Falcon F900 SERIES, G9341, G9341F User, Installation And Servicing Instructions

1

F900 SERIES

User, installation and servicing instructions

FRYER

G9341, G9341F

Read these instructions before use

T100889

DRAFT REV 9

Published: 08.09.16

DATE PURCHASED:

MODEL NUMBER:

SERIAL NUMBER:

DEALER:

SERVICE PROVIDER:

2

Falcon Foodservice Equipment

HEAD OFFICE

Wallace View, Hill foots Road, Stirling. FK9 5PY. Scotland.

WEEE Directive Registration No. WEEE/DC0059TT/PRO

At end of appliance life, dispose of appliance and any replacement parts in a safe

manner, via a licensed waste handler. Appliances are designed to be dismantled

easily and recycling of all material is encouraged whenever practicable.

Dear Customer,

Thank you for choosing Falcon Foodservice Equipment.

This manual can be downloaded from www.falconfoodservice.com or scan

here

IMPORTANT: Please keep this manual for future reference.

3

SYMBOLS•

• SPANNER • SCREWDRIVER • COOKING OIL • GREASE

• SPARK IGNITION • FLAME • WARNING • VIEWPORT

• ALLEN KEY • IGNITER

4

This appliance may be discoloured due to testing.

These instructions are only valid if the country code appears on the

appliance. If the code does not appear on the appliance, refer to the

technical instructions for adapting the appliance to the conditions for

use in that country.

Installation must meet national or local regulations. Attention must be

paid to: gas safety (installation & use) regulations, health and safety at

work act, local and national building regulations, fire precautions act.

Gas appliances must have a stop cock fitted in the supply pipe work.

The user must be familiar with the location and operation of this device

in order to turn off the supply of gas in the event of an emergency.

This appliance has been CE- marked o the basis of compliance with the

Low voltage & EMC Directives for voltages stated on the Data Plates.

To prevent shocks, all appliances must be earth bonded.

The unit is fitted with equipotential connection at the rear on the base.

We recommend supplementary electrical protection with the use of a

residual current device. (RCD).

This equipment is for professional use only and must be used by

qualified persons.

The installer must instruct the responsible person(s) of the correct

operation and maintenance of the appliance.

Unless otherwise stated, parts which have been protected by the

manufacturer must not be adjusted by the installer.

Take care when moving an appliance fitted with castors.

The appliance must be serviced regularly by a qualified person. Service

intervals should be agreed with the service provider.

Check that no damage has occurred to the appliance or supply cord

during transit. If damage has occurred, do not use the appliance.

Ensure supply cord is routed free from appliance to avoid damage.

Only competent persons are allowed to service or convert the appliance

to another gas type.

Installation, periodic testing, repair & fixed wired connections should

only be undertaken by a competent electrician.

The appliance has been designed and approved to use Falcon Kick

plates: Non Falcon kick plates could potentially adversely affect the

performance of the appliance by restricting the air to the appliance.

5

CONTENTS

1 APPLIANCE INFORMATION ......................................................................................... 6

2 OPERATION .................................................................................................................. 7

2.1 COMPONENT PARTS ............................................................................................ 7

2.2 CONTROLS G9341/F ............................................................................................. 8

2.3 USING THE APPLIANCES ..................................................................................... 9

3 CLEANING AND MAINTENANCE ............................................................................... 11

4 SPECIFICATION ......................................................................................................... 12

4.1 TABLE A ............................................................................................................... 12

4.2 TABLE B – G20 .................................................................................................... 13

4.3 TABLE B – G30/G31 ............................................................................................. 13

5 DIMENSIONS / CONNECTION LOCATIONS .............................................................. 14

6 INSTALLATION ........................................................................................................... 15

6.1 SITING / CLEARANCES ....................................................................................... 15

6.2 VENTILATION ...................................................................................................... 16

6.3 GAS /ELECTRIC SUPPLY & CONNECTION ........................................................ 16

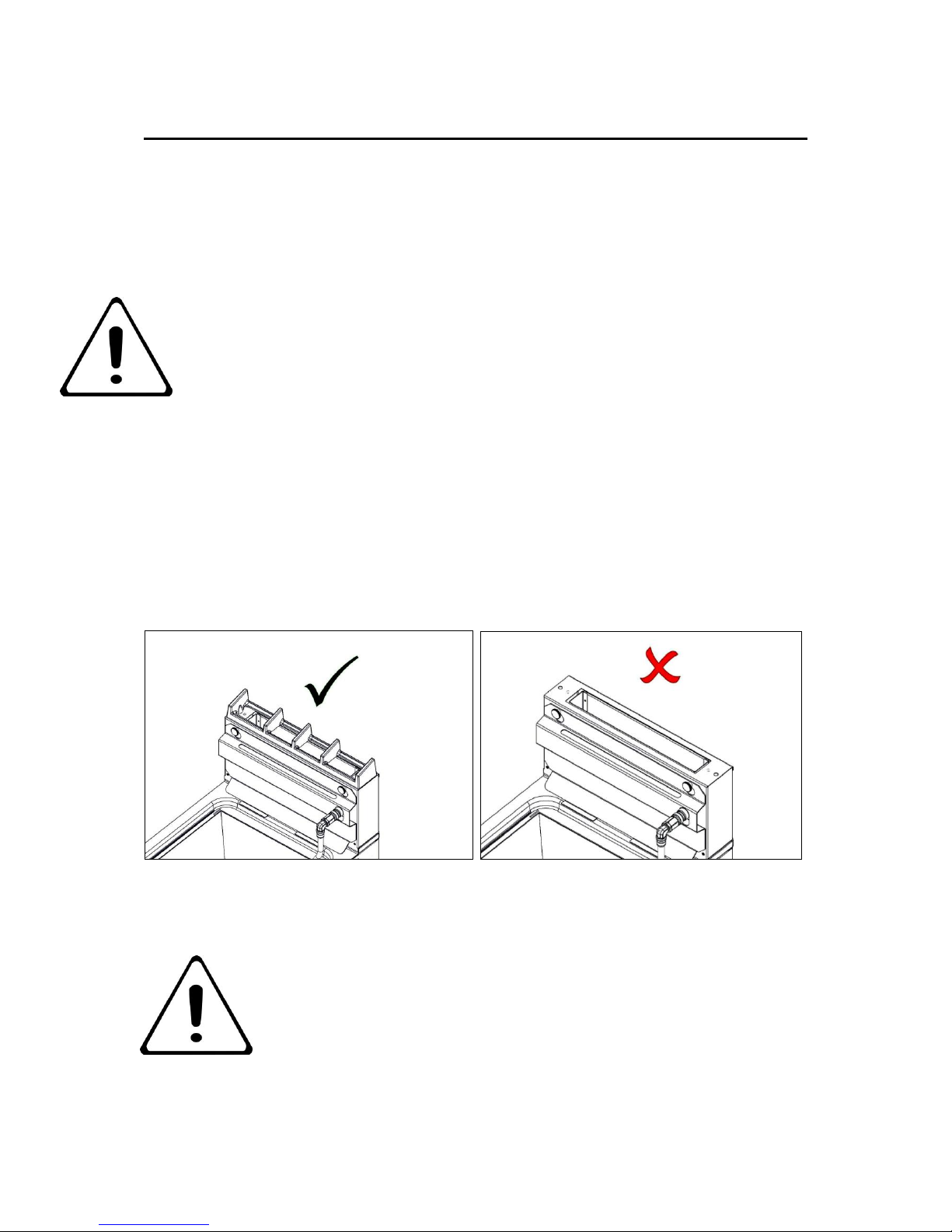

6.4 ASSEMBLY .......................................................................................................... 17

6.5 COMMISSIONING ................................................................................................ 18

6.6 SUITING .............................................................................................................. 20

7 CONVERSION .............................................................................................................. 22

7.1 GAS CONVERSION CHECK LIST ....................................................................... 22

8 SERVICING .................................................................................................................. 24

8.1 DOOR ................................................................................................................... 24

8.2 CONTROL PANEL ............................................................................................... 24

8.3 FASTRON CONTROLLER & NEONS ................................................................... 25

8.4 SWITCH PANEL ................................................................................................ ... 26

8.5 SWITCH & NEON REMOVAL ............................................................................... 27

8.6 ACCESS TO SPARK BOX .................................................................................... 28

8.7 SIT GAS REGULATOR ACCESS ......................................................................... 29

8.8 PUMP & TIMER REMOVAL .................................................................................. 29

8.9 PUMP & TIMER REMOVAL .................................................................................. 30

8.10 TIMER PUMP SETTINGS ..................................................................................... 30

9 ACCESSORIES ........................................................................................................... 31

9.1 SPLASH GUARD.. ................................................................................................ 31

9.2 DRAIN HOSE.. ..................................................................................................... 31

10 FAULT FINDING........................................................................................................... 32

11 SPARE PARTS. ........................................................................................................... 33

12 SERVICE INFORMATION. ........................................................................................... 33

6

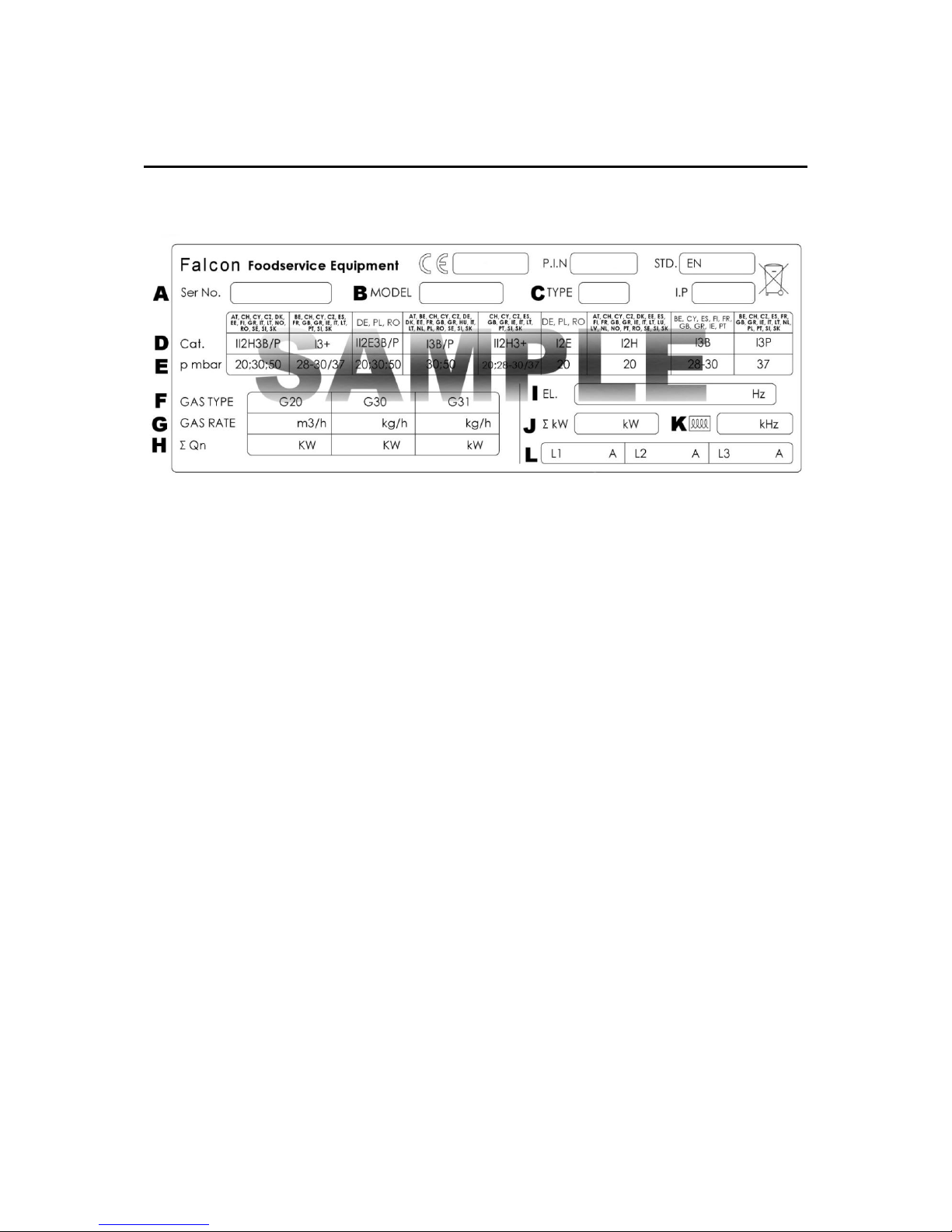

1 APPLIANCE INFORMATION

This appliance has been CE-marked on the basis of compliance with the relevant EU

directives for the heat inputs, gas pressures and voltages stated on the data plate.

A - Serial No

B - Model No

C - Flue Type

D - Gas Category

E - Gas Pressure

F - Gas Type

G - Gas Rate

H - Total Heat Input

I - Electrical Rating

J - Total Electrical Power

K - Magnetic Field Frequency

L - Electrical Phase Loading

7

2 OPERATION

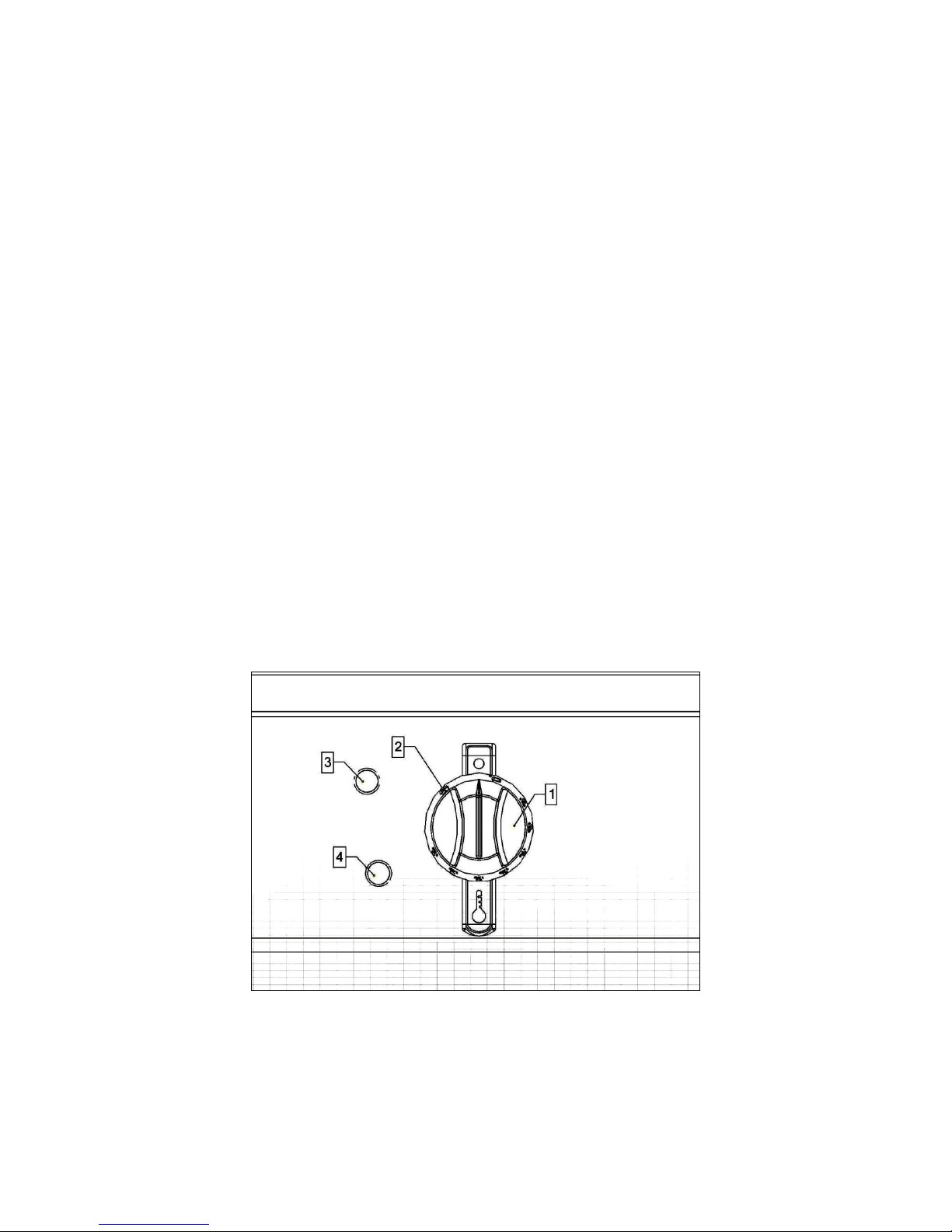

2.1 COMPONENT PARTS

FRYER

A – TEMPERATURE CONTROL F – DRAIN VALVE

B – POWER NEON (RED) G – OIL BUCKET

C – HEAT DEMAND NEON (AMBER) H – SAFETY LIMITER

D – BURNER RESET I – PUMP SWITCH

E – Power ON/OFF RESET J – QUICK RELEASE RETURN PIPE

8

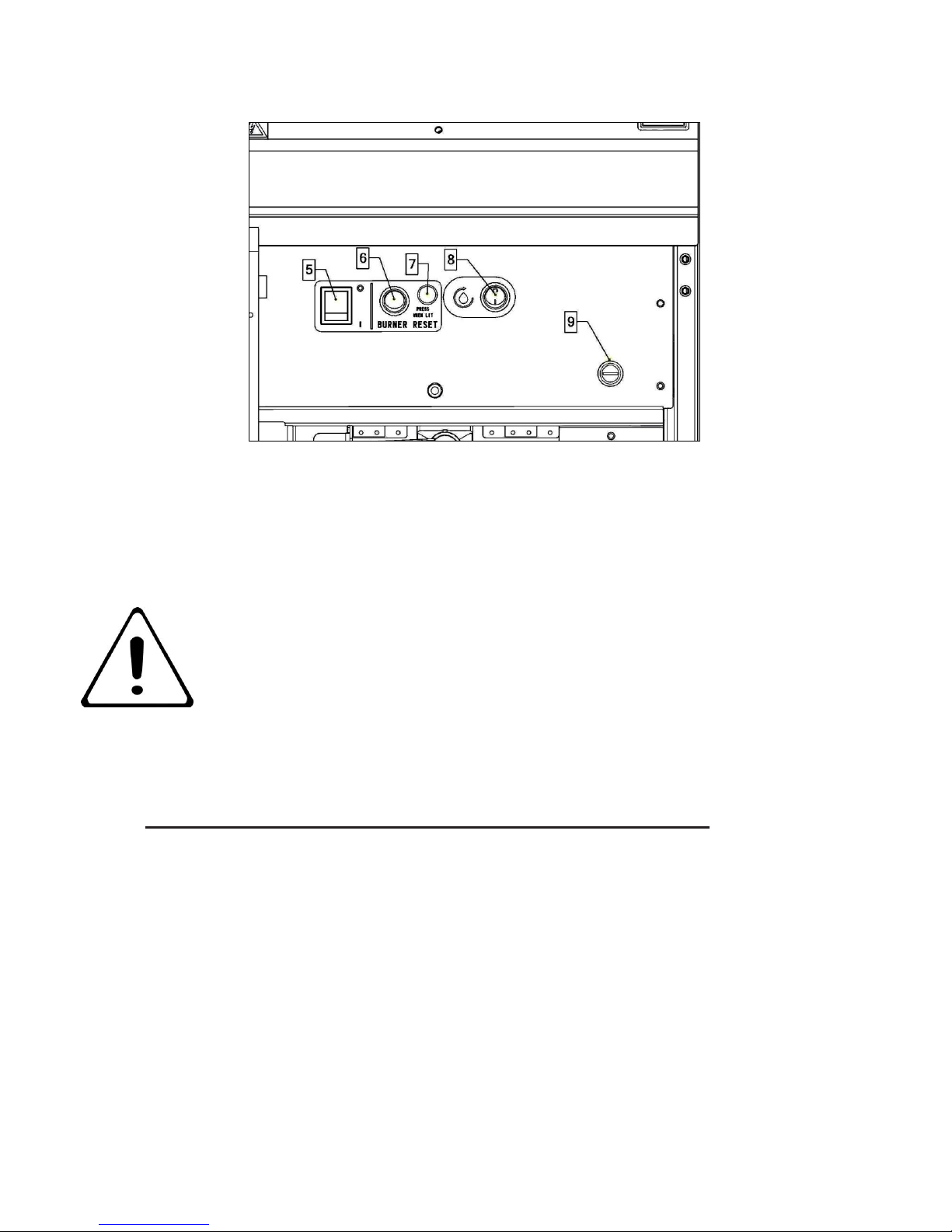

2.2 CONTROLS G9341/F

2.2.1 ON/OFF Temperature control knob

Temperature Selection (140 -190°C) (Unit off when control is in position

Indicated).

2.2.2 Fat Melting Position

2.2.3 Power on Indicator

2.2.4 Heat Demand Indicator

Illuminates when the thermostat demands heat, i.e. oil temperature is

more than

5⁰ C below temperature setting.

Extinguishes when desired temperature is reached.

2.2.5 Burner and Temperature Controls on/off Switch

Cuts power and temperature controls

2.2.6 Burner Lock-out Switch

(Reset burner for further lighting attempts when burner lockout indicator is

Illuminated).

2.2.7 Burner lock-out Indicator (Indicates flame failure).

2.2.8 Filtration Pump Switch (G9341F only)

Energizes filtration pump when burner is in OFF (O) position.

2.2.9 Temperature Safety Limiter Reset Button

Located inside red recess below black cover.

9

2.3 USING THE APPLIANCES

2.3.1 Always clean the appliance before use. See section 3.0

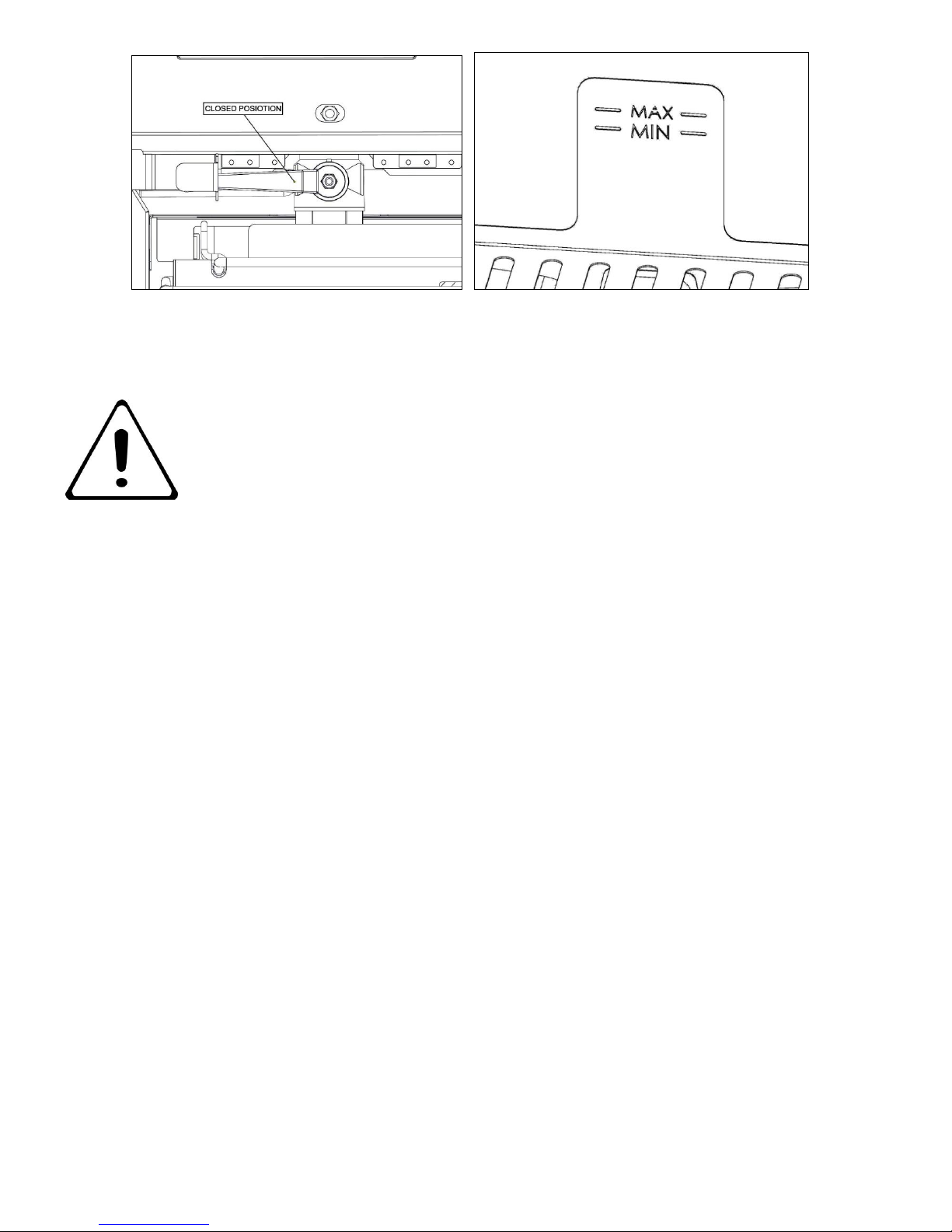

2.3.2 Ensure drain valve is closed. Fill pan with cooking medium to -MIN- (maximum cold

fill mark). Do not fill medium past MAX level mark.

MIN- Level Mark: Medium should NEVER be allowed to drop below this

mark. Should this occur, top up immediately or switch fryer OFF.

CAUTION: SUITABLE PROTECTIVE CLOTHING

MUST BE WORN when topping up whilst fat in fryer is hot.

Medium and Foodstuffs

Food will increase in volume during cooking - follow these rules:

NEVER ADD WATER TO FRYING MEDIUM AT ANY TIME!

10

2.3.3 Switch power on 2.2.5

2.3.4 Set temperature 2.2.1. If solid fat is to be used, Ensure FAT MELT CYCLE is

selected for this process 2.2.2

Medium should not be overheated as this will increase the risk of fire.

Note: NEVER leave a working unit unattended.

Note: Fryer is fitted with a thermal safety device. This will stop heating of

medium if it becomes overheated. This appliance will always fail

safe.

2.3.5 Fryer maximum basket loading.

Pre-blanched chilled fries– 2 x 1.5kg baskets.

Frozen fries – 2 x 1.2kg baskets

2.3.6 Turn burner off. Set temperature control 2.2.1 as above and set 2.2.5 to

Off.

2.3.7 Filtration Instructions.

After filtering wait 30 seconds before removing bucket.

Switch burner off by means of burner ON/OFF Switch

Wait 15/20 mins to allow oil to cool

Lift safety drain cover

Open drain valve

Allow oil to drain from pan

Switch to filter pump

Cycle oil until pan is clear of debris

Close drain valve and allow pan to fill

Continue as indicated in lighting instructions

11

3 CLEANING AND MAINTENANCE

3.1.1 Turn off and cool down.

3.1.2 All surfaces are easier to clean if spillage is removed before it becomes burnt on,

cleaned daily.

THE APPLIANCE MUST NOT BE STEAM CLEANED. DO NOT USE ACID OR

HALOGEN-BASED (e.g. chlorine) DESCALING LIQUIDS, FLAMMABLE

LIQUIDS, CLEANING AIDS OR CLEANING POWDERS.

Stainless Steel Surfaces

It should be noted that certain scouring pads including nylon types can easily mark

stainless steel. Care should be exercised during cleaning process.

When rubbing stainless steel with a cloth, always rub in grain direction.

3.1.3 The flue capper can be removed for cleaning but must be replaced for use

FAILURE DUE TO LACK OF PROPER CLEANING IS NOT

COVERED BY WARRANTY

12

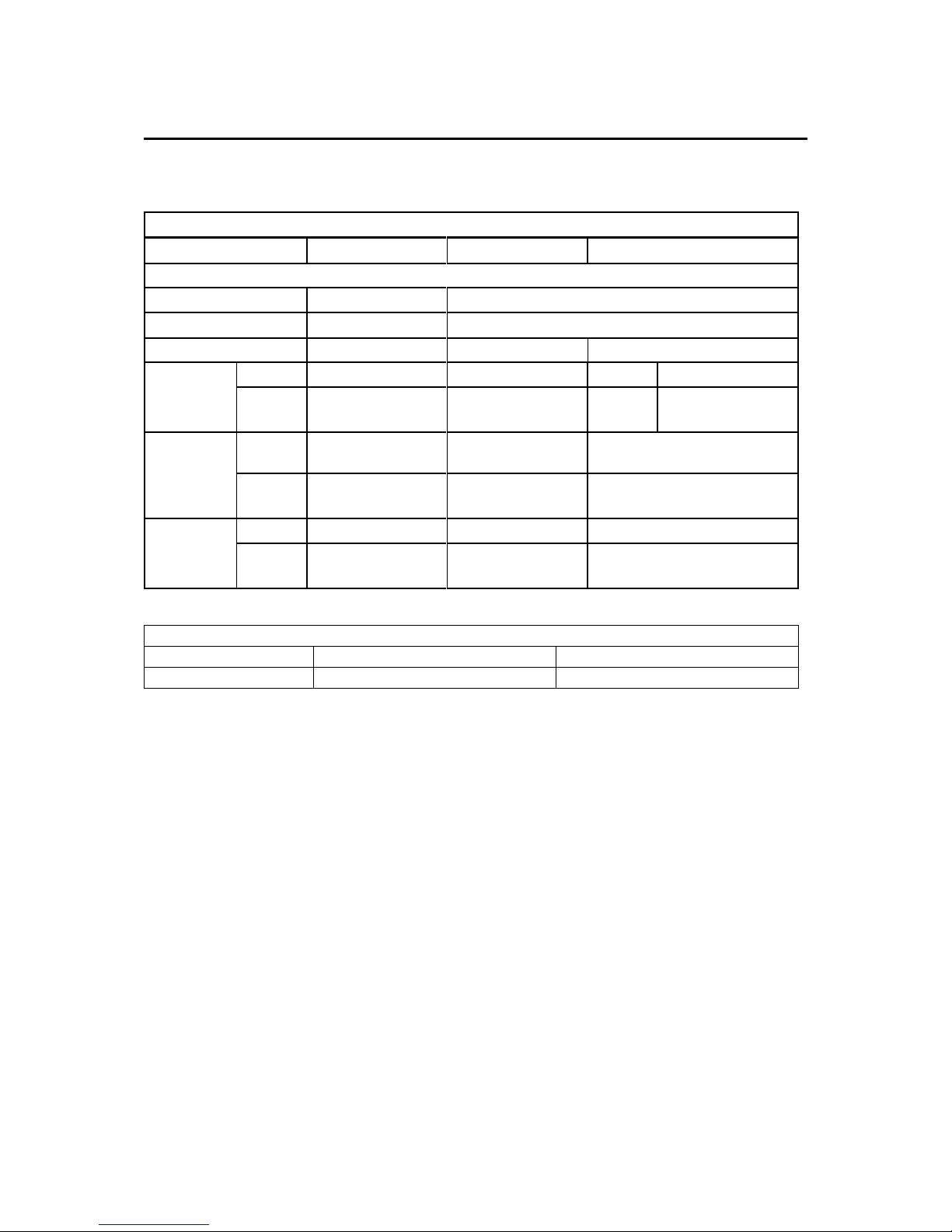

4 SPECIFICATION

4.1 TABLE A

TABLE A

G20

G31

G30

G9341/F Fryer

Injector

Ø2.7

Ø1.7

Pilot Injectors

Polidora G31.2

Polidora G25

Low Rate Screw

N/A

Supply

Pressure

mbar

20

37

29

50

Inches

w.g

8.3

14.9

11.6

20.

Operating

Pressure

mbar

14

34.5

29

Inches

w.g

5.6

13.9

11.6

Low rate

Pressure

mbar

N/A

N/A

N/A

Inches

w.g

N/A

N/A

N/A

TABLE A -1

Rated Voltage

Rated Current

G9341/F

230V

3.55 amps

Loading...

Loading...