Page 1

Installation Instructions

Falcon Electro-mechanical

Swing Operator

Models: 8230 & 8240

640072-00(C) © 2012 Ingersoll-Rand Company Limited

Phone: 1-877-671-7011

Page 2

CONTENTS

General

stnenopmoCmetsySdnastraPtnemecalpeR

kcehCtcudorPdnaetiSnoitallatsnI-erP.1

noitallatsnIrotarepO.2

3. Wiring

noitallatsnIrevoCdnamrA.4

kcehClanoitarepO.5

tnemtsujdArotarepO.6

ecivreSrofesaeleR.7

8. Falcon Software

11-12

GENERAL

The Falcon Operator is a low energy automatic electromechanical swinging door operator for

use on hinged, center pivoted and offset pivoted doors. When activated, the Falcon drives the

door to full open position, then electrical power is turned off and the door is closed by spring

force. The activating circuit opens the door from any position in the closing swing. During a

power failure, the Falcon Operator acts as a manual door closer (Size 3). Door opening and

closing cycles, including opening speed, back check speed, hold open time delay, closing

speed, latch position, and backcheck position are adjustable.

!

WARNING

Always disconnect main

power to the operator

prior to servicing

or cleaning.

!

CAUTION

This operator is for

indoor use only.

!

CAUTION

Do not mount any

accessories directly to

the operator.

2

2

3

4-5

6

6-7

8

9-10

11

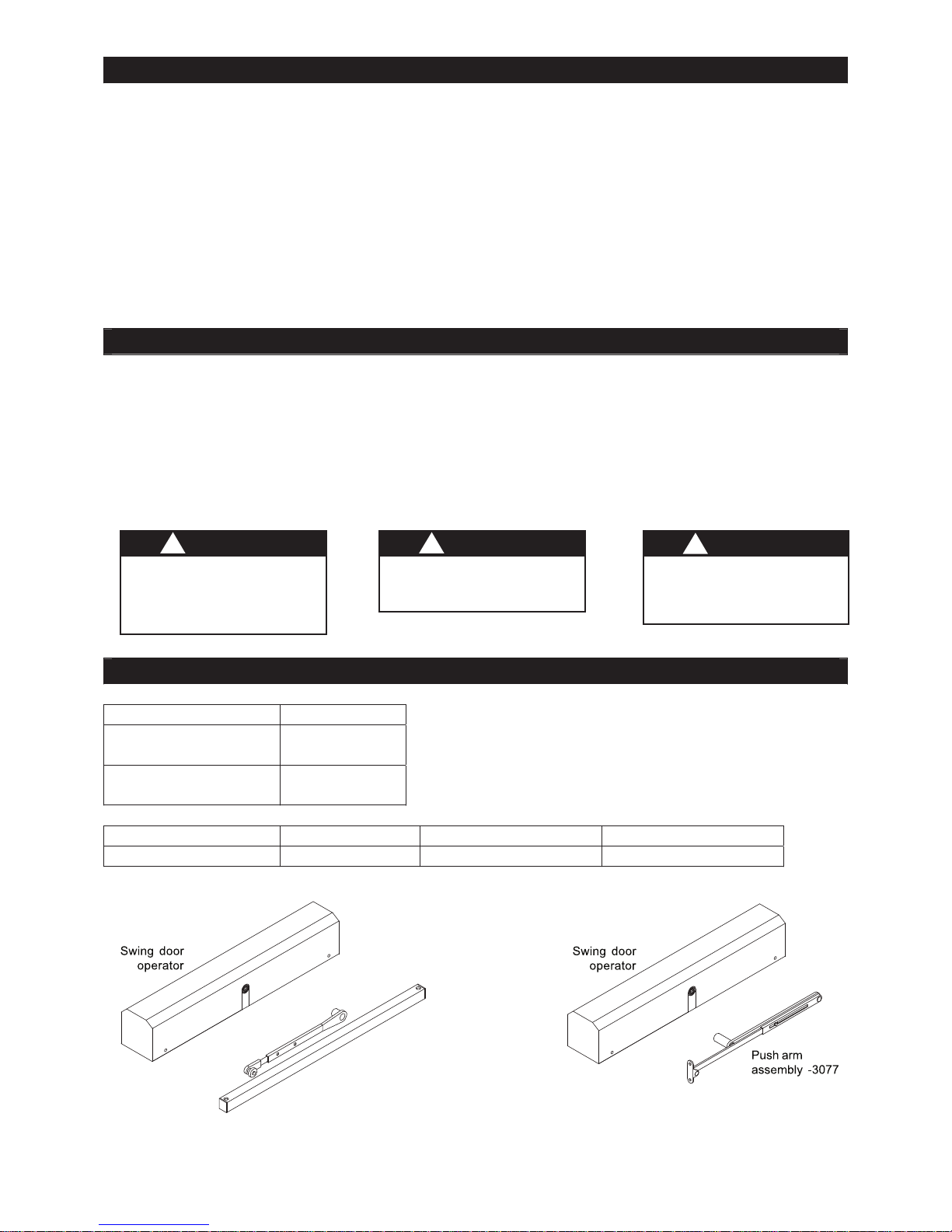

REPLACEMENT PARTS & SYSTEM COMPONENTS

Part 26” Header

Control Box 8230-3462

8240-3462

Gear Box 8230-3454

8240-3454

Part Pull Standard Push Finish

Arm Assembly 8230-3077T 8240-3077 AL689

26” Pull System

(screw pack not shown)

Pull arm -3077T

and track -3038

Arm & track assy -3077PLCM

26” Push System

(screw pack not shown)

21fo2egaP

Page 3

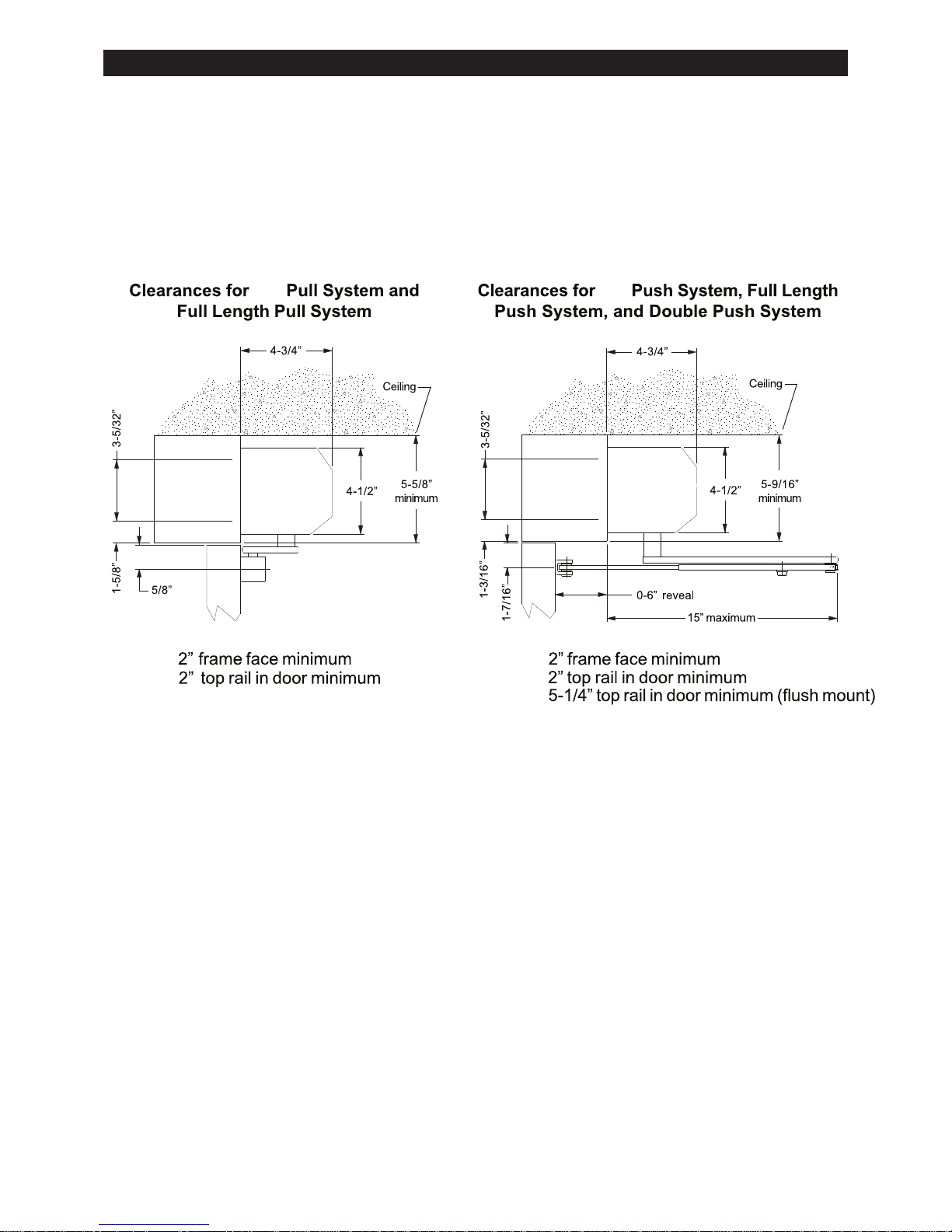

1. PRE-INSTALLATION SITE & PRODUCT CHECK

1.1 Check that the product model is correct for the required application.

1.2 Check that all parts listed on the Bill of Material are in the shipping container.

1.3 Check the architectural drawings and final approved shop drawings for the position

of frame and structural openings.

1.4 Check header and frame dimensions and required clearances.

26”

1/8” max reveal

26”

1.5 Check Door Width: 26” minimum for 26” Push Operator

30” minimum for 26” Pull Operator

1.6 Check that Door Weight is 200 lbs. or less. For heavier door, consult factory.

1.7 Check that a 115 volt, single phase, 60 Hz, fused 15 amp, 3-wire power supply is available

at the side jamb with approximately 12” of wire available to connect to the Operator.

UL approved flexible conduit is recommended for the 115 volt power line.

The 115 volt power supply must be a dedicated circuit from the main circuit breaker panel

and must NOT be connected into any building lighting system that operates florescent

lights.

Page 3 of 12

Page 4

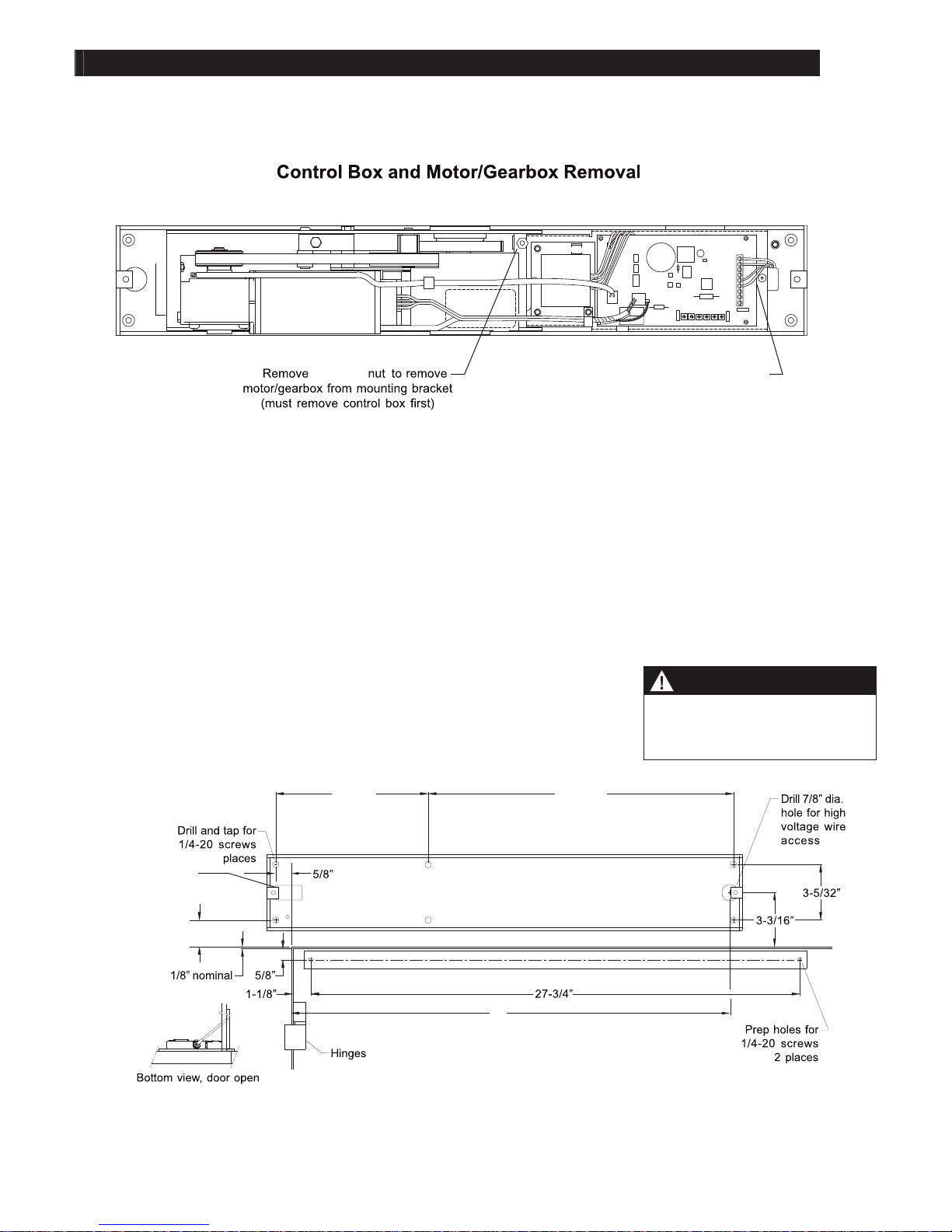

2. OPERATOR INSTALLATION

2.1 Remove Control Box from Operator Mounting Bracket, then remove Motor/Gearbox from

Bracket:

26” Pull, 26” Push

1/4” - 20

Remove screw to remove control

box from mounting bracket

2.2 Prepare Header/Frame and Door: 26” Pull System..............................See below

5egaP............................metsyShsuP”62

5egaP..................noitacilppAtnuoMporD

2.3 Install Operator Mounting Bracket on Header/Frame. Do not install the center screws

until you’ve attached the Motor Gearbox assembly in step 2.4

2.4 Install Motor/Gearbox on Operator Mounting Bracket. If there is not a mounting surface

for both screws on the Gearbox, use the ¼”-20 nut removed in 2.1 to secure the

gearbox. Then install the Control Box.

2.5 Proceed to Chapter 3: Wiring (page 6).

CAUTION

When mounting to an aluminum

26” Pull System

Header/Frame and Door Preparation

6”1/5-518”/3-9

frame, the use of rivet nuts is

strongly recommended.

Drill 1/2” hole in jamb

6

tube in this area for low

voltage wire access

1-11/16”

Page 4 of 12

Control

Box

Gearbox

24”

Page 5

2. OPERATOR INSTALLATION (CNTD)

26” Push System

Header/Frame and Door Preparation

6”1/5-518”/3-9

6

Control

Box

Gearbox

1-3/16”

5/8”

Drop Mount Application (26” Push System Only)

Header/Frame and Door Preparation

6”1/5-51

8”/3-9

4

Page 5 of 12

Page 6

3. WIRING

CAUTION

Make sure all wires are properly dressed and secured to prevent interference

Route all wiring away from moving parts, sharp edges, and heat sources

Use copper conductors only

Do not modify the factory wiring or connect into existing electrical circuits or devices

3.1 Refer to the appropriate wiring diagram for the Control Box (page 12) or the diagram

supplied for custom applications.

Connect the following cables:

Ground Cable (Ground the Operator properly with the earth from main supply)

Hall Effect Cable (Do not wrap the Hall Effect Cable around the Motor Power Cable)

Motor Power Cable (Do not wrap the Motor Power Cable around the Hall Effect Cable)

Control Box Power Cable

3.2 Connect activate and lock accessories, as needed.

Refer to the accessory instructions for any accessories used.

Do not connect any remote activating device to the door unless it is located within

line of sight of the door.

3.3 When wiring is complete, proceed to Chapter 4: Arm and Cover Installation (page 6)

4. ARM & COVER INSTALLATION

WARNING

Keep hands, clothing, wires, tools, etc., AWAY FROM Operator Motor

when the Operator Motor is turned on

4.1 Make sure the Operator Power is connected.

4.2 Install a jumper across the control box Main Act and Main Act Com.

4.3 The operator motor will activate and drive to the Full Open position, and remain there.

4.4 Push Arm Installation.

4.4.1 Open the door to 90˚, and attach the Main Arm to the operator spindle at 90˚ to the

opening (+/- 10˚) with the 8mm socket head screw (see fig. 1).

4.4.2 Remove the arm locking screw from the Rod & Shoe. Insert rod into forearm tube and

reinstall the arm locking screw loosely. Attach Rod & Shoe to door. With the door open to 90˚,

tighten the arm locking screw (see fig. 2).

8mm Socket

Head Screw

±10°

Fig. 1

Page 6 of 12

Arm Locking

Screw

Fig. 2

Page 7

4. ARM & COVER INSTALLATION (CNTD)

4.5 Pull Arm Installation

4.5.1 Slide the pull arm roller into the track, then insert a track end cap on each end of the

track and install track to door.

4.5.2 Attach the Pull Arm to the track roller with the roller locking screw and to the operator

spindle loosely with the 8mm socket head screw. Open the door to 90°, and tighten the 8mm

socket head screw (see fig. 3).

4.5.3 Attach arm if required. Due to the mesh of the arm to operator spindle, the door may be

open to slightly more or less than 90°. To adjust arm, remove arm adjustment screws, push

door open to 90° and reinstall arm screws (see fig. 4).

Pull Arm

Arm Locking

Screw

8mm Socket

Head Screw

Arm Adjustment

Screws

Fig. 3

Fig. 4

4.6 Remove the jumper from the control box Main Act and Main Act Com. The door should close.

4.7 Connect actuator wiring as required (see page 12).

4.8 Test the operator. (See Chapter 5: Operational Check on page 8)

4.9 Adjust the operator as required. (See Chapter 6: Operator Adustment on page 9)

4.10 Install the cover assembly onto the operator.

4.11 Release the operator for service. (See Chapter 7: Release for Service on page 11)

Page 7 of 12

Page 8

5. OPERATIONAL CHECK

5.1 Activate the operator using the activation device.

The operator will perform one sizing cycle.

Sizing Cycle: Occurs after power is turned on and a legitimate activation signal

is received. During the sizing cycle, the door opens and closes one time.

5.2 If the door does NOT OPEN AT ALL during the sizing cycle:

• Check the door for binding.

• If an electromechanical lock is being used, check that the lock disengages before the

operator opens the door.

• Check fuses, circuit breakers and connections.

• Adjust the operator and check the door operation

(See chapter 6: Operator Adjustment on

Below are default settings:

Opening Speed 9:00

Back Check Speed 3:00

Hold Open Time Delay 10:00

Latch Position 12:00

Closing Speed 12:00

Back check position 4:00 (Fully clockwise)

page 9)

5.3 If the door does NOT OPEN FULLY during the sizing cycle:

• Check the door for binding.

• Increase the back check speed slightly and re-check the door operation.

Repeat until door opens fully.

5.4 If the door OPENS TOO FAST during the sizing cycle, decrease the back check speed

slightly and re-check the door operation. Repeat until the door opens at desired speed.

5.5

After the sizing cycle is completed and the door(s) are closed, apply a maintained

activation signal. Check that the door remains open while the signal is applied.

5.7 When the door is operating properly, continue with Step 4.11 on

page 7.

Page 8 of 12

Page 9

6. OPERATOR ADJUSTMENT

See table below and diagrams (page 10) for operator feature adjustment.

After adjusting, cycle the door several times to check for proper operation.

NOTE

Adjust Operator for the SLOWEST operation practical, in accordance with the latest

revisions of the Americans with Disabilities Act (ADA); ANSI/BHMA A156.19 Standards

for Power-Assisted and Low Energy Power-Operated Doors; and local codes.

Opening Speed: 5 seconds or more Latch Location: 10 degrees or more

Closing Speed: 3 seconds or more Latch Speed: 1.5 seconds or more

Features Control Description Counter

Clockwise

Opening

Speed

Back Check

Speed

Opening

Speed

Back Check

Speed

Controls opening speed of door Slower Faster

Controls the speed of the door

Slower Faster

near the full open position to

prevent door slamming

Hold Open

Time Delay

Back Check

Position

Hold Open

Time Delay

Back Check

Position

Controls the length of time the

door remains in the full open

position: 1 sec to 30 sec

Door position where back check

speed engages

Less Time

Down to

1 sec

Less

Pressure

Required

Latch

Position

Latch

Position

Door position at which

deceleration towards full closed

Less

Latch

begins in order to prevent door

slamming

Closing

Speed

Closing

Speed

Controls closing speed of door Slower Faster

Clockwise

More Time

Up to

30 sec

More

Pressure

Required

More Latch

Delayed

DLY ON: Delays opening of door for

Activation

Push and

PNG ON: Pushing the door open 5°

Go

Page 9 of 12

strike applications (1 second

delay)

causes operator to open door

for remainder of open cycle

Page 10

6. OPERATOR ADJUSTMENT (CNTD)

Fuse

Fuse

Main

Power

12 VAC

Power

Motor

Delay

On

Off

Open

Speed

Delay

Back

Check

Speed

Speed

Open

Back

Check

Pos

Speed

Check

Back

Close

Speed

Pos

Check

Back

Latch

Pos

Speed

Close

Hold

Open

Pos

Latch

Push

-nGo

Open

Hold

On

Off

Go

-nPush

Page 10 of 12

Page 11

7. RELEASE FOR SERVICE

7.1 Remove all tools, installation equipment and debris from the vicinity of the door.

7.2 MANDATORY: Install all Safety, Traffic Control and Instruction Labels onto the door,

as required.

Failure to do this will leave the INSTALLER LIABLE for any accidents that occur.

7.3 Give verbal instruction on how to properly operate the door to the owner or

person in charge.

7.4 Give verbal instruction to the owner or person in charge on periodic inspection of the

door for the following:

• Occasional damage

• Developing problems

• Minor preventative maintenance

7.5 Provide the owner or person in charge with a contact name and phone number to call

for future service and maintenance.

Be sure to install all Safety, Traffic Control and Instruction Labels

8.1 Operation:

8.1.1 Sizing

From start-up (Sizing), the door will activate via:

Main Input (Main Act and Main Act Com).

The first motion of the door will be towards the Door Open position. The speed during

Sizing is automatic and cannot be set from a potentiometer.

The door drives to full open and the system sets the open counter to full open.

The door closes at Closing Speed. The system sets the closed counter to Full Closed

when the latch goes up at the Closed position.

IMPORTANT

onto the door, as required

8. FALCON SOFTWARE

The system calculates all other parameters required for normal operation based on the

two values of Full Open and Full Closed.

Page 11 of 12

Page 12

8.1.2 Standard Operation

Upon a legitimate activation signal, the door accelerates to opening speed while

monitoring the current load on the drive output. If the current exceeds the specified

level, the door will stop and close.

The door travels at it’s set speed (based on the potentiometer setting) until it reaches

the Back Check position, where it will decelerate to the Back Check Speed.

The door will stop at the Hold Open position and remain there until an activation or the

Hold Open Timer is cleared.

The door then closes at its Closing Speed (based on the potentiometer setting) up to the

latched position.

If the Closing Speed is decreased by driving the motor in the open direction (a fixed

setting), power is added to allow the spring to continue closing the door to the Full

Closed position.

8.2 Wiring

8. FALCON SOFTWARE (CNTD)

For clarity, not all

components are shown

J8, 10-position

Control Box Power Cable

J1, 6-position

Main Power Cable

on the control box PC board

J5, 2-position

Motor Power Cable

J3, 4-position

Hall Effect Cable

120VAC

Input

Page 12 of 12

Plug cables into

these receptacles

External

24 VDC

Power Supply

12VAC

12VAC

Safety Sen

Safety GND

Main Act

Main Act Com

Relay N/O

Relay Com

Relay N/C

24VDC +

24VDC -

should be connected in parallel

Black DC-

Depending on Device

Connect

Fail Safe to Relay N/C

Fail Secure to Relay N/O

Control box

grounding stud

Multiple activation devices

Activation Device

N/O Dry Contacts

Electric Lock,

Electric Strike, etc.

Loading...

Loading...