Falcon G3830, G3860, G3865 Installation And Servicing Instructions

G3830, G3860, G3865 Fryers

INSTALLATION and

SERVICING INSTRUCTIONS

This appliance must be installed and serviced by a competent person as stipulated by the

Gas Safety (Installation & Use) Regulations.

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions

and National Regulations in force at the time of installation. Particular attention MUST be paid to:

Gas Safety (Installation & Use) Regulations

Health And Safety At Work etc. Act

Local and National Building Regulations

Fire Precautions Act

The appliance has been CE-marked on the basis of compliance with the Gas Appliance Directive for

the Countries, Gas Types and Pressures as stated on the data plate.

WARNING: TO PREVENT SHOCKS, ALL APPLIANCES WHETHER GAS OR ELECTRIC,

MUST BE EARTHED.

On completion of the installation, these instructions should be left with the Engineer-in-Charge for

reference during servicing. Further to this, The Users Instructions should be handed over to the User,

having had a demonstration of the operation and cleaning of the Appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING

AND COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED

PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a maintenance

contract be arranged with SERVICELINE. Visits may then be made at agreed intervals to carry out

adjustments and repairs. A quotation will be given upon request to the contact numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement

parts in a safe manner, via a licenced waste handler.

Units are designed to be dismantled easily and recycling of all

material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT

Phone: 01438 363 000 Fax: 01438 369 900

T100760 Ref.1

Detailed recommendations are contained in

Institute of Gas Engineers published documents:

IGE/UP1, IGE/UP/2

BS6173 and BS5440

IMPORTANT INFORMATION

Warranty Policy Shortlist

Warranty does not cover :-

• Correcting faults caused by incorrect installation of a product.

• Where an engineer cannot gain access to a site or a product.

• Repeat commission visits.

• Replacement of any parts where damage has been caused by misuse.

• Engineer waiting time will be chargeable.

• Routine maintenance and cleaning.

• Gas conversions i.e. Natural to Propane gas.

• Descaling of water products and cleaning of water sensors where softeners/ conditioners are not fitted,

or are fitted and not maintained.

• Blocked drains

• Independent steam generation systems.

• Gas, water and electrical supply external to unit.

• Light bulbs

• Re-installing vacuum in kettle jackets.

• Replacement of grill burner ceramics when damage has been clearly caused by misuse.

• Where an engineer finds no fault with a product that has been reported faulty.

• Re-setting or adjustment of thermostats when unit is operating to specification.

• Cleaning and unblocking of fryer filter systems due to customer misuse.

• Lubrication and adjustment of door catches.

• Cleaning and Maintenance

• Cleaning of burner jets

• Poor combustion caused by lack of cleaning

• Lubrication of moving parts

• Lubrication of gas cocks

• Cleaning/adjustment of pilots

• Correction of gas pressure to appliance.

• Renewing of electric cable ends.

• Replacement of fuses

• Corrosion caused by use of chemical cleaners.

1.4 GAS SUPPLY

The incoming service must be of sufficient size to supply

full rate gas without excessive pressure drop. A gas meter

is connected to the service pipe by Gas Supplier.

Any existing meter should be checked by the supplier to

ensure that it is of adequate capacity to pass required

rate of gas for the unit, in addition to any other gas

equipment that has been installed.

The multifunctional control has an in-built governor

therefore an external device does not require to be fitted.

Installation pipework should be fitted in accordance with

IGE/UP/2. This should not be smaller than gas inlet

connection.

G3830 - Rp½ (½" BSP)

G3860 - Rp¾ (¾" BSP)

G3865 - 2 x Rp½ (½" BSP)

An inlet manifold may be purchased to connect G3865 to

1 x Rp¾ (¾" BSP) mains inlet.

An isolating cock must be located close to the unit to

allow shutdown during an emergency or servicing.

The installation should be checked for gas tightness and

purged as specified in IGE/UP/1.

1.5 ELECTRICAL SUPPLY

Not applicable to these units.

1.6 WATER SUPPLY

Not applicable to these units.

1.7 TOTAL GAS RATES NATURAL and PROPANE GAS

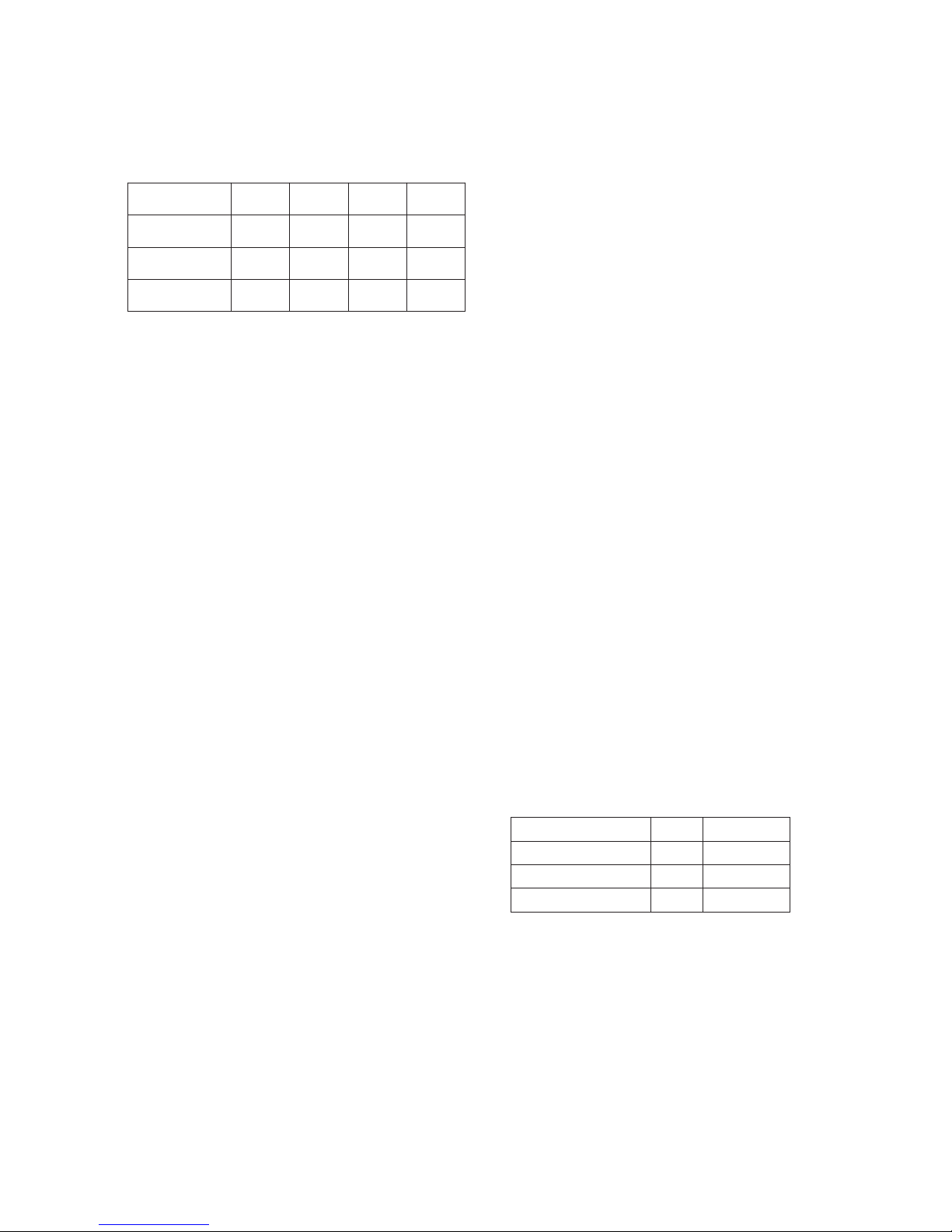

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

1.2 SITING

The unit should be installed on a level, fireproof surface

in a well lit, draught free position. A clear space of 150mm

should be left between the rear and sides of the fryer and

any combustible wall.

If the floor is constructed of combustible material,

then local fire requirements should be checked to ensure

compliance.

Important

If appliance is to be installed in suite formation with other

matching units, the instructions for all models must be

consulted to determine the necessary clearances to any

combustible rear wall or overlying surface. Some models

require greater clearances than others and the largest

figure quoted in individual instructions will therefore

determine clearance of complete suite adjoining

appliances.

1.3 VENTILATION

Adequate ventilation must be provided to supply sufficient

fresh air for combustion. This should allow easy removal

of combustion products which may be harmful to health.

Recommendations for Ventilation of Catering Appliances

are given in BS5440:2.

For multiple installations, the requirements for individual

units require to be added together. Installation should be

carried out in accordance with local and/or national

regulations which apply at the time. A competent installer

MUST be employed.

Model

Width

(mm)

Depth

(mm)

Height

(mm)

Weight

(kg)

G3830 Fryer

300 770 870 59

G3860 Fryer

600 770 870 74

G3865 Fryer

600 770 870 99

SECTION 1 - INSTALLATION

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER.

Model kW Btu/hr

G3830 Fryer 18.1 61,757

G3860 Fryer 32.5 110,890

G3865 Fryer 2 x 18.1 2 x 61,757

Loading...

Loading...