Page 1

Page 2

Falcon has teamed up with Groen, leaders in steaming and boiling technology,

based in the USA.

Groen were established in 1907 and are recognised as the world’s largest

manufacturer of steam-jacketed kettles, braising pans and pressureless steamers.

The Products include Floor Standing and Table Top mounted Tilting Kettles with

capacities from 10 to 227 litres. Braising Pans (40 to 152 litre capacity) and

Jacketed Boiling Pans (76 to 303 litre capacity) are also available.

These products add an extra dimension to the comprehensive range of Falcon

equipment used throughout the catering and hospitality industry. Whether its those

special á la carte or banqueting occasions the heavy demands of the armed forces,

prison services, health care and educational establishments, Groen’s partnership with

Falcon assures the caterer the confidence associated with reliable equipment

manufactured to the highest standards.

INTRODUCTION TO STEAM JACKETED KETTLES

Self Contained Floor Model Kettles

Floor Standing Tilting Kettles

Table Top Steam Jacketed Kettles

Floor Kettles – Direct Steam

Direct Steam Table Top Kettles, Options & Accessories

INTRODUCTION TO TILTING BRAISING PANS

Tilting Braising Pans

INTRODUCTION TO HyPerSteam

™

STEAMERS

What Makes HyPerSteam

™

Different?

HyPerSteam

™

Steamers (Counter-Top)

HyPerSteam

™

Steamers

HyPerSteam

™

Steamers

Kettle Options and Accessories & Sizing Guide

Braising Pan Menu Guide

HyPerSteam™ Menu & Features Guide

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Steam Jacketed Kettles All products that

otherwise might be prepared in a stockpot, can be prepared more quickly

and efficiently in a Groen Steam Jacketed Kettle. There is a Groen Kettle

that is perfect for your operation and menu requirements.

Tilting Braising Pans The Groen Braising Pan

is now considered the most versatile piece of cooking equipment available today.

Excellent for pan frying, kettle & griddle cooking, and braising. The versatility

of the Groen Braising Pan makes it ideal for foodservice operations of all sizes.

HyPerSteam™Steamers The Groen Hypersteam

range of steamers is a true breakthrough in steamer technology. Atmospheric

steam generators coupled with a powerful fan increase steam velocity.

The result is faster cooking times with even cooking temperatures throughout.

Contents

Page 3

WATER OR

PRODUCT

OUTER

JACKET

INNER

JACKET

STEAM

UNDER

PRESSURE

BOILING

WATER

HEATING

ELEMENTS

(ELECTRIC)

1

Introduction to Steam Jacketed Kettles

Steam jacketed kettles cook faster, yet cost less to operate, and provide more even, gentle heating.

How do they deliver this unique combination of power and cooking precision?

The Amazing Thermal Efficiency Of Steam...

Steam carries approximately six times the energy of boiling water and gives up that energy upon

contact with a colder surface. This simple fact makes steam an ideal heat transfer medium, and

steam jacketed kettles the ideal way to cook, reheat and hold a wide variety of menu items.

Unique Kettle Construction...A steam jacketed kettle is formed from two stainless steel

hemispheres, which are nested and welded to form a space or “jacket” to contain steam.

Groen Kettles Cook Faster

A stock pot only transfers heat on the bottom. A kettle transfers heat through the entire jacketed

bottom and sides. Steam jacketed kettles have 3-4 times more heat transfer surface area than

the same size stock pot, which means faster heat up and faster cook times.

Groen Kettles Are More Efficient

Kettles transfer more of their energy into the food product. Range burners only heat the bottom of

the stock pot and can be inefficient. Groen gas heated kettles are 58-65% efficient and electric

models are even more efficient. Faster cook times mean less energy used and lower fuel bills.

Direct steam kettles can operate from an existing steam source, for even greater energy savings.

Groen Kettles Save Labour

A single chef or cook can prepare larger batches of your soups and other popular menu specialties,

in a steam kettle. With even heating and precise temperature control, there is less need for

constant "pot watching" and frequent stirring. Gear assisted manual and power tilts make product

transfer and portioning fast and easy. With larger single batch capabilities, you can reduce

repetitive work and utilise more automated prep equipment. Kettles are major labour savers.

Groen Kettles Improve Consistency & Reduce Product Loss From Burn-on

Groen kettles don't have "hot spots" and don't require constant stirring to avoid product burn-on and

scorching. Steam jacketed kettles are ideal for preparation of delicate sauces, cream based soups,

dessert fillings and heat sensitive confections. Even unskilled employees can consistently cook, reheat

and hold menu items, batch after batch, day after day. Groen kettles are more "forgiving" than range

top preparation methods and they make employee training easier.

Groen Kettles Reduce Heavy Lifting...

Counterbalanced tilting kettles and models equipped with product drawoff valves reduce the need

for heavy lifting and simplify product transfer and portioning.

Groen Kettles Are Easier To Clean...

A Groen kettle can braise that meat, simmer a great sauce and boil three kinds of pasta, with

fewer pans and less pan and utensil washing. And less burn-on means less pot scrubbing.

Kettles Cook Faster & Use Less Energy!

HEATING TIME ENERGY USED

IN MINUTES KWH

70

60

50

40

30

20

10

35Kg OF 18° C WATER TO 100° C

(MIN)

180% LONGER

42% MORE ENERGY

FASTER

SAVE ££

7

6

5

4

3

2

1

(KWH)

GROEN

TDB/7-40

KETTLE

GROEN

TDB/7-40

KETTLE

(2) 20 QUART STOCK POTS

ON RANGE TOP SECTION

(2) 20 QUART STOCK POTS

ON RANGE TOP SECTION

When steam enters that jacket space from a built-in steam generator, it is aself-contained kettle.

When steam is piped in from a remote boiler, it is called a direct steam kettle.

Efficient Steam Heat T ransfer...When steam enters the jacket, it expands to fill the entire

space and transfers its energy load to the inner kettle wall and then into the water or food being

heated. Heat is transferred uniformly through the entire jacketed hemisphere surface area. There

are no hot spots or temperature variations.

The Steam Pressure/T emperature Relationship...At atmospheric pressure, steam is

100°C. Under pressure, water boils and converts into steam at temperatures above 100°C.

For example, at 3.5 bar, steam is 148°C. The rated maximum steam pressure of kettles varies by

type, but typically is 1.5 -3.45 bar and higher on food processing and some cook-chill production

kettles. This relationship between pressure and steam is important if more rapid heating or

browning (caramelization of sugars) is required in a steam kettle. Then kettle models with higher

rated pressures should be considered.

How do Steam Jacketed Kettles Work?

See page 14 for Kettle sizing and options.

Page 4

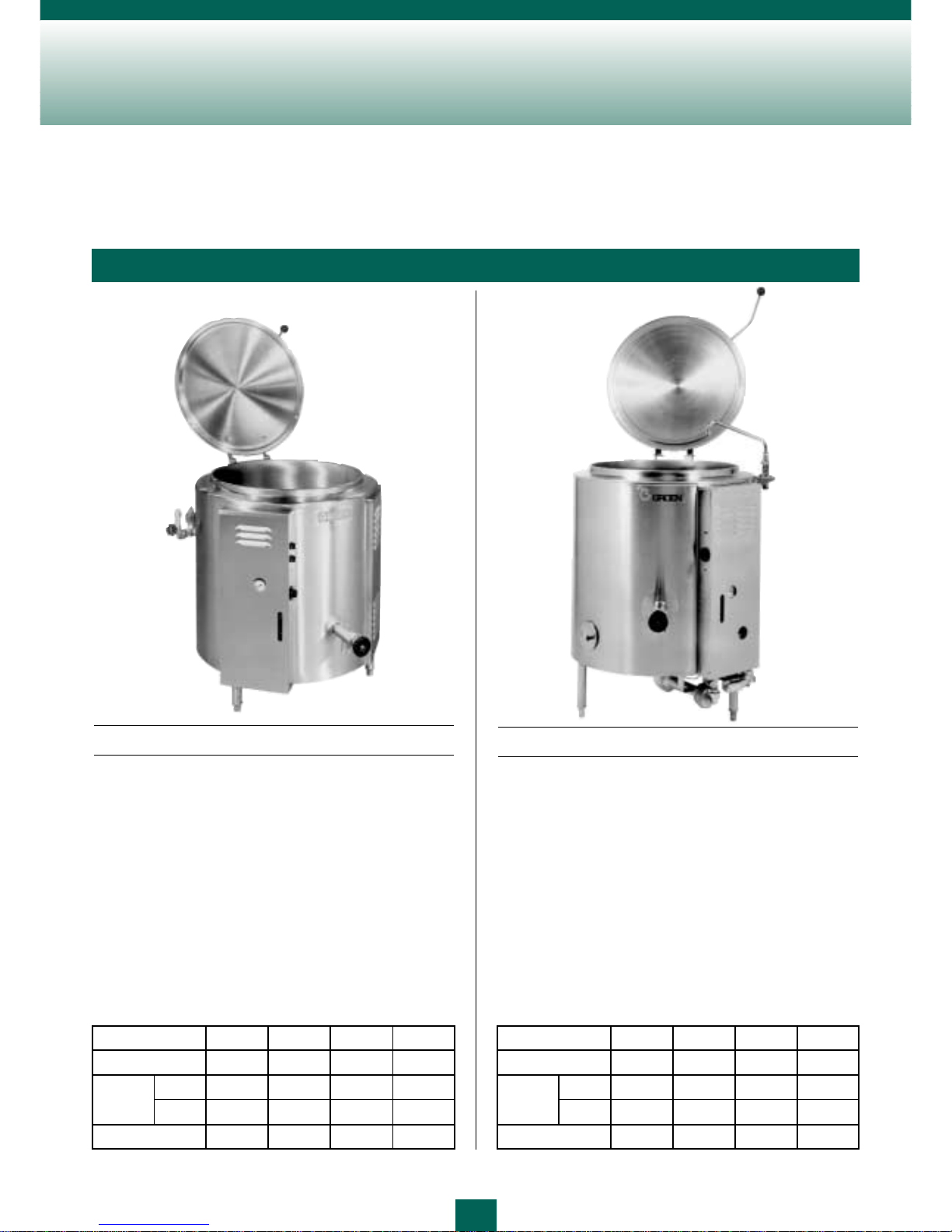

Groen self-contained, floor model kettles are perfect for preparing vegetables, stews,

pasta, sauces, soups, gravies and much more. These steam jacketed kettles

out-perform range top cooking with superior energy efficiency, high speed performance

and greater productivity. Each gas or electric heated model makes its own steam.

No remote steam source or boiler is required. All models are thermostatically controlled

to heat and hold any product at the desired temperature, without scorching. Product

transfers are accomplished with a tangent draw-off (stationary models) or a convenient,

self locking tilt mechanism (tilting models).

Non-Tilting Kettles

Model EE, Steam Jacketed Boiling Pan

Self Contained Floor Model Kettles

• Electric heated, self-contained steam source

• Air insulated sheathing over hot cooking surfaces

• 50mm tangent draw-off valve standard

• Energy saving hinged cover standard

• Precise thermostatic temperature control

• Low water safety control

• Your choice of 76, 151, 227 & 303 litre models

• Options: 75mm tangent draw-off, triple cooking basket inserts (TRI-BC),

water faucets, 316 stainless steel interior

Model AH/1

• Gas heated, self-contained steam source

• Dependable electronic ignition

• Insulated stainless steel sheathing over hot cooking surfaces

• 50mm tangent draw-off valve standard

• Energy saving hinged cover standard

• Precise thermostatic temperature control

• Low water safety control

• Your choice of 76, 151, 227 & 303 litre models

• Options: 75mm tangent draw-off, basket inserts, water faucets,

stainless steel interior, spray with flexible hose

Capacity (In litres)

MODELS (Electric) EE-20 EE-40 EE-60 EE-80

76 151 227 303

972 1226 1200 1291

660 813 914 965

12kW 24kW 24kW 36kW

Dimensions

(In mm)

Left to Right

Front to Back

Electric Rating

Capacity (In litres)

MODELS (Gas) AH/1-20 AH/1-40 AH/1-60 AH/1-80

76 151 227 303

991 1143 1245 1295

933 972 1041 1080

100,000

BTU’s/HR

100,000

BTU’s/HR

145,000

BTU’s/HR

145,000

BTU’s/HR

Dimensions

(In mm)

Left to Right

Front to Back

Gas Rating

2

Page 5

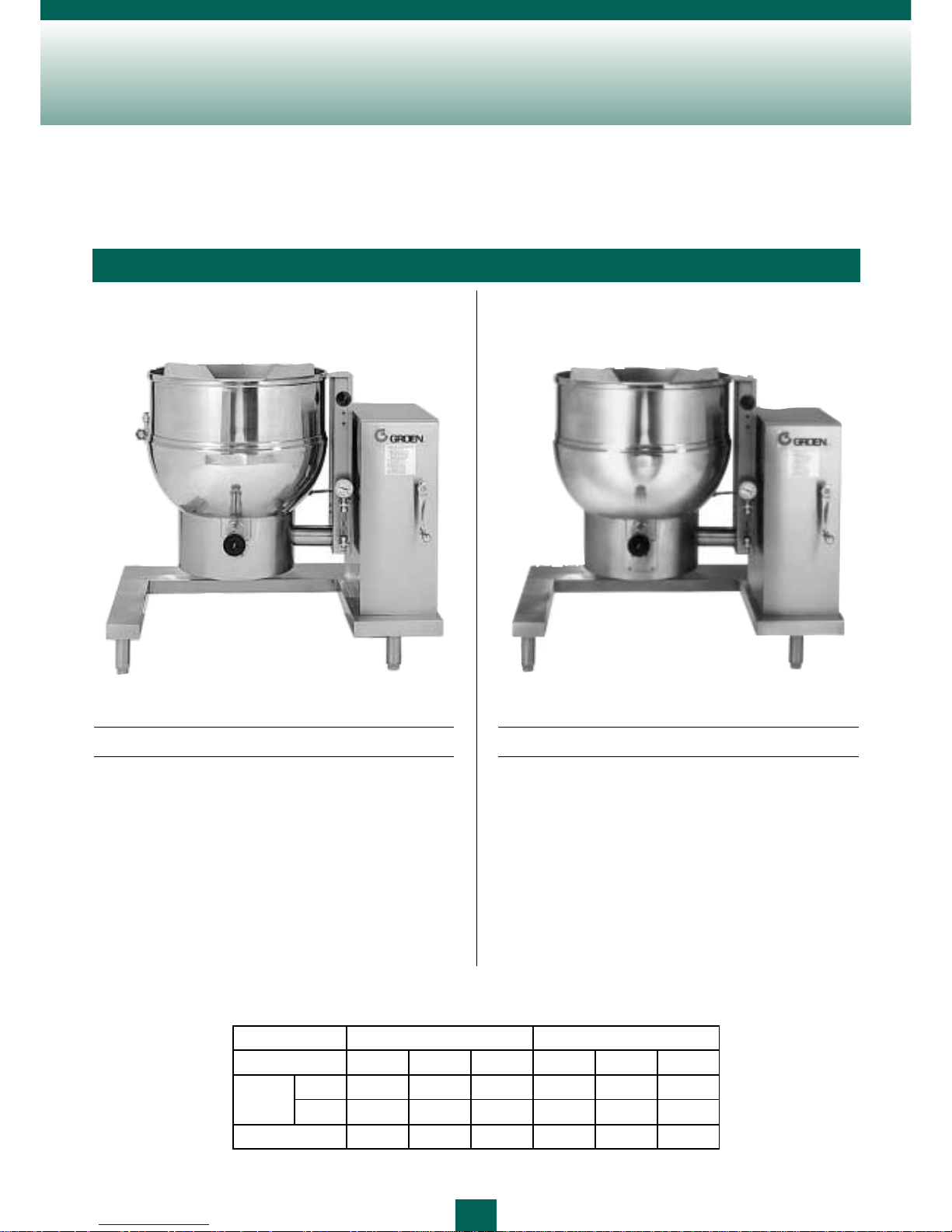

Stationary (Non-Tilting) KettlesTilting Kettles

Model DEE/4

• Electric heated, self-contained steam source

• Smooth gear assisted manual tilting kettle body

• Reinforced bar rim and large butterfly shaped pouring lip

• Precise thermostatic temperature control

• Low water safety control

• Your choice of 76, 151 & 227 litre models

• Options: Cover, 50mm tangent draw-offs, basket inserts,

water faucet with swivel tap, spray with flexible hose

Model DH

• Gas heated, self-contained steam source

• Patented fin tube burner assembly 62-65% efficient

• Dependable electronic ignition

• Smooth gear assisted manual tilting kettle body

• Reinforced bar rim and large butterfly shaped pouring lip

• Precise thermostatic temperature control

• Low water safety control

• Your choice of 76, 151 & 227 litre models

• Options: Cover, 50mm tangent draw-offs, basket inserts,

water faucet with swivel tap, spray with flexible hose

Capacity (In litres)

MODELS Electric MODEL DEE/4 Gas MODEL DH

76 151 227 76

889 1194 1194 889

781 876 924 889

12kW 24kW 24kW

72,000

BTU’s/HR

151

1194

918

100,000

BTU’s/HR

227

1194

1114

150,000

BTU’s/HR

Dimensions

(In mm)

Left to Right

Front to Back

Electric/Gas Rating

3

Floor Standing Tilting Kettles

Page 6

4

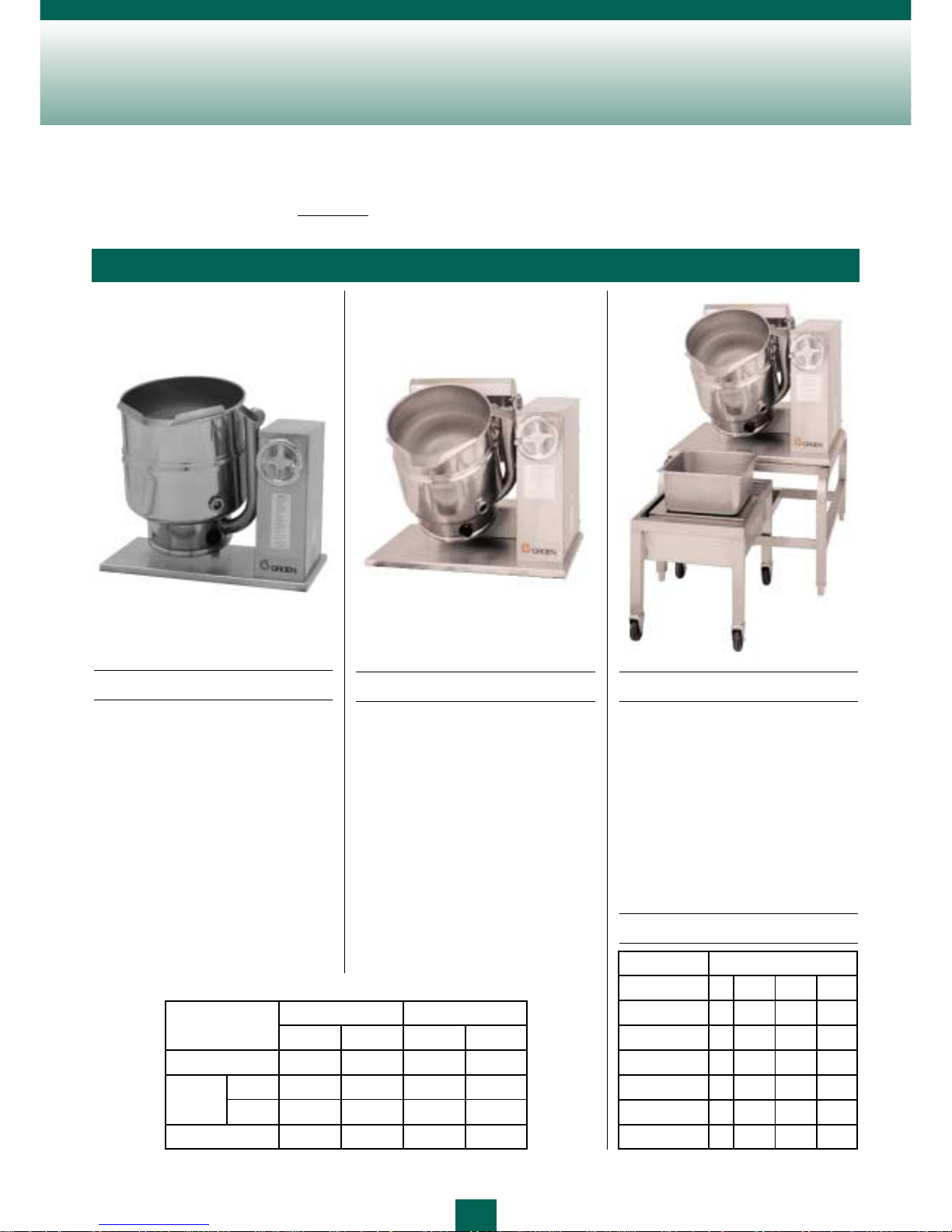

Self Contained Table Top Models

Model TDB/7

Table Top Kettles

• Electric heated, self-contained steam source

• Two thirds jacketed construction

• Counterbalanced manual tilt

• Reinforced bar rim and large butterfly shaped

pouring lip

• Precise thermostatic temperature control

• Low water safety control

• Your choice of 18 and 38 litre models

• Options: Lift-off cover, basket insert,

TS/9 stand, table or cabinet mounting, left hand tilt,

spray with flexible hose

Model TDH

• Gas heated, self-contained steam source

• Patented fin tube burner assembly 62% efficient

• Energy saving electronic ignition standard

• Two thirds jacketed construction

• Counterbalanced manual tilt

• Reinforced bar rim and large butterfly shaped

pouring lip

• Precise thermostatic temperature control

• Your choice of 18 and 38 litre models

• Options: Lift-off cover, basket insert,

TS/9 stand, table or cabinet mounting, left hand tilt,

spray with flexible hose

Model TS/9 Stand

TS/9 STAND ORDERING GUIDE

Groen can provide sturdy, easy to clean stand TS/9

for mounting our table top kettles. It provides the ideal

kettle work height.

New TS/9 stands can be ordered with a pull-out drain

sink, with cover that doubles as a splash shield.

Stand shown with TDB/7 kettle.

Capacity (In litres)

MODELS TDB/7-20

Electric SELF-CONTAINED Gas SELF-CONTAINED

TDB/7-40 TDH-20 TDH-40

18 38 18 38

451 467 686 730

603 670 610 686

6kW 12kW

31,000 BTU’s/HR 52,000 BTU’s/HR

Dimensions

(In mm)

Front to Back

Left to Right

Electric/Gas Rating

MODELS

TDB/7-20 & 40

TDH-20

TDH-40

TD/FPC

TDB/7-20

TDB/7-40

Table of Dimensions

(in mm)

Table

Size

Width

Front to

Back

Height

2

3

3

3

3

3

686 711 568

762 940 568

762 940 568

762 940 568

762 940 568

762 1041 568

Groen table top steam jacketed kettles are up to 3 times faster and twice as energy efficient

as range top cooking. From soups and stews to pasta and vegetables, Groen table top

kettles are versatile, labour saving performers. All Groen kettles have a hand polished

finish for easy clean-up and hygiene, and feature a reinforced bar rim to resist hard use.

Compact, table top kettles are available in capacities up to 38 litres and may be direct

steam heated or come with a self-contained gas or electric heated steam source.

Page 7

5

When house steam or a remote steam source is available, floor mounted, direct steam

jacketed kettles add productivity and efficiency to any kitchen. Models come in a full

range of sizes (from 76 to 568 litres) to meet the production requirements of any type

of foodservice operation. Reinforced bar rim and one-piece welded construction make

these kettles the most durable, maintenance free cooking equipment available today.

Non-Tilting Kettles Tilting Kettles

Model PT

(Pedestal Mounted)

Model FT

(Tri-Leg Mounted)

Floor Kettles – Direct Steam

• Direct steam heated

• Two thirds jacketed construction

• All stainless pedestal (Model PT) or Tri-Leg (Model FT) mounting

• 50mm tangent draw-off valve standard

• Energy saving hinged cover standard

• Reinforced bar rim construction

• Your choice from 76 through to 568 litres capacity

• Options: 75mm tangent draw-off, triple cooking basket inserts (TRI-BC),

water faucets, stainless steel interior

• Direct steam heated

• Two thirds jacketed construction

• All stainless pedestal (Model D) or Tri-Leg (Model DL) mounting

• Smooth warm and gear assisted manual tilting kettle body

• Reinforced bar rim and large butterfly shaped pouring lip

• Your choice from 76 through to 303 litres capacity

• Options: Cover, tangent draw-off, triple cooking basket inserts (TRI-BC),

water faucets

Model D

(Pedestal Mounted)

Model DL

(Tri-Leg Mounted)

Models

PT & FT

Dimensions

(In mm)

Capacity (In litres)

76 151 227 303

749 851 978 1003

571 724 825 876

914 914 991 1092

378

1054

978

1118

473

1067

1016

1219

568

1168

1130

1219

Front to Back

Left to Right

Rim Height

Capacity (In litres)

76 151 227 303

584 762 864 –

927 1092 1194 –

791 978 1092 –

Model D

Dimensions

(In mm)

Front to Back

*

Left to Right

Rim Height

733 876 972 997

921 1092 1194 1245

914 965 1118 1219

Model DL

Dimensions

(In mm)

Front to Back

Left to Right

Rim Height

*Doesn’t include wall clearance. Add 89mm for tangent draw-off.

Page 8

6

Direct Steam Table Top Kettles Table Top Kettle Options & Accessories

Model TDC/3

• Direct steam heated

• Two thirds jacketed construction

• Counterbalanced manual tilt

• All stainless steel trunnion

support posts

• Reinforced bar rim and large butterfly

shaped pouring lip

• Your choice of 3, 6, 9 & 18

litre models

• Options: Lift-off cover, basket insert,

custom table and cabinet mounting

Model TDA/1-40

• Direct steam heated

• Two thirds jacketed construction

• Counterbalanced manual tilt

• All stainless steel trunnion

support posts

• Reinforced bar rim and large butterfly

shaped pouring lip

• 38 litre capacity

• Options: Lift-off cover, basket insert,

custom table and cabinet mounting

Covers

Kettle covers reduce heatup times, save

energy, reduce the heat and humidity load

on ventilation and HVACsystems and make

the kitchen more comfortable for cooks and

staff. Covers also can be used to control

moisture content and reduction during

cooking. Covers are standard on stationary

floor models, with liftoff or hinged covers

available for most other models.

Water Fill Faucets

Every Groen kettle is provided with

a sturdy bracket with knockout,

for mounting a water fill faucet. Available in

single pantry (hot or cold) or double pantry

(hot & cold) styles, fill faucets speed recipe

preparation, eliminate carrying buckets of

water and simplify kettle cleanup.

Draw-off Valves

Groen stationary floor model kettles come

standard with 50mm draw-off valves. Larger

product outlets are available on these

models, to make transfer of thick and chunky

product easier. In addition, draw-off valves

are available on all tilting floor model kettles,

to provide an additional

product transfer option.

Cooking Baskets

Basket inserts are stainless steel wire baskets

designed to make it easier to load, cook and

unload product, when boiling vegetables,

shellfish and pasta.

A single basket is available for table

top models, while floor models can be

ordered with a triple basket set (TRI-BC), for

preparing three different products at the

same time.

Table & Stands

Groen can provide sturdy, easy to clean

stands for mounting our table top kettles.

Please refer to page 4 for details.

Capacity (In litres)

MODELS

TDC/3-3 TDC/3-6 TDC/3-10 TDC/3-20 TDA/1-40

3691838

336 387 340 387 502

327 378 327 378 679

Dimensions

(In mm)

Front to Back

Left to Right

See page 14 for further option details.

Page 9

7

Introduction to Tilting Braising Pans

Groen has continuously refined the basic design to meet the needs of high volume commercial and

institutional foodservice operations.

The Groen Braising Pan is now considered the single most versatile piece of cooking equipment

available today.

With its unique combination of large griddle surface, liquid capacity, quick tilting body and special

vented cover, it can perform the duties of a range, grill, oven, kettle, steamer, holding and thawing oven,

bain marie and more…

No other single piece of equipment can griddle cook pancakes and eggs for breakfast, kettle cook soup

and grill hamburgers for lunch; and cook pasta with sauce, steam vegetables, and prepare pudding or

jelly for dinner.

Groen/Quality…Tilting Braising Pans

The Groen Braising Pan does all this and can reduce your energy bill, cut labour, reduce waste, and produce

consistently high quality meals.

The versatility of the Groen Braising Pan makes it ideal for Commercial and institutional

foodservice operations of all sizes. Whether you are producing a single staple or an extensive

list of special items, a Groen Braising Pan can reduce preparation times, save energy,

increase batch consistency and save effort. A Groen Braising Pan is the logical choice

when replacing a range top, when you remodel your kitchen or when designing

a new foodservice operation from the ground up.

See page 15 for menu ideas and cook times.

Heat T ransfer Fins

Groen precision welds up to 130 heat transfer fins to the bottom of

Gas Heated Braising Pan models.

These fins ensure an even heat distribution over the entire cooking

surface . . . no hot and cold spots.

Groen Burner Design

Groen’s Gas burner assembly design which delivers an average efficiency

rating of 60%.

That’s the highest in the industry and translates into energy savings for you.

HFP Series

Page 10

8

Tilting Braising Pans

When ordering specify natural or propane (gas).

Capacity (In litres)

MODEL HFP/2-3 HFP/2-4

114 151

1245 1499

956 956

104,000

BTU’s/HR

144,000

BTU’s/HR

Dimensions

(In mm)

Left to Right

Front to Back

Gas Rating

Manual Tilt

Model HFP/2-3

• Gas heated, 60-65% efficient

• Heat transfer fins spread heat evenly

• Dependable electronic ignition

• Easy to clean open leg design

• Smooth action manual tilt (23 turns to full tilt)

• Heavy duty cover with condensate vent

• 75mm radius coved pan corners

• Factory installed faucet bracket

• Your choice of two sizes with 230mm pan depth standard

• Options: Water faucet with swivel tap.

The expansive cooking surface of the braising pan readily handles all

griddle work. Kilos of bacon or sausage, dozens of hamburgers, grilled

sandwiches, pancakes or french toast are handled with ease.

Add breakfast or snacks to your menu or back up existing griddles.

Only a portion of heating capacity is required for heaviest griddle loads.

Groen braising pans fry heavy loads of chicken or fish and deep fry

doughnuts, chicken and fish fillets with extra fast recovery time assured.

Thermostatic control regulates oil temperature to prevent breaking

down and thinning.

Braising pans can do all types of liquid cooking. Total capacities range

from 114 litres (Size 3) through 151 litres (size 4). Wide temperature

range provides for simmering and rapid boiling. High temperature flat

griddle surface is ideal for browning meat in the first step of stew, chilli,

or chop suey preparation.

Groen braising pans can be used to roast or bake all types of meat

and poultry. Product is supported in the braising pan on wire racks.

With cover closed, the cooking action is the same as a conventional oven.

Thermostatic control allows cooking at normal temperatures

(66°-93°C). Low temperature wet roasting reduces shrinkage and holds in

all the natural flavour.

Groen braising pans are the best suited appliance for quantity braising

of meat and poultry. Quick browning then simmering with the cover

down, brings out the natural flavour while sealing in the natural juices.

Compared to an oven, cooking time is less than half.

Griddle Cooking

Pan Frying

Kettle Cooking

Oven Roasting

Braising

Equipment Versatility Critical in Today’s Kitchens

Page 11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Introduction to HyPerSteam

™

Steamers

Exclusive HyPerSteam™Features…

Performance Features That Deliver…

9

See page 16 for cooking information and features guide.

Faster steam velocity reduces cook times.

Large ports eliminate scale common with small ports or jets.

Allows proper steam flow around multiple 2

1

/

2

deep pans.

Saves money, ensures dependable operation… longer unit life.

Eliminates odour and flavour transfer between foods…

a problem with no-drain steamers.

Safer door design… just warm when operating.

Operator can open door while holding a loaded pan.

More flexibility for kitchen layout and future movement.

Door won’t sag, reduces leaks.

For frequent use when timed cooking isn’t required.

Simple to use – simple employee training.

Helps protect unit from costly component failure… reminds operator to clean generator.

Makes it faster and easier for operator to descale.

Less water on the floor, safer for employees.

Fewer valves, gauges and components to fail.

No compensating timer required, no waiting for cavity to warm up.

Faster morning startup, less preheat required. More pan capacity in less space.

Helps reduce sediment and loose scale buildup.

Powerful fan in cavity

Large steam entry port(s)

Full 3

1

/

2

“

pan slide spacing

Simple operator descaling through cavity or access port.

Free venting cavity drain with spray condenser.

Solid, insulated one piece door

Easy open no hands latch.

Field reversible door.

Strong continuous hinge.

Constant steam setting.

Simple mechanical 60 minute timer

“Clean Me” steam generator descaling warning light/system.

Integrated condensate collection sink with drain (HY-6 Series)

Atmospheric steam generator (Twin generators on HY-6 Series).

Warm cavity-true instant steam system.

Ready to steam in 6-8 minutes from a cold start.

Narrow unit width: 6 Series only 546mm, 12 & 24 pan models 816mm wide.

Automatic steam generator flushing when unit is shut off.

Page 12

10

What Makes HyPerSteam

™

Different?

HyPerSteam is a radical departure from traditional convection steamers.

Aware of the problems associated with conventional steamers, Groen

engineers designed a line of steamers that: 1) cook faster; 2) are more

dependable, have fewer parts and problems and 3) can be easily

descaled by the operator. In addition, the HyPerSteam family of steamers are compact,

simple to operate, simple to service, and both energy and water efficient!

HyPerSteam . . . created a new class of steamers.

Let’s review these breakthrough differences in steamer technology . . .

Standard Pressure Boiler

Convection Steamer

HyPerSteam™– Twin Atmospheric Steam

Generator / Convection Steamer

Standard Steamer Technology

• Large pressure boiler which requires safety valves, water level glass

and pressure gauges.

• Float type water level controls with moving parts.

• Steam channelled through manifolds to small ports or orifices... which can clog

and scale up.

• A pressure boiler that requires descaling by a Service Agent or experienced

maintenance personnel, requires tools, and can cost hundreds of pounds each time.

• Doors that sag, leak, aren’t adjustable . . . often difficult to open, hard and noisy

to close.

• The single large pressure boiler provides steam to multiple cavities. Any boiler

problem disables the entire unit.

• Single large pressure boiler must operate at full capacity, even if you are preparing

a single portion or pan load.

New HyPerSteam™Technology

• Atmospheric steam generator(s) with fewer parts and fewer potential problems.

• Water level sensors...with no moving parts.

• Steam enters cavity through large diameter steam port, which can’t scale up

or clog. Steam is circulated by a powerful fan.

• Operator can descale the unit without tools or a service call, through an easy

access port.

• Door is adjustable, even field reversible. Strong continuous hinge resists sagging,

closes with gentle push or slam, with a no-hands latch.

• Multiple independent steam generators serving each steamer cavity.

One generator/cavity pair still operates, if the other goes down.

• Independent generator/cavity pairs allow use of single cavity for smaller loads...

saves energy and water.

STEAM LINES

ALSO PROVIDE

GENERATOR

ACCESS FOR

DESCALING

TWIN

ATMOSPHERIC

STEAM

GENERATORS

ATMOSPHERIC

CAVITY

ATMOSPHERIC

CAVITY

ATMOSPHERIC

CAVITY

POWER

TAKE-OFF

PROVIDES

STEAM FOR

KETTLE,ETC.

PRESSURE

BOILER

PRESSURE

GAUGE

SOLENOID

VALVES

STEAM

DISTRIBUTION

MANIFOLD

ATMOSPHERIC

CAVITY

STEAM

CIRCULATING

FAN

STEAM

CIRCULATING

FAN

Page 13

HyPerSteam

™

Steamers

Most of the innovative HyPerSteam performance features are also available in a compact

three pan countertop steamer. And now you can order stacked 3 pan models offering

6 pan capacity, and order a single unit with stacking kit to mount on an existing

Model HY-3E unit.

Counter-Top Models Counter-Top HyPerSteam

™

Model HY-3E (shown with optional stand and pan racks)

• Atmospheric electric steam generator

• Powerful fan in cavity

• Free venting drain eliminates flavour transfer

•“Clean Me” steam generator descaling warning system

• Simple steam generator descaling through cavity

• Warm cavity – Instant Steam feature

• Rugged field reversible door

• 60 minute timer with constant steam setting

• Condensate collection tray under door

• Hidden magnetic door switch

• Condensate collection box standard

• Options include support stand, pan racks for support stand and 100mm legs

Model HY-5E

• 15.5kw self contained electric steam generator

• All stainless steel construction

• Powerful fan in cavity

•“Clean Me” descaling warning system

• Simple steam generator descaling

• Rugged field reversible door

• 60 minute timer with constant steam setting

• Condensate collection tray under door

• Hidden magnetic door switches

• Options include support stand, stacking kit, pan racks spray condenser.

HY-3E

(2)HY-3E

Model

3

6 (2 x 3)

Pan Capacity

406

838

Height

*

(mm)

549

549

Width (mm)

783

783

Depth (mm)

1 x 8kW

2 x 8kW

Power Input

*Without Stand

11

HY-5E

HY-5EF

(with stand)

Model

5

5

Pan Capacity

571

1284

Height

*

(mm)

549

549

Width (mm)

783

783

Depth (mm)

15.5kW

15.5kW

Power Input

*Shown with Stand

Page 14

12

HyPerSteam is a true breakthrough in steamer technology, designed to eliminate most

common steamer problems. Twin atmospheric steam generators allow independent

operation of each cavity, to match capacity to your production needs and provide a

built-in backup steamer. A powerful fan in each cavity increases steam velocity.

We call this accelerated conduction heat transfer process HyPerDuction. The result is

FASTERCOOKING TIMES!“Clean Me” warning light and easy access for descaling,

allows operator to descale their own steamer without a service call or tools.

Electric HyPerSteam

™

Gas HyPerSteam

™

Model HY-6E

HyPerSteam

™

Steamers

• Twin, independent electric steam generators

• 9kW input per steam generator

• Powerful fan in each cavity

• Free venting drain eliminates flavour transfer

•“Clean Me” steam generator descaling warning system

• Simple steam generator descaling through cavity

• Warm cavity – True instant steam feature

• Rugged field reversible door

• 60 minute timer with constant steam setting

• Condensate collection sink with drain

• Hidden magnetic door switch

Model HY-6G

• Twin, independent gas steam generators

• 45,000 BTU input each – 65% efficient

• Powerful fan in each cavity

• Free venting drain eliminates flavour transfer

•“Clean Me” steam generator descaling warning system

• Simple steam generator descaling through cavity

• Warm cavity – True instant steam feature

• Rugged field reversible door

• 60 minute timer with constant steam setting

• Condensate collection sink with drain

• Hidden magnetic door switch

• Standing pilot with electronic ignition standard

HY-6E

HY-6G

Model

6 (2 x 3)

6 (2 x 3)

Pan Capacity

1489

1489

Height (mm)

546

546

Width (mm)

868

868

Depth (mm)

18kW

90,000

BTU’s/HR

Gas/Electric

Rating

Page 15

All the “HyPerformance…HyReliability” features introduced with the popular

HyPerSteam line are available in larger HyCapacity Models. HyCapacity HyPerSteams are

available in 12 pan models. Two powerful fans and two 38mm diameter steam entry

ports ensure fast and uniform cooking. HyCapacity HyPerSteams have more pan capacity,

more operator flexibility and require less space than old fashioned pressure steamers.

The range of products included in this brochure are currently being supplied into various

applications such as prisons, hospitals, restaurants, hotels and schools.

Falcon Catering Equipment supply the Prison service with Groen equipment with the

most popular items being the DH-40, a gas heated 152 Litre capacity tilting kettle and

the HY 6G, a gas heated six pan steamer. These products have the seal of approval

from the prison service and is on their list of approved equipment.

Hospitals throughout the UK, are reaping the rewards by using Groen equipment.

Not only are the units very fuel-efficient but they can also be used to prepare a variety

of products, thereby reducing the need for additional equipment.

Some other recent examples of sites which have purchased Groen include:

Electric HyCapacity HyPerSteam

™

The Perfect Choice

Model HY-12E/HY-12G

(Single 12 Pan Cavity)

• Powerful 32kW/160,000 BTU/hr atmospheric steam generator

• Two powerful fans per cavity

• Two 38mm diameter steam entry ports per cavity

• Free venting drain eliminates flavour transfer

• Adjustable side rack accepts either steam or bake pans

• Simple steam generator descaling through cavity

•“Clean Me” generator descaling warning system

• Warm cavity – True instant steam capability

• Rugged, insulated, field reversible door

• 60 minute timer with constant steam setting

• Ready to steam in 6 minutes, from cold start

• London University

• Marriot Hotels

• Hilton Hotels

• Iceland Frozen Foods

• Northwick Park

HY-12E

(No Stand)

HY-12G

(No Stand)

Model

12

12

Pan Capacity

1753

1753

Height

*

(mm)

816

816

Width (mm)

1000

1000

Depth (mm)

32kW

160,000

BTU’s/HR

PowerInput

Electric

Gas

Fuel

*Shown with Stand

13

• Quadrant

• John Lewis

• Morgan Stanley Call Centre

• The Seafood Restaurant

• Royal Academy of Music

Page 16

14

Kettle Options & Accessories

Sizing and Portion Guide

Accessory items will increase the versatility, labour and energy savings of your Groen equipment.

Kettles

TDH ••••• •

EE S

*

•••S •••

DEE/4 •

*

•••• ••

AH/1 S

*

•••S •••

DH •

*

•••• ••

PT, FT S

*

•••S • S •

D, DL

*

•••••S •

TS/9 Stands

Cabinet Mounting

Hinged

Covers

Basket Inserts

Lift-Off

Single

Triple

Fill Faucet

Etch Markings

50mm Tangent Draw-Off

75mm Tangent Draw-Off

Flanged Feet

Kettle Brush Set

S

= Standard

•

= Available Option or Accessory

*

= Available/Hoist Required

TABLE

TOP

FLOOR MODELS

Groen Steam Jacketed Kettles are available in a wide range of types, styles and

capacities. There is a Groen kettle that is perfect for your operation, menu mix and

production volume requirement. See pages 1 - 6 to help you choose the type or style

kettle that is right for you.

Check out the table below for help in sizing that kettle. Some things to remember when

sizing a kettle:

• It is better and often more cost effective to purchase a slightly larger kettle than your

current volume requires. You can always make a 76 litres batch in a 151 litre kettle.

It will provide extra capacity for growth, carryout business etc.

• Two smaller kettles may provide more production flexibility than one larger kettle,

for use by multiple chefs or simultaneous preparation of several menu items.

• All kettles require head space or “freeboard” for safe operation.

Nominal kettle capacity is the calculated maximum volume when filled to the rim.

You need a minimum 50-75mm of clearance below the rim for stirring and to avoid

boilover etc. This working capacity is about 80% of rim or nominal capacity and the

figure you should use in determining kettle size.

Kettle Size (litres) Number Of Portions Per Batch

Nominal

Capacity

9.5

18.0

38.0

76

151

227

303

Working

Capacity

7.5

14.5

30.5

61

121

182

242

57gms

(2 Oz.)

128

256

512

1024

2048

3072

4096

114gms

(4 Oz.)

64

129

256

512

1024

1536

2048

170gms

(6 Oz.)

42

86

170

341

682

1024

1365

227gms

(8 Oz.)

32

64

128

256

512

768

1024

284gms

(10 Oz.)

25

51

102

204

409

614

819

340gms

(12 Oz.)

21

43

85

170

341

512

682

397gms

(14 Oz.)

18

37

73

146

292

438

585

454gms

(16 Oz.)

16

32

64

128

256

384

512

Page 17

15

Versatile is the one word that best describes the Groen braising pan. You can roast,

braise, fry, steam cook, kettle cook, thaw, warm and serve in a Groen pan. You can

expand and vary your menu without adding equipment or changing your kitchen layout.

That’s equipment versatility!

Listed below are sample menu items you can prepare in a Groen braising pan. Cook

times are only approximate and don’t include preparation or warm up time. Actual cook

times will depend on the condition and size of ingredients, kitchen temperature and

other variables.

Braising Pan Menu Guide

Menu Item

Breakfast

Scrambled Eggs 100 servings 5 min.

Pancakes 24 1

1

/2 min/side

French Toast 48 slices 7-8 min.

Sausage 80 ser vings 5 min.

Bacon 90 servings 10-12 min.

Hash Browns 13.6 kilos 15-17 min.

Potato Pancakes 60 ser vings 7-8 min.

Poached Eggs 75 servings 5 min.

Snacks

Grilled Cheese 48 7-8 min.

Hamburger 60 (113g) 5 min.

Cheeseburger 60 5 min.

Steak Sandwich 26 (198g) 5 min.

Hot Dogs 34 kilos 7 min.

Meats

Pork Roast 45 kilos 31/2 hrs.

Beef Roast 45 kilos 2

1

/2 hrs.

Corned Beef 45 kilos 45 min.

Lamb Roast 45 kilos 2

1

/2 hrs.

Beef Tips 23 kilos 1 hr.

Veal (sauteed) 9 kilos 25 min.

Ribs 500 portions 2 hrs.

Steak 50 portions 15-18 min.

Pork Chops 50-100 12-15 min.

Ground Beef (frozen) 25 kilos 1 hr.

Taco Meat 79 kilos 1 hr 10 min.

Swiss Steak 61 kilos 1 hr.

Salisbury Steak 350 por tions 1 hr.

Pepper Steak 23 kilos 1 hr.

Beef Stroganoff

Italian Roast Beef 91 kilos 2

1

/4 hrs.

Meat Loaf 16 loaves 1

1

/2 hrs.

Chicken 68 kilos 40 min.

Turkey 12.7 kilos 2 hrs.

Fish Fillets 50-100 10-14 min.

Quantity/

Portions

Approx.

Time

Menu Item

Other Entrees

Stuffed Peppers 100 portions 55 min.

Crepes 15-20 5 min.

Chicken Cacciatore 500 por tions 1 hr.

Chicken A La King 200 servings

Beef Stew 68 ltr 3 hrs.

Chilli 400 servings 20 min.

Spaghetti 100 servings 1-2 hrs.

Chop Suey 68 ltr 2 hrs.

Vegetables

Zucchini 300-400 portions 10-15min.

Green Peppers 5 bushels 35 min.

Corn 4.5 kilos 8 min.

Peas 4.5 kilos 8 min.

Beans 4.5 kilos 15 min.

Carrots 4.5 kilos 8 min.

Potatoes

(cut & peeled) 4.5 kilos 25 min.

Side Orders

Noodles 13.6 kilos 5-20 min.

Dumplings 175 portions 10 min.

Crabmeat Stuffing 250 servings 30 min.

Refried Beans 18 kilos 2

1

/2 hrs.

Potato Salad 37.8 ltr till warm

Gravy 87 ltr 15 min.

Sauces 68 ltr 25 min.

French Fries 50 servings 12 min.

Mexican Rice 100 servings 20 min.

Desserts

Chocolate Mousse 200-300 portions 15 min.

Pudding 850 portions 10 min.

Yogurt 113.5 ltr 1 hr.

Custard 400 servings 8-10 min.

Jelly 400 servings 45 min.

Quantity/

Portions

Approx.

Time

Page 18

16

Faster Cook Times

All HyPerSteam Models are designed for optimum cooking performance, with a powerful fan

in the cavity, two in HyCapacity models; adequate spacing between pans; and steam

generators sized to deliver 2-3 KW per pan in electric models and at least 90,000 BTU’s

per hour input in gas models.

Fans strategically located in the steamer cavity increase the velocity of steam, which sweeps

away insulating layers of cold air and condensate, speeding heat transfer to the food.

A minimum of 13mm spacing between pans eliminates nesting of pans and allows better

circulation of steam between full pan loads.

HyPerSteam cook times are often comparable to the cook times delivered by pressure

steamers, if the “pressure up” and “pressure down” time delays are added to the actual

cook times delivered by pressure steamers . . . AND the colour, texture, flavour and

nutritional value is superior to pressure cooked foods.

A Features Guide For Selecting Your Steamer

Some Typical HyPerSteam™ Cook Times

HyPerSteam

™

Menu & Features Guide

Product

Asparagus, Whole Spears

Type/

Condition

Fresh

Weight

of count

227g

Number

of Pans

1-Perf

Cook Time

(Minutes)

3-5

Beans, Green Cut Frozen 2.7kg 3-Per f 5

Beans, Lentils Dry 0.45kg

1-Perf/

Solid

25-30

Beans, Refried Canned 3.4kg 1-Solid 10-12

Beef, Ground (80%) Fresh 1.13kg 1-Per f 4

Broccoli, Florets Fresh 453.5g 1-Per f 4-5

Carrots, Baby Whole Frozen 2.7kg 3-Per f 5

Chicken, Whole (For Deboning) Fresh 1.75kg 1-Perf 34

Corn, Cut Frozen 3.4kg 3-Perf 6

Corned Beef Fresh 1.6kg 1-Per f 26

Halibut, Fillets Frozen 170g 1-Per f 8

Hard Boiled Eggs Fresh 24 3-Perf 13

Product

Hot Dogs (8 per lb.)

Type/

Condition

Frozen

Weight

of count

48-57g

Number

of Pans

1-Perf

Cook Time

(Minutes)

6-8

Lasagna Noodles Dry 1.36kg 3-Perf 17-18

Lobster Tails Frozen 21-200g 3-Perf 13

Mostaccoli, Pasta

Frozen/

Cooked

1.36kg

1-Perf/

Solid

10

Potatoes, Red (New) Fresh 1.81kg 1-Per f 18

Potatoes, Whole Russet Fresh 226.8g 1-Perf 40

Rice, White Dry 1.13kg 1-Solid 17-20

Salmon, Fillets Frozen 128g

1-Perf/

Solid

7

Scallops, Bay Fresh 0.9kg 1-Perf 3

Shrimps, Shell On (26-30 count) Fresh 0.9kg 1-Perf 3

Spinach, Block Frozen 4kg 3-Perf 16

*Your actual cook times may vary due to normal differences in raw ingredient quality, portion size, production quality, room temperature, and the condition of product and your steamer at time of preparation.

*Stacked Hy-3E and HY-5E models require multiple electric power connections

•

= Standard Feature

Twin Atmospheric Steam Generators

Power Input Per 2

1

/2” pan

Powerful Fan in Each Cavity

Descaling Indicator System

Easy Descaling Through Cavity

Warm Cavity-Instant Steam Feature

Patented Field Reversible Door

60 Min. Electromechanical Timer

Constant Steam Setting

Condensate Collection Sink With Drain

Hidden Magnetic Door Switch

Single Point Utility Connections*

Built in Condensate Air Break

Power Take-Off For Kettles

Space Saving Unit Width (mm)

single electric

2.67kW

•

•

•

•

•

•

•

Collection Tray

•

•

•

NA

533

single electric

3.1kW

•

•

•

•

•

•

•

Collection Tray

•

•

•

NA

533

•

15,000 BTU’s

•

•

•

•

•

•

•

•

•

•

•

NA

533

•

3kW

•

•

•

•

•

•

•

•

•

•

•

NA

533

2.75kW

•

•

•

•

•

•

•

Collection Tray

•

•

•

NA

813

13,000 BTU’s

•

•

Control Panel Port

•

•

•

•

Collection Tray

•

•

•

NA

813

Key HyPerSteam™Features HY-3E HY-5E HY-6G HY-6E HY-12E HY-12G

Page 19

Loading...

Loading...