Falcon F900 SERIES, G9541R, G9541CR, G9581, G9581R User, Installation And Servicing Instructions

...

1

F900 SERIES

User, installation and servicing instructions

GAS GRIDDLE

G9541, G9541R, G9541CR, G9581, G9581R, G9581CR

Read these instructions before use

T100891

DATE PURCHASED:

MODEL NUMBER:

SERIAL NUMBER:

DEALER:

SERVICE PROVIDER:

REV. 2

Published: 31/03/2016

2

Falcon Foodservice Equipment

HEAD OFFICE

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of appliance life, dispose of appliance and any replacement parts in a safe

manner, via a licensed waste handler. Appliances are designed to be dismantled

easily and recycling of all material is encouraged whenever practicable.

Dear Customer,

Thank you for choosing Falcon Foodservice Equipment.

This manual can be downloaded from www.falconfoodservice.com or scan

here.

IMPORTANT: Please keep this manual for future reference.

3

SYMBOLS

• SPANNER • SCREWDRIVER • COOKING OIL • GREASE

• SPARK IGNITION • FLAME • WARNING • VIEWPORT

• ALLEN KEY •IGNITER

4

These instructions are only valid if the country code appears on the

appliance. If the code does not appear on the appliance, refer to the

technical instructions for adapting the appliance to the conditions for use

in that country.

Installation must meet national or local regulations. Attention must be paid

to: gas safety (installation & use) regulations, health and safety at work act,

local and national building regulations, fire precautions act.

To prevent shocks, all appliances must be earthed.

This equipment is for professional use only and must be used by qualified

persons.

The installer must instruct the responsible person(s) of the correct

operation and maintenance of the appliance.

Only competent persons are allowed to service or convert the appliance to

another gas type.

Gas appliances must have a stop cock fitted in the supply pipe work. The

user must be familiar with the location and operation of this device in order

to turn off the supply of gas in the event of an emergency.

Unless otherwise stated, parts which have been protected by the

manufacturer must not be adjusted by the installer.

Take care when moving an appliance fitted with castors.

The appliance must be serviced regularly by a qualified person.

Service intervals should be agreed with the service provider.

This appliance may be discolored due to testing.

5

CONTENTS

1.0 APPLIANCE INFORMATION ..................................................................................... 6

2.0 OPERATION .............................................................................................................. 7

2.1 COMPONENT PARTS ............................................................................................ 7

2.2 CONTROLS ............................................................................................................ 7

2.3 USING THE APPLIANCE ....................................................................................... 8

3.0 CLEANING AND MAINTENANCE .............................................................................. 9

4.0 SPECIFICATION ........................................................................................................ 9

5.0 DIMENSIONS / CONNECTION LOCATIONS ........................................................... 10

6.0 INSTALLATION ........................................................................................................ 11

6.1 SITING / CLEARANCES ....................................................................................... 11

6.2 VENTILATION ...................................................................................................... 11

6.3 GAS SUPPLY & CONNECTION ........................................................................... 12

6.4 ASSEMBLY .......................................................................................................... 13

6.5 COMMISSIONING ................................................................................................ 13

7.0 CONVERSION ......................................................................................................... 14

7.1 GAS CONVERSION CHECK LIST ....................................................................... 14

8.0 SERVICING ............................................................................................................. 14

8.1 CONTROL PANEL ................................................................................................ 14

8.2 ACCESS PANEL .................................................................................................. 15

8.3 INJECTORS ......................................................................................................... 15

8.4 PILOT REMOVAL ................................................................................................. 16

8.5 PILOT ASSEMBLY ............................................................................................... 16

8.6 GAS VALVE.......................................................................................................... 17

8.7 PRESSURE ADJUSTMENT ................................................................................. 18

8.8 SAFETY THERMOSTAT REMOVAL .................................................................... 18

8.9 PLATE / THERMOSTAT BULB REMOVAL........................................................... 19

8.10 BURNER .............................................................................................................. 23

8.11 GOVERNOR ......................................................................................................... 23

9.0 FAULT FINDING ...................................................................................................... 24

10.0 SPARE PARTS ........................................................................................................ 25

11.0 SERVICE INFORMATION ........................................................................................ 25

6

1.0 APPLIANCE INFORMATION

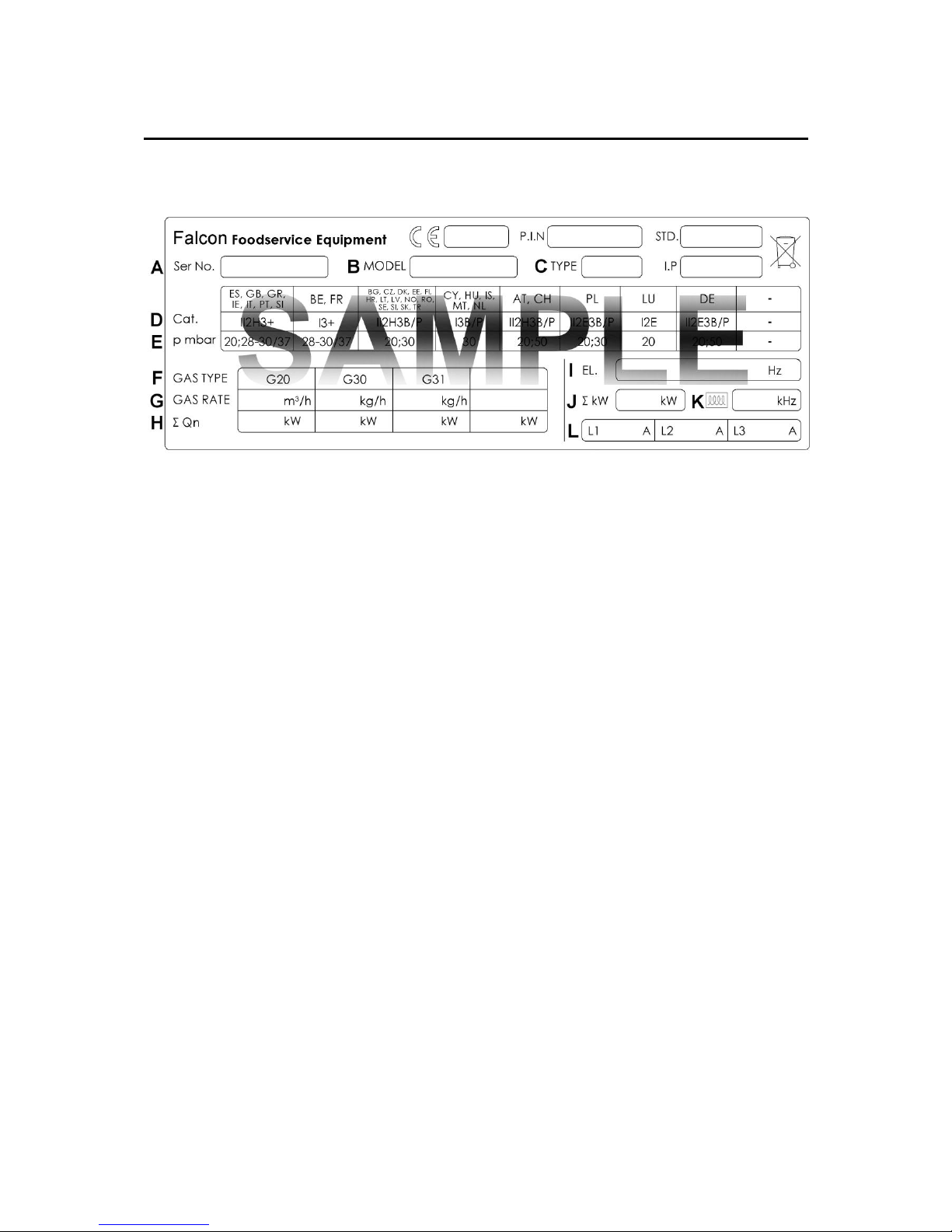

This appliance has been CE-marked on the basis of compliance with the relevant EU

directives for the heat inputs, gas pressures and voltages stated on the data plate.

A - Serial No

B - Model No

C - Flue Type

D - Gas Category

E - Gas Pressure

F - Gas Type

G - Gas Rate

H - Total Heat Input

I - Electrical Rating

J - Total Electrical Power

K - Magnetic Field Frequency

L - Electrical Phase Loading

7

2.0 OPERATION

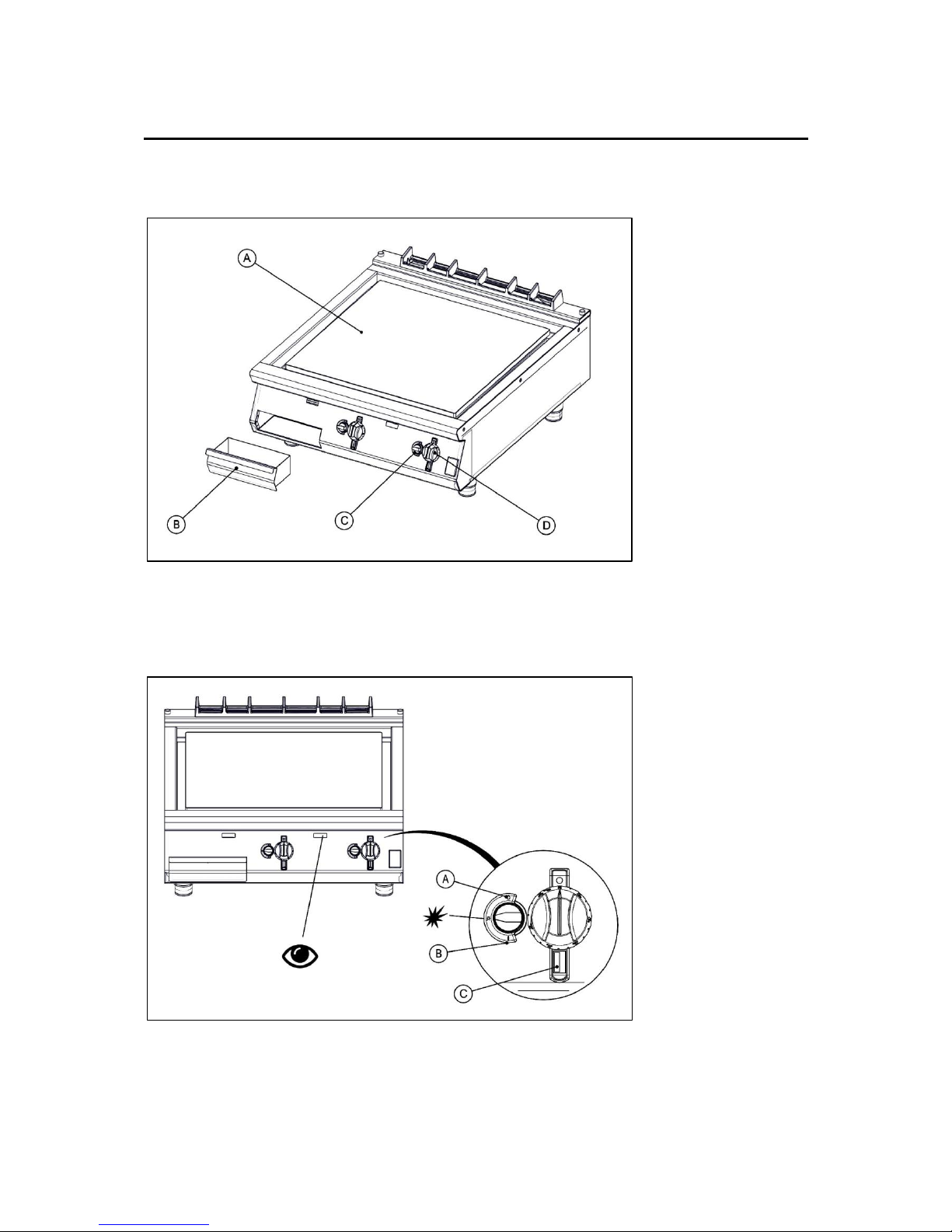

2.1 COMPONENT PARTS

2.2 CONTROLS

A – Cooking Plate

B – Fat Jug

C – Gas Control

D – Temperature Control

A – Gas OFF

B – Gas ON

C – Zone Indicator

8

2.3 USING THE APPLIANCE

2.3.1 Before use, clean the appliance. See section 3.

2.3.2 Ignite the burners as shown. Push the knob in to turn.

2.3.3 Use temperature control knob to adjust temperature.

2.3.4 The minimum temperature of the hottest point of the plate is as follows:

G9541, G9541R, G9581, G9581R

G9541CR, G9581CR

Temperature

290°C

260°C

IF A BURNER TURNS OFF, WAIT 3 MINUTES BEFORE RELIGHTING.

2.3.5 Turning The Burner Off

Turn pilot knob to ‘OFF’ position. Look through the view port to make sure the burner

is off.

Loading...

Loading...