Falcon G6478 Installation And Servicing Instructions

RZZ 349 Ref. 1

G6478 STEAMING OVEN

INSTALLATION and

SERVICING INSTRUCTIONS

The appliance must be installed and serviced by a competent person as stipulated by the Gas Safety

(Installation & Use) Regulations.

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions and

National Regulations in force at the time of installation. Particular att ention MUST be paid to -

Gas Safety (Installation & Use) Regulations

Health And Safety At Work etc. Act

Local and National Building Regulations

Fire Precautions Act

The appliance has been CE-marked on the basis of compliance with the Gas Appliance Directive for the

Countries, Gas Types and Pressures as stated on the Data Plate.

WARNING - TO PREVENT SHOCKS, ALL APPLIANCES WHETHER

GAS OR ELECTRIC, MUST BE EARTHED

On completion of the installation, these instructions should be left with the Engineer-in-Charge for reference

during servicing. Further to this, The Users Instructions should be handed over to the User, having had a

demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY

RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance Contract be

arranged with AFE SERVICELINE. Visits may then be made at agreed intervals to carry out adjustments and

repairs. A quotation will be given upon request to the contact numbers below.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

PO Box 37, Foundry Loan, Larbert.

Stirlingshire. Scotland. FK5 4PL

AFE SERVICE LINE CONTACT -

PHONE - 01438 363 000 FAX - 01438 369 900

Detailed recommendations are contained

in Institute of Gas Engineers

published documents :

IGE/ UP/ 1, IGE/ UP/ 2

BS6173 and BS5440

kW (net) Btu/hr (gross)

12.1 45,400

Main Burner Pilot Burner

SIT No. 36

SIT No. 19

ù 3.2mm

ù 1.9mm

NATURAL

PROPANE

mbar inches w.g.

3.8

14.8

9.5

37

NATURAL

PROPANE

mbar inches w.g.

20 8

37 14.8

Burner Pressure Supply Pressure

SECTION 1 - INSTALLATION

1.2 SITING

The appliance must be installed on a firm, level floor

in a well lit position.

This unit can be positioned to within 150mm of a

combustible wall.

Important

If unit is to be installed with other appliances, the

Instructions for all models must be consulted to

determine the necessary clearance to any

combustible rear wall or overlying surface. Some

units require greater clearance than others and the

largest figure quoted in the individual Instructions will

determine the clearance for the complete suite of

adjoining appliances.

1.3 VENTILATION

The appliance flue discharges vertically at the rear.

There must be no direct connection of the flue to any

mechanical extraction system or the outside air.

Siting the appliance under a ventilated canopy is

the ideal arrangement.

Adequate ventilation, whether natural or mechanical,

must be provided to ensure sufficient fresh air for

combustion and for removal of combustion products,

which may be harmful to health. Recommendations

for ventilation for Catering Appliances are given in

BS 5440:2. Further, to ensure sufficient room

ventilation, guidance on the volume of ventilation air

required for different kinds of catering equipment is

given in the table.

For multiple installations, the requirements should be

added together. Installation should be made in

accordance with local and/ or national regulations

applying at the time, and a competent installer must

be employed.

1.4 GAS SUPPLY

The incoming service must be of sufficient size to

supply full rate without excessive pressure drop.

A gas meter is connected to the service pipe by the

Gas Supplier. Any existing meter should be checked

by th e Gas Supplier to ensu re the meter is of

adequate capacity to pass the required rate of gas

for the unit in addition to any other gas equipment

installed.

Installation pipe work should be fitted in accordance

with IGE/UP/2. The pipe work should not be smaller

than the unit gas inlet connection, ie. Rp

1

/

2

(1/2" BSP). An isolating cock must be located close

to the appliance to allow shut-down during an

emergency or servicing. The installation must be

tested for gas soundness. details of this procedure

can be found in IGE/UP/1.

1.5 ELECTRICAL SUPPLY

Not applicable to this appliance.

1.6 WATER SUPPLY

The appliance is intended for connection to a main

water supply only, connection is

1

/2" BSP.

Supply pressure must be within the range of 2.5 to

7 bar. A stop cock must be fitted in an easily

accessible position on the supply to enable shut off

for cleaning and maintenance.

The front trough drain should be sited over a floor

grating where possible.

1.7 GAS RATE - NATURAL and PROPANE GAS

1.8 INJECTOR SIZE -

NATURAL and PROPANE GAS

1.9 OPERATING PRESSURE

EQUIPMENT

Ventilation Rate Required

m

3

/ min ft3/min

Range, Unit Type 17 600

Pastry Oven 17 600

Fryer 26 900

Grill 17 600

Steak Grill 26 900

Boiling Pan 17 600

Steamer 17 600

Sterilizing Sink 14 500

Bains Marie 11 400

Tea/ Coffee Machine 8.5 - 14 300 - 500

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL

WIDTHmmDEPTHmmHEIGHTmmWEIGHT

kg

G6478 600 840 1590 110

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

A

B

C

3

1

2

A pressure test point is provided on burner inlet

supply, accessible when facia panel is removed.

1.10 BURNER ADJUSTMENT

The burner has a fixed air inlet and gas injector.

NO ADJUSTMENT IS REQUIRED.

The pressure must be checked as detailed in

Section 1.9.

SECTION 2 - ASSEMBLY and

COMMISSIONING

2.1 ASSEMBLY

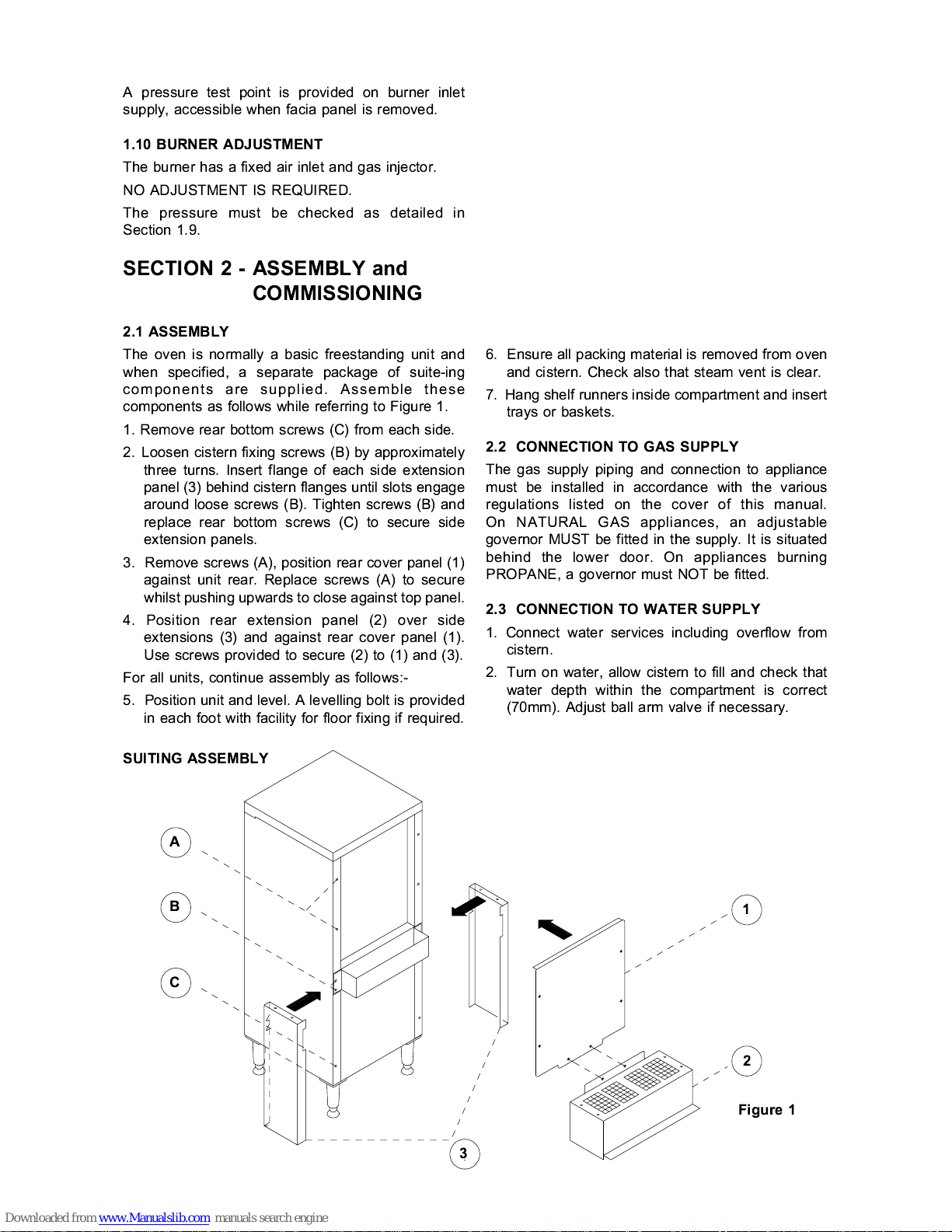

The oven is normally a basic freestanding unit and

when specified, a separate package of suite-ing

components are supplied. Assemble these

components as follows while referring to Figure 1.

1. Remove rear bottom screws (C) from each side.

2. Loosen cistern fixing screws (B) by approximately

three turns. Insert flange of each side extension

panel (3) behind cistern flanges until slots engage

around loose screws (B). Tighten screws (B) and

replace rear bottom screws (C) to secure side

extension panels.

3. Remove screws (A), position rear cover panel (1)

against unit rear. Replace screws (A) to secure

whilst pushing upwards to close against top panel.

4. Position rear extension panel (2) over side

extensions (3) and against rear cover panel (1).

Use screws provided to secure (2) to (1) and (3).

For all units, continue assembly as follows:-

5. Position unit and level. A levelling bolt is provided

in each foot with facility for floor fixing if required.

SUITING ASSEMBLY

6. Ensure all packing material is removed from oven

and cistern. Check also that steam vent is clear.

7. Hang shelf runners inside compartment and insert

trays or baskets.

2.2 CONNECTION TO GAS SUPPLY

The gas supply piping and connection to appliance

must be installed in accordance with the various

regulations listed on the cover of this manual.

On NATURAL GAS appliances, an adjustable

governor MUST be fitted in the supply. It is situated

behind the lower door. On appliances burning

PROPANE, a governor must NOT be fitted.

2.3 CONNECTION TO WATER SUPPLY

1. Connect water services including overflow from

cistern.

2. Turn on water, allow cistern to fill and check that

water depth within the compartment is correct

(70mm). Adjust ball arm valve if necessary.

Figure 1

Loading...

Loading...