Falcon G3840, G3840F Installation, Servicing And User Instructions Manual

G3840/G3840F FRYERS

INSTALLATION, SERVICING

and USER INSTRUCTIONS

These appliances must be installed and serviced by a qualified person as stipulated by the Gas Safety

(Installation & Use) Regulations.

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions

and National Regulations in force at the time of installation. Particular attention MUST be paid to -

Gas Safety (Installation & Use) Regulations I.E.E. Regulations for Electrical Installations

Health And Safety At Work etc. Act Electricity at Work Regulations

Local and National Building Regulations

Fire Precautions Act

Detailed recommendations are contained in DW172 Institute of Gas Engineers published

documents : IGE/ UP/ 1, IGE/ UP/ 2, IGE/ UP/ 4, BS6173 and BS5440

These appliances have been CE-marked on the basis of compliance with the Gas Appliance Directive

for the Countries, Gas Types and Pressures as stated on the data plate.

WARNING TO PREVENT SHOCKS, ALL APPLIANCES, GAS OR ELECTRIC, MUST BE EARTHED.

On completion of the installation, these instructions should be left with the Engineer-in-Charge for

reference during servicing. Further to this, the user instructions should be handed over to the user,

having had a demonstration of the operation and cleaning of the appliance.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance

Contract be arranged with SERVICELINE. Visits may then be made at agreed intervals to carry out

adjustments and repairs. A quotation will be given upon request to the SERVICELINE contact

numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts in a safe manner,

via a licenced waste handler. Units are designed to be dismantled easily and recycling of

all material is encouraged whenever practicable.

This equipment is ONLY FOR PROFESSIONAL USE, and shall be operated by QUALIFIED persons.

It is the responsibility of the supervisor or equivalent to ensure that users wear SUITABLE

PROTECTIVE CLOTHING and to draw attention to the fact that some parts will, by necessity, become

VERY HOT and will cause burns if touched accidentally.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT

Phone: 01438 363 000 Fax: 01438 369 900

T100806 Ref. 6

2

IMPORTANT INFORMATION

Warranty Policy Shortlist

Warranty does not cover :-

• Correcting faults caused by incorrect installation of a product.

• Where an engineer cannot gain access to a site or a product.

• Repeat commission visits.

• Replacement of any parts where damage has been caused by misuse.

• Engineer waiting time will be chargeable.

• Routine maintenance and cleaning.

• Gas conversions i.e. Natural to Propane gas.

• Descaling of water products and cleaning of water sensors where softeners/ conditioners are not fitted,

or are fitted and not maintained.

• Blocked drains

• Independent steam generation systems.

• Gas, water and electrical supply external to unit.

• Light bulbs

• Re-installing vacuum in kettle jackets.

• Replacement of grill burner ceramics when damage has been clearly caused by misuse.

• Where an engineer finds no fault with a product that has been reported faulty.

• Re-setting or adjustment of thermostats when unit is operating to specification.

• Cleaning and unblocking of fryer filter systems due to customer misuse.

• Lubrication and adjustment of door catches.

• Cleaning and Maintenance

• Cleaning of burner jets

• Poor combustion caused by lack of cleaning

• Lubrication of moving parts

• Lubrication of gas cocks

• Cleaning/adjustment of pilots

• Correction of gas pressure to appliance.

• Renewing of electric cable ends.

• Replacement of fuses

• Corrosion caused by use of chemical cleaners.

------------------------------------------------------------------------------------------------------------------------------------------

Contents

Section

1.

Topic

Installation

Page No.

1 - 4

2. Assembly and Commissioning 4 - 6

3. Servicing 7 - 8

4. Spare parts 8

5. Critical dimensions 9

6. Operating instructions 10 - 11

7. Changing/filtering oil 11 - 12

8. Cleaning and maintenance 12 - 13

9. Preparation of solid fats/oil 13

10. Cooking Hints 13

11. Wiring Diagrams 14 - 15

Circuit Diagrams 16 - 17

3

Inlet Burner pressure

pressure

at manifold

Natural Gas 20mbar 14mbar (+/- 0.75mbar)

Propane Gas 37mbar 34.6mbar (+/- 1mbar)

SECTION 1 - INSTALLATION

UNLESS OTHERWISE STATED, PARTS WHICH HAVE

BEEN PROTECTED BY THE MANUFACTURER ARE

NOT TO BE ADJUSTED BY THE INSTALLER.

Please ensure that any plastic coatings are removed prior

to use. Before operation, pan requires to be thoroughly

cleaned and dried.

Discolouration of heated parts is caused by factory

testing to ensure a satisfactory unit. It does not affect

quality or performance.

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

Model

Width

(mm)

Depth

(mm)

Height

(mm)

Weight

(kg)

G3840 Fryer 400 770 1090 83

G3840F Fryer 400 770 1090 94

Pan oil capacity: 18 litres cold, good quality oil

(to -MIN- mark)

1.2 SITING

Each unit must be installed on a firm level floor in a welllit draught free position. The fryer should be installed in

a freestanding position to prevent any possibility of

sideways tipping under force. The means of restraint may

be the manner of installation, such as connection to

a battery of appliances or installing the fryer in an alcove,

or by separate means, such as adequate ties.

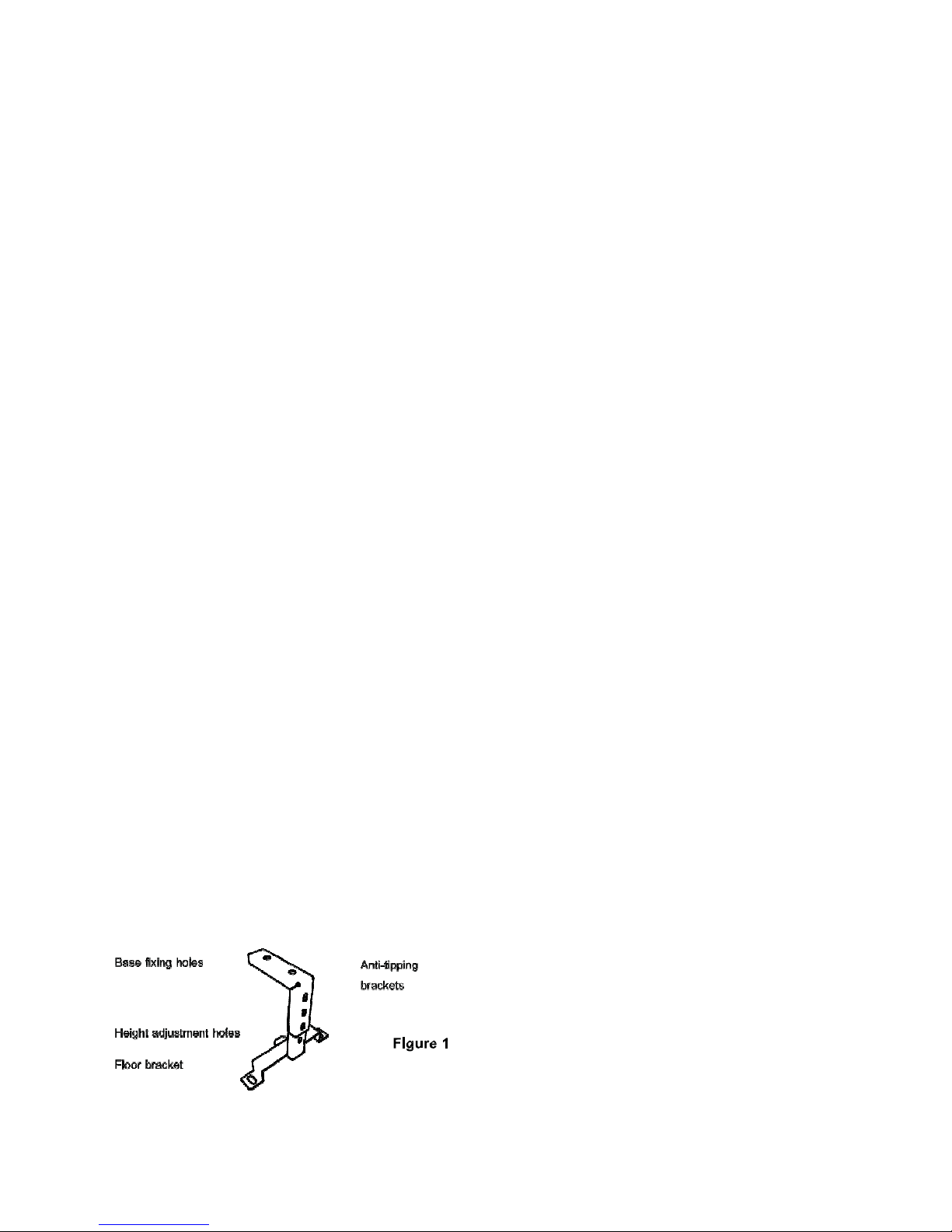

1.2.1 Anti-tipping Kit

An anti-tipping mechanism is supplied with unit. If these

are to be fitted, the brackets must be fitted to locate the

fryer in the correct position relative to any walls as

detailed below. Fixing holes are provided in the fryer base

to accommodate the bracket. The bracket should be fitted

as detailed in Figure 1. The retaining chain has a quick

release eyelet. Secure to fixing point and secure bracket

to floor after alignment with anti-tipping device attached to

the fryer. Adjust to slide below floor bracket.

Figure 1 - Anti-tipping Bracket

1.2.2 Clearances

The unit requires a clearance of at least 150mm to rear

between unit and any combustible wall.

Important

If fryer is to be installed with other appliances then the

instructions for every model should be consulted to

determine the necessary clearance to any combustible

wall or overlying surface.

Some appliances require greater clearance distances

than others. The largest clearance will therefore

determine overall distance for a complete suite of

adjoining appliances.

1.3 VENTILATION

The appliance ventilation requirements should be in line

with national and local regulations.

The ventilation rate for these models is 26m³/min.

The appliance flue discharges vertically from top of unit.

There must be no direct connection of flue to any

mechanical extraction system or outside air. The fryer

should be installed under a ventilated canopy.

Adequate ventilation, whether natural or mechanical must

be provided to ensure sufficient fresh air for combustion

and for removal of combustion products which may be

harmful to health.

For multiple installations, requirements should be added

together. Installations should be made in accordance with

local and/or national regulations applying at the time.

A competent engineer must be used for any installation

work.

1.4 GAS SUPPLY (Both models)

To be checked at installation, gas conversion or repair.

The SIT gas valve, situated at rear RH side of unit and

accessible by removing RH side, has an in-built

governor. The inlet pressure should be checked at valve

inlet test nipple using a manometer and burner pressure

should be set at test nipple on burner manifold, again by

means of a manometer as per values indicated on

Page 3 (for either natural or propane gas). This is

achieved by removing brass dust screw from valve

governor and adjusting governor accordingly using a

screwdriver - clockwise rotation increases pressure.

Note: Propane requires governor to be adjusted

clockwise to maximum adjustment. i.e. fully open

4

The incoming service must be of sufficient size to supply

full rate without excessive pressure drop. A gas meter is

connected to service pipe by gas supplier. Any existing

meter should be checked preferably by gas supplier to

ensure that it is adequate to deal with rate of gas

supply required.

The gas supply tubing or hose shall comply with

national requirements in force. It shall be periodically

examined and replaced as necessary.

Installation pipe work should be fitted in accordance with

IGE/UP/2. The size of pipes from meter to unit must not

be less than that of appliance inlet connection.

A 3/4" BSP inlet connection is fitted to unit.

An isolating valve must be located close to the unit to

facilitate shut down during an emergency or routine

servicing. This must be easily accessible to the user.

The installation must be tested for gas tightness as stated

in IGE/UP/1.

Domestic type, flexible rubber tube connections

must NOT be used with this appliance.

Only tube complying with BS669 Part 2, specification

of corrugated metallic flexible hoses for catering

appliances, shall be used.

1.5 ELECTRICAL SUPPLY

The unit is equipped with a 3-core flexible cord with

standard 3 pin plug fitted with a 13A fuse. A regular

13A socket outlet can be used.

If supply is provided through a distribution fuse box,

it must be via a fuse with a maximum rating of 13A.

In the event of mains cable being replaced, any new

cable should comply with 60245 IEC 57 designation.

(H05 RN - F)

Rated Voltage Rated Current

G3840/G3840F

230V~ 3.55amps

THE APPLIANCE MUST BE EARTH BONDED.

1.6 TOTAL RATED HEAT INPUTS

Natural and Propane Gas

22kW (nett) 82,500 btu/hr (gross)

1.7 INJECTOR SIZES

Natural Gas

Burner Pilot

2 x Ø2.6mm Polidora G31.2

Propane Gas

Burner Pilot

2 x Ø1.7mm Polidora G25

SECTION 2 - ASSEMBLY and

COMMISSIONING

The gas supply piping and connection to appliance must

be installed in accordance with the local regulations in

conjuncion with those listed on the cover of this manual.

2.1 ASSEMBLY

a) Unpack appliance

b) Unpack fryer baskets and accessories.

c) Place basket support grid and basket in pan.

d) Level appliance and fit all service protection kits.

(Anti-tilt kit is supplied).

2.2 CONNECTION TO A GAS SUPPLY

Connect gas supply and test for gas soundness.

Caution - Ensure that pan contains an acceptable level

of liquid before igniting burner.

Due to the presence of mains electrics, integral pipe work

should be checked for gas soundness using an

appropriate gas leak detector.

Caution - Installation engineers should note that for first

time connection of fryer, it is essential that inlet supply to

fryer be completely purged of air prior to first lighting

attempt. Otherwise, since this is a “light pilot first every

time” system, it will take a significant number of attempts

to light due to the small amount of air bled from pipe by

pilot at each attempt.

This should not be initially treated as a fault.

Please note that several attempts will still be required

after air purge for first time lighting. This is due to the

capacity of valve and governor.

2.3 CONNECTION TO AN ELECTRICAL SUPPLY

Ensure flexible cable does not come into contact with any

hot parts. The fuse rating should be 13A.

Colour coding of power supply cables is as follows:

Live - Brown, Neutral - Blue, Earth - Green/Yellow

2.4 STARTING UP

When using fat melting cycle and loading solid fat for the

first time, always remove fryplate as detailed in Section 9.

Solid fat should be in direct contact with fryer pan.

Refer to Section 9.

5

1

3

2

4 5

3

4

2

1

4 5

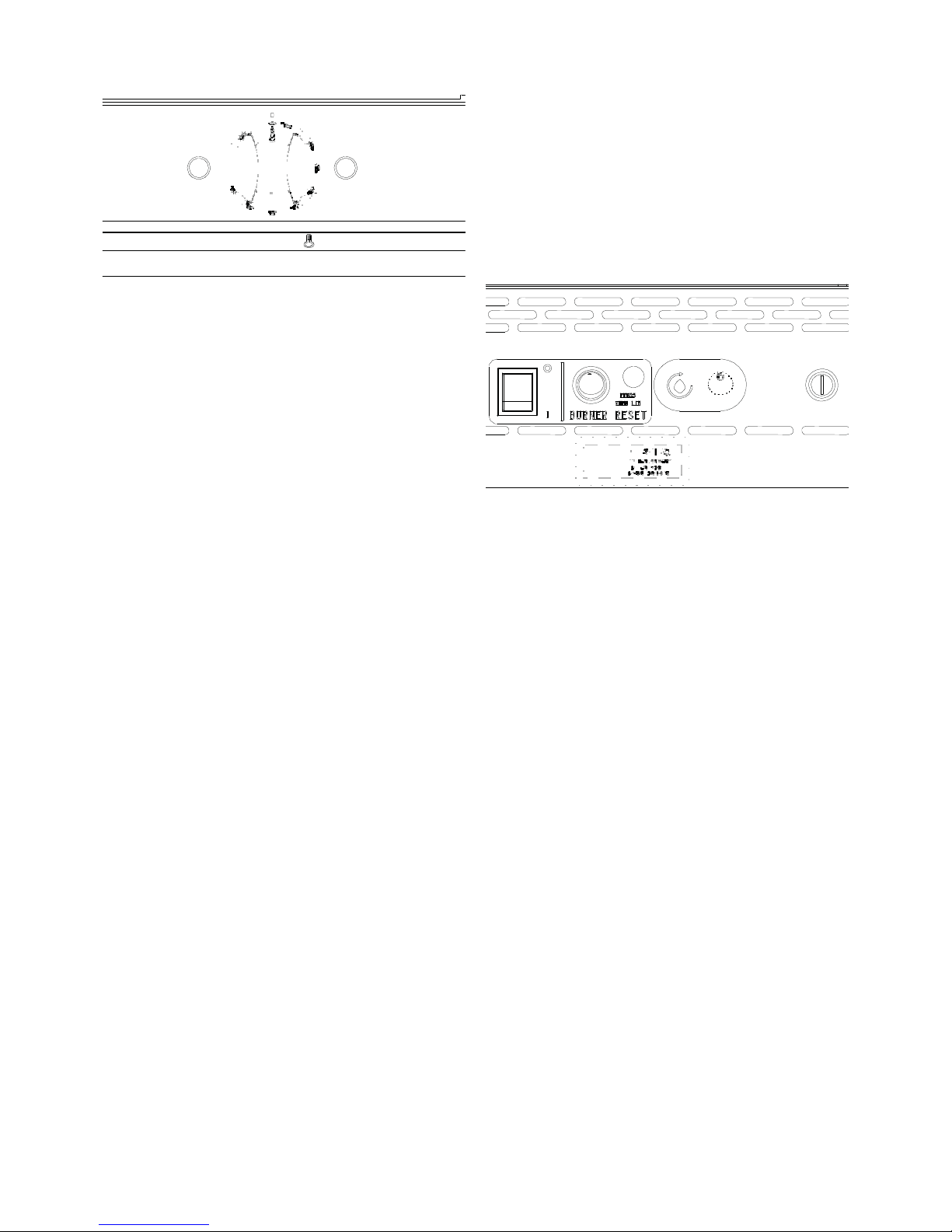

2.4.1 G3840 Fryer Control Panel (See Figure 2)

2

3

4

1

2.4.2 G3840 & G3840F - Additional Controls

(See Figure 3)

The following additional controls are located behind

cabinet door.

1. Burner and Temperature Controls ON/OFF Switch

Cuts power to burner and temperature controls.

2. Burner Lockout Indicator

Indicates flame failure.

Figure 2 – G3840 Control Panel

1.

ON/OFF and Temperature Control Knob

Temperature Selection (140 - 190°C). (Unit is off when

control is in position indicated).

1

3

2

2.

Fat Melt Position

Feature for slow pulsed heating of solid fats.

3.

Power on indicator.

4.

Heat Demand Indicator

Illuminates when thermostat demands heat, i.e. oil

temperature is more than 5⁰C below temperature setting.

Extinguishes when desired temperature is reached.

Figure 3 - Additional Controls

3.

Burner Lock-Out Reset Switch

Resets burner for further lighting attempts when burner

lockout indicator is illuminated.

4.

Filtration Pump Switch (G3840F only)

Energises filtration pump when burner switch is in

OFF(O) position.

5.

Temperature Safety Limiter Reset Button

Located inside red recess, below black cover.

2.4.3 G3840 and G3840F Controller Diagnostic

Indicators (On printed circuit board of

controller, behind control panel)

Green LED ‘ON’ indicates heat demand.

Green LED ‘OFF’ indicates no heat demand.

Red LED flashes if temperature probe is either short or

open circuited.

Red LED is permanently ‘ON’ to indicate system is OK.

Set point is +/-7⁰C of mid-set point.

6

2.5 PRE-COMMISSIONING CHECK

1.

Clean out pan thoroughly using hot water and

detergent. Rinse out and dry thoroughly.

Note

For further detail with regard to cleaning, refer to

Section 8.

2.

Ensure drain valve is closed. Fill pan with clean

cooking oil to -MIN- (maximum cold fill mark)

indicated on fryplate. (See Figure 5)

Note: MAX refers to maximum hot fill mark.

3.

With gas supply still shut off, turn on electrical mains

supply.

4.

Open door and press temperature limit thermostat

reset button (red), refer to Section 2.6. Set burner

switch to Position 'I' (ON position).

5.

Turn control knob to desired temperature (140⁰C) and

heat demand indicator will illuminate (Figure 2,

item 4).

6.

Fryer ignition sequence will commence and spark

may be heard before unit locks out.

Note: Ignition system will attempt a second sequence,

14 seconds after completion of first try if no flame is

detected during first attempt. (Unit will only lock out after

2nd attempt).

7.

Neon next to burner switch inside door will

illuminate to indicate lockout has occurred and that

no burner flame is present. G3840 / G3840F

Additional controls - Item 2 on Figure 3.

8.

Turn gas supply on.

9.

Press lockout reset switch. See Figure 3 (Lock out

indicator will extinguish).

10.

Burner will ignite and heat indicator will illuminate to

signify that burner is on.

If lockout should occur, repeat Steps 9 -10 until air is

bled from supply and burner lights.

11.

When burner flame is established, check for gas

leaks. Care should be taken because mains voltage

is present. Isolate after gas checks.

2.5.1 Checking Controller Operation

To check operation of controls, refer to Using The

Controller - Section 6.2.3.

2.5.2 Checking Oil Filtration Pump

To check operation of oil filtration pump, refer to

Section 7.

Important

After installation, the responsible technician should check

for gas leaks and ensure the appliance is operating safely

and satisfactorily before handing over to the user.

2.6 TEMPERATURE LIMIT THERMOSTAT

The unit is equipped with an additional temperature limit

thermostat, independent of main controller.

In the case of operating thermostat failure, allowing oil

temperature to rise above predetermined legislation safe

zone (230⁰C), limit device will activate and cut power to

controller. It will also stop the flow of gas to burner,

refer to Figure 3.

a) Turn burner and temperature controls ON/OFF knob

to OFF position.

b) Allow oil to cool below 180⁰C

c) Reset red button on limit thermostat with a pen or

similar item, refer to Figure 3.

d) Turn burner and temperature controls ON/OFF knob

to ON position.

e) Re-select temperature.

f) If limit thermostat reactivates carry out fault finding on

temperature control circuitry.

2.7 INSTRUCTION TO USER

After installing and commissioning appliance, please

hand Instructions to user or purchaser and ensure that

the person(s) responsible understands the instructions to

correctly operate and clean unit in a safe manner.

Emphasis should be given to safe operation and use of

drain valve and oil bucket. Oil bucket should not be

overfilled to allow safe movement. Oil should be allowed

to cool before any manual handling.

Note: The oil container may be heavy. Drain small

amounts at a time if necessary, before lifting container.

Manual handling regulations should be observed.

It is important to ensure that location of gas shut-off valve

is made known to user and that procedure for operation

in an emergency be demonstrated.

Loading...

Loading...