Page 1

E3830 and E3860

DOMINATORPLUS Fryers

INSTALLATION and

SERVICING INSTRUCTIONS

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions

and National Regulations in force at the time of installation. Particular attention MUST be paid to:

BS7671 IEE Wiring Regulations

Electricity at Work Regulations

Health And Safety At Work Act

Fire Precautions Act

This appliance has been CE-marked on the basis of compliance with the Low Voltage and EMC

Directives for the voltages stated on the data plate.

WARNING: THIS APPLIANCE MUST BE EARTHED.

On completion of the installation, these instructions should be left with the Engineer-in-Charge for

reference during servicing. Further to this, The Users Instructions should be handed over to the User,

having had a demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING

AND COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED

PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a maintenance

contract be arranged with SERVICELINE. Visits may then be made at agreed intervals to carry out

adjustments and repairs. A quotation will be given upon request to the contact numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement

parts in a safe manner, via a licenced waste handler.

Units are designed to be dismantled easily and recycling of all

material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT

Phone: 01438 363 000 Fax: 01438 369 900

T100774 Ref. 5

Page 2

IMPORTANT INFORMATION

Warranty Policy Shortlist

Warranty does not cover :-

• Correcting faults caused by incorrect installation of a product.

• Where an engineer cannot gain access to a site or a product.

• Repeat commission visits.

• Replacement of any parts where damage has been caused by misuse.

• Engineer waiting time will be chargeable.

• Routine maintenance and cleaning.

• Gas conversions i.e. Natural to Propane gas.

• Descaling of water products and cleaning of water sensors where softeners/ conditioners are not fitted,

or are fitted and not maintained.

• Blocked drains

• Independent steam generation systems.

• Gas, water and electrical supply external to unit.

• Light bulbs

• Re-installing vacuum in kettle jackets.

• Replacement of grill burner ceramics when damage has been clearly caused by misuse.

• Where an engineer finds no fault with a product that has been reported faulty.

• Re-setting or adjustment of thermostats when unit is operating to specification.

• Cleaning and unblocking of fryer filter systems due to customer misuse.

• Lubrication and adjustment of door catches.

• Cleaning and Maintenance

• Cleaning of burner jets

• Poor combustion caused by lack of cleaning

• Lubrication of moving parts

• Lubrication of gas cocks

• Cleaning/adjustment of pilots

• Correction of gas pressure to appliance.

• Renewing of electric cable ends.

• Replacement of fuses

• Corrosion caused by use of chemical cleaners.

Page 3

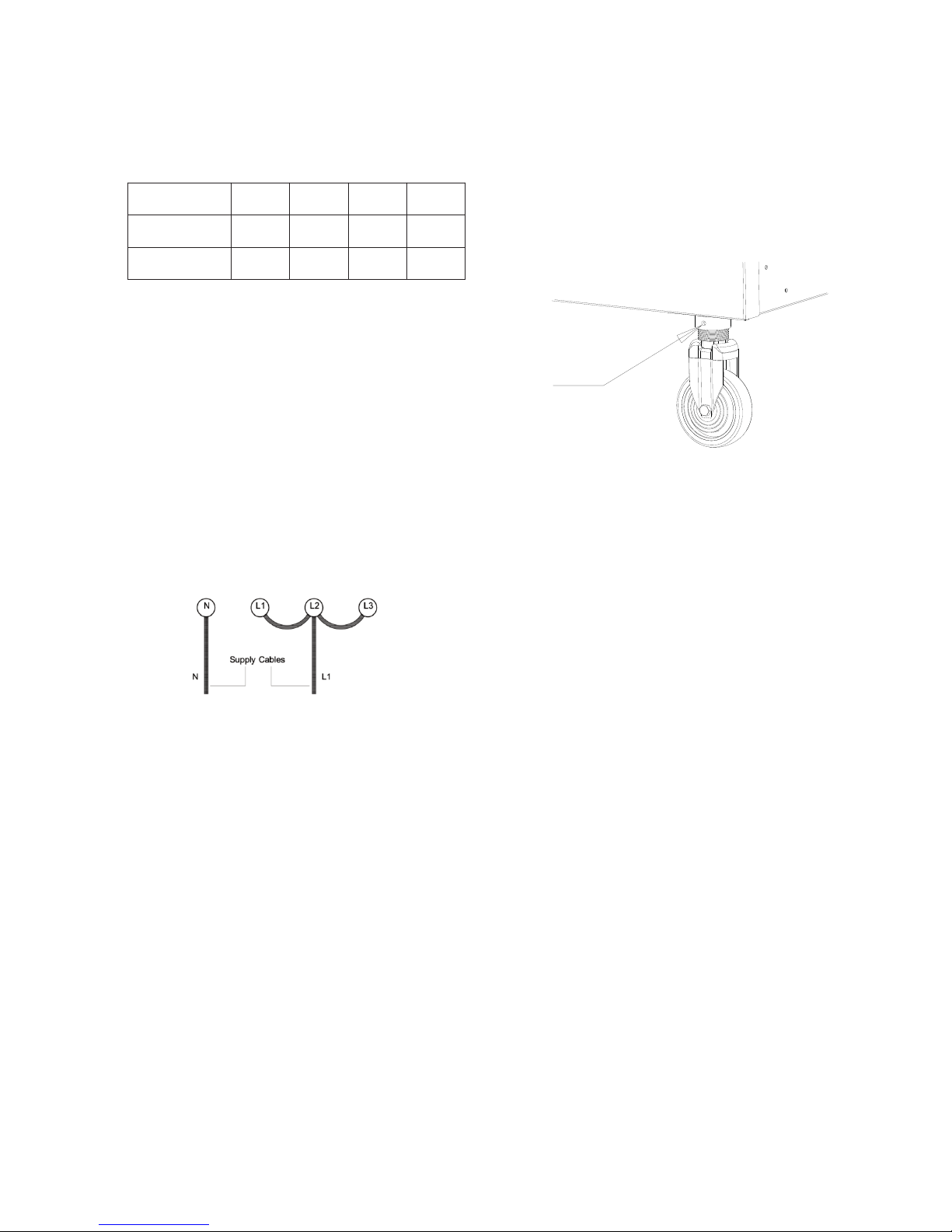

Castors

Undo grub screw and use a spanner to adjust the castor

height. Turn clockwise to raise level and anti-clockwise

to lower.

Secure grub screw when task is completed.

2.2 CONNECTION TO THE ELECTRICAL SUPPLY

To gain access to terminals, proceed as follows:-

Remove fixings at unit rear to remove cover and access

electrical connections.

Undo cable gland.

Feed cable through cable gland into electrical box.

Connect leads to respective terminals.

Tighten cable gland.

Replace cover.

If single phase connection is required, refer to Section 1.3

for details.

2.3 COMMISSIONING

Fill pan with oil to mark on element guard

(i.e. approximately 20 litres for E3830 model and 40 litres

for E3860 model) and switch on at isolator switch.

Turn thermostat to maximum setting and check that it

operates at the correct temperature of 190°C.

The importance of never switching on the elements

unless they are covered by oil or water must be stressed.

DO NOT USE SOLID FAT.

2.4 INSTRUCTION TO USER

After installing and commissioning appliance, hand user

instructions to user or purchaser.

Ensure that person(s) responsible is (are) made familiar

with use and maintenance of unit.

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

1.2 SITING

Before connecting appliance to electricity supply, it must

be correctly positioned and levelled. Levelling is effected

by turning the lower area of the adjustable legs.

If desired, feet that allow floor-fixing may be specified at

time of order.

1.3 ELECTRICAL CONNECTION

The unit is designed for use on AC supplies only and

terminals are normally arranged for either 2 phase

operation (E3830 model) or 3 phase (E3860 model).

If single phase supply has been specified, a bridging link

is provided with the appliance and should be connected

as detailed below.

Cable entry is located at appliance rear in the form of a

cable gland.

A suitably rated isolating switch with contact separation of

at least 3mm in all poles must be installed. All wiring must

be executed in accordance with regulations listed on title

page of this document.

Warning - This appliance must be earthed.

1.4 ELECTRICAL RATINGS

The electrical rating is stated on appliance data plate.

SECTION 2 ASSEMBLY and COMMISSIONING

2.1 ASSEMBLY

The appliance is supplied complete and ready to be

connected to the mains supply.

Position unit in desired location and level it. Turn lower

section of each leg clockwise to raise corresponding

corner height or anti-clockwise to lower it.

Model

Width

(mm)

Depth

(mm)

Height

(mm)

Weight

(kg)

E3830 Fryer

300 770 890 45

E3860 Fryer

600 770 890 73

SECTION 1 - INSTALLATION

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER.

Grub

screw

Page 4

SECTION 3 - SERVICING and

MAINTENANCE

BEFORE ATTEMPTING ANY MAINTENANCE TASK,

ISOLATE THE APPLIANCE AT THE MAIN SUPPLY.

TAKE STEPS TO ENSURE THAT IT MAY NOT BE

INADVERTENTLY SWITCHED ON.

3.1 ELECTRICAL CONTROL GEAR

The terminals are located at rear of unit. The contactor is

contained within box at front.

To gain access, open door and remove cover panel

behind.

The control thermostat and neon lamps are mounted on

the facia panel, which is secured by four fixings.

3.2 NEON INDICATOR LAMPS

These must be replaced by new lamps in event of failure.

To replace a faulty lamp, first remove facia panel and pull

off push-on terminals. Remove lamp by undoing fixing nut

at rear.

3.3 THERMOSTATS

The fryer has two thermostats.

The adjustable control thermostat is mounted upon

control panel.

The safety thermostat is located within the element box.

It has a fixed setting and manual re-set button at rear of

element box. In the event of control thermostat failure and

resultant overheating of frying medium, safety

thermostat will trip supply to elements before oil

temperature becomes dangerous.

To restore circuit having rectified the fault,

it is necessary to press the re-set button. This is situated

within the turret which projects through element box rear.

The oil must be allowed to cool to enable safety

thermostat to be re-set.

A defective safety or control thermostat cannot be

repaired and must be replaced. The capillary tubes pass

through pan wall and are sealed with small glands which

must not be overtightened. The phial must be fixed in

position within pan before tightening gland. The phial tip

should protrude from protective tube by 33mm.

Thermostat capillary tube must be covered with sleeve

insulation. Safety stat phial should be located centrally

within element clip.

3.4 CONTACTOR

This should require little or no maintenance under normal

circumstances. After long service, the burner contacts

may become pitted and at that point, new contacts should

be fitted.

3.5 ELEMENTS

These are individually replaceable. Access to terminals

and fixing nuts is gained upon removing element box

cover. When fitting a new element, ensure that sealing

gasket is fitted and tighten fixing nut firmly, preferably with

the aid of a tubular box spanner or socket.

When re-fitting element box cover, check condition of oil

resistant gasket. Do not use excessive force when

securing cover as this may deform it and allow oil to enter

box.

3.6 CLEANLINESS

To maintain maximum performance, the pan must be kept

clean. Periodically, oil must be drained off and the pan

should be filled with water and detergent. Boil up contents

and drain whilst still hot before flushing out with clean

water. Thoroughly dry pan and all fittings before re-filling

with oil. The elements can be lifted and hinged backward

to gain full access to all surfaces of pan and elements.

3.7 TILT SWITCH

Located in element terminal box, this component should

require no maintenance.

SECTION 4 - SPARES

When ordering spares, quote the unit type and serial

number. This information will be found on data plate

located on cover panel behind door.

An identity label is also provided on front frame.

Page 5

E3830 WIRING DIAGRAM

Page 6

E3860 WIRING DIAGRAM

(4 Element Version)

Page 7

MAINS TERMINAL BLOCK

25

24

23

22 27

16

3

2

1

19

252423 2722

16

321

19

26

AMBER NEON

1521

RED NEON

17

21

OPERATING STAT

18 20

CONTACTOR

A1 A2

7

9

810

15

17

28

18

11

TERMINAL BLOCK

28

14

TILT SWITCH

SAFETY STAT

2014

ELEMENT

9

ELEMENT

8

ELEMENT

7

ELEMENT BOX

ELEMENT

10

ELEMENT

11 26

E3860 WIRING DIAGRAM

(5 Element Version)

Page 8

H

H

L1 L2

N

1

3

5

1314

6

4

2

1

2

CONTACTOR

IMO MC-14-S-10

7

8

RH ELEMENT

5kW @ 230V

14

13

5

RED NEON

12, 15

A1A2

10

SAFETY STAT

(TRIP POINT

230 ° C)

OPERATING STAT

(0 °

C - 190

° C)

9 16 11

TILT SWITCH

(LOWERED POSITION)

18

6 15

AMBER NEON

1

2

3

4

5

6

7

5

2

1

9

16 11

6, 18

12

15

10

13

147

8

LH ELEMENT

5kW @ 230V

1

2

6

7

354

17

ELEMENT

BOX

E3830 CIRCUIT DIAGRAM

Page 9

H

H

H

H

ELEMENT

BOX

27

4

5

3A

2A

1

7

8, 15

25, 26

16, 23, 24

16, 23, 24

16, 17, 21

16, 17

28

1420

3

1

19

AMBER NEON

21

15

28

TILT SWITCH

(LOWERED POSITION)

142018

OPERATING STAT

(0 °

C - 190

° C)

SAFETY STAT

(TRIP POINT

230 ° C)

16, 17

A1 A2

17, 21

RED NEON

19

23

26

7

8

CONTACTOR

IMO MC-24-S-00

1

3

1

3

5 6

4

2

N

L2L1 L3

2

2, 18

2510

249

9, 10

16, 23, 24

25, 26

ELEMENT POSITIONS ARE WHEN VIEWED FROM FRONT OF APPLIANCE

H1 - OUTSIDE LH ELEMENT ( 5kW @ 230V )

H2 - CENTRE LH ELEMENT ( 5kW @ 230V )

H3 - CENTRE RH ELEMENT ( 5kW @ 230V )

H4 - OUTSIDE LH ELEMENT ( 5kW @ 230V )

1

2

3

4

2B

3B

E3860 CIRCUIT DIAGRAM

(4 Element Version)

Page 10

H

H

H

H

H

ELEMENT

BOX

27

7, 8

10, 11

25

23

16

26

15, 28

1420

3

1

19

AMBER NEON

1521

28

TILT SWITCH

(LOWERED POSITION)

142018

OPERATING STAT

(0

°

C - 190

°

C)

SAFETY STAT

(TRIP POINT

230

°

C)

16, 17

A1 A2

17, 21

RED NEON

19

23

25

8

10

CONTACTOR

IMO MC-24-S-00

1

3

1

3

5 6

4

2

N

L2L1 L3

2

2, 18

2611

2499 24

ELEMENT POSITIONS ARE WHEN VIEWED FROM FRONT OF APPLIANCE

H1 - OUTSIDE LH ELEMENT ( 3.65kW @ 230V )

H2 - INSIDE LH ELEMENT ( 3.65kW @ 230V )

H3 - CENTRE ELEMENT ( 3.65kW @ 230V )

H4 - INSIDE RH ELEMENT ( 3.65kW @ 230V )

H5 - OUTSIDE RH ELEMENT ( 3.65kW @ 230V )

2

1

3

4

17

17

227

5

22

E3860 CIRCUIT DIAGRAM

(5 Element Version)

Loading...

Loading...