Falcon E7204, E7211, E7208/2, E7211 Rack, E7211 Trolley Installation And Servicing Instructions

...Page 1

E7204, E7208 and E7211

Forced Convection Ovens

CAUTION: Read the instructions before

using the appliance.

INSTALLATION and SERVICING

INSTRUCTIONS

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these

instructions and National Regulations in force at the time of installation. Particular attention

MUST be paid to –

BS7671 IEE Wiring Regulations

Electricity at Work Regulations

Health And Safety At Work Act

Fire Precautions Act

This appliance has been CE-marked on the basis of compliance with the Low Voltage and EMC

Directives for the voltages stated on the Data Plate

WARNING -THIS APPLIANCE MUST BE EARTHED

On completion of the installation these instructions should be left with the Engineer-in-Charge for

reference during servicing. Further to this, The Users Instructions should be handed over to the

User, having had a demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE

INSTALLING AND COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE

SPECIFIED PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE

CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance

Contract be arranged with SERVICELINE. Visits may then be made at agreed intervals to carry

out adjustments and repairs. A quotation will be given upon request to the contact numbers

below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts in a safe

manner, via a licensed waste handler.

Units are designed to be dismantled easily and recycling of all material is

encouraged whenever practicable.

Falcon Foodservice Equipment

Head Office and Works

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

ServicelinePHONE : 01438 363 000

Warranty Policy Shortlist

Warranty does not cover :Correcting faults caused by incorrect installation of a product.

Where an engineer cannot gain access to a site or a product.

T100683 Ref.5

Page 2

Repeat commission visits.

Replacement of any parts where damage has been caused by misuse.

Engineer waiting time will be chargeable.

Routine maintenance and cleaning.

Gas conversions i.e. Natural to Propane gas.

Descaling of water products and cleaning of water sensors where softeners/conditioners are not

fitted, or are fitted and not maintained.

Blocked drains.

Independent steam generation systems.

Gas, water and electrical supply external to unit.

Light bulbs.

Re-installing vacuum in kettle jackets.

Replacement of grill burner ceramics when damage has been clearly caused by misuse.

Where an engineer finds no fault with a product that has been reported faulty.

Re-setting or adjustment of thermostats when unit is operating to specification.

Cleaning and unblocking of fryer filter systems due to customer misuse.

Lubrication and adjustment of door catches.

Cleaning and Maintenance:

Cleaning of burner jets

Poor combustion caused by lack of cleaning

Lubrication of moving parts

Lubrication of gas cocks

Cleaning/adjustment of pilots

Correction of gas pressure to appliance

Renewing of electric cable ends

Replacement of fuses

Corrosion caused by use of chemical cleaners.

Electrical Safety and Advice Regarding Supplementary Electrical Protection

Commercial kitchens and foodservice areas are environments where electrical appliances may be located

close to liquids, or operate in and around damp conditions, or where restricted movement for installation

and service is evident.

The installation and periodic inspection of the appliance should only be undertaken by a qualified, skilled

and competent electrician; and connected to the correct power supply suitable for load as stipulated by the

appliance data label.

The electrical installation and connections should meet the necessary requirements to local electrical

wiring regulations and electrical safety guidelines.

We recommend:-

Supplementary electrical protection with use of a residual current device (RCD).

Fixed wiring appliances incorporate a locally situated switch disconnector to connect to, which is

easily accessible for switching off and safe isolation purposes. The switch disconnector must meet

the specification requirements of IEC 60947.

Page 3

SECTION 1 – INSTALLATION

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE

MANUFACTURER ARE NOT TO BE ADJUSTED BY THE INSTALLER

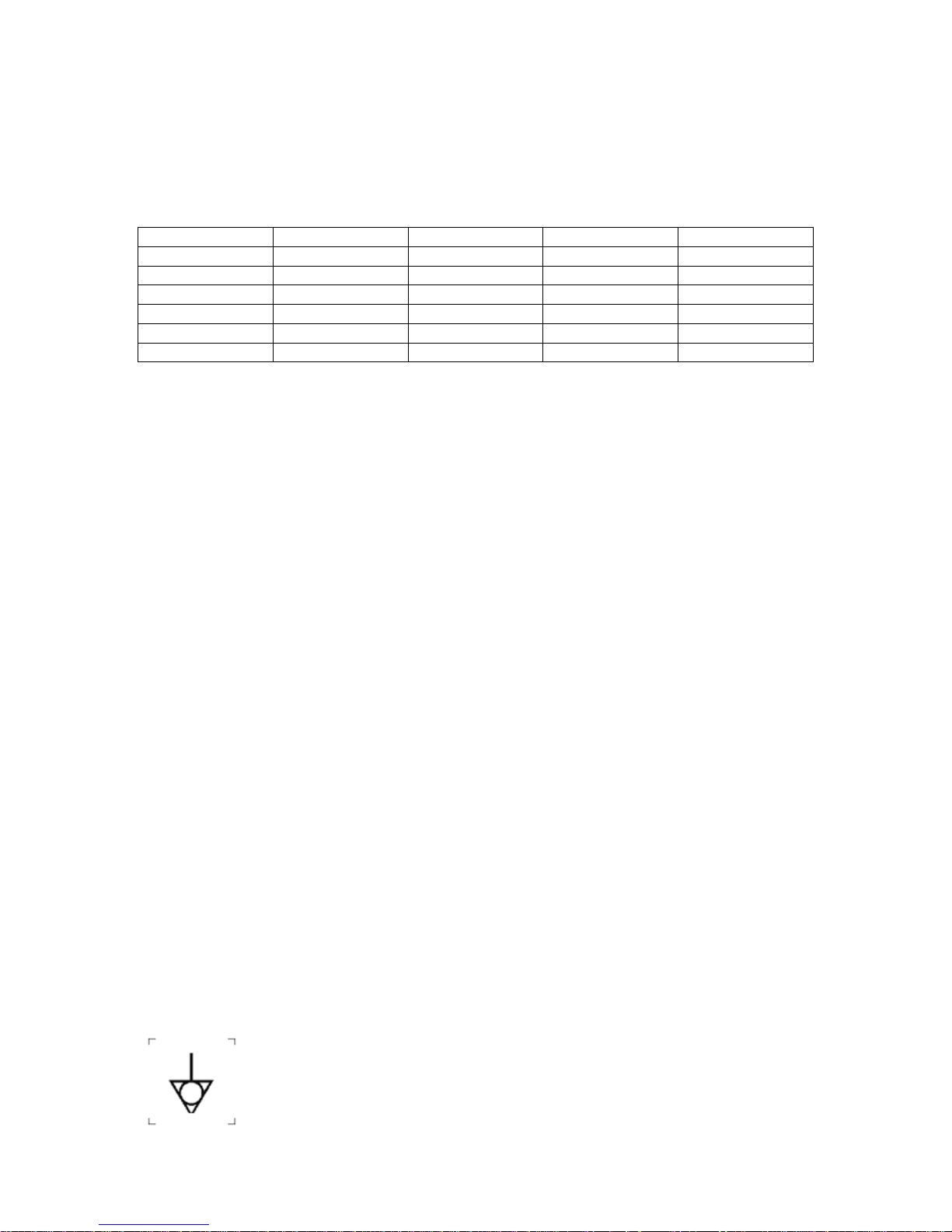

1.1 MODEL NUMBER, NETT WEIGHTS and DIMENSIONS

MODEL

WIDTH mm

DEPTH mm

HEIGHT mm

WEIGHT kg

E7204

860

1015

1470

170

E7208

1000

1070

1525

220

E7208/2

1000

1070

1910

420

E7211

1000

1070

1525

270

E7211 Trolley

820

740

910

32

E7211 Rack

680

560

830

37

1.2 SITING

The oven must be situated on a reasonably level surface. The unit feet are adjustable to

facilitate levelling however, the adjustment range is limited.

Installation must be executed in accordance with local and/or national regulations listed on

the cover of this manual. A competent installer must be employed.

1.2.1 Installing Clearances

A clearance of at least 150mm must be allowed from any combustible wall. Clearance must

also be allowed at the rear from any non-combustible wall to let cooling air into the rear fan.

If practicable, it is recommended that a clearance of at least 400mm be allowed from any

side wall. This will provide access for adjustment of the rear levelling bolts and to effect

removal of the RH side panel to facilitate servicing. If the unit is being installed as part of a

suite, it is further recommended that it be positioned at the RH end to provide unrestricted

access for servicing of controls etc.

If the unit is to be installed in a suite, either centrally or adjacent to a wall with a 'boxed in'

void at the rear, it is important that the void be adequately ventilated. This will ensure a

supply of air to the motor cooling fan at the rear of the oven.

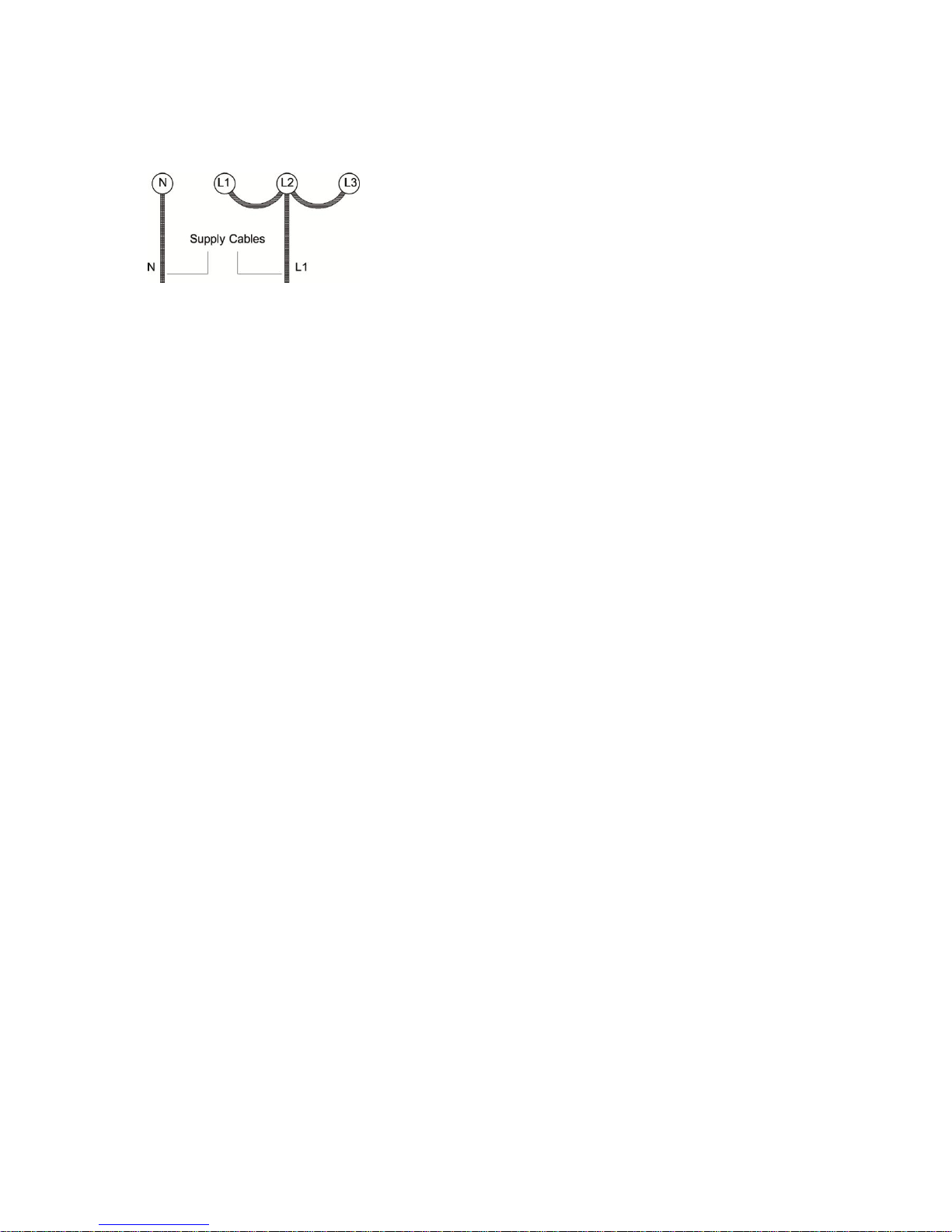

1.3 ELECTRICAL SUPPLY

This unit is suitable for AC supplies only. The standard terminal arrangement is for 3 phase,

4 wire connection, but by linking the 3 line terminals, the unit can be connected to a single

phase supply.

The cable entry is at the bottom RH rear of the unit via a 32mm dia conduit. Access to the

terminals is gained by removing the RH side panel.

A suitably rated isolating switch with a minimum 3mm contact separation in all poles must be

installed and the wiring executed in accordance with the relevant regulations listed on the

front cover of this manual.

Warning

The appliance must be earthed. (An earth terminal is provided).

The appliance is also provided with a terminal for the connection of an

external equipotential conductor. This terminal is in effective electrical contact

with all fixed exposed metal parts of the appliance, and shall allow the

connection of a conductor having a nominal cross-sectional area of up to 10

mm². It is located on the rear panel and is identified by the following label and

must only be used for bonding purposes.

Page 4

Note

When connecting to a single phase supply, the three line terminals must be connected

together using the wire links provided. It is important that the links and incoming supply cable

are connected exactly as shown in the following diagram.

1.4 ELECTRICAL RATING

The electrical loadings are as stated on the appliance data plate.

1.5 FAN UNIT

This is a unit specially developed for use in forced convection ovens. It has two fans directly

mounted on the motor shaft. The larger fan is inside the oven, the purpose being to circulate

air around the cooking space whilst the smaller externally mounted fan serves to cool the

motor.

1.6 INSTRUCTION TO USER

Hand the USER'S INSTRUCTIONS to the user or purchaser and ensure that the instructions

for the correct use and cleaning are properly understood.

The location of the electrical supply switch should be made known to the user for use in an

emergency or during cleaning.

SECTION 2 - ASSEMBLY and COMMISSIONING

Warning

Due to the appliance weight (see Section 1.1), it is recommended that when lifted manually,

that it be supported by 4 people (one at each corner).

Important

Care must be taken when lifting heavy loads and ensure that correct lifting techniques are

employed. For reference see the HSE publication, Manual Handling of Loads Regulations.

2.1 ASSEMBLY

2.1.1 Oven without Stand

a) Unpack unit and remove all loose components from oven compartment.

b) Manoeuvre oven to required position and level using the adjustable feet. Also, refer to

Section 2.1.3 if applicable.

c) Connect electricity supply.

d) Insert the shelves within the oven.

Note

Feet can be secured to floor using holes provided.

2.1.2 Oven with Stand

a) Unpack unit and stand. Remove all loose components from oven compartment.

b) Ensure the leg securing bolts are turned fully back.

c) Lift oven on to stand. If a stand is fitted with castors, these should be locked.

d) Tighten leg stand securing bolts.

e) Manoeuvre unit into position.

f) For stand on castors, fit securing chain to prevent straining the electrical cable.

Page 5

g) For fixed stand, level using the adjustable feet. Also, refer to Section 2.1.3 if applicable.

Note

Feet can be secured to floor using holes provided.

2.1.3 Oven with Trolley

a) Unpack oven, trolley and rack assembly as detailed in Section 2.1.2, items a) to d).

b) Manoeuvre unit into required location and level by turning adjustable feet as required.

Feet should also be used to line up unit base with trolley tray.

c) Connect to electricity supply.

Note

Feet can be fixed to floor using holes provided in feet.

2.2 COMMISSIONING THE APPLIANCE

These units have two mode switches.

For controls refer to users instruction fig 1

Fan Mode Switch: Heat up/cool down.

In the heat-up mode, the required Cook Mode must be selected: Cook only/Cook & Hold.

The ovens are fitted with a bi-directional fan controlled by a PLC (programmable logic

controller). The fan timings are:

For heat-up mode (door closed):

Operation

Duration (seconds)

OFF (start up)

12

then repeat loop:

Anti-clockwise

120

OFF

12

Clockwise

120

OFF

12

For cool down mode (door open):

OFF (start up)

5

Anti-clockwise

continuous

The on/off knob is fitted on thermostat spindle.

Turn knob clockwise to switch fan and elements on.

Turn knob fully anti-clockwise to switch off.

2.2.1 Basic Checks

a) Ensure all packing material has been removed. If unit is fitted with shelf runners, ensure

oven grid shelves slide in and out properly.

b) Switch on main supply, red neon should light.

c) With doors open and switch set to Cool Down, turn thermostat knob clockwise to switch

fan on.

d) Check fan rotates anti-clockwise.

E7204/E7208 models only

e) Push oven light switch to observe oven light(s) operate.

2.2.2 System Operational Checks

Select Cook Only Mode (Timer set to 'MAN')

a) Set thermostat to 200oC. Heat Required neon (Amber) should illuminate.

Page 6

b) Allow oven to heat up. Amber neon will go out when desired temperature is reached.

Check that centre oven temperature corresponds to setting. The temperature will cycle

around set point and the thermostat will switch the elements on and off to maintain setting.

c) Check fan stops when doors are opened, this should also cut power to elements. Amber

neon will stay lit if temperature is below desired setting.

d) Check fan rotates with doors open or closed when the fan switch is pressed to cool down

mode.

e) Return to heat-up mode to check timer operation. This should switch off the elements and

sound a buzzer at the end of a pre-set time interval. Turn timer knob to 'MAN' setting and

observe that cook thermostat is activated and buzzer stops.

Select the Cook & Hold Mode (Mode switch neon should illuminate).

a) Check timer operates as required. Cook thermostat should operate until timer zeros.

When this occurs, operation should switch to Hold thermostat.

b) With oven remaining in this mode, check centre oven temperature settles to 80oC. (+/5oC).

SECTION 3 - SERVICING

Warning

BEFORE CARRYING OUT ANY MAINTENANCE ON THIS APPLIANCE ENSURE THE

UNIT ELECTRICITY SUPPLY IS ISOLATED.

Controls are removed as follows:

Note

When replacing wiring connections, refer to wiring diagram contained in this manual from

which it can be seen that all wires are numbered.

3.1 CONTROL PANEL

a) Undo fixings at top of panel.

b) Pull hinged panel forward.

3.2 RH SIDE PANEL

a) Open control panel.

b) Undo front edge fixings.

c) Pull panel sideways at front and push back to clear rear catches.

3.3 LH SIDE PANEL

a) Open oven doors.

b) Undo front edge fixings.

c) Pull panel sideways at front and push back to clear rear catches.

3.4 OUTER BACK PANEL

Undo fixings along perimeter and remove panel.

3.5 LOWER FRONT COVER PANEL

a) Undo fixings along lower edge.

b) Open oven doors and undo fixings along top.

c) Pull panel off.

3.6 DIN RAIL MOUNTED RELAYS

a) Remove RH side panel as detailed in Section 3.2.

b) Remove electrical terminals.

c) Pull relay away from base to replace it.

d) To replace relay base, unclip from din rail by levering lower edge catch downward.

e) Replace in reverse order.

3.7 PLC, CONTACTORS and CONNECTOR BLOCKS

a) Remove side panel.

Page 7

b) Remove electrical connections, noting positions.

c) Unclip component by levering lower edge catch downward.

d) Replace in reverse order.

3.8 COOK THERMOSTAT

a) Open control panel as detailed in Section 3.1.

b) Disconnect electrical leads.

c) Remove knob and undo fixings which secure thermostat to panel.

d) Undo capillary tube securing clip fixing.

e) Undo phial and bracket fixings from inside oven chamber.

f) Ease phial through hole in oven side panel.

g) Replace in reverse order.

3.9 HOLD THERMOSTAT

a) Remove side panel as detailed in Section 3.2.

b) It is possible to adjust hold thermostat temperature between 75 and 85oC by means of the

spindle.

To Remove:

c) Disconnect electrical leads.

d) Undo fixings which secure thermostat to inner control panel.

3.10 TIMER

a) Open control panel as detailed in Section 3.1.

b) Remove knob and undo fixings securing timer to panel.

c) Disconnect electrical leads.

d) Replace in reverse order.

3.11 BUZZER, INPUT MAINS FILTER and START/RUN RELAY

a) Remove side panel as detailed in Section 3.2.

b) Disconnect electrical leads.

c) Remove fixing which secures component to inner control panel.

d) Replace in reverse order.

3.12 INDICATOR LAMPS and SWITCHES

a) Open control panel as detailed in Section 3.1.

b) Disconnect leads from part being replaced.

c) Push component from location.

d) Replace in reverse order.

3.13 DOOR SWITCH

a) Remove bottom front panel. (See Section 3.5)

b) Undo fixings to remove switch from support bracket.

c) Disconnect electrical leads.

d) Replace in reverse order.

3.14 MOTOR UNIT

Remove unit from inside compartment as follows:

a) Remove shelves and hangers.

b) Remove fixings and withdraw fan baffle.

c) Remove fixing bolt from shaft.

d) Using a taper puller, remove fan impellor.

e) Remove fixings which secure motor to oven rear panel. Pull unit forward and rest upon

oven base.

f) Remove motor terminal wires, noting locations and withdraw assembly from chamber.

g) Remove motor by undoing fixings (one per leg in 'spider' mounting).

h) Fit replacement motor in reverse order.

Note

Page 8

Oven baffle is not symmetrical, fixings have been offset to ensure correct relocation.

3.15 OVEN LAMPS

To Replace Bulb

a) Undo lens cover fixings.

b) Undo bulb and replace.

c) Refit lens cover and ensure seal is not damaged.

To Replace Assembly

a) Remove LH outer side panel. (See Section 3.3)

b) Disconnect electrical connections.

c) Undo lens cover fixings.

d) Unclip housing from aperture.

Replace in reverse order.

3.16 CAPACITOR

a) Remove side panel.

b) Disconnect two capacitor leads at terminal block.

c) Undo fixing on capacitor base and remove unit.

d) Replace in reverse order.

3.17 ELEMENTS

a) Remove oven shelves and hangers.

b) Remove fixings and withdraw fan baffle.

c) Remove element plate and spacer bracket fixings. Pull elements forward until all

terminals are inside oven. This will also bring oven safety thermostat mounting plate forward.

d) Remove terminals taking care that wire end remains inside oven.

e) Remove element fixing screws.

f) Replace in reverse order. Take care to ensure that safety thermostat bracket is correctly

positioned.

Note

Oven baffle is not symmetrical, fixings have been offset to ensure correct relocation.

3.18 OVEN SAFETY THERMOSTAT

a) Safety thermostat can be reset by means of a thin tool under control compartment on

Right Hand side Section 3.1 & 3.2 above.

b) Press inset button on safety thermostat with thin tool to reset.

Warning

If safety thermostat has been activated and requires to be reset, this could be an indication

that additional parts are faulty.

c) To remove safety thermostat, access can be gained by removing side panel as detailed in

Section 3.1 & 3.2 above, disconnect electrical leads and undo safety stat fixing nut under

base.

d) Replace in reverse order.

3.19 OVEN DOOR SEAL REPLACEMENT

Seal is fitted to front frame using countersunk screws.

When fitting new seal, place metal strip in position, pierce holes in seal and secure to holes

in front frame.

3.20 DOOR REMOVAL

a) Remove bottom front panel. (See Section 3.5)

b) Open doors through 90 degrees and remove fixings which secure door to bottom door

bracket.

Page 9

c) Lift door up slightly, ease sideways to clear bottom bracket and withdraw from top hinge

pin.

3.21 DOOR LINKAGE SPROCKET

a) Remove door. (See Section 3.20)

b) Slacken turnbuckles to allow chain to be slipped from sprocket.

c) Push out roll pin which holds sprocket upon lower hinge pin. Push out roll pin holding

door switch cam if RH sprocket is being removed.

d) Pull up lower hinge pin and remove sprocket.

e) Replace in reverse order. Refer to door linkage adjustment section for alignment and

tensioning of components.

3.22 DOOR LINKAGE CHAIN and ROD

a) Remove bottom front panel. (See Section 3.5)

b) Slacken turnbuckle to remove tension from chains.

c) Remove spring clip from link which joins chain to turnbuckle. Push out joining link and

withdraw chain rod assembly.

d) Replace in reverse order, referring to door linkage adjustment section, door linkage

alignment section and Figures 2 and 3.

3.23 DOOR LINKAGE ADJUSTMENT and TENSIONING

Due to operational stretching of components or removal for maintenance, occasions will

arise when the door linkage mechanism will require adjustment.

The method to use is as follows:-

Push door handle until RH door makes contact with seal. The LH door should now be 12 to

15mm proud of the RH door at vertical join.(see Figure 2) If LH door is less than this

dimension, slacken both turnbuckle locknuts and rotate LH turnbuckle toward chain and the

right turnbuckle away from chain by the same amount.

Repeat procedure until desired dimension is achieved. If LH door is greater than desired

setting then above procedure should be carried out in reverse.

After doors are synchronised, the linkage should be put under tension by slightly twisting the

turnbuckles toward one other by the same small amount.

The tension should be such that no free play is available between chains and their

sprockets.

Page 10

3.24 DOOR LINKAGE ALIGNMENT

When linkage components have been disturbed during repair, the initial coarse assembly,

alignment will be achieved by positioning the chains on their sprockets as indicated in Figure

3. Doors should be in the closed position when carrying out this task.

3.25 DOOR CATCH MECHANISM

a) Open doors and remove front and rear fixings which secure top panel. Withdraw top panel

by lifting at rear to clear flue outlet cover and slide it forward. Twist rear slightly to one side to

clear locating angles at top panel front sides.

b) Unhook spring and remove nut and split pins from top of toggle plate pins.

c) Replace new component(s). Take care to re-assemble in correct order.

d) Replace top panel.

3.26 DOOR WINDOW (E7204 & E7208 ONLY)

a) Remove door as described in Section 3.20.

b) Remove all top and bottom door flange fixings plus those that secure sealing strip to side

flange.

c) Lay door down on outer surface and prise out inner lining. Window assembly may now be

removed.

d) When only replacing one single glass panel, dismantle frame by removing all fixings

around window assembly periphery.

e) Replace glass and sealing strip if necessary. Carefully re-assemble window structure.

f) Re-fit all door components in reverse order.

SECTION 4 – SPARES

Page 11

When ordering spares, please quote Model number, serial number and voltage as stated on

data plate.

Element Outer 732920019

Element Inner 732920018

Terminal Block White Nylon 531740420

Thermostat Cook 731910500

Thermostat Hold 732920055

Thermostat Oven Safety Klixon 535420015

Thermostat Oven Safety EGO 732920130

Buzzer White 535500035

Buzzer Black 734510130

Cooling Fan 735400360

Door Seal E7204 531930526

Door Seal E7208 532930043

Door Seal E7211 531940099

Neon Red 730962010

Neon Amber 730962040

Cool/Heat Switch 732920047

Cook/Hold Switch 732920051

Fan Switch 732910481

Timer c/w Knob 732910495

Oven Light Switch 535500037

Control Knob 732920048

Oven Fan 732920008

Fuse 8A 732920068

P.L.C Controller 732920059

Contactor MC22B 731350070

Relay-Fan 732920062

Relay Single Pole 535770128

Realy Start/Run 732920066

Terminal Block Assembly 732920069

Filter Suppression 732920096

Microswitch Door 531925260

Oven Lamp Assy 732910390

Oven Lamp 732910350

Page 12

Page 13

Loading...

Loading...