Page 1

T100644 Ref. 3

E350/38 and E350/39

COUNTER TOP FRYERS

INSTALLATION and

SERVICING INSTRUCTIONS

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions and

National Regulations in force at the time of installation. Particular attention MUST be paid to -

BS7671 IEE Wiring Regulations

Health And Safety At Work Act.

Electricity At Work Regulations.

Fire Precautions Act

This appliance has been CE-marked on the basis of compliance with the Low Voltage and EMC Directives for

the voltages stated on the unit data plate.

WARNING - THIS APPLIANCE MUST BE EARTHED

On completion of the installation these instructions should be left with the Engineer-in-Charge for reference

during servicing. Further to this, The Users Instructions should be handed over to the User, having had a

demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY

RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance Contract be

arranged with SERVICELINE. Visits may then be made at agreed intervals to carry out adjustments and

repairs. A quotation will be given upon request to the contact numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts

in a safe manner, via a licenced waste handler.

Units are designed to be dismantled easily and recycling of all

material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT -

PHONE - 01438 363 000 FAX - 01438 369 900

Page 2

Warranty Policy Shortlist

Warranty does not cover :-

Correcting faults caused by incorrect installation of a product.

Where an engineer cannot gain access to a site or a product.

Repeat commission visits.

Replacement of any parts where damage has been caused by misuse.

Engineer waiting time will be chargeable.

Routine maintenance and cleaning.

Gas conversions i.e. Natural to Propane gas.

Descaling of wat er products and cleaning of water sensors wher e softeners/conditioners are not fitted, or are

fitted and not maintained.

Blocked drains.

Independent steam generation systems.

Gas, water and electrical supply external to unit.

Light bulbs.

Re-installing vacuum in kettle jackets.

Replacement of grill burner ceramics when damage has been clearly caused by misuse.

Where an engineer finds no fault with a product that has been reported faulty.

Re-setting or adjustment of thermostats when unit is operating to specification.

Cleaning and unblocking of fryer filter systems due to customer misuse.

Lubrication and adjustment of door catches.

Cleaning and Maintenance

Cleaning of burner jets

Poor combustion caused by lack of cleaning

Lubrication of moving parts

Lubrication of gas cocks

Cleaning/adjustment of pilots

Correction of gas pressure to appliance.

Renewing of electric cable ends.

Replacement of fuses

Corrosion caused by use of chemical cleaners.

Page 3

SECTION 1 - INSTALLATION

1.2 SITING

The appliance must be installed on a firm counter or

table or alternatively on a special purpose built stand

supplied by Falcon. The unit may be installed to

within 25mm of any wall or partition at the rear and

sides.

A vertical clearance of 900mm between the top of the

unit and any overlying combustible surface must be

provided and Fire Regulations must be complied with.

1.3 ELECTRICAL SUPPLY

The fryers are equipped with a single cable entry

situated at the rear, suitable for a 20mm conduit

connection.

A suitably rated isolating switch with contact

separation of at least 3mm in all poles must be

installed and all wiring executed in accordance with

the regulations listed on the title page of this man ual.

THESE APPLIANCES MUST BE EARTHED.

An earth terminal is located within the terminal

compartment for this purpose.

1.4 ELECTRICAL RATINGS

The fryers are for use on AC supplies only. Either 3

phase/ 4 wire or single phase supplies can be used.

The electrical loadings are stated on the appliance

data plate.

SECTION 2 - ASSEMBLY and

COMMISSIONING

2.1 ASSEMBLY

a) Remove feet from bag and screw into locations on

unit base prior to positioning.

b) Position appliance and carefully level it. Use feet

adjusters when mounting on a counter or table.

To mount a unit on purpose built stand, refer to

instructions supplied with stand.

c) The appliance is supplied complete and ready to

connect to the mains supply.

2.2 CONNECTION TO THE ELECTRICAL SUPPLY

To gain access to terminals proceed as follows:

Remove knob at drain valve lever end. Use a 6mm

spanner on lever and a 10mm spanner on knob.

Remove two fixings in upper flange panel, i.e. below

front hob.

Move panel slightly forward at top until it clears hob.

Lift panel slightly upward thus releasing lower fixing

and remove panel.

Note

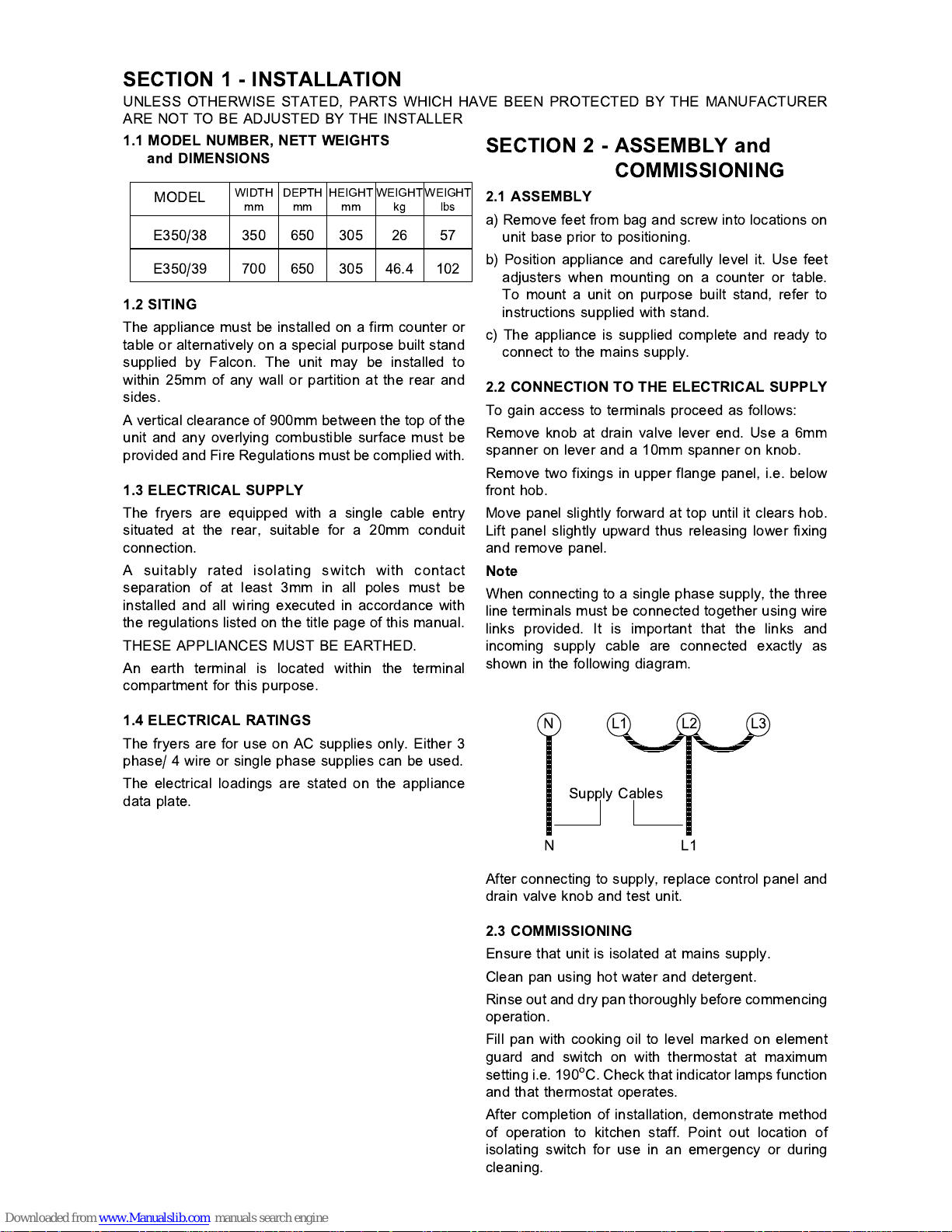

When connecting to a single phase supply, the three

line terminals must be connected together using wire

links provided. It is important that the links and

incoming supply cable are connected exactly as

shown in the following diagram.

After connecting to supply, replace control panel and

drain valve knob and test unit.

2.3 COMMISSIONING

Ensure that unit is isolated at mains supply.

Clean pan using hot water and detergent.

Rinse out and dry pan thoroughly before commencing

operation.

Fill pan with cooking oil to level marked on element

guard and switch on with thermostat at maximum

setting i.e. 190

o

C. Check that indicator lamps function

and that thermostat operates.

After completion of installation, demonstrate method

of operation to kitchen staff. Point out location of

isolating switch for use in an emergency or during

cleaning.

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL

WIDTHmmDEPTHmmHEIGHTmmWEIGHTkgWEIGHT

lbs

E350/38 350 650 305 26 57

E350/39 700 650 305 46.4 102

1.1 MODEL NUMBER, NETT WEIGHTS

and DIMENSIONS

NL1L2L3

Supply Cables

NL1

Page 4

SECTION 3 - SERVICING

BEFORE ATTEMPTING ANY MAINTENANCE,

ISOLATE THE APPLIANCE AT THE MAIN SWITCH

AND TAKE STEPS TO ENSURE THAT IT IS NOT

INADVERTENTLY SWITCHED ON.

3.1 CONTROL PANEL - TO REMOVE

a) Drain pan by inserting drain pipe over a suitable

receptacle then pull out drain lever and move it to

the right.

b) Remove knob at drain valve lever end using a 6mm

spanner on lever and a 10mm spanner on knob.

c) Remove two screws in upper flange of facia panel

i.e. below front hob.

d) Move panel slightly forward at top until clear of hob

then lift panel slightly upward thus releasing lower

fixing and to remove panel.

3.2 CONTROL THERMOSTAT

and INDICATOR LAMPS

If these prove faulty they are not normally repairable

and must be replaced using the following procedures:

3.2.1 Control Thermostat

In order to replace control thermostat, it will be

necessary to remove unit from stand or table location.

Adopt the following procedure :

a) Drain pan(s).

b) Remove control panel as detailed in Section 3.1.

c) Note positions and remove wires.

d) Using a 'stubby' pozi screwdriver, remove

thermostat from control panel.

e) Disconnect supply connections and remove fryer

from location to enable it to be turned on its side

later.

f) Remove element as detailed in Section 3.3.

g) Remove cover plate from element hinge block

through which thermostat capillary tube passes.

Manoeuvre tube and phial through moving hinge

tube.

h) From front, remove two fixings which secure base

plate and remove plate.

j) Turn unit on to its side. Feed capillary tube and

phial through hole in base of hinge block and

remove thermostat.

k) Replace in reverse order. Take care that capillary

tube is well clear of element terminals.

m) Replace elements (see Section 3.3). Also replace

base and control panels.

n) Fill pan with oil and heat it up.

Carry out installation tests.

Note

When replacing a cotrol thermostat, fit existing

insulating sleeving over capillary tubing. Ensure that

no portion of tubing is exposed to possible contact

with live parts. Coil excess tube by wrapping it around

a suitable mandrel of approximately 25mm diameter.

3.2.2 Indicator Lamps

Remove control panel as detailed in Section 3.1.

Pull off lamp connections and undo nut that secures it

at rear. Remove lamp and replace in reverse order.

3.3 ELEMENT

To replace heating element proceed as follows:

a) Drain pan.

b) Remove basket support bar from element and fully

raise element.

c) Remove 10 pozidriv screws in underside of

element terminal box.

d) Remove element terminal box bottom cover plate.

This can be effected by prising up lower edge with

a screwdriver.

e) Lower element and remove element guard (4

screws). Also undo clips that secure thermostat

phial to element assembly.

f) Remove push-on element connections, first noting

their locations.

g) Remove two hex-headed screws which secure

element assembly to terminal box. Remove

element, taking care not to kink or otherwise

damage thermostat capillary tube.

Replace element in reverse order ensuring that oil

resistant gasket is fitted under element mounting

plate.

Note that thermostat phial is fitted in third hairpin of

element from left, clamps being applied to centres

of three element sheaths.

3.4 SAFETY THERMOSTAT

3.4.1 To Reset

In the event of a control thermostat failure that results

in overheating of oil, safety thermostat will interrupt

and switch off all power to elements.

To re-establish circuit, it will be necessary to reset

safety thermostat.

First allow fryer to cool, then remove control panel as

detailed in Section 3.1.

On single pan fryer (E350/38), safety thermostat is

reset by depressing tubular rod situated immediately

below drain valve.

In the case of the double pan fryer (E350/39), two

safety thermostats are located at rear of unit between

two pans.

Reach in and depress red reset button (left and right

thermostats appropriate to left and right pans).

Page 5

3.4.2 To Replace

In order to replace safety thermostat it will be

necessary to remove unit from its location on stand

or table. Adopt the following procedure:

a) Drain pan.

b) Remove control panel as detailed in Section 3.1.

c) Disconnect supply connections and remove unit

from its location to enable it to be turned on its

side later.

d) Remove element as detailed in Section 3.3.

e) Remove cover plate on element hinge block

through which capillary tube passes. Manoeuvre

capillary tube and phial through moving hinge

tube.

f) From front, remove two fixings that secure the

base plate and remove the plate.

g) Turn the appliance on to its side and remove

safety thermostat from mounting bracket. Pull off

connections.

h) Feed capillary tube and phial through hole in base

of hinge block and remove the thermostat.

j) Replace thermostat in reverse order, taking care

that capillary tube is well clear of element

terminals.

k) Replace elements (see Section 3.3). Also replace

base panel and the control panel.

m) Fill pan with oil and heat it up. Carry out installation

tests.

3.5 DRAIN VALVE - TO REMOVE

Drain pan.

Remove control panel as detailed in Section 3.1.

Undo compression fitting nut at rear of valve,

adjacent to pan (turn it clockwise).

Remove saddle clamp at front and remove valve.

Fit a new valve in reverse order. Apply a small

quantity of high melting point grease to sliding parts of

operating lever and also to circular shaped plate on

which end of spindle runs.

3.6 TILT SWITCH

Located in element terminal box, this component

should require no maintenance.

Page 6

E350/38 Fryer Wiring Diagram

Page 7

E350/39 Fryer Wiring Diagram

Loading...

Loading...