Page 1

RZZ 209 Ref.1

E350/30

FOUR HOTPLATE RANGE

INSTALLATION and

SERVICING INSTRUCTIONS

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions and

National Regulations in force at the time of installation. Particular attention MUST be paid to -

BS7671 IEE Wiring Regulations

Electricity at Work Regulations

Health And Safety At Work Act

Fire Precautions Act

This appliance has been CE-marked on the basis of compliance with the Low Voltage and EMC Directives for

the voltages stated on the Data Plate

WARNING -THIS APPLIANCE MUST BE EARTHED

On completion of the installation these instructions should be left with the Engineer-in-Charge for reference

during servicing. Further to this, The Users Instructions should be handed over to the User, having had a

demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY

RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance Contract be

arranged with AFE SERVICE. Visits may then be made at agreed intervals to carry out adjustments and

repairs. A quotation will be given upon request to contact numbers below.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

PO Box 37, Foundry Loan, Larbert.

Stirlingshire. Scotland. FK5 4PL

SERVICE LINE CONTACT -

PHONE - 01438 751 111 FAX - 01438 369 900

Page 2

SECTION 1 - INSTALLATION

1.2 SITING

The appliance should be installed on a firm level floor

in a well lit position. Should the unit be required to be

positioned in close proximity to a wall, partition or

decorative finish, etc. the surface must be

constructed of non-combustible material.

Alternatively it may be clad in a suitable

non-combustible insulating material. Close attention

should be paid to Fire Regulations.

1.3 ELECTRICAL SUPPLY

The appliance is designed for use on AC supplies

only and can be operated on either a 3 phase/4 wire

AC supply or a single phase AC supply by using the

bridging links supplied.

Warning

This appliance must be earthed. (An earth terminal is

provided).

The connection to the mains electric supply must be

made through a suitable isolating switch with a

contact separation of at least 3mm in all poles.

Wiring should conform to I.E.E. regulations and the

installation should satisfy the local supply authority.

1.4 ELECTRICAL RATINGS

The electrical rating is as stated on unit data plate.

Note

The hotplates embody a temperature limiting device.

This automatically cuts off part of the element circuit

should the plate become overheated due to being left

switched on without a pot on it.

SECTION 2 - ASSEMBLY

a) Place the appliance in position and carefully level it

by turning the feet adjusters. Holes are provided in

the feet to enable the appliance to be fixed to the

floor if this is considered necessary.

b) Open the door and remove all packing material etc.

c) Connect the unit to the electrical supply (terminals

underneath).

Note

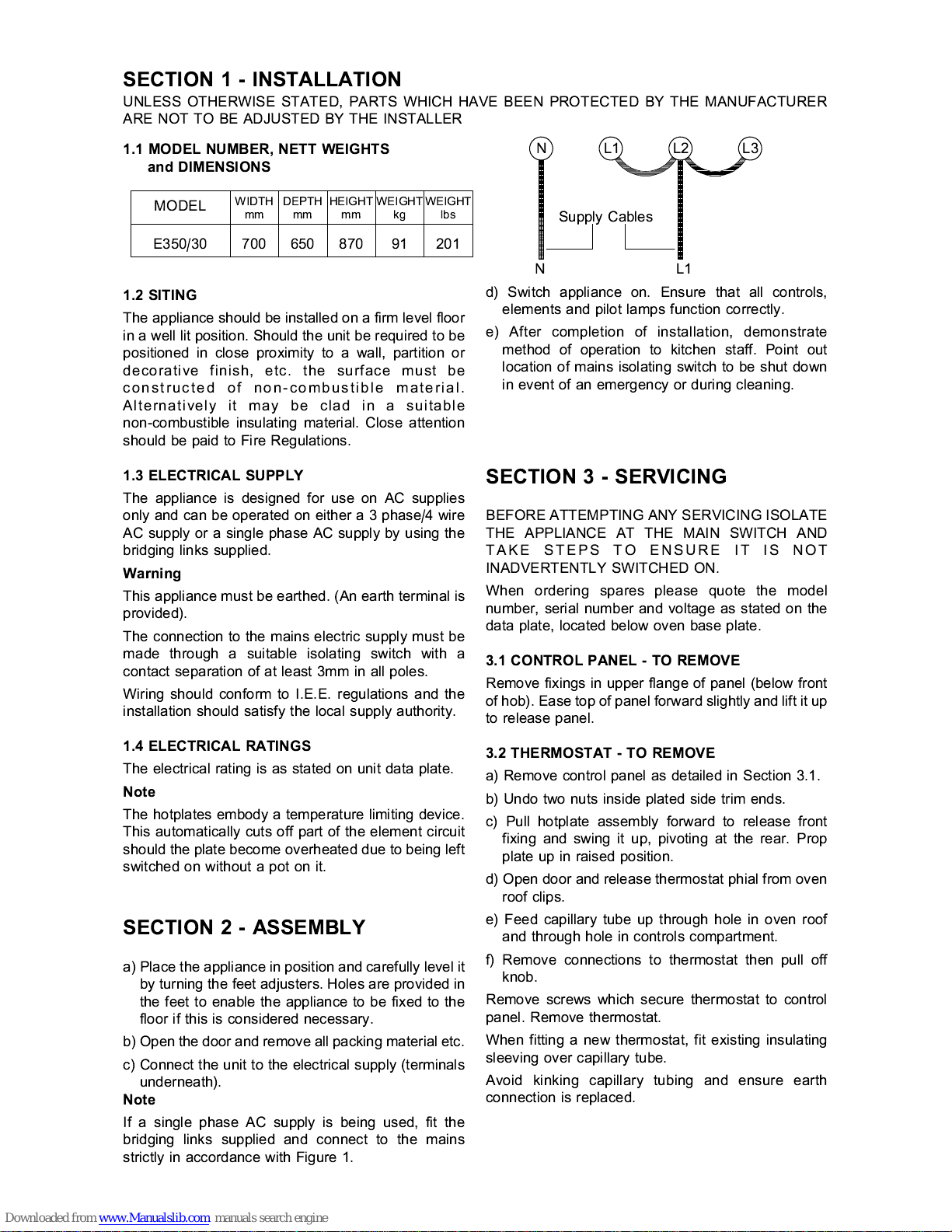

If a single phase AC supply is being used, fit the

bridging links supplied and connect to the mains

strictly in accordance with Figure 1.

NL1L2L3

Supply Cables

NL1

d) Switch appliance on. Ensure that all controls,

elements and pilot lamps function correctly.

e) After completion of installation, demonstrate

method of operation to kitchen staff. Point out

location of mains isolating switch to be shut down

in event of an emergency or during cleaning.

SECTION 3 - SERVICING

BEFORE ATTEMPTING ANY SERVICING ISOLATE

THE APPLIANCE AT THE MAIN SWITCH AND

TAKE STEPS TO ENSURE IT IS NOT

INADVERTENTLY SWITCHED ON.

When ordering spares please quote the model

number, serial number and voltage as stated on the

data plate, located below oven base plate.

3.1 CONTROL PANEL - TO REMOVE

Remove fixings in upper flange of panel (below front

of hob). Ease top of panel forward slightly and lift it up

to release panel.

3.2 THERMOSTAT - TO REMOVE

a) Remove control panel as detailed in Section 3.1.

b) Undo two nuts inside plated side trim ends.

c) Pull hotplate assembly forward to release front

fixing and swing it up, pivoting at the rear. Prop

plate up in raised position.

d) Open door and release thermostat phial from oven

roof clips.

e) Feed capillary tube up through hole in oven roof

and through hole in controls compartment.

f) Remove connections to thermostat then pull off

knob.

Remove screws which secure thermostat to control

panel. Remove thermostat.

When fitting a new thermostat, fit existing insulating

sleeving over capillary tube.

Avoid kinking capillary tubing and ensure earth

connection is replaced.

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL

WIDTHmmDEPTHmmHEIGHTmmWEIGHTkgWEIGHT

lbs

E350/30 700 650 870 91 201

1.1 MODEL NUMBER, NETT WEIGHTS

and DIMENSIONS

Page 3

3.3 HOTPLATES - TO REMOVE

a) Remove facia panel as detailed in Section 3.1 and

raise hotplate assembly as detailed in Section 3.2.

b) Remove hotplate connections and undo central

fixing nut. This will allow hotplate to be removed

from top.

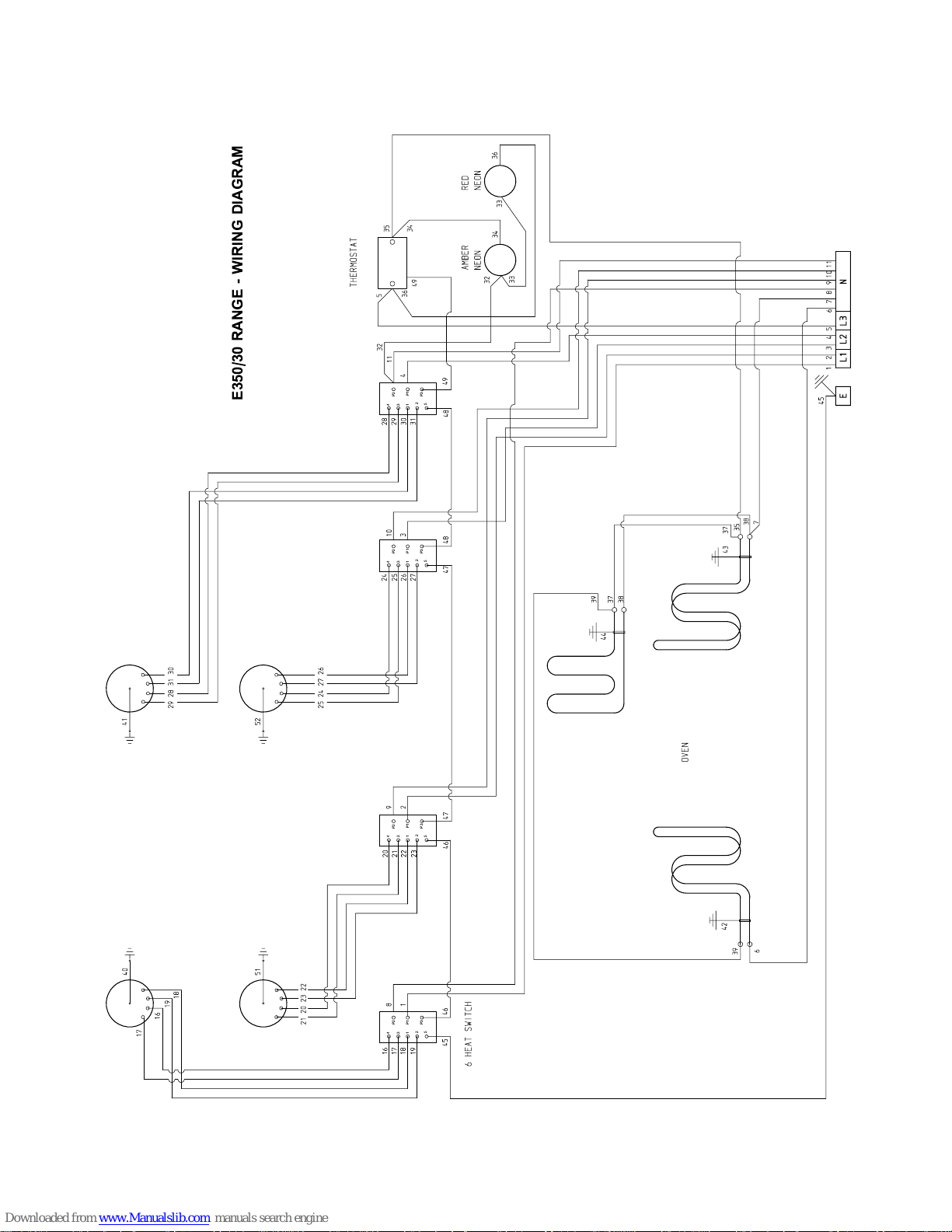

Fit replacement plate in reverse order, referring to

wiring diagram when re-connecting.

3.4 CONTROL SWITCHES - TO REMOVE

a) Remove control panel as detailed in Section 3.1.

b)Remove switch conn ections, note cable

arrangement.

c) Pull off control knob and undo fixing screws to

release switch. Fit new switch in reverse order,

ensure that earth bonding wire is attached to it.

3.5 PILOT LAMPS - TO REMOVE

a) Remove control panel as detailed in Section 3.1.

b) Pull off connections to lamp.

c) Remove nut at panel rear to release lamp. Fit

replacement in reverse order.

3.6 OVEN ELEMENTS - TO REMOVE

a) Remove control panel as detailed in Section 3.1.

b) Remove outer side panels as follows. Undo

screws in rear flange of panel. Swing panel rear

outward slightly then forward to release front fixing.

c) Open door and remove base panel.

d) Remove element connections and undo fixing nut.

e) Withdraw element from inside oven. Replace

element in reverse order, ensu ring small earth

bonding wire connection is securely fastened in

place.

Page 4

431

2

5

P2

P1

P3

431

2

5

P2

P1

P3

431

2

5

P2

P1

P3

431

2

5

P2

P1

P3

E350/30 RANGE - WIRING DIAGRAM

Loading...

Loading...