Falcon G350/9, G350/10 User Instructions

T100693 Ref. 1

G350/9 and G350/10

CHARGRILLS

USERS INSTRUCTIONS

SECTION 1 - GENERAL DESCRIPTION

SECTION 2 - LIGHTING and OPERATIONS

SECTION 3 - COOKING HINTS

SECTION 4 - CLEANING and MAINTENANCE

These appliances have been CE-marked on the basis of compliance with the Gas Appliance Directive

for the Countries, Gas Types and Pressures as stated on the Data Plate.

These Appliances MUST BE installed by a competent person in compliance with the INSTALLATION AND

SERVICING INSTRUCTIONS and National Regulations in force at the time. Particular attention MUST be paid

to the following:

Gas Safety (Installation & Use) Regulations

Health and Safety at Work Act

Furthermore, if a need arises to convert the appliance for use with another gas, a competent person must be

consulted. Those parts which have been protected by the manufacturer MUST NOT be adjusted by the User.

Users should be conversant with the appropriate provisions of the Fire Precautions Act and the requirements of

the Gas Safety Regulations. in particular the need for regular servicing by a competent person to ensure the

continued safe and efficient performance of the Appliance.

Upon receipt of the User's Instruction manual, the installer should instruct the responsible person(s) of the

correct operation and maintenance of the Appliance.

This equipment is ONLY FOR PROFESSIONAL USE, and shall be operated by QUALIFIED persons. It is the

responsibility of the Supervisor or equivalent to ensure that users wear SUITABLE PROTECTIVE CLOTHING

and to draw attention to the fact that, some parts will, by necessity, become VERY HOT and will cause burns if

touched accidentally.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts

in a safe manner, via a licenced waste handler.

Units are designed to be dismantled easily and recycling of all

material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT -

PHONE - 01438 363 000 FAX - 01438 369 900

SECTION 1 - GENERAL DESCRIPTION

The G350/9 and G350/10 simulated charcoal grills

are part of the Falcon 350 series of equipment. All

individual units comprising the series are of modular

dimensions, enabling suites of units to be installed in

a matching line whether counter-mounted, as are

these appliances, or floor-mounted i.e. ranges and

fryers.

The two models are similar in design, G350/9 unit is

350mm wide and G350/10 is 700mm wide.

G350/10 model has two burners, each individually

controlled by a safety tap: ignition being manual by

means of a taper. The G350/9 unit has a single

burner. The heat inputs are 19.2kW (70,000 Btu/hr)

and 9.6kW (32,750 Btu/hr) respectively.

The cooking surface consists of a number of cast iron

brander bars. (Three on G350/9 and Six on G350/10),

which can be used in any of four positions by

adjusting tilt handles and turning bars over.

During cooking process, excess fat is drained down

grooves in the bars into a removable fat drawer at

bottom of unit. Behind fat drawer is a removable drip

tray which collects lava rock remnants, food particles

etc.

Figure 1 - G350/9 Chargrill

Figure 2 - G350/10 Chargrill

SECTION 2 - LIGHTING and OPERATIONS

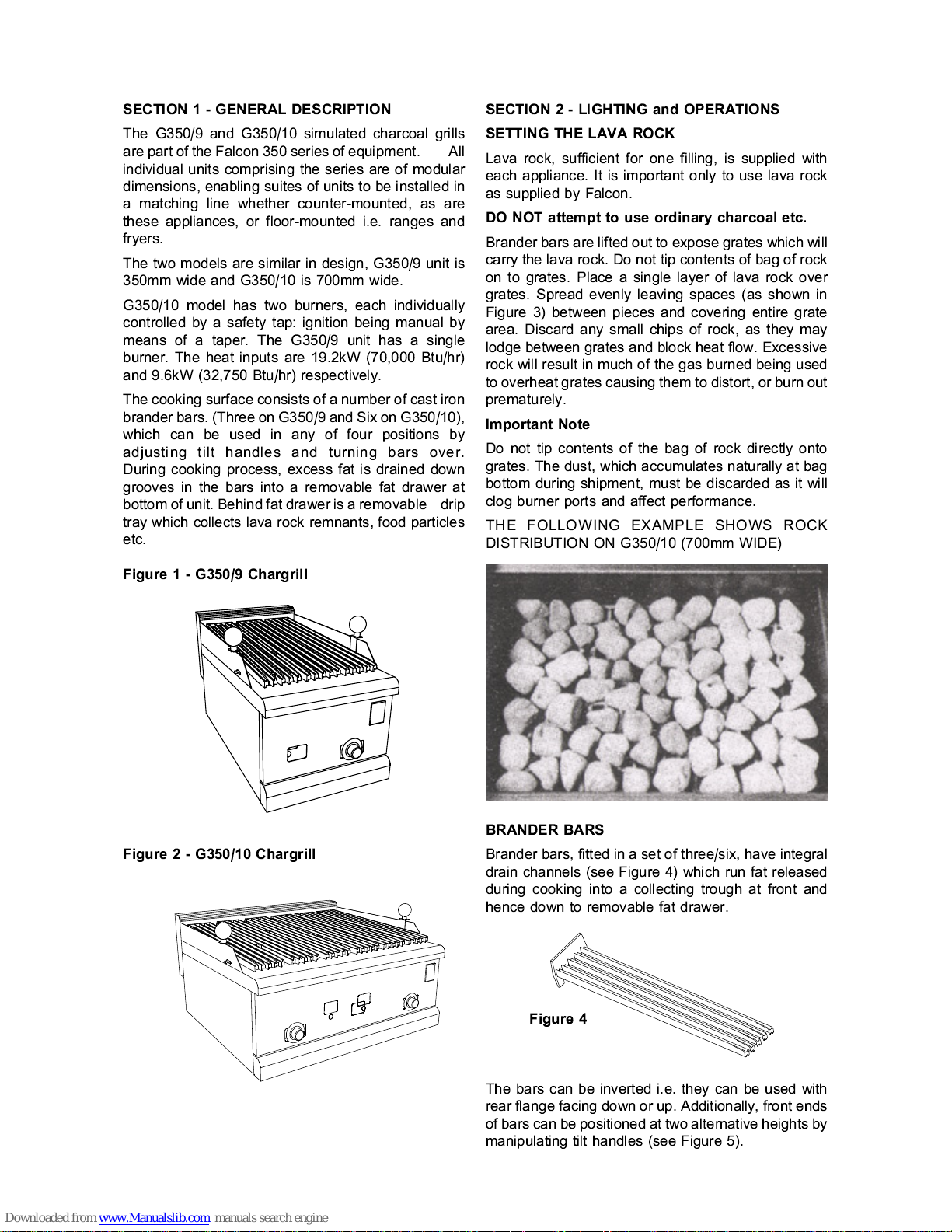

SETTING THE LAVA ROCK

Lava rock, sufficient for one filling, is supplied with

each appliance. It is important only to use lava rock

as supplied by Falcon.

DO NOT attempt to use ordinary charcoal etc.

Brander bars are lifted out to expose grates which will

carry the lava rock. Do not tip contents of bag of rock

on to grates. Place a single layer of lava rock over

grates. Spread evenly leaving spaces (as shown in

Figure 3) between pieces and covering entire grate

area. Discard any small chips of rock, as they may

lodge between grates and block heat flow. Excessive

rock will result in much of the gas burned being used

to overheat grates causing them to distort, or burn out

prematurely.

Important Note

Do not tip contents of the bag of rock directly onto

grates. The dust, which accumulates naturally at bag

bottom during shipment, must be discarded as it will

clog burner ports and affect performance.

THE FOLLOWING EXAMPLE SHOWS ROCK

DISTRIBUTION ON G350/10 (700mm WIDE)

BRANDER BARS

Brander bars, fitted in a set of three/six, have integral

drain channels (see Figure 4) which run fat released

during cooking into a collecting trough at front and

hence down to removable fat drawer.

Figure 4

The bars can be inverted i.e. they can be used with

rear flange facing down or up. Additionally, front ends

of bars can be positioned at two alternative heights by

manipulating tilt handles (see Figure 5).

Loading...

Loading...