Falcon i91104, i91105, i9042, i9043, i9085 User, Installation And Servicing Instructions

...Page 1

F900 SERIES

User, installation and servicing instructions

INDUCTION RANGE

i91104, i91105

Read these instructions before use

REV 1

Published: 31/3/16

DATE PURCHASED:

MODEL NUMBER:

SERIAL NUMBER:

DEALER:

SERVICE PROVIDER:

T100953

Page 2

2

Falcon Foodservice Equipment

HEAD OFFICE

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of appliance life, dispose of appliance and any replacement parts in

a safe manner, via a licensed waste handler. Appliances are designed to

be dismantled easily and recycling of all material is encouraged whenever

practicable.

Dear Customer,

Thank you for choosing Falcon Foodservice Equipment.

This manual can be downloaded from www.falconfoodservice.com or scan

here.

IMPORTANT: Please keep this manual for future reference.

Page 3

3

SYMBOLS

•SPANNER • SCREWDRIVER • COOKING OIL • GREASE

• SPARK IGNITION • FLAME • WARNING • VIEWPORT

• ALLEN KEY •IGNITER

Page 4

4

These instructions are only valid if the country code appears on the appliance.

If the code does not appear on the appliance, refer to the technical instructions

for adapting the appliance to the conditions for use in that country.

Installation must meet national or local regulations. Attention must be paid to:

safety (installation & use) regulations, health and safety at work act, local and

national building regulations, fire precautions act.

All apparatus connected to a potable water network and including water drain

device has to be provided with an air break before its discharge to the

drainage system. Type AA.

To prevent shocks, all appliances must be earthed.

This equipment is for professional use only and must be used by qualified

persons.

The installer must instruct the responsible person(s) of the correct operation

and maintenance of the appliance.

Unless otherwise stated, parts which have been protected by the

manufacturer must not be adjusted by the installer.

Take care when moving an appliance fitted with castors.

The appliance must be serviced regularly by a qualified person. Service

intervals should be agreed with the service provider.

“Check that no damage has occurred to the appliance, power cable and plug

top during transit.

If damage has occurred do not use the appliance.

Installation, periodic testing, repair and fixed wiring connections should only

be undertaken by a competent electrician

Ensure that the mains power cable is routed free from the appliance to avoid

damage.

We recommend supplementary electrical protection with the use of a residual

current device (RCD).

The appliance has been designed and approved to use Falcon kick plates,

non Falcon kick plates could potentially adversely affect the performance of

the appliance by restricting the air to the appliance.

Page 5

5

CONTENTS

1.0 APPLIANCE INFORMATION ........................................................................... 6

2.0 OPERATION .................................................................................................... 7

2.1 COMPONENT PARTS .................................................................................. 8

2.2 CONTROLS .................................................................................................. 9

2.3 USING THE INDUCTION HOB ..................................................................... 9

3.0 CLEANING AND MAINTENANCE ................................................................. 12

3.1 TURN OFF AND ALLOW TO COOL DOWN ............................................... 12

3.2 HOB ............................................................................................................ 12

3.3 OVEN .......................................................................................................... 12

4 SPECIFICATION ............................................................................................... 13

5 DIMENSIONS / CONNECTION LOCATION ...................................................... 13

6 INSTALLATION ................................................................................................. 14

6.1 SITING / CLEARANCES ............................................................................. 14

6.2 ELECTRICAL SUPPLY AND CONNECTION ............................................... 14

6.3 ASSEMBLY ................................................................................................... 14

6.4 COMMISSIONING ...................................................................................... 15

6.5 INSTRUCTION TO USER ........................................................................... 15

6.6 SUITING........................................................ Error! Bookmark not defined.

7 SERVICING ....................................................................................................... 18

7.1 CONTROL PANEL ...................................................................................... 18

7.2 OVEN DOOR REMOVAL ............................................................................ 19

7.3 ACCESSING THE GENERATOR AND ELECTRICS .................................. 21

7.4 REMOVING COIL ASSEMBLY ................................................................... 25

7.5 OVEN TOP ELEMENT REMOVAL ............................................................... 27

7.6 OVEN BOTTOM ELEMENT REMOVAL ..................................................... 28

8.0 FAULT FINDING ................................................................................................ 29

8.1 ERROR CODE TABLE ............................................................................... 29

9.0 CIRCUIT DIAGRAM ....................................................................................... 33

10.0 WIRING DIAGRAM ..................................................................................... 34

11.0 SPARE PARTS ........................................................................................... 37

12.0 SERVICE INFORMATION .......................................................................... 37

Page 6

6

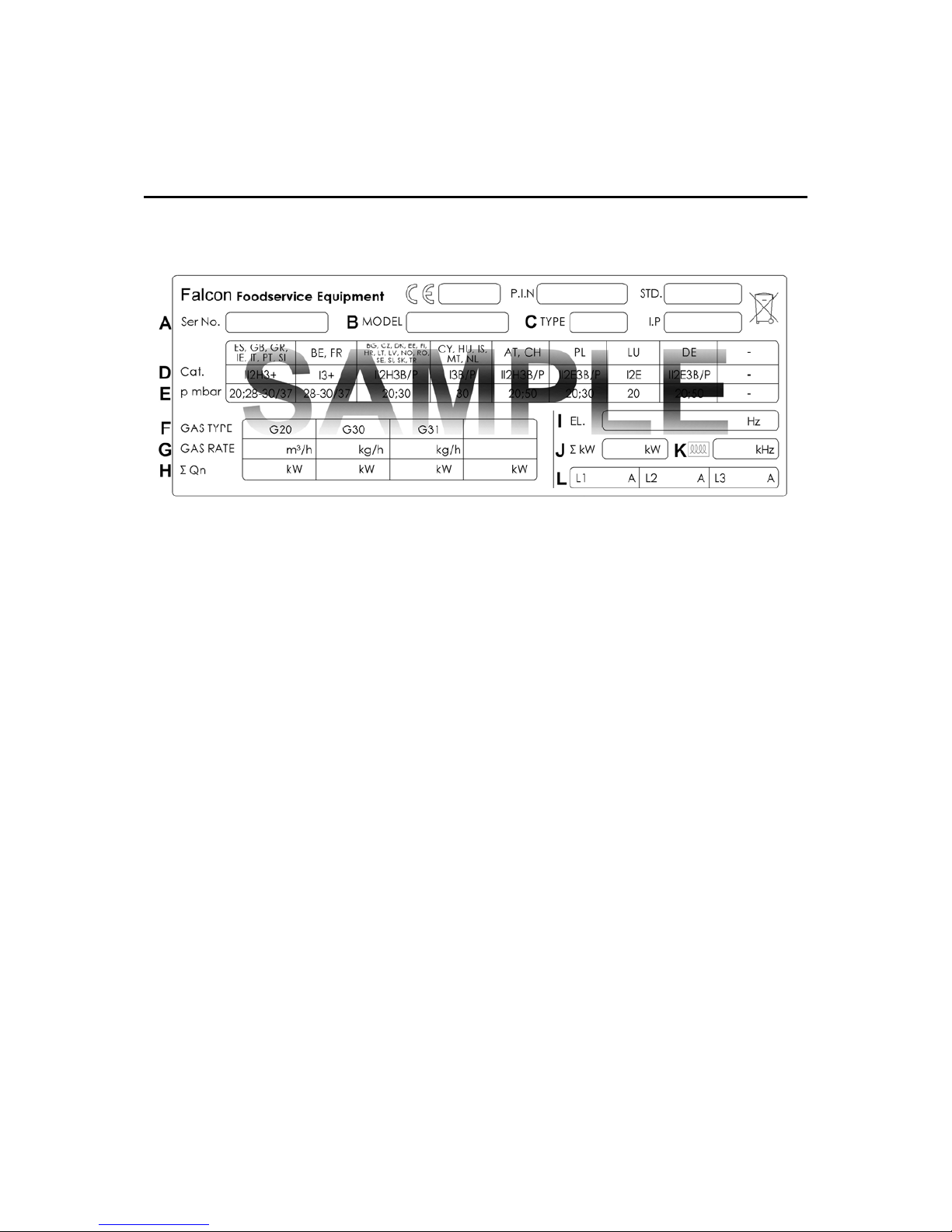

1.0 APPLIANCE INFORMATION

This appliance has been CE-marked on the basis of compliance with the relevant EU

directives for the heat inputs, gas pressures and voltages stated on the data plate.

A - Serial No •

B - Model No •

C - Flue Type •

D - Gas Category •

E - Gas Pressure •

F - Gas Type •

G - Gas Rate •

H - Total Heat Input •

I - Electrical Rating •

J - Total Electrical Power •

K - Magnetic Field Frequency •

L - Electrical Phase Loading •

Page 7

7

2.0 OPERATION

IF GLASS-CERAMIC TOP IS CRACKED OR BROKEN IMMEDIATELY

DISCONNECT APPLIANCE FROM POWER SUPPLY AND CONTACT

YOUR SERVICE AGENT.

THE AIR INTAKE FILTER MUST BE IN POSITION DURING

OPERATION IT SHOULD BE CLEANED REGULARLY AND DO NOT

OBSTRUCT AIR FILTER ENTRY BELOW.

USERS MUST BE MADE AWARE THAT INDIVIDUALS FITTED

WITH A PACEMAKER SHOULD CONSULT THEIR DOCTOR IF IN A

CLOSE PROXIMITY TO THIS UNIT. THIS INDUCTION UNIT

EMANATES AN 18 KHz TO 20 KHz OUTPUT THAT MAY AFFECT

OLDER TYPES OF PACEMARKER.

USE OF THE CORRECT TYPE OF PAN IS ESSENTIAL FOR

CORRECT OPERATION.

DO NOT PLACE ANY METAL OBJECTS, SUCH AS KITCHEN

UTENSILS, CUTLERY, ALUMINIUM FOIL, OR PLASTIC VESSELS, ON

THE GLASS-CERAMIC TOP.

THE USER MUST ALSO BE AWARE OF POTENTIAL TO HEAT

JEWELLERY AND DISRUPT ELECTRONIC EQUIPMENT PLACED

OVER THE INDUCTION ZONES MAGNETIC FIELD.

DO NOT PLACE CREDIT CARDS, ETC, ON THE GLASS-CERAMIC

TOP AS DATA COULD BE WIPED OFF.

NEVER LEAVE THE INDUCTION HOB UNSUPERVISED WHEN IN

USE. THE GLASS-CERAMIC TOP MUST NOT BE USED FOR

STORAGE.

DAMAGED PANS CAN REDUCE THE APPLIANCE EFFICIENCY.

Page 8

8

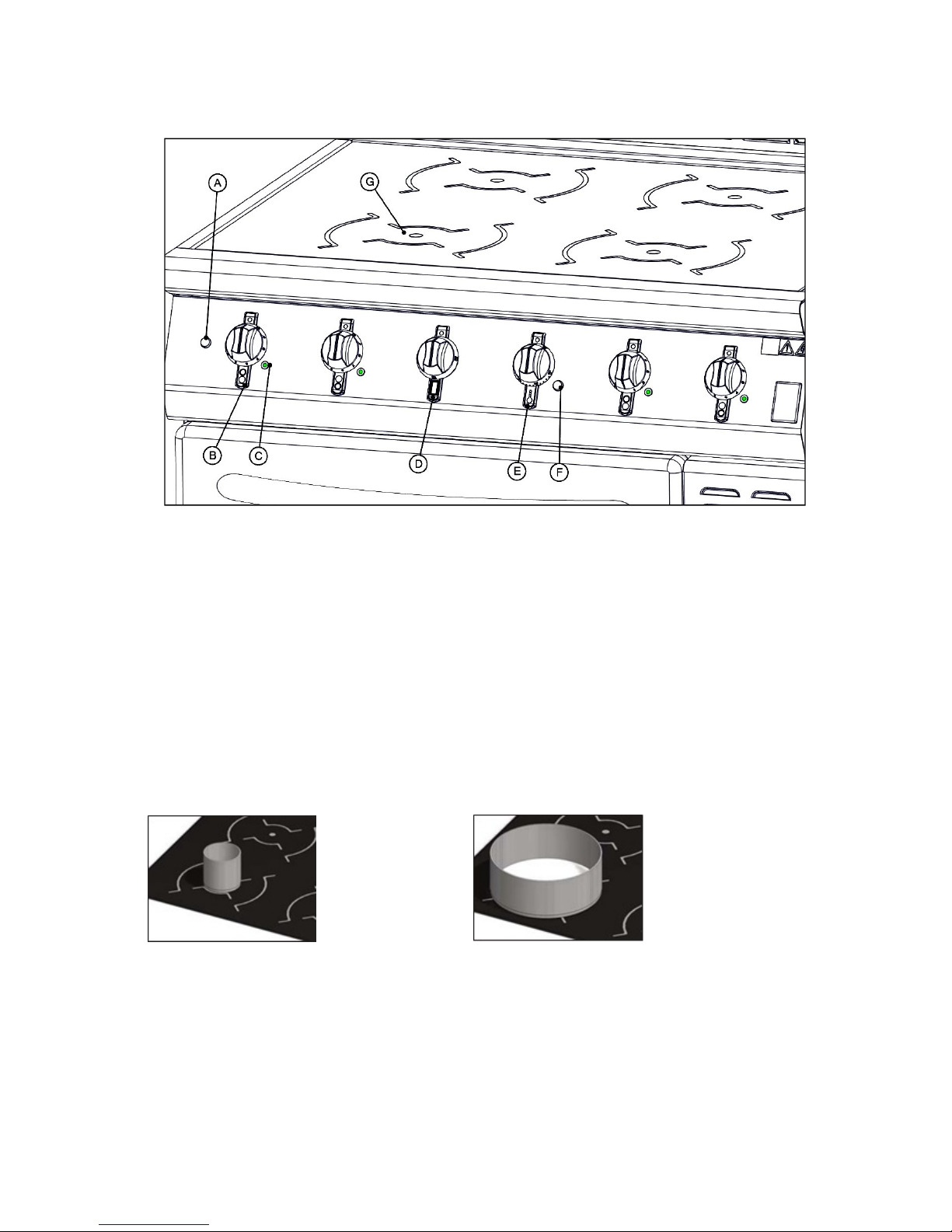

2.1 COMPONENT PART S

A - Door

B - Drip tray

C - Shelf

D – Hob zone Control

E –Oven zone Control

F – Oven temperature control

G – Glass hob

H –Flue capper

I - Filter

Page 9

9

2.2 CONTROLS

A - Power neon (red).

B - Hot zone indicator.

C - Zone LED (green).

D - Oven Indicator.

E - Oven temperature indicator.

F – Oven heat neon (amber).

G – Cooking surface area.

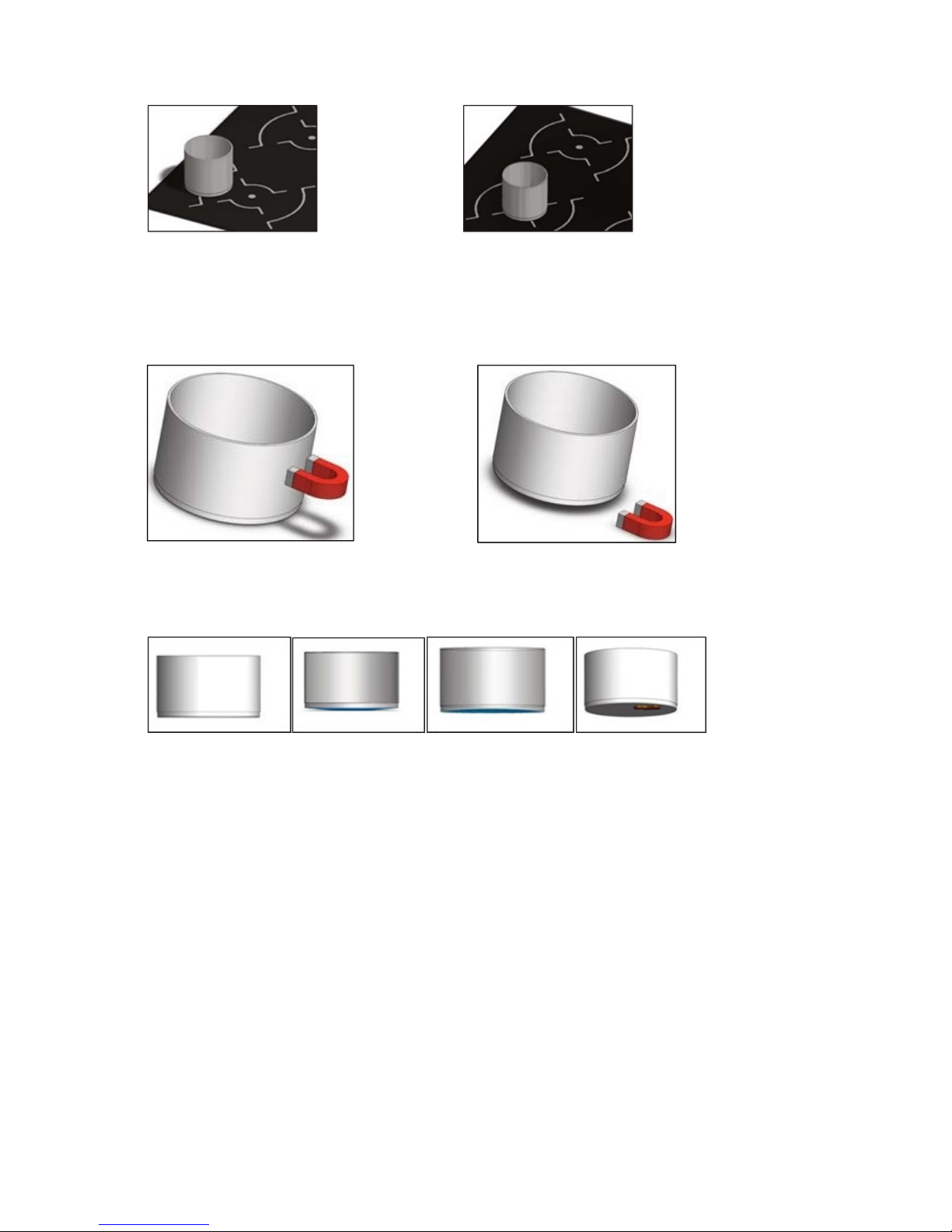

2.3 USING THE INDUCTION HOB

2.3.1 Ensure you use the correct size of pot.

<Ø120 Ø120 – Ø270

2.3.2 Ensure the pots are central in the cooking zone

Page 10

10

2.3.3 Ensure you use the correct type of pot

2.3.4 Ensure you use a clean flat bottom pan

Page 11

11

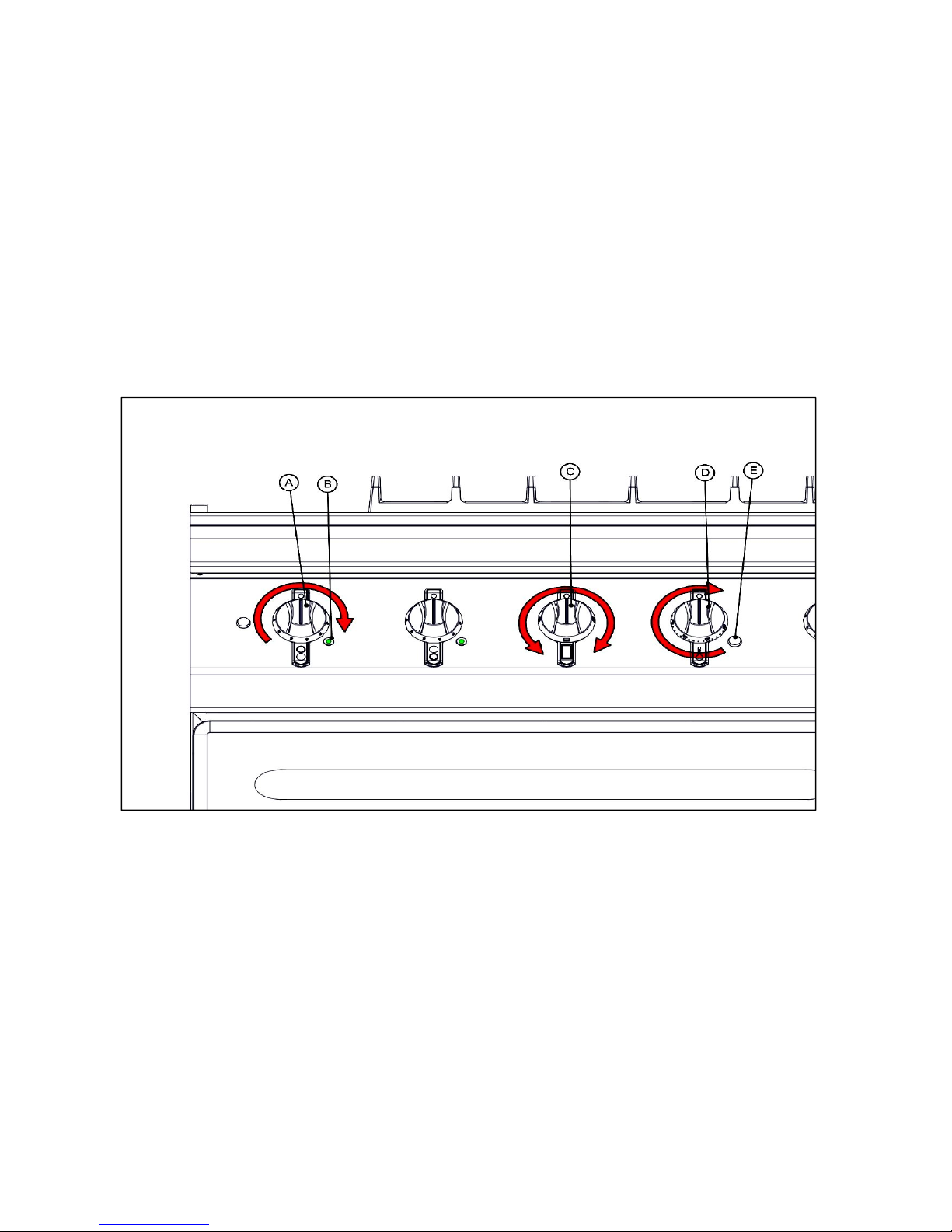

2.3.5 To turn on hob cooking zone turn required control (A.) The green L.E.D (B)

will light. If you remove the pot from the cooking zone the L.E.D will flash at 1

second intervals to indicate that the cooking zone is still active.

2.3.6 To use oven switch oven zone control to required setting (C).

2.3.7 Use temperature control knob to adjust temperature (D), (E) heat demand

neon will light when heat is demanded.

2.3.8 Caution: Opening the oven door will result in the escape of hot air. Care

should be taken to avoid being burnt by such action.

2.3.9 To switch off, turn control knobs to off position.

Page 12

12

3.0 CLEANING AND MAINTENANCE

3.1 TURN OFF AND ALLOW TO COOL DOWN

3.2 HOB

3.2.1 Clean the glass hob with hot soapy water

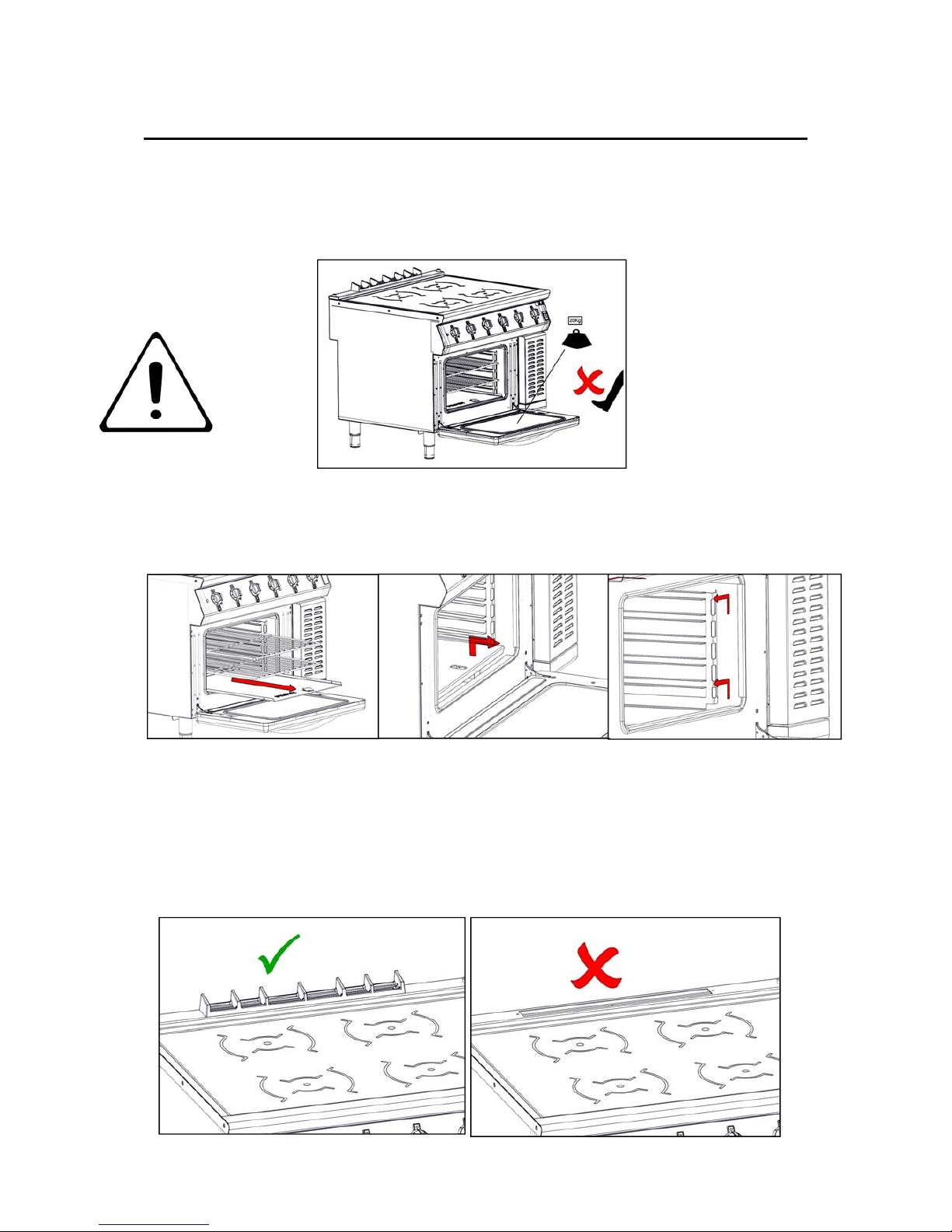

3.3 OVEN

3.3.1 Turn off and let cool down.

3.3.2 Remove base tray, base plate and shelf hangers.

3.3.3 Clean oven using soap and water.

3.3.4 Clean shelves and base tray using soap and water.

3.4 FLUE CAPPER

3.4.1 The flue capper can be removed for cleaning but must be replaced for use.

Page 13

13

CLEAN THE AIR INTAKE FILTER REGULARLY. FAILURE TO

CLEAN THE FILTER REGULARLY MAY CAUSE PROBLEMS WHICH

WILL NOT BE COVERED BY WARRANTY. THE AIR INTAKE FILTER

MUST BE IN PLACE DURING OPERATION.

DO NOT ATTEMPT TO REPAIR OR REPLACE ANY PART OTHER

THAN THE AIR INTAKE FILTER. REFER TO THE ERROR CODE LIST

TO DEBUG THE PROBLEM.

4 SPECIFICATION

These appliances are suitable for AC supplies only.

Three phase & neutral 5 wire connection

MODEL VOLTAGE POWER L1 L2 L3

i91104 400V 3N~ 20.2KW 30.8A 30.4A 30.4A

i91105 400V 3N~ 26.2KW 38.6A 38.0A 38.0A

5 DIMENSIONS / CONNECTION LOCATION

Page 14

14

6 INSTALLATION

6.1 SITING / CLEARANCES

CAUTION: IF SUITING THE NECESSARY CLEARANCES TO ANY

COMBUSTIBLE WALL MUST BE THE LARGEST FIGURE GIVEN

FOR INDIVIDUAL APPLIANCES INSTRUCTIONS.

6.2 ELECTRICAL SUPPLY AND CONNECTION

6.2.1 Remove rear access panel to access the inlet terminal (see 6.2.2)

6.2.2 Cable entry at unit rear. A suitable rated isolating switch with contact

separation of at least 3mm in all poles must be installed and wiring executed in

accordance with relevant regulations.

This appliance is also provided with a

terminal for connection of an external

equipotential conductor. This terminal is in

effective electrical contact with all fixed

exposed metal parts of the appliance, and

shall allow the connection of conductor

having a nominal cross-section area of up

to 10mm². It is located at the rear of the unit

and identified by the following label and

must only be used for bonding purposes.

The electrical connections color code is shown in the table below.

PHASE I PHASE II PHASE III

NEUTRAL

EARTH

Brown Black Grey

Blue

Green/Yellow

MAINS INPUT CONNECTION CABLE IS NOT SUPPLIED; SUITABLE

CABLE WILL CONFORM TO CODE DESIGNATION IEC 60245-57.

6.3 ASSEMBLY

6.3.1 Unpack, position appliance and level using feet or castor adjusters as shown below.

Page 15

15

6.3.2 Ensure fan intake filter is fitted and secured in position below control panel.

6.3.3 Connect to an electrical supply (see 6.2)

6.4 COMMISSIONING

6.4.1 Switch all cooking zones on to position 10 (A).

6.4.2 Ensure all L.E.Ds light and begin to flash (B).

6.4.3 Place a pan suitable for induction cooker tops, filled with water, upon a

cooking zone. The pan minimum diameter cannot be less than 120mm.

6.4.4 Ensure that corresponding L.E.D stops flashing and remains lit. This indicates

that “Pan detection” feature is working.

6.4.5 Repeat on all different cooking zones.

6.4.6 Leave pots to heat until water boils and switch controls to maintain simmer.

6.4.7 Switch control off.

6.4.8 Set oven control to each setting (C).

6.4.9 Use temperature control (D) to adjust temperature for each setting.

6.5 INSTRUCTION TO USER

After installation and commissioning is completed, please hand the user instructions

to the user and ensure that the person/s responsible understand the instructions

regarding correct operation and cleaning of the appliance.

PLEASE FILL OUT THE INFORMATION TABLE ON THE FRONT

COVER AFTER COMMISSIONING.

Page 16

16

6.6 SUITING

“Patent pending, application no. GB 1511389.7”

6.6.1 Before leveling and suiting units ensure the units are fully built, including all

accessories and castings.

6.6.2 Undo the 4 fixing screws on the control panel and remove.

6.6.3 Remove the hob rear infill and replace with rear suiting plate and fixings.

6.6.4 Remove the front side panel countersunk screw and suiting plate.

NOTE: The DLS system is designed to give a quick and easy suiting

solution. If you require an improved seal between appliances we

recommend you use, a food grade, high temperature silicon

sealant. This can be supplied by Falcon part no – 523400021

6.6.5 Run a bead of silicon 5mm from profile edge as highlighted below.

Page 17

17

6.6.6 Slide suited units into position.

6.6.7 Right hand unit: Screw the M5 x 40 screw (supplied in the kit) into one of the

suiting plates as shown and then insert through the front fixing holes of both

units.

6.6.8 (B) Left hand unit: Slide the penny and lock washer on to the screw and

secure using the M5 nut.

6.6.9 (C) Remove the front bolts from feet, insert base tie plate and secure the bolts

back into position.

6.6.10 (D) Replace fixings on the rear hob and tighten screw caps into

position.

6.6.11 Replace control panel.

A

D

Page 18

18

7 SERVICING

BEFORE ATTEMPTING ANY MAINTENANCE, ISOLATE THE APPLIANCE AT

THE MAINS ISOLATING SWITCH AND TAKE STEPS TO ENSURE THAT IT

CANNOT BE INADVERTENTLY SWITCHED ON.

7.1 CONTROL PANEL

7.1.1 Remove control panel and controls as shown.

7.1.2 Control switch: - Identify wires that relate to switch and LED attached to the

generator unit and disconnect.

Page 19

19

7.1.3 Unscrew and remove as shown

Set DIP switch settings on new control switch to match removed switch.

7.1.4 Re-assemble in reverse order.

7.1.5 LED`s are polarity driven with the Green cable negative and the purple cable

positive. The Green cable connects to the spade above LED body flat side.

7.2 OVEN DOOR REMOVAL

THE HINGE SPRING SHOULD BE UNDER TENSION AND NO ATTEMPT

SHOULD BRE MADE TO REMOVE THE PINS WHEN DOOR IS OFF

7.2.1 Turn off and cool down.

Page 20

20

7.2.2 Open the door fully and push an Ø4mm pin into the hole on each hinge.

7.2.3 Holding the door with both hands half way down each side, rotate and lift up

until the hinge hits the top of the hinge aperture.

Page 21

21

7.2.4 Rotate hinge out of hinge aperture and lift door away.

7.3 ACCESSING THE GENERATOR AND ELECTRICS

7.3.1 Remove filter.

7.3.2 Remove front panel.

Page 22

22

7.3.3 Remove cross supports.

7.3.4 Pull generator and electrics out as shown.

Page 23

23

A- CONTACTOR FOR SAFETY CIRCUIT?

B- CONTACTOR FOR TOP OVEN ELEMENT

C- CONTACTOR FOR BOTTOM OVEN ELEMENTS?

D-RELAY

E-MCB-40A 3P TYPE D

F-COOLING FAN

G-SAFETY STAT

H-INDUCTION GENERATOR

I-FUSE 2A

7.3.5 Remove generator canopy (screws both sides) as shown.

7.3.6 Disconnect Generator wires

Page 24

24

7.3.7 Loosen top screws and remove lower screws (both sides) to remove

generator.

Page 25

25

7.4 REMOVING COIL ASSEMBLY

7.4.1 Disconnect the wires to the coil.

7.4.2 Remove the fixings holding the coil carrier to the hob.

7.4.3 Remove the four fixings holding the coil to the carrier take care not to lose

the springs.

Page 26

26

DO NOT USE THE UNIT IF THE CERAMIC TOP IS CHIPPED,

CRACKED OR BROKEN. THE PANEL NEEDS TO BE REPLACED.

WHEN REPLACING COILS, ENSURE THAT SPACERS ARE IN

POSITION AND ONLY FITTED WITH A SINGLE, LAYERED SPACER

AS INDICATED.

THE INDUCTION GENERATOR UNIT IS HEAVY AND IT MAY BE

REQUIRED THAT TWO PEOPLE ARE INVOLVED WITH THE

CHANGING PROCEDURE.

Page 27

27

7.5 OVEN TOP ELEMENT REMOVAL

7.5.1 Inside oven chamber, unscrew element fixing clips and loosen two screws at

rear of element.

7.5.2 Disconnect from wiring and remove top element from oven.

Page 28

28

7.6 OVEN BOTTOM ELEMENT REMOVAL

7.6.1 Remove screws from Element fixing plate as required.

7.6.2 Disconnect wires and remove element from oven.

Page 29

29

8.0 FAULT FINDING

Note: Most faults can be rectified by simply switching unit off for 10 seconds. After

this time, turn power back on at mains supply. If fault continues to occur after such

action then please refer to the table. This will provide a solution to rectify the

condition.

8.1 ERROR CODE TABLE

If any fault becomes apparent during the tests, an error code may display on an LED

as a series of flashes. These flashes correspond to the numbers in the left column of

the following table.

For example, 6 short flashes followed by a long flash would indicate error code 06 –

“internal temperature too high”.

CODE ERROR CAUSE ACTION

01

Coil Pan Detection

Error.

Use of Unsuitable pan material Use suitable pan.

Reset appliance

Switch appliance OFF for 10

seconds then ON.

Defective coil

Check all electrical

connections to the inductor coil

Replace defective Coil

02

No Inductor Coil

Current.

Reset appliance

Switch appliance OFF for 10

seconds then ON.

Inductor Coil connection failure

Check all electrical

connections to the inductor coil

Replace defective Coil

03

Generators Internal

Heat Sink Too High.

Reset appliance

Switch appliance OFF for 10

seconds then ON.

Air routes blocked.

Check below appliance & rear

of Appliance for potential Air

Flow Obstructions.

Air Filter blocked (Requires

Cleaning).

Check Filter - Does it require

cleaning / Replacing?

Generator Fan(s) Malfunctioned.

Due to electrical fault.

Replace Generator

Generator Fan(s) blowing instead

of sucking.

Replace Generator

Generator Temperature sensor

defective.

Replace Generator -

Page 30

30

04

Cooking Zone

Temperature Too

High Or Remains

Constant During

Cooking.

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Pan empty / Too Hot

Test Disc may be

overheated – allow for

cooling.

Cooking Zone Self

Protected due to Abnormal

Heat Build up

Allow Cook Zone to cool

for couple of Minutes

Temperature sensor faulty

(Constantly records a

Ambient Temperature)

Check all electrical

connections to the

inductor coil

Replace defective Coil

05

Controls Failure

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Controls faulty or

incorrectly Wired

Check all electrical

connections to the

controls & Generator

Replace defective

Controls Assembly

06

Generators

Internal

Temperature Too

High.

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

See Fault 3 See Fault 3

07

Cooking Zone

Temperature

Sensor

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Temperature sensor faulty /

Malfunctioned

Check all electrical

connections to the

inductor coil

Replace defective Coil

08

Mains Supply

Failure

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Fault in mains supply

Is there a Phase(s) Down

Has supply been

interrupted intermittently?

Has MCB Tripped

Has Supply Under / Over

Voltage?

Page 31

31

09

N/A N/A N/A

10

Communication

Error

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Failure on LIN or CAN-Bus

Check all

communications

connections

11

Initialisation Error

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Software Failure while

initialising hardware

Wait. The generator will

reset every 30 seconds.

Replace Generator .

12

Current Reading

Failure

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Generator suspects

Current being generated

does not reflect what

appliance controls are set

for.

Check Mains Supply

Check all electrical

connections within

appliance.

Replace Suspect Coil

Replace Generator .

13

Mains Connection

Error

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Mains voltage too high or

too low

See Fault 8

14

Mains Connection

Error

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

Mains voltage too high or

too low

See Fault 8

15

Coil Electrical

Circuit SelfProtected.

Reset Appliance

Switch Appliance OFF for

10 Seconds then On.

See Fault 4 See Fault 4

O1

Oven will not

operate

No power to unit

Check oven zone

(element selector) switch

is on, turn temperature up

Page 32

32

O2

Oven will not

operate

Safety stat tripped Call engineer

O3

Oven slow to heat Wrong element setting

Check element

selector(oven zone)

switch

O4

Oven slow to heat Faulty element Call engineer

Page 33

33

9.0 CIRCUIT DIAGRAM

i91104/5 Circuit Diagram

Page 34

34

10.0 WIRING DIAGRAM

i91104/5 Wiring diagram

Page 35

35

i91104/5 Wiring diagram

Page 36

36

i91104/5 Coil Wiring Diagram

Page 37

37

11.0 SPARE PARTS

Main Spare Parts

Oven top element- 733440003

Oven bottom element- 730962060

Control panel i9184 733940000

Power neon red- 730962010

Heat demand neon amber- 730962040

Hot zone control switch- 734250016

Oven zone control switch- 733440002

Oven thermostat switch- 734000032

Safety thermostat- 733940002

Hot zone control knob- 733920000

Oven temperature control knob- 733440000

Oven zone control knob- 733440001

Hot zone LED 734250006

MCB 40A 3P TYPE-D 734250009

Induction Quad Generator 20Kw 734250001

Induction Quad Generator 14Kw 734250012

When ordering spare parts please quote the following;

Model Number

Serial Number

This information will be found on the data plate attached to the appliance. (see1.0)

12.0 SERVICE INFORMATION

It is recommended to have a maintenance contract with a local service provider.

SERVICELINE CONT ACT:

(UK only)

Phone: +441438 363 000

Warranty Policy Shortlist

For our warranty policy please go to www.falconfoodservice.com

Loading...

Loading...