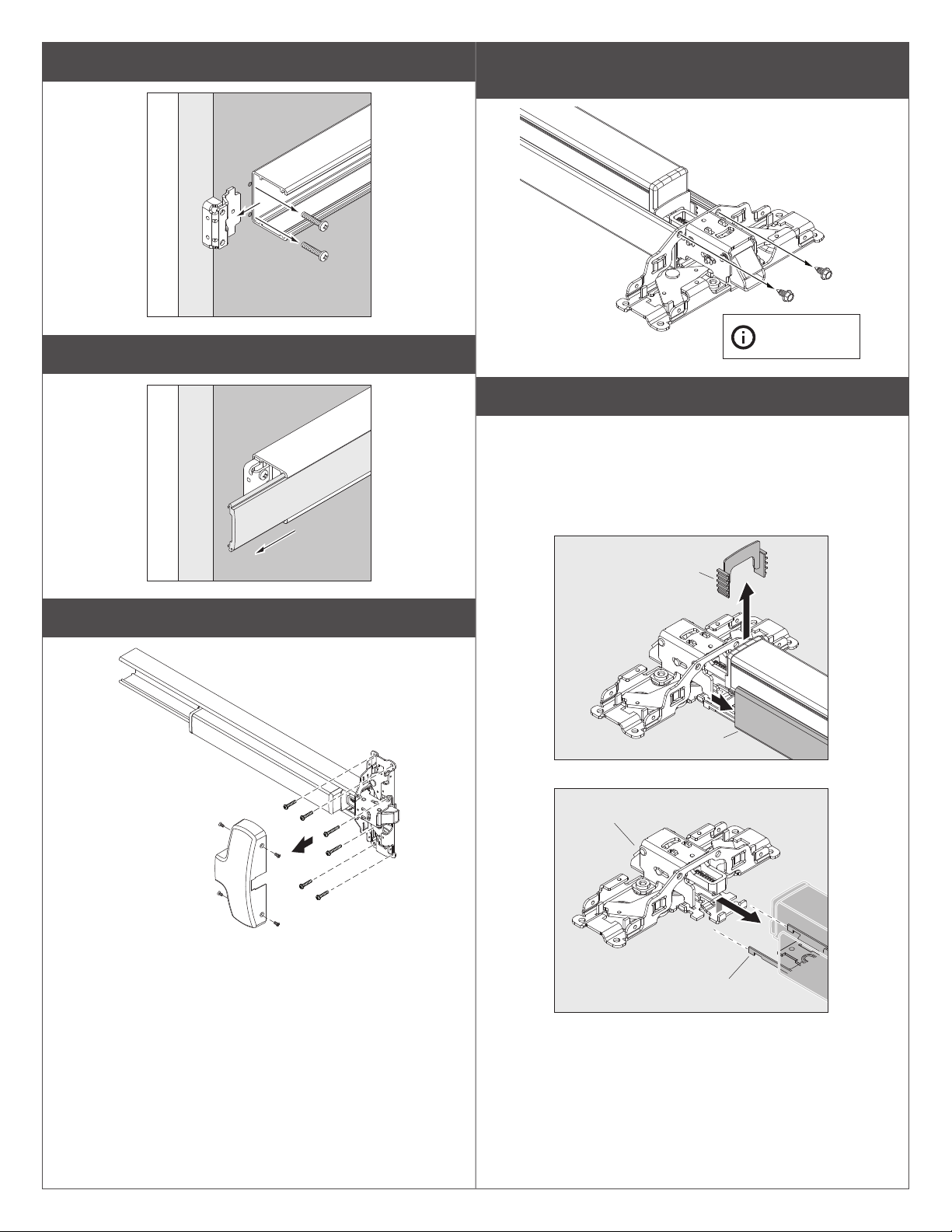

1 Remove end cap

Page 2

2 Remove device end mounting bracket from door

3 Slide back, remove and discard old cover plate

5 With device laying on a table or bench, remove the 2

screws that connect mechanism case to center case

Use long shank

screwdriver.

6 Unhook baseplate from center case

a. Slide back mechanism case about 2” to access hooking

parts.

b. Push bar guides will come loose and will need to be

reinstalled later.

c. Unhook baseplate from center case.

4 Remove center case cover and device from door

b

a

center

case

pushbar

guide

mechanism

case

baseplate

b

a

c

Page 3

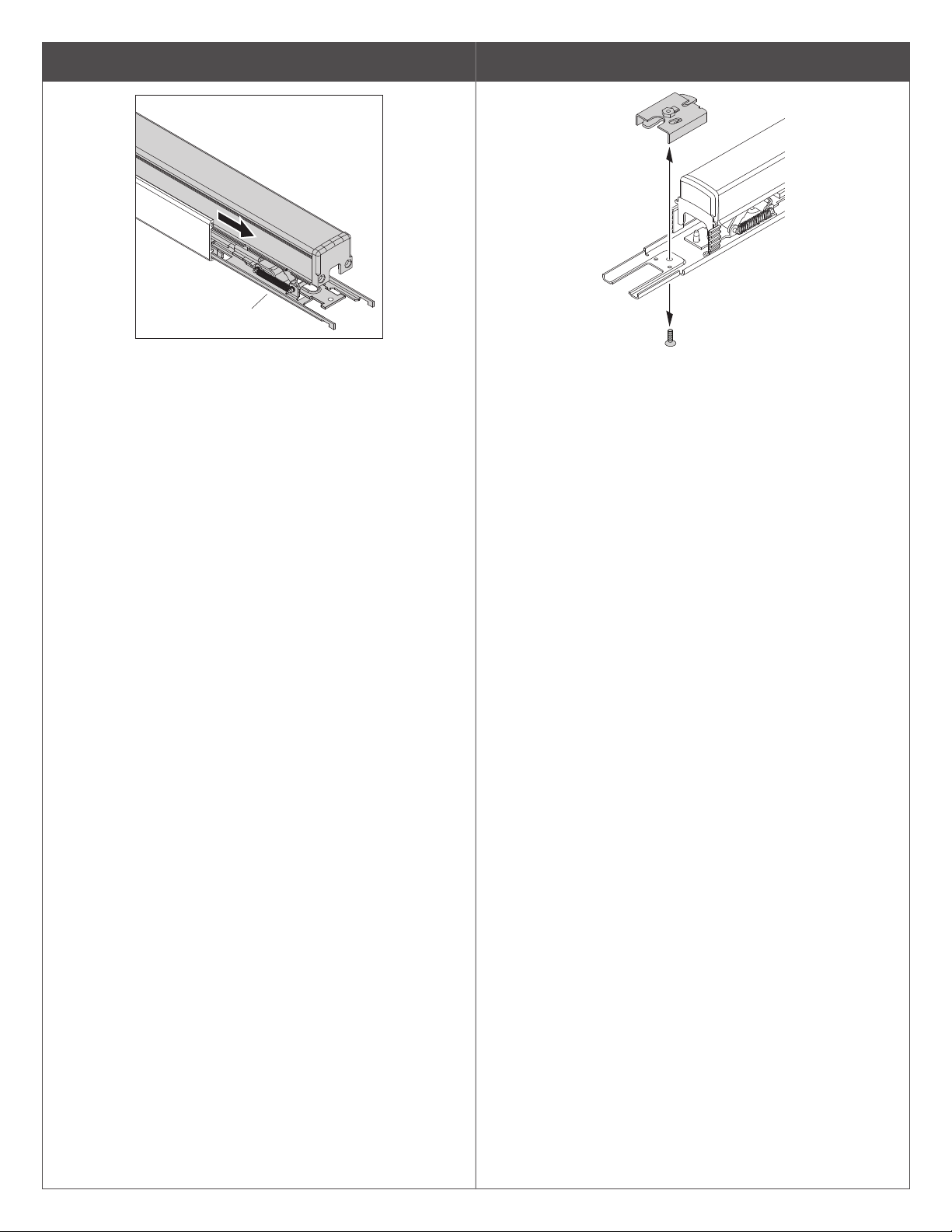

7 Slide baseplate out of mechanism case

baseplate

8 Remove any existing dogging assembly

d.

e.

f. Slide m

32

Page 4

sticker

Use #1 Phillips

screwdriver

9 Secure motor assembly

a. Turn baseplate assembly upside down so pushpad is

resting on a at surface and motor mounting location is on

the left.

motor mounting

location

pushpad

b. Place motor in left hand with LED status sticker facing

toward you. Gently extend silver hook arm outward (about

Z\x”) until you meet some resistance, then hold.

b

LED

status

d. Set motor on at surface.

e. Push down rmly on baseplate so it bottoms out against

push pad.

f. While depressing baseplate, lift up motor assembly and

guide it along elongated baseplate slot until motor lip slips

over baseplate.

e

c. While tilting baseplate assembly away from you slightly,

move extended hook arm into position under baseplate. A

post will be hanging down from baseplate; the hook arm

should sit on the near side of that post. Rotate the motor

assembly to hook the arm over the baseplate axle pin that

is closest to the baseplate. Do not pull out on motor at this

step.

pin

post

f

Lip slips over baseplate

g. Release baseplate. Secure motor assembly with 2 small

self-tapping screws (provided).

90°

h. Turn baseplate and motor assembly right side up.

Page 5

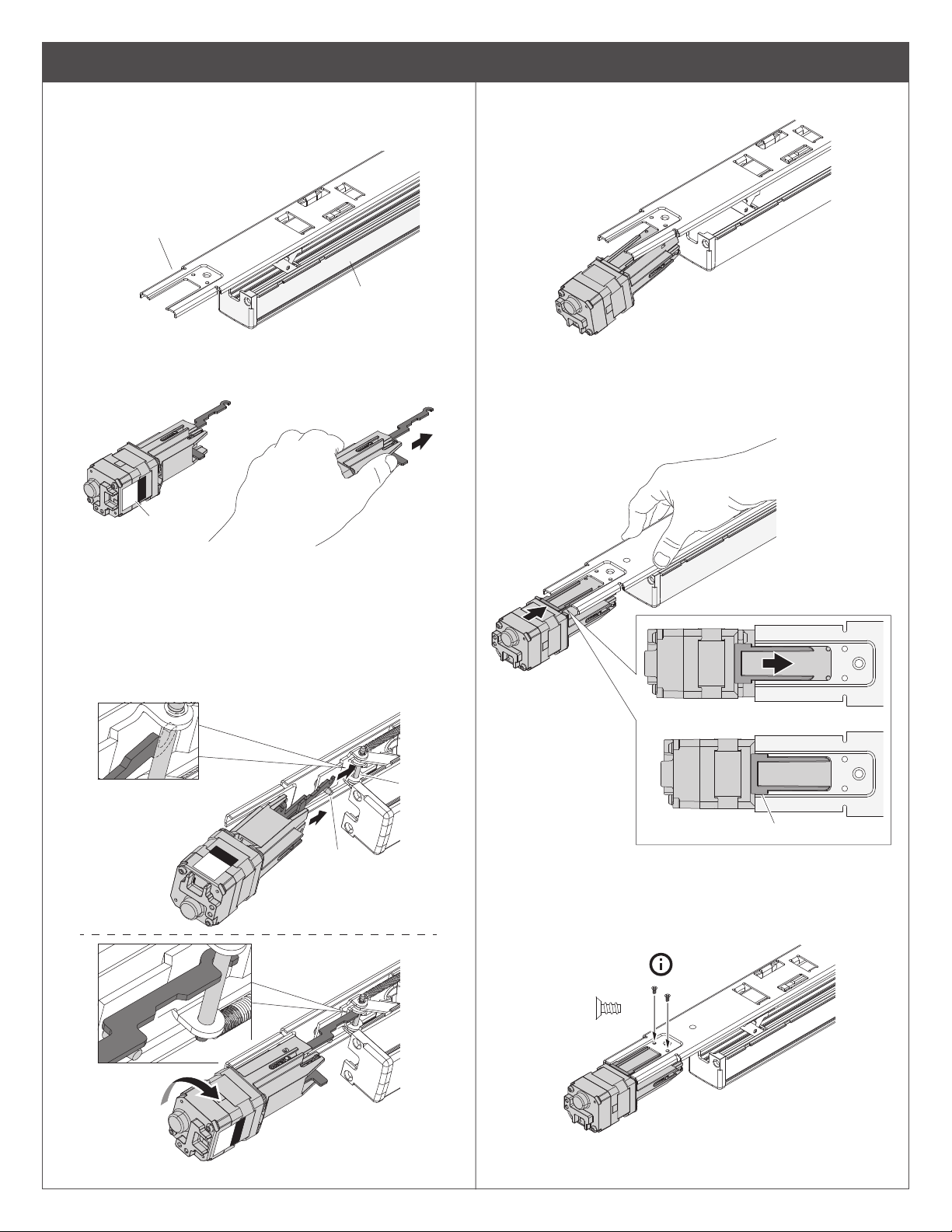

10 Slide mechanism case onto baseplate

Insert pushbar guide ahead of motor

assembly and hold in place (a) while sliding

mechanism case onto baseplate (b)

a

b

11 Reconnect center case to baseplate via hooking parts

13 Reattach mechanism case to center case

Use long shank

screwdriver.

14 Reattach device to door

12 Insert remaining pushbar guide (nearest the center

case) and slide mechanism case against center case

a

b

x4

x2

54

Page 6

MEL Wiring and Conguration (page 1 of 3)

15 Complete wiring

If not wiring at this time, DO NOT DISCARD CABLE!

After installing device or conversion kit, if there is room, store the cable inside the mechanism

case until the electrical wiring occurs. Otherwise, store the cable in a designated location.

a. Drill wire access hole.

b. Route furnished 6’ MEL two-piece cable thru device end mounting bracket to connect MEL device to power transfer wires.

c. Plug cable connector into MEL motor.

d. Reinstall end mounting bracket.

e. Refer to table below to route proper gauge wires (from electric hinge, EPT, or door loop) to PS900-Series power supply.

⁵⁄₁₆"

⁵⁄₈"

Dia.

a

connect to power

transfer wires

b

PS900-Series power

supply with 900-Series

option board(s)

installed

end mounting bracket

c

d

MEL device used

with EPT, Electric

Hinge, or Door Loop

Distance

(one way)

200’ 18AWG

320’ 16AWG

500’ 14AWG

800’ 12AWG

Wire

Gauge

e

Power wires to MEL are not polarized.

MEL Electrical Load

Voltage: 24 VDC

Current: 1.0 A inrush (0.5 sec)

0.14 A holding

electric hinge shown

(an EPT or door loop

may also be used)

MEL exit

device

Page 7

MEL Wiring and Conguration (page 2 of 3)

WARNING

To avoid risk of electric shock, turn off AC power to power supply before

installing or wiring option board.

16 Conrm equipment compatibility

MEL is compatible with the following equipment (refer to individual instructions as needed):

• PS900-Series power supplies - PS902, PS904, PS906, PS914

• 900-Series option boards - 900-2RS, 900-4R, 900-4RL

17 Install 900-2RS, 4R, or 4RL option board(s) into power supply

Review Available 900 series Option

a

Board Mounting Locations (Gray)

Plug Option Board Cable into

b

any Available Option Connector

PS902

PS904

PS914

PS906

1

1 2

1

PS902

1 Board

Option 1

PS904, 914

2 Boards

Option 2

Option 1

1

Option 2

Option 1

c

Secure Board(s) with Screws

PS906

3 Boards

Option 3

WARNING

Fire alarm (FA) option board required if MEL is installed in fire exit hardware.

2

3

Notes:

1. 24 VDC output setting required when MEL device connected.

2. If installing board in location 2 or 3, rotate board 180˚.

3. Latchbolt retraction of (2) sequenced MEL devices requires more than 1 second to

complete.

4. When powering multiple components, verify that the amperage requirements of all

components combined does not exceed the power supply output rating.

76

Page 8

MEL Wiring and Conguration (page 3 of 3)

18 Connect input and output wires to option board (2RS shown)

Sequential Mode - Typical Wiring

Individual Mode - Typical Wiring

PS900

Series

Note:

Fail secure

output only

allowed if

approved by

Authority Having

Jurisdiction

PS900

Series

SC I1 01 I2 02 GND

120/240 VAC

50/60Hz

SC I1 01 I2 02 GND

2RS

Access

Control

Devices

120/240 VAC

50/60Hz

2RS

for

1 & 2

Access

Control

for

Device 2

Input I1 will activate both outputs

EPT-2/10

MEL Device 1

Input I1 will activate output 1

Input I2 will activate output 2

EPT-2/10

MEL Device 2

EPT-2/10

MEL Device 2

19 Check operation

a. Activate each input and verify all MEL devices operate properly.

b. If any device does not operate properly, see next page for troubleshooting.

Access

Control

for

Device 1

EPT-2/10

MEL Device 1

Page 9

MEL Troubleshooting

20 If necessary, troubleshoot operation (LED is only visible with the mechanism case removed)

Power at

the MEL

24 VDC

24 VDC low

29 VDC or

greater

13 VDC or

lower

0 VDC

*For information about adjusting exit devices, you can nd their installation instructions in the

support area at www.allegion.com/us or call Technical Services at 1-877-671-7011

MEL Response Condition/Solution

LED - solid green

Latchbolt - retracted

LED - solid red after latchbolt

attempts to retract multiple

times

LED - ashing green/red

Latchbolt - not retracted

LED - ashing green

Latchbolt - retracted

LED- ashing red

Latchbolt - will not retract

LED - o

Latchbolt - not retracted

Operation normal, latch retracted immediately

Latchbolt cannot fully retract mechanically

Remove power. Depress pushbar and make sure

latchbolt retracts and extends fully. If necessary,

disconnect any vertical rods or mortise lock from

device center case, and reapply power. If motor

holds, mechanical adjustments may be required

per the device instructions.*

Excessive tamper (while power applied, the

pushpad was pulled out at least 3 times)

Wait 15 seconds and latchbolt will retract again OR

remove and reapply power to clear condition.

Voltage low during latchbolt retraction

(latchbolt retracts at reduced force)

Wire length is too long, wire gauge is too small, or

power supply has poor regulation.

Input voltage is too high for proper operation

Wrong power supply, power supply defective.

Input voltage is too low for proper operation

Wrong power supply, power supply defective or not

set to the proper output voltage.

To set, remove AC power from power supply,

change power supply setting from 12 to 24 VDC,

then reapply AC power and verify proper operation.

No input voltage

Problem with the power supply, control switch, or

wiring.

LED

on Device

98

Page 10

21 Install MEL cover plate

Do not cut from recessed end of cover plate

recessed

area

Install this

end first

recessed end

back of new

MEL cover plate

back of old

cover plate

Page 11

22 Reinstall end cap

23 Reinstall center case cover

1110

Page 12

Warnings look like this:

Cautions look like this:

Warnings and Cautions

WARNING

Warnings indicate potentially hazardous conditions, which if not

avoided or corrected, may cause death or serious injury.

CAUTION

Cautions indicate potentially hazardous conditions, which if

not avoided or corrected, may cause minor or moderate injury.

Cautions may also warn against unsafe practices.

Notices look like this:

Directions look like this:

Notices indicate a condition

that may cause equipment

or property damage only.

Directions identify a step that

may or may not apply to your

product configuration. It also

may direct you to another

part of the instruction.

Customer Service Servicio al cliente Service à la clientèle

1-877-671-7011 www.allegion.com/us

© Allegion 2019

Printed in U.S.A.

941367-00 Rev. 03/19-a

Loading...

Loading...