Page 1

T100839 Rev.8

DATE PURCHASED:

MODEL NUMBER:

SERIAL NUMBER:

DEALER:

SERVICE PROVIDER:

USERS, INSTALLATION AND SERVICING INSTRUCTIONS

ELECTRIC BRATT PAN

E3800

Page 2

SYMBOLS

PLEASE READ THIS MANUAL

This manual should be read carefully before operating, installing

or servicing the appliance.

WARNING!

Please pay particular attention to sections of the manual which

has this Warning symbol. If ignored, it may result in personal

injury or damage to the appliance.

Dear Customer,

Thank you for choosing Falcon Foodservice Equipment.

This manual can be downloaded from www.falconfoodservice.com where you

also can see the full range of our products and latest news.

IMPORTANT: Please keep this manual for future reference.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of appliance life, dispose of appliance and any replacement parts in a safe

manner, via a licensed waste handler. Appliances are designed to be dismantled

easily and recycling of all material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

2

Page 3

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT

Phone: 01438 363 000

CONTENTS

INTRODUCTION .................................................................................................................................. 4

OPERATION ......................................................................................................................................... 6

Controls .............................................................................................................................................. 7

Using the Bratt Pan .......................................................................................................................... 7

GETTING THE MOST OUT OF THE APPLIANCE ........................................................................ 8

CLEANING AND MAINTENANCE .................................................................................................... 9

SPECIFICATION .................................................................................................................................. 9

Model Number covered in this group of products ..................................................................... 10

Technical Data ................................................................................................................................ 10

DIMENSIONS / ELECTRICAL CONNECTION LOCATIONS ..................................................... 10

INSTALLATION .................................................................................................................................. 10

Unpacking ........................................................................................................................................ 11

Siting / Clearances ......................................................................................................................... 11

Electric Supply & Connection ....................................................................................................... 12

Water Supply................................................................................................................................... 12

Assembly ......................................................................................................................................... 12

Commissioning ............................................................................................................................... 13

SERVICING......................................................................................................................................... 13

Wiring Diagram(s) .......................................................................................................................... 20

FAULT FINDING ................................................................................................................................ 20

SPARE PARTS................................................................................................................................... 23

SERVICE INFORMATION ................................................................................................................ 24

3

Page 4

INTRODUCTION

This appliance has been CE-marked on the basis of compliance with

the Low Voltage and EMC Directives for the voltages stated on the

data plate as shown below:

IMPORTANT!

4

Page 5

It is most important that these instructions be consulted before

operating, installing and commissioning this appliance. Failure to

comply with the specified procedures may result in damage or the

need for a service call.

The installer must ensure that the installation of the appliance is in conformity with

these instructions and National Regulations in force at the time of installation.

Particular attention MUST be paid to: BS7671 IEE Wiring Regulations, Electricity

at Work Regulations, Health And Safety At Work Act, Fire Precautions Act.

TO PREVENT SHOCKS, ALL APPLIANCES MUST BE EARTHED.

This equipment is ONLY FOR PROFESSIONAL USE, and shall be operated by

QUALIFIED persons. It is the responsibility of the Supervisor or equivalent to ensure

that users wear SUITABLE PROTECTIVE CLOTHING and to draw attention to the

fact that, some parts will, by necessity, become VERY HOT and will cause burns if

touched accidentally.

Upon receipt of the Instructions manual, the installer must instruct the responsible

person(s) of the correct operation and maintenance of the appliance.

Regular servicing by a qualified person is recommended to ensure the continued

safe and efficient performance of the appliance.

5

Page 6

OPERATION

6

Page 7

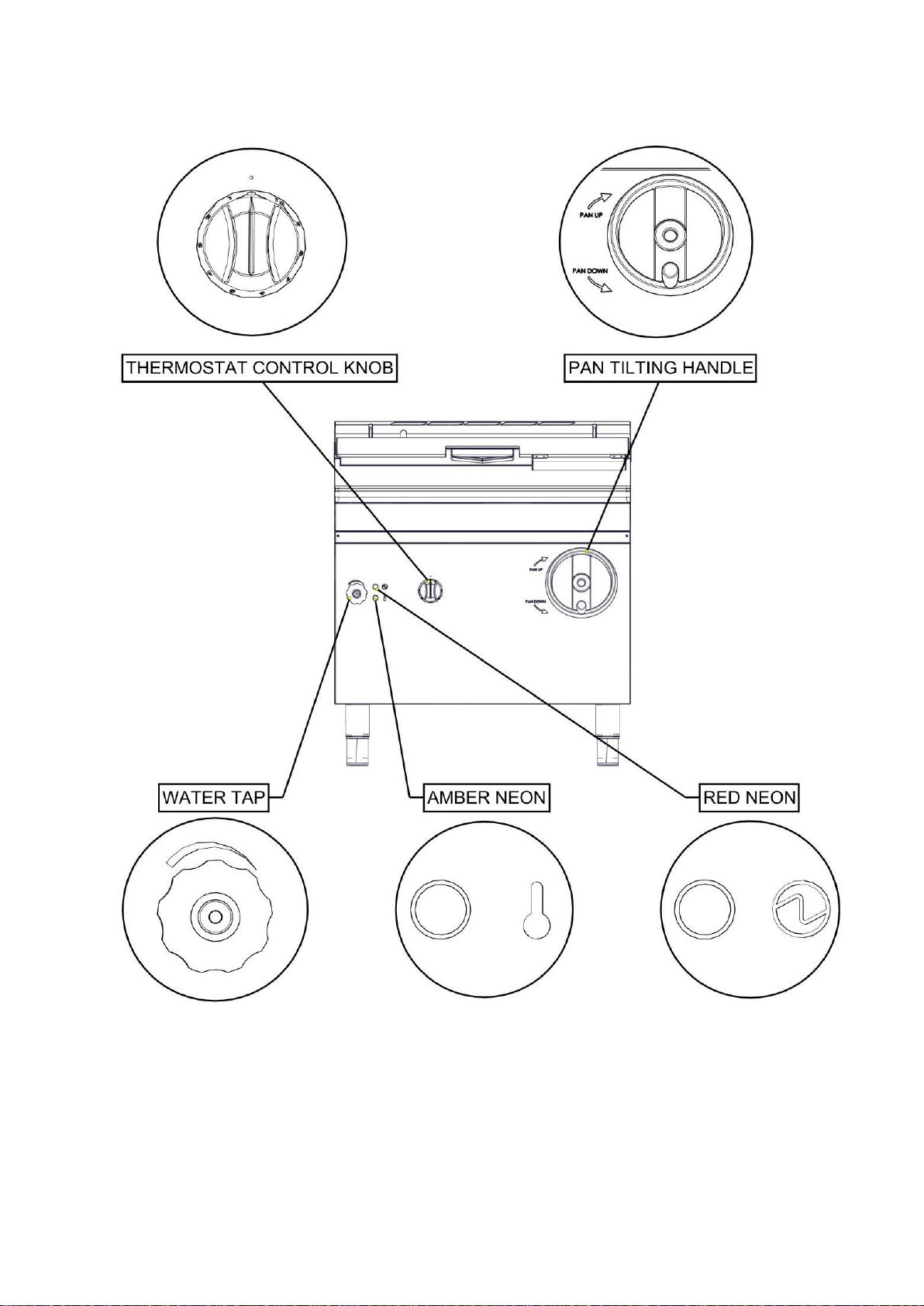

Controls

• OFF Position

Variable

temperature

setting

100°C - 300°C.

Turn handle

to lift pan up

and down.

Turn tap to turn

water ON and

OFF.

Indicates that

the heating

element is ON.

Indicates when

mains electricity

is ON.

Using the Bratt Pan

1. Ensure pan is fully lowered using the pan tilting handle.

7

Page 8

2. Turn mains electricity ON. The Red neon will illuminate.

3. Turn thermostat control knob to desired temperature. Amber neon will

illuminate.

4. When the desired temperature is reached, the Amber neon will go OFF.

5. If cooking a liquid based food, ensure it does not go over the MAX mark as

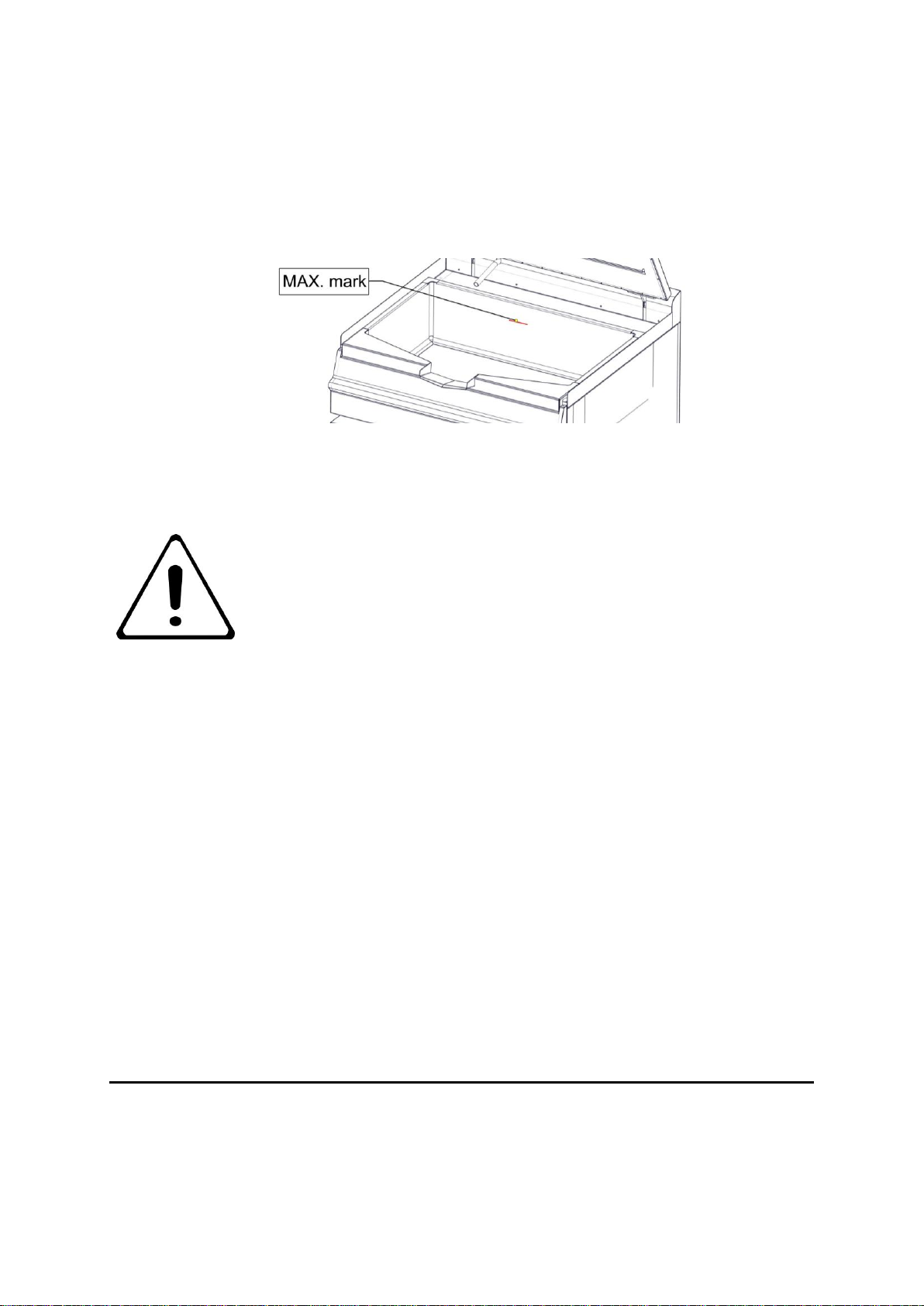

shown below.

6. Turn ON the water tap to top up if necessary.

7. To empty the contents of the pan, first ensure the thermostat control knob is

turned OFF. Lift the pan with the pan tilting handle and the content will start

pouring out of the spout.

DO NOT DEEP FRY WITH THIS APPLIANCE.

GETTING THE MOST OUT OF THE APPLIANCE

SAVE ENERGY AND RUNNING COST BY TURNING OFF THE APPLIANCE WHEN NOT

IN USE.

8

Page 9

Griddling

Note that the centre of the pan is hotter than the edges when griddling.

Simmering and Stewing

Lid can be left slightly ajar if a gentle simmer is desired. As mentioned in griddling, the centre

of the pan is hotter so the content may tend to stick to the pan more around the middle.

CLEANING AND MAINTENANCE

All surfaces are easier to clean if spillage is removed before it becomes burnt on and if

appliance is cleaned daily.

CAUTION: Failure due to lack of proper cleaning is not covered by

warranty.

BEFORE ANY CLEANING IS UNDERTAKEN, ENSURE ISOLATING COCK IS TURNED

OFF AND CANNOT BE INADVERTENTLY TURNED ON.

WARNING – DO NOT ATTEMPT TO CLEAN THIS APPLIANCE WITH A JET OF WATER

OR STEAM CLEAN.

Clean pan as soon as possible after use with hot water and detergent. Soap filled steel wool

pads may be used to remove stubborn deposits. After cleaning, empty water from pan using

the pan tilting handle to lift the pan.

Do not use proprietary cleaners, especially those with a high caustic content on appliance

surfaces. This is particularly important when appliance is hot. Such cleaners can cause

serious damage or discolouration and only a soap or detergent solution should be used.

.

SPECIFICATION

9

Page 10

Model Number covered in this group of products

E3800

7.7

L1 11.2

L2 11.2

L3 11.2

TECHNICAL DATA - TABLE A

MODEL NUMBER

Current (A) at

230V

Total Power (kW)

E3800 800mm wide manual lift electric Bratt Pan

Technical Data

DIMENSIONS / ELECTRICAL CONNECTION LOCATIONS

INSTALLATION

10

Page 11

Unpacking

150mm from any combustible wall.

Well lit draught free area.

Level, Fireproof surface.

150mm

150mm

1. Remove all packaging from the appliance.

2. Remove all plastic coating that is on the appliance by peeling them off.

3. Ensure there are no missing parts to the appliance.

4. Ensure there are no damages to the appliance.

5. Fit Lid handle using fixings supplied, and locate water inlet pipe in position in the rear

flue at the left hand side.

Siting / Clearances

CAUTION: If suiting, the necessary clearances to any combustible wall

MUST BE the largest figure given for individual appliances instructions.

If a Gully is used in the premises, ensure it covers

the highlighted area.

11

Page 12

Electric Supply & Connection

Phase 1

Phase 2

Phase 3

Neutral

Earth

BROWN

BLACK

GREY

BLUE

GREEN/YELLOW

The location of the electrical connection is shown in “Dimensions/Electrical Connection

Location” Chapter. The appliance is suitable for AC supplies only. The standard terminal

arrangement is: 3 phase & neutral 5 wire connection (400V 3N~)

IF THE CABLE IS DAMAGED, IT MUST BE REPLACED BY A SUITABLY

QUALIFIED PERSON. A suitably rated isolating switch with contact

separation of at least 3mm in all poles must be installed and wiring executed

in accordance with relevant regulations. Access to mains terminal block is

gained by removing the control panel.

Water Supply

Connection to the water supply is via a ½” BSPP male threaded fitting at rear.

A threaded bush is supplied with the appliance to increase the size to ¾” (If required).

Water supply pressure should not exceed 500kPa (5 bar).

Assembly

1. Position appliance and carefully level using feet adjusters as shown below.

2. Appliances with castors should be fitted with accessories supplied according to

separate instructions provided.

3. Connect appliance to electric and water supply as stated in the previous section.

12

Page 13

Commissioning

NOTE: Prior to operation, ensure that ALL packing material has been removed. For

instructions on how to use the appliance, see ‘Operation’ chapter. For relevant figures,

please see ‘Technical Data’.

1. Turn appliance on and ensure Red Neon illuminates.

2. Turn water tap on and ensure it is working correctly without any leakage.

3. Empty water using the pan tilting handle to lift the pan up.

4. Lower the pan and turn thermostat control knob to 200°C. Ensure Amber neon

illuminates.

5. Wait till Amber neon turns OFF and measure the temperature at the middle of the

pan. Ensure it reaches around 220°C (±10°C).

6. Turn OFF appliance. Red neon should turn OFF.

If the appliance does not operate correctly please refer to the ‘Servicing’ section and rectify

the problem.

ENSURE THAT KITCHEN PERSONNEL UNDERSTAND THE CORRECT

OPERATION AND CLEANING OF APPLIANCE AND THAT SUCH

INDIVIDUALS ARE AWARE OF THE MAINS ISOLATING SWITCH

LOCATION.

PLEASE FILL OUT THE INFORMATION TABLE ON THE FRONT COVER

AFTER COMMISSIONING.

SERVICING

BEFORE ATTEMPTING ANY SERVICING, ENSURE ISOLATING COCK

IS TURNED OFF AND CANNOT BE INADVERTENTLY TURNED ON.

AFTER ANY MAINTENANCE TASK, CHECK APPLIANCE TO ENSURE

THAT IT PERFORMS CORRECTLY AND CARRY OUT ANY

NECESSARY ADJUSTMENTS AS DETAILED IN ‘COMMISSIONING’.

Symbols on drawings:

+ denotes a positive head screw requires to be removed.

– denotes a flat head screw requires to be removes.

denotes a nut or a hex head bolt requires to be removed.

13

Page 14

REMOVAL OF FRONT FASCIA / ACCESS TO ELECTRICS BOX

1 2 3

4

5 6

To gain access to the electrics box, first the front fascia must be removed.

14

Page 15

7

When removing the front fascia, care should be taken not to damage

the neon cables.

NEONS

Neons are attached to the front fascia. To replace them, remove the connections and the

nut.

15

Page 16

OPERTAING THERMOSTAT

1

2

The operating thermostat is located on the cover of the electrics box. To replace, remove the

clip that secures the thermostat capillary. Pull out thermostat phial then remove the two

screws on the cover of the electrics box..

When replacing the thermostat phial back into the hole, ensure that the

phial is pushed right back into the tube and reattach the Vidaflex.

16

Page 17

SAFETY THERMOSTAT

Safety thermostat is located on the left side of the electrics box. Push the button protruding

out from the bottom of the box to reset. To replace, remove the same clip that’s shown in the

operating thermostat. Pull out phial then remove the two screws.

When replacing the thermostat phial back into the hole, ensure that the phial is pushed right

back into the tube and reattach the Vidaflex.

TILT SWITCH

Tilt switch is located beside the electrics box.

17

Page 18

CONTACTOR

The contactors are located in the electrics box. To replace, lever it out by

using a flat headed screwdriver.

ELEMENTS

Lift Pan fully up to get access to the Element Box. To gain access to just the element

connections, remove the element connection cover a shown below.

18

Page 19

To replace the elements, first the element box must be removed as shown.

When replacing the bottom two elements, the thermostat tube must be removed as well.

They are all attached by hex nuts.

When replacing the Elements, ensure it is secured tightly to the pan base.

19

Page 20

Ensure Thermostat Tube is attached tightly to the Elements.

Wiring Diagram – 400V 3N~ Appliance

20

Page 21

21

Page 22

Wiring Diagram – 440V 3N~ Appliance

22

Page 23

FAULT FINDING

FAULT

POSSIBLE CAUSES

REMEDY

Red and Amber neon not

lighting.

No power from the supply.

Restore supply.

Blown fuse.

Replace fuse.

Faulty mains supply cord.

Replace supply cord.

Faulty Neons.

Replace Neons.

Amber neon not lighting but

Red neon is on.

Safety Thermostat tripped or

faulty.

Reset Thermostat. If faulty,

replace.

Operating Thermostat.

Check connections. If faulty,

replace.

Amber Neon.

Contactors.

Slow/Poor heating.

Operating Thermostat out of

calibration.

Replace Operating

thermostat.

Faulty Elements or

connections.

Check each connection to

the three elements. If any of

them are faulty, replace.

MAIN SPARES LIST

PART NAME

SPARES NUMBER

Red Neon

730962010

Amber Neon

730962040

Operating Thermostat

731910500 (S/S) 732150020 (DX)

Safety Thermostat

732150006

Tilt Switch

531750540

Contactor

734310440

Element

732150001

1A anti surge fuse

535420014

SPARE PARTS

When ordering spare parts please quote the following;

Appliance type

Serial number

This information will be found on data plate attached to base plate.

23

Page 24

SERVICE INFORMATION

In order to obtain maximum performance from this appliance we would recommend that a

maintenance contract be arranged with SERVICELINE. Visits may then be made at agreed

intervals to carry out adjustments and repairs. A quotation will be given upon request to the

contact number below:

SERVICELINE CONTACT:

Phone: 01438 363 000

Warranty Policy Shortlist

Warranty does not cover the following:-

• Correcting faults caused by incorrect installation of a product.

• Where an engineer cannot gain access to a site or a product.

• Repeat commission visits.

• Replacement of any parts where damage has been caused by misuse.

• Engineer waiting time will be chargeable.

• Routine maintenance and cleaning.

• Gas conversions i.e. Natural to Propane gas.

• Descaling of water products and cleaning of water sensors where softeners/ conditioners

are not fitted, or are fitted and not maintained.

• Blocked drains

• Independent steam generation systems.

• Gas, water and electrical supply external to appliance.

• Light bulbs

• Re-installing vacuum in kettle jackets.

• Replacement of grill burner ceramics when damage has been clearly caused by misuse.

• Where an engineer finds no fault with a product that has been reported faulty.

24

Page 25

• Re-setting or adjustment of thermostats when appliance is operating to specification.

• Cleaning and unblocking of fryer filter systems due to customer misuse.

• Lubrication and adjustment of door catches.

• Cleaning and Maintenance

• Cleaning of burner jets

• Poor combustion caused by lack of cleaning

• Lubrication of moving parts

• Lubrication of gas cocks

• Cleaning/adjustment of pilots

• Correction of gas pressure to appliance.

• Renewing of electric cable ends.

• Replacement of fuses

• Corrosion caused by use of chemical cleaners.

25

Loading...

Loading...