Page 1

211 EEO Ceramic

User’s Manual

&

Installation and Servicing Instructions

U1 353 01

Page 2

Page 3

Users Manual 211 EEO Dual Fuel

Page 3

Contents

211 GEO Dual Fuel Range 4

Control Panel Layout 4

General Information 5

Warranty & Service 5

Be safe 5

The Hob 6

Oven Operation 8

Oven Fitments 8

Left Hand Oven Cooking Chart 10

Right Hand Fan Oven Cooking Chart 12

Grill Operation 14

The Ambient Drawer 15

Cleaning 16

Troubleshooting 18

General Safety Instructions 20

Optional Extras 22

Splashback Fitting Instructions 22

Utensil Rack Fitting Instillation 22

Flue Spacer Fitting Instructions 23

Installation and Servicing Instructions 24

SECTION 1 - INSTALLATION 24

SECTION 2 - ASSEMBLY and COMMISSIONING 26

SECTION 3 - SERVICING 26

Circuit Diagram Top 30

Circuit Diagram Bottom 31

Page 4

Users Manual 211 EEO Dual Fuel

Page 4

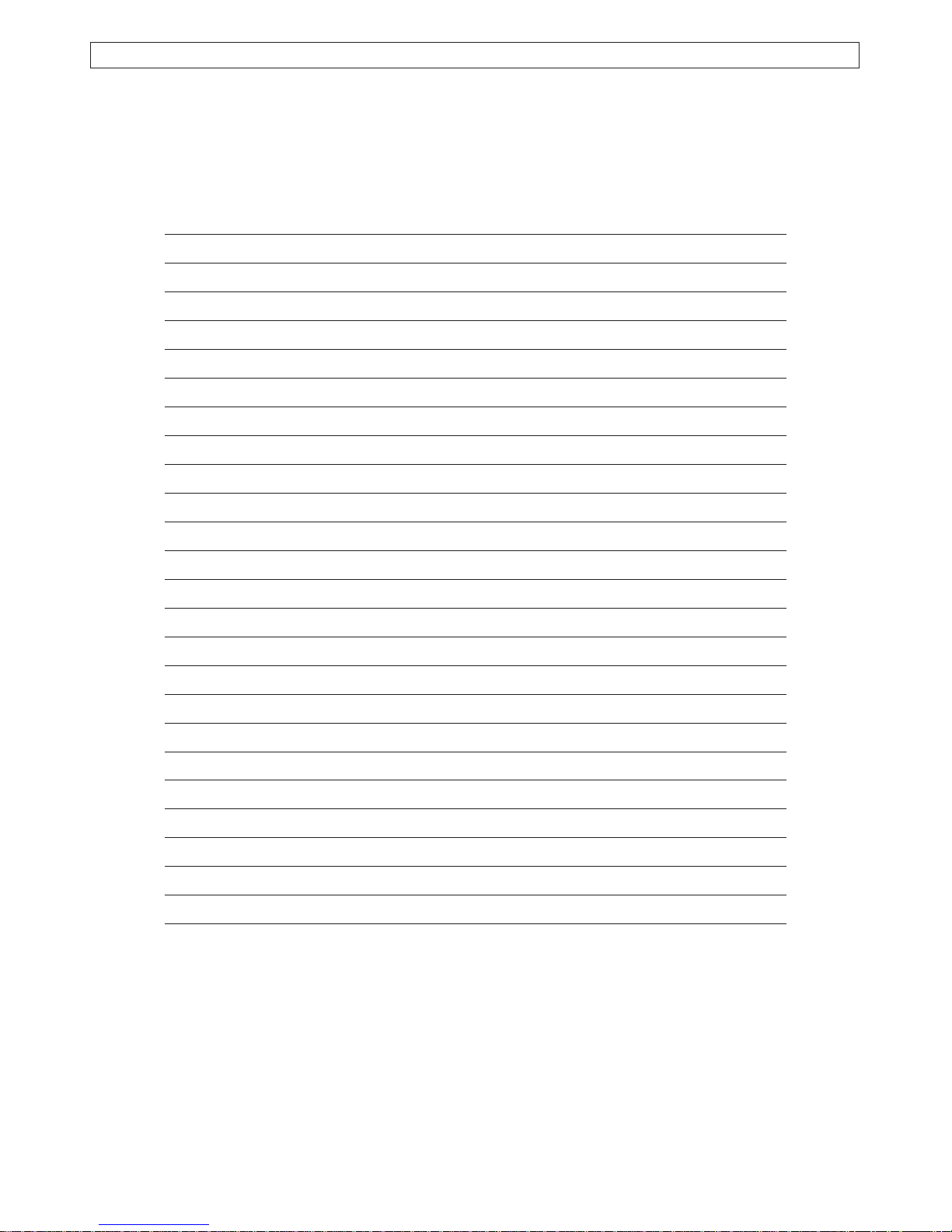

211 GEO Dual Fuel Range

Control Panel Layout

Page 5

Users Manual 211 EEO Dual Fuel

Page 5

General

Information

These units have been CE-marked

on the basis of compliance with the

EMC and Low Voltage Directive for

the Countries stated on the Data

Plate.

The Range must be installed by a

competent person, in compliance

with the Installation and Servicing

Instructions and National Regulations in force at the time. In the UK,

particular attention should be paid to

the following: -

I.E.E Regulations for Electrical Installations

Health and Safety at Work Act

The User must not adjust parts that

have been protected by the manufacturer. Regular servicing by a

competent person must be carried

out to ensure the continued safe and

efficient performance of the appliance.

Warning - THIS APPLIANCE

MUST BE EARTHED!

The installer should instruct the

User with regard to correct operation and maintenance of the unit

before handing over this manual.

Some parts will, by necessity, become very hot and will cause burns

if touched accidentally .

CUSTOMER CARE

This cooker has been manufactured

in accordance with the safety aspects that European Standards

demand.

Please keep this manual close at

hand and available to anyone who

may use the Range.

By following all the recommendations made in these instructions you

will be able to make best possible

use of your cooker .

The installer will ensure that the unit

is correctly fitted and adjusted. Safe

and efficient use requires that it be

serviced regularly. Frequency of

service is dependent upon usage.

Only competent persons should

be allowed to make adjustments.

Replacement parts are available

from your supplier not direct from

Falcon. When ordering, please

quote the Serial Number, which

can be found on the data plate located externally at the rear of the

unit.

We would advise that extra care

be taken when using and cleaning the unit.

YOUNG CHILDREN SHOULD NOT

BE ALLOWED NEAR THE APPLIANCE.

Cooking produces heat and moisture. Ensure the room is well

ventilated. If mechanical extraction

is required we recommend the installation of a Falcon Extraction

Hood.

Note

The unit will emit a slight odour

when used for the first time; this will

quickly disappear .

Warranty & Service

For details of the Falcon Warranty

and Service arrangements please

see the separate ‘Customer Care’

leaflet.

Be safe

We recommend you read pages 20 21 if you have not used an ceramic

electric cooker before. We describe

some basic guidelines on how to

use a cooker safely.

Page 6

Users Manual 211 EEO Dual Fuel

Page 6

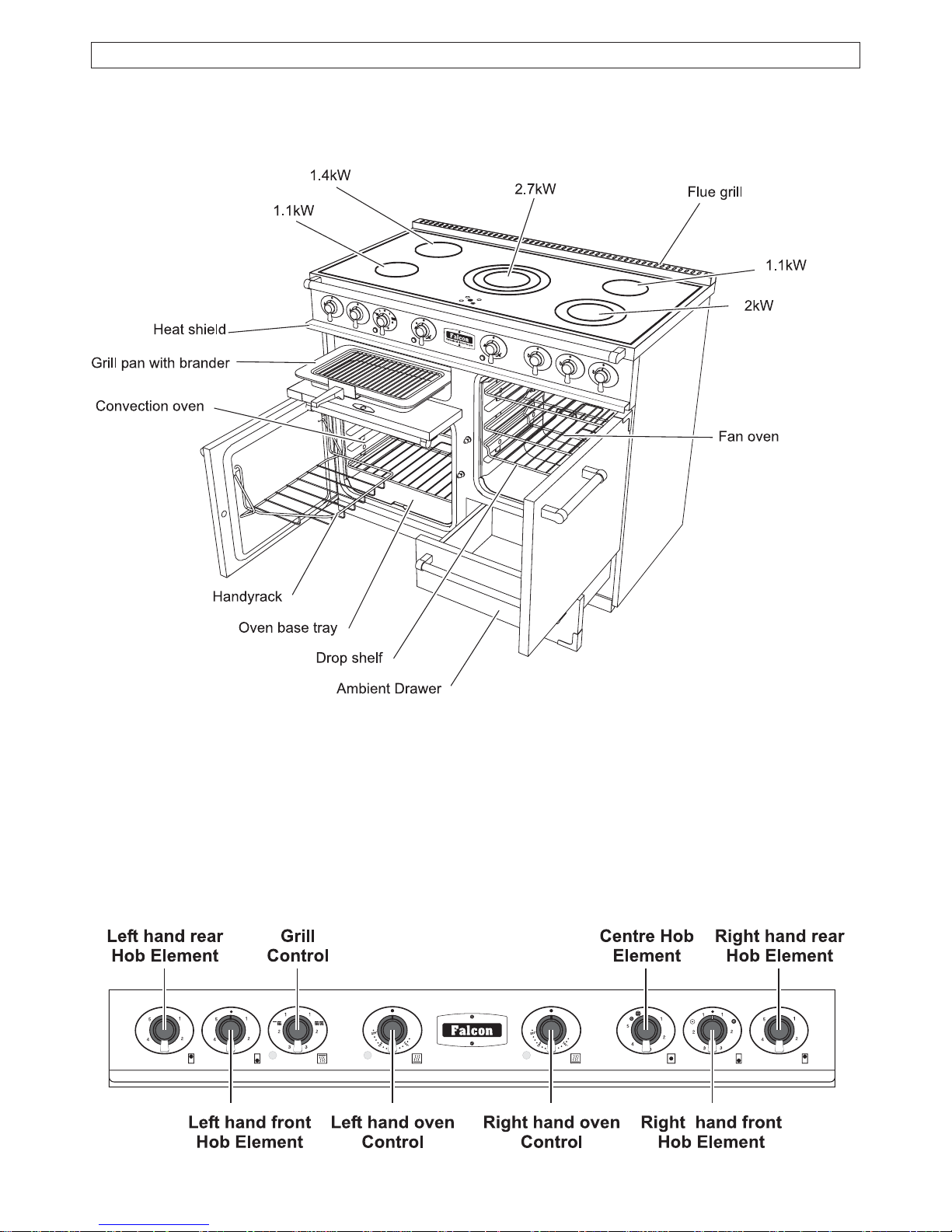

The Hob

When you cook on a ceramic hob its

very

important to use the right sort of pans...

1

Use only pans that are suitable for cer amic hobs.

We recommend stainless steel and enamelled steel

pans because pots and pans with copper or aluminium bases leave traces on the hob that are difficult

to remove.

Glass-ceramic cookware is not suitable because of its

poor conductivity .

2

Pots and pans should have thick, smooth, flat bottoms.

This ensures that there is the maximum heat transfer

from the hob to the pan, making cooking quick and energy efficient.

Never use a round bottomed Wok e ven with a stand.

3

The very best pans have bases that are very slightly

curved in when cold. If y ou hold a ruler across the bottom

you will see a small gap in the middle. When the y heat up

the metal expands and lies flat on the cooking surface .

Make sure that the base of the pan is clean and dry to

prevent an y residue burning onto the hob panel. This also

helps prevent scratches and deposits (such as lime

specks).

4

Always use pans that are the same size as (or slightly

larger than) the areas marked on the hob top. Using

smaller pans wastes heat, and any spillage will be burnt

on. Using a lid will help the contents boil more quic kly.

5

These are the various hob areas

6

The drawing by each knob indicates which area that knob

controls. This one is the left hand rear control.

The setting you need depends on the kind of pan you use

and the quantity of food. Higher settings are required for

larger quantities of food.

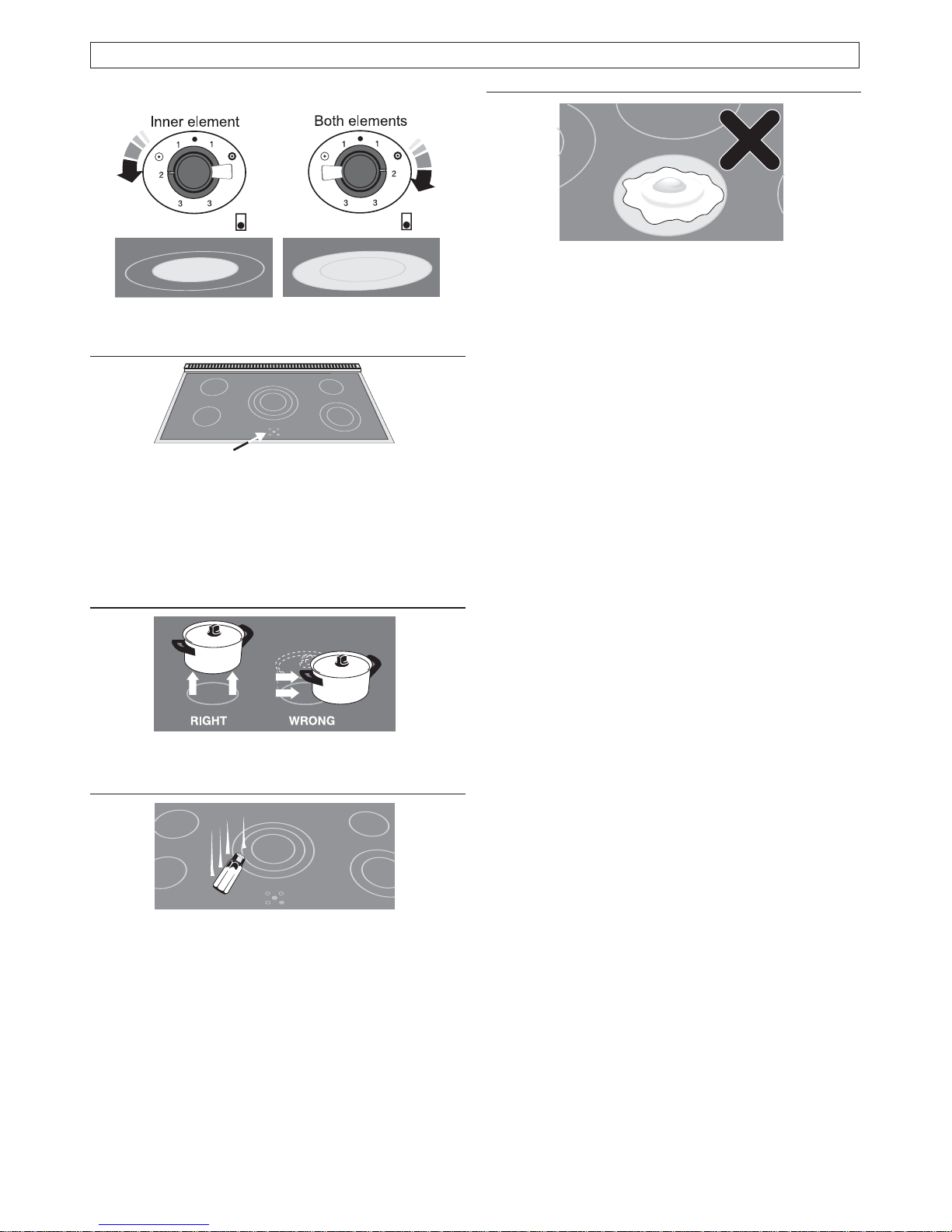

7

The areas marked with concentric circles have more than

one element.

The centre hob area has 3 elements.

To operate the inner element

only, turn the knob clockwise to

Settings 1 - 5

(1: low est / 5: highest).

To use the middle

and inner elements, turn the

knob to

before

turning anti-clockwise to the setting

you need.

To operate ALL the elements, turn the knob

to before turning

anti-clockwise to the

setting you want.

To return to a previous element combination, turn knob to

OFF position and start again.

Page 7

Users Manual 211 EEO Dual Fuel

Page 7

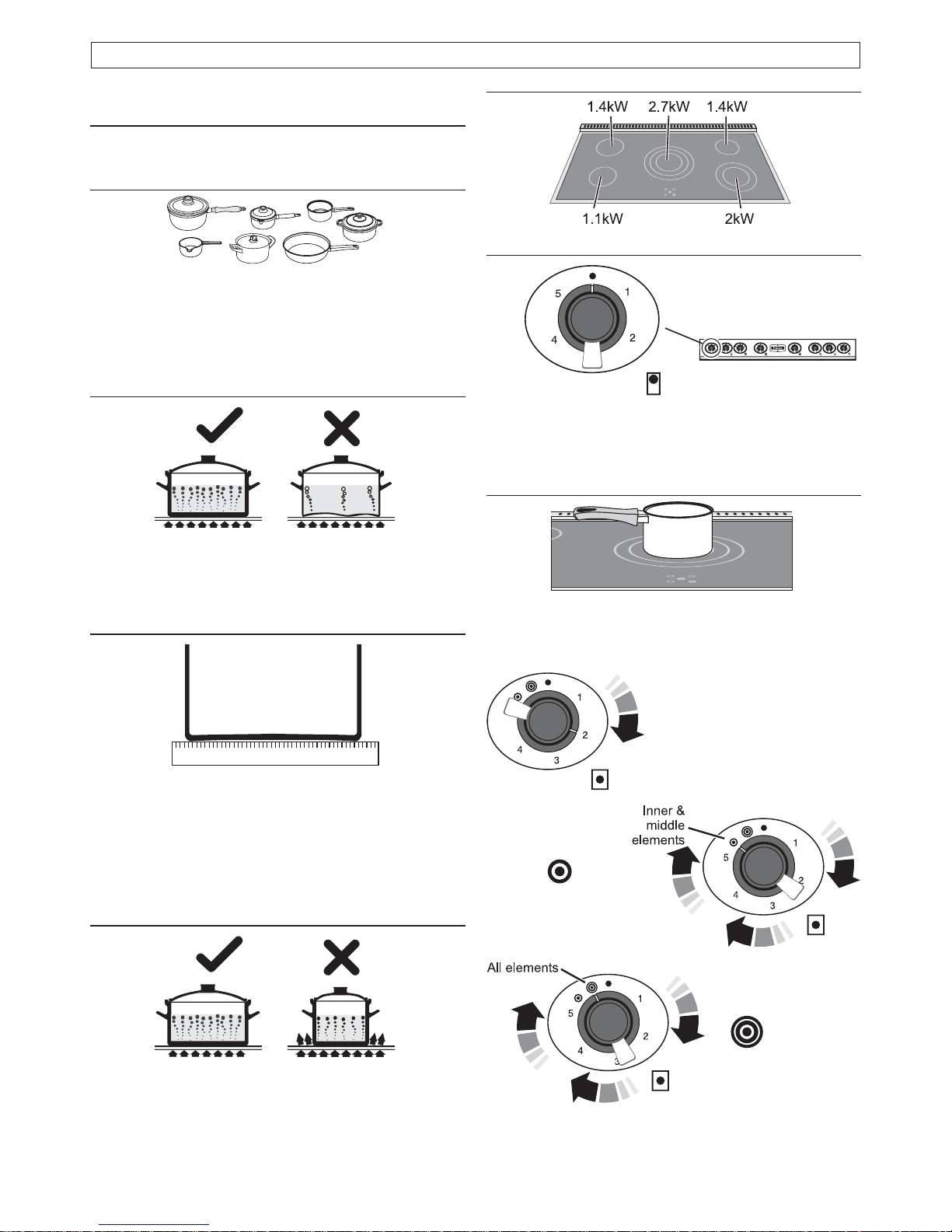

The right hand front hob area has two elements.

Turn the control knob clockwise to heat the whole area for

larger pans - turn it the other way to just heat the inner part

for smaller pans.

8

There are indicator lights for each of the cooking areas.

These come on when a hob control is turned on and stay

lit while the surface cools. Always take care before touching the surface ev en when it is turned off - it may be hotter

than you think.

WARNING

EVEN WHEN INDICATORS GO OUT, THE SURFACE

MA Y NOT HAVE COOLED COMPLETELY .

9

Always lift pans off the hob . Sliding pans ma y cause marks

and scratches. Always turn the control to the off position

before removing a pan.

10

Although the ceramic surface is very strong, a heavy or

sharp falling object (a salt cellar for example) might cause

the surface to crack. If you find a crack in the surface im-

mediately disconnect the appliance from the supply and

arrange for its repair .

Care should be taken that no water seeps into the appliance.

11

Never cook directly on the surface .

The kind of pan you use and the quantity of food affects

the setting required. Higher settings are required for

larger quantities of food.

Naturally, the surface must be washed after use in order

to prevent it from becoming scr atched or dirty.

When cooking on the hob you may see the hob area y ou

are using switch off and on. This is caused by a safety

device that limits the temperature of the hob. It is quite

normal, especially when cooking at high temperatures. If

it happens a lot with a particular pan however it may

mean the pan is not suitable – perhaps too small or too

uneven - for a ceramic hob .

Sugar spillage will permanently damage the hob and

therefore must be cleaned off with care immediately.

Never let sugar spillage cool before trying to remove it.

If sugar or foods with high sugar content, aluminium foil

or plastic items are accidentally allowed to melt on the

hob surface remov e them immediately from the hot cooking area using a scraper to avoid any possib le damage to

the surface. See ‘Cleaning y our cook er’.

Never cut directly on the cooking surface.

Don't cook directly on the hob surface i.e. without a pan

or utensil

Don’t use the hob as a work surface

Don’t drag or slide utensils across the hob surface

Don’t place anything between the base of the pan and

the hob surface (i.e. asbestos mats, aluminium foil,

Wok stand)

Don't leave utensils, foodstuffs or combustible items on

the hob when it is not in use. (e.g. tea towels, frying

pans containing oil)

Don't place plastic or aluminium foil, or plastic containers

on the hob

Don't leave the hob zones switched on unless being

used for cooking

Don't place large preserving pans or fish kettles across

two heating zones

Don't place utensils partly covering a heating zone. Al-

ways place utensils centrally.

Never allow anyone to climb or stand on the hob.

Page 8

Users Manual 211 EEO Dual Fuel

Page 8

Oven Operation

During use the appliance becomes hot. Care should be taken

to avoid the touching heating elements inside the ovens.

The Ovens

This model includes two types of

oven. Before using either f or the first

time, heat to 200°C for 30 minutes to

dispel manufacturing odours.

Right Hand Oven - Fan Assisted

The fan draws air from the oven to

be heated by the element. The hot

air is then forced around the cavity

via the top and bottom of the rear

panel and circulates this continuously around the food resulting in

quicker heat transf er.

Left Hand Oven - Conventional

Oven

This oven is fitted with two elements .

The top which is visible and the

other located below the bottom

panel. The Browning Feature is

provided by the top element and can

be used at the end of any normal

cooking cycle to achieve an extra

browning effect on au-gratin dishes

or as a meat crisper.

Both oven controls are clearly

marked on the facia.

To Operate either Oven

a) Check the electricity supply is

switched on.

b) Turn the oven knob clockwise to

the desired temperature.

c) The neon indicator light will come

on until pre-set temperature is

reached.

d) The neon will cycle on and off to in-

dicate that the oven temperature is

being maintained.

Note

Cooking times may vary from those

of your previous unit and temperatures may also require to be

increased when other sections of the

range are in use.

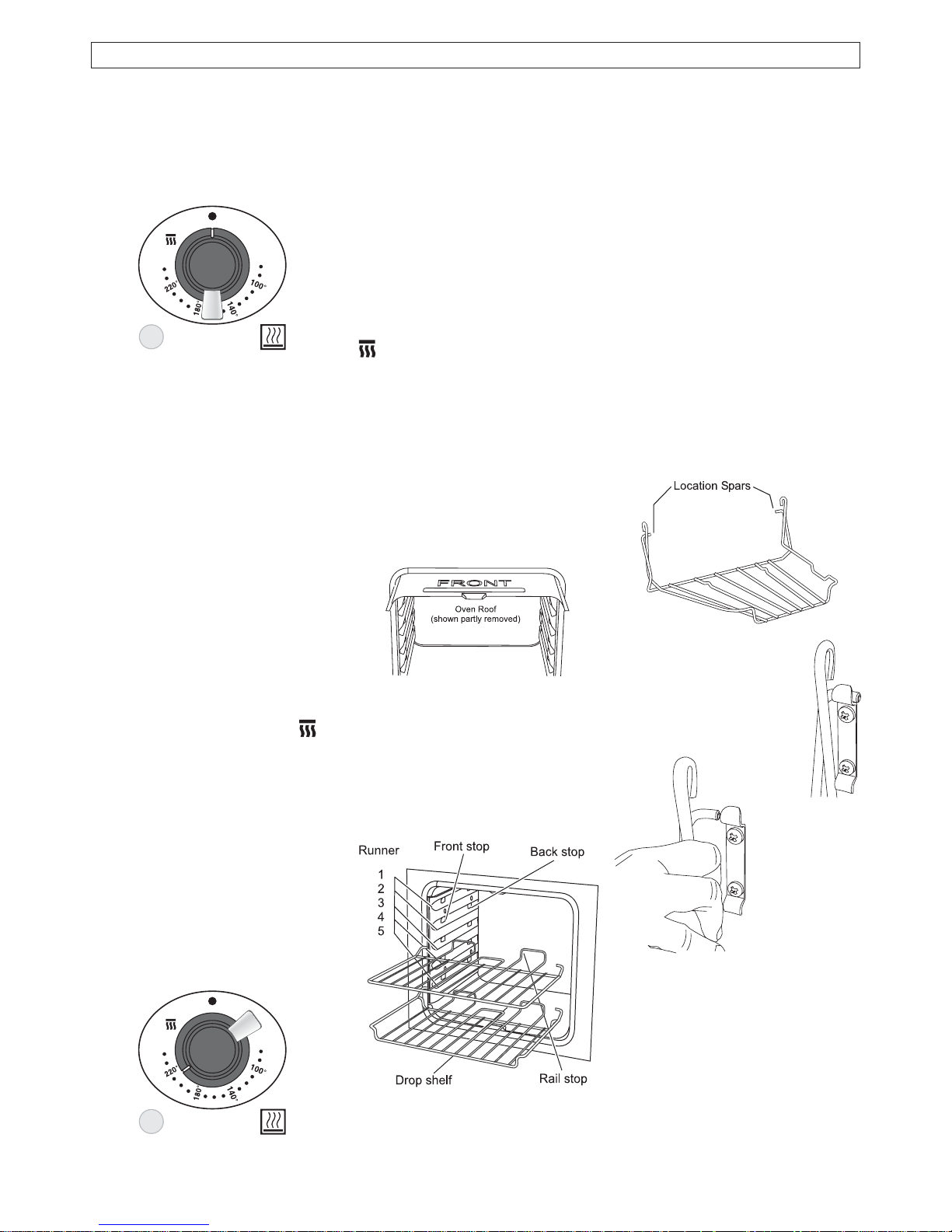

Using The Browning Element

When the cooking cycle is over, turn

the left hand oven thermostat knob to

the Browning Position indicated on

the facia.

Important Note

The upper and lower elements will

switch off automatically and operate

the browning element only.

Oven Fitments

Oven Roof (Right Hand

Oven only)

Ensure that removable roof is in correct position, pushed firmly to oven

cavity rear .

Shelves

Two shelves are provided with each

oven. A drop shelf is also supplied.

The shelves may be used in any of

the five positions and should always

be pushed firmly to the oven rear.

To remov e a shelf, pull f orw ard to the

stop position and tilt upward.

Replace in reverse order.

When preparing more than one item

per shelf, always leave a fingers

width between them so that the air

can circulate.

Do not push a dish (or dishes) too

far back on shelf as over-browning

may occur.

To Fit the Handyrack

(Left Hand Oven only)

The Handyrack should only be used

with the supplied meat tin, which is

designed to fit the Handyrack. Any

other vessel could be unstable.

To fit the Handyrack, locate

one side of it on the door

bracket.

Then spring the

other side out to

clip it onto the

other bracket.

Note

The Handyrack is designed for use

in left hand OVEN ONLY.

The Handyrack can be used instead of a shelf. There are two

fitting two positions on the door.

Remove a shelf and locate the other

to avoid Handyrack. The shelf must

always be located before positioning

Page 9

Users Manual 211 EEO Dual Fuel

Page 9

Handyrack. Failure to comply with

this instruction may damage your

appliance.

The maximum weight that can be

held by the rack is 5.5kg.

When rack is used in the highest position, other dishes may be cooked

on the fifth position. When used in

lowest position, another dish may be

prepared on the second shelf position.

Roasting Tin with Integral

Trivet

The roasting tin will hold an oven

ready joint or fowl up to a weight of

5.5kg. The trivet reduces fat splash

during open roasting.

To Reduce Fat Splash

Dry meat and vegetables thoroughly

before loading oven. Potatoes or

other vegetables that require to be

roasted around the joint should first

be brushed with oil or melted fat before positioning. Use a smaller tin for

roasting lesser joints or small

amounts of vegetables. Do not use

aluminium foil to cover shelves, linings or oven roof .

Foil should only ever be used to

cover food. It is important to avoid

blocking the ov en v ent.

Baking T rays

For even browning, the recommended size of tray is 320mm x

305mm. Two such tr a ys are supplied

with the unit.

Up to 16 small cakes, biscuits,

scones etc. may be prepared per

tray.

The tray front trim should be placed

level with shelf front edge.

For extra base browning of pastry

dishes, pre-heat a tray for 15 minutes before placing dish in tray

centre. If small dishes (i.e. less than

140mm diameter) are used, these

should be placed on a baking tray.

In circumstances where spillage or

boiling over may occur during the

cooking process, always place the

dish on a suitable baking tray.

Cooking Hints

Cooking high moisture content foods can

create a ‘steam

burst’, when the

oven door is

opened. When

opening the

oven stand well

back and allow

any steam to disperse.

When the oven is on,

don’t leave the door

open for longer than necessary, otherwise the knobs may get very hot.

The following operations may be

performed in either or both ovens:-

• Baking • Roasting • Pot Roasting •

Braising

The right hand oven is fan-assisted

with six shelf positions and three

shelves supplied. The result of even

distribution of heat within the cavity

means that temperatures and times

will be less than those of a natural

convection ov en.

The left hand oven has five shelf positions. A standard shelf, drop shelf

and Handyrack are supplied. This

oven relies upon natural convection

(zonal heat) for cooking.

The control has been calibrated to

achieve a desired setting as a measurement of the centre temperature

(Shelf 3). If the oven is found to be

hotter or cooler than the specified

mark, the thermostat may require to

be replaced.

With regard to the left hand oven,

the heat will rise regardless of the

centre temperature and the cavity

top will always be hotter than the

lower area.

This situation can be advantageous,

i.e.

Shelf I Browning Meringues,

Crispy Bacon.

Shelves 2 & 4 Baked items

(Scones, etc.)

Shelf 3 Ribs of Beef

When using the left hand oven, it is

important to note that because of

the heat variation, the food shelf positions require to be changed during

the cooking cycle. This is particularly

applicable to baked items such as

scones, biscuits, etc. Shelf Positions

2 and 4 should be utilised in such instance.

With regard to the cooking charts in the case of single tray cooking, it

is recommended that Positions 2 or

3 be utilised. In the case of two shelf

cooking, Positions 2 and 4 should be

used. This is also relevant if the digits 2, 3 and 4 appear in the shelf

column.

USING A PROBE

A hand held thermometer is an asset to any kitchen and is particularly

useful in the preparation of meat,

fish and dishes such as paté. A

probe is recommended for checking

that a joint or piece of poultry is sufficiently cooked by inserting the

probe through the thickest part of

the meat.

When using a probe it is important to

seek the centre of the foodstuff being prepared.

Page 10

Users Manual 211 EEO Dual Fuel

Page 10

Left Hand Oven Cooking Chart

MEAT and MEAT PRODUCTS Cooking Method °C Shelves Time (mins)

Topside of Beef (3.6kg) Braised 160 2, 3, 4 (5) 165

Beef Steaks (142g Rump) Braised 190 2, 3, 4 110

Forerib of Beef (3.6kg) Roast 190 4 (5) 140

Fillet of Beef (2.3kg) Roast 220 2, 3, 4 85

Leg of Lamb (2.3kg) Roast 200 2, 3, 4 (5) 120

Loin of Lamb (1.4kg) Roast 220 2, 3, 4 60

Shoulder of Lamb (2.3kg) Pot Roast 200 2, 3, 4 125

Leg of Pork (4.1kg) Roast 190 2, 3, 4 (5) 170

Loin of Pork (2.3kg) Roast 220 2, 3, 4 110

Gammon (4.1kg) Bake 180 4 (5) 170

Savoury Meatballs Braised 200 2, 3, 4 7 0

Cottage Pie Bake 200 2, 3, 4 4 0

Steak Pie Bake 220 2, 3, 4 3 0

Moussaka Bake 200 2, 3, 4 3 5

Lamb Hot Pot Bake 200 2, 3, 4 50

Lasagne Bolognaise Bake 220 2, 3, 4 65

Beef Olives Braised 180 2, 3, 4 120

POULTRY Cooking Method °C Shelves Time (mins)

Whole Chicken (1.6kg) Roast 200 2, 3, 4 (5) 80

Chicken Legs Roast 200 2, 3, 4 3 5

Chicken Supremes Baked 220 2, 3, 4 2 5

Chicken Drumsticks Roast 200 2, 3, 4 2 5

Whole Duck (2.3kg) Roast 190 2, 3, 4 (5) 110

Duck Breast Roast 190 2, 3, 4 35

Whole T urkey (8.2kg) Roast 150 5 240

Chicken Casserole Br aised 20 0 2, 3, 4 80

FISH Cooking Method °C Shelves Time (mins)

Haddock Fillets (Crumbed) Baked 22 0 2, 3, 4 9

Cod Fillets (Crumbed) Baked 22 0 2, 3, 4 10

Whole Mackerel Baked 200 2, 3, 4 11

Rainbow Trout Baked 220 2, 3, 4 11

Herring Fillets (Oatmeal) Baked 22 0 2, 3, 4 9

Salmon Steaks Baked 20 0 2, 3, 4 12

Fish Pie (Potato Topped) Baked 200 2, 3, 4 15

Salmon En Croute (Individual) Bake d 200 2, 3, 4 30

Fish Cakes (Individual) Baked 22 0 2, 3, 4 20

FARINACEOUS Cooking Method °C Shelves Time (mins)

Rice Pilaff Braised 220 2, 3, 4 20

Vegetarian Lasagne Baked 20 0 2, 3, 4 55

Macaroni Au Gratin Baked 200 2, 3, 4 40

POTATOES Cooking Method °C Shelves Time (mins)

Roast P otatoes Roast 220 2, 3, 4 30

Fondant Potatoes Braised 220 2, 3, 4 35

Dauphinoise P otatoes Baked 200 2, 3, 4 30

Jacket Potatoes Baked 20 0 2, 3, 4 55

Boulangere Potatoes Bak e d 2 2 0 2, 3, 4 30

Bretonne P otatoes Baked 200 2, 3, 4 40

Page 11

Users Manual 211 EEO Dual Fuel

Page 11

VEGETABLES Cooking Method °C Shelves Time (mins)

Red Cabbage Braised 200 2, 3, 4 60

Parsnips Roast 220 2, 3, 4 30

Stuffed Whole Tomatoes Baked 20 0 2, 3, 4 12

Celery Braised 200 2, 3, 4 60

Stuffed Marrow Ba k e d 190 2, 3, 4 45

Whole Onions Roast 220 2, 3, 4 50

Whole Lettuce Braised 190 2, 3, 4 40

Whole Leeks Braised 200 2, 3, 4 25

Fennel Braised 200 2, 3, 4 45

Stuffed Peppers Bak e d 220 2, 3, 4 40

MISCELLANEOUS Cooking Method °C Shelves Time (mins)

Pizza Baked 220 2, 3, 4 15

Quiche Lorraine B a k ed 190 2, 3, 4 30

Pastry Shells (Blind) Baked 190 2, 3, 4 10

Yorkshire Pudding (Individual) Baked 230 2, 3, 4 25

Toad In The Hale Baked 230 2, 3, 4 30

BAKERY GOODS Cooking Method °C Shelves Time (mins)

Soda Bread Baked 220 2, 3, 4 35

French Breed Baked 220 2, 3, 4 25

Loaf Bread Baked 220 2, 3, 4 30

Dinner Rolls B a k ed 220 2, 3, 4 20

Chelsea Buns Baked 220 2, 3, 4 20

Vol-au-vent Cases Baked 220 2, 3, 4 15

Sausage Rails Bake d 220 2, 3, 4 18

Croissants Baked 220 2, 3, 4 20

Sultana Scones Baked 230 2, 3,4 10

Meringue Shells Baked 90 2, 3, 4 19 0

Muffins Baked 220 2, 3, 4 30

Shrewsbury Biscuits Baked 160 2, 3, 4 25

Gingerbread Round Baked 180 2, 3, 4 35

Viennese Rosettes Baked 160 2, 3,4 25

Apple Turnovers Baked 220 2, 3, 4 30

Chocolate Sponge Baked 180 2, 3, 4 25

Victoria Sponge Baked 180 2, 3, 4 25

Banana Loaf Baked 180 2, 3,4 50

Mincemeat Pies B a k e d 220 2, 3, 4 20

Fruit Slice Baked 190 2, 3, 4 35

Profiteroles Baked 220 2, 3, 4 22

Rich Fruit Cake Baked 150 4 150

Cherry Cake Baked 160 2, 3, 4 60

Shortbread Baked 160 2, 3, 4 30

SWEETS and DESSERTS Cooking Method °C Shelves Time (mins)

Eves Pudding Baked 200 2, 3, 4 50

Bread and Butter Pudding Baked 180 2, 3, 4 45

Apple Tart Baked 200 2, 3, 4 35

Bakewell Tart Bake d 190 2, 3, 4 35

Queen of Puddings Bake d 200 2, 3, 4 20

Rice Pudding Baked 180 2, 3, 4 90

Rhubarb Crumble Baked 190 2, 3, 4 30

Stuffed Apples Baked 200 2, 3, 4 20

Pavlova Baked 110 3 & 5 145

Creme Caramel Baked 160 2, 3, 4 30

Jam Roll Baked 190 2, 3, 4 35

Page 12

Users Manual 211 EEO Dual Fuel

Page 12

Right Hand Fan Oven Cooking Chart

MEAT and MEAT PRODUCTS Cooking Method °C Shelves Time (mins)

Topside of Beef (2.3kg) Braised 150 3, 6 150

Beef Steaks (142g Rump) Braised 180 2, 4, 6 100

Forerib of Beef (3.6kg) Roast 180 3, 6 125

Fillet of Beef (2.3kg) Roast 210 2, 4, 6 75

Leg of Lamb (2.3kg) Roast 180 2, 4, 6 110

Loin of Lamb (1.4kg) Roast 200 2, 4, 6 50

Shoulder of Lamb (2.3kg) Pot Roast 190 2, 4, 6 115

Leg of Pork (4.1kg) Roast 180 3, 6 160

Loin of Pork (2.3kg) Roast 200 2, 4, 6 100

Gammon (4.1kg) Bake 170 3,6 1 60

Savoury Meatballs Braised 190 2, 4, 6 60

Cottage Pie Bake 190 2, 4, 6 35

Steak Pie Bake 200 2, 4, 6 30

Moussaka Bake 190 2, 4, 6 30

Lamb Hot Pot Bake 190 2, 4, 6 45

Lasagne Bolognaise Bake 200 2, 4, 6 60

Beef Olives Braised 170 2, 4, 6 110

POULTRY Cooking Method °C Shelves Time (mins)

Whole Chicken (1.6kg) Roast 190 2, 4, 6 75

Chicken Legs Roast 190 2, 4, 6 30

Chicken Supremes Baked 200 2, 4, 6 20

Chicken Drumsticks Roast 190 2, 4, 6 20

Whole Duck (2.3kg) Roast 180 2, 4, 6 100

Duck Breast Roast 180 2, 4, 6 30

Whole T urkey (8.2kg) Roast 130 5 220

Chicken Casserole Br aised 190 2, 4, 6 70

FISH Cooking Method °C Shelves Time (mins)

Haddock Fillets (Crumbed) Baked 200 2, 4, 6 8

Cod Fillets (Crumbed) Baked 200 2, 4, 6 9

Whole Mackerel Baked 190 2, 4, 6 10

Rainbow Trout Baked 200 2, 4, 6 10

Herring Fillets (Oatmeal) Baked 200 2, 4, 6 8

Salmon Steaks Baked 190 2, 4, 6 11

Fish Pie (Potato Topped) Baked 190 2, 4, 6 14

Salmon En Croute (Individual) Bake d 190 2, 4, 6 25

Fish Cakes (Individual) Baked 200 2, 4, 6 15

FARINACEOUS Cooking Method °C Shelves Time (mins)

Rice Pilaff Braised 200 2, 4, 6 18

Vegetarian Lasagne Baked 190 2, 4, 6 50

Macaroni Au Gratin Baked 190 2, 4, 6 30

POTATOES Cooking Method °C Shelves Time (mins)

Roast P otatoes Roast 200 2, 4, 6 25

Fondant Potatoes Braised 200 2, 4, 6 30

Dauphinoise P otatoes Baked 190 2, 4, 6 25

Jacket Potatoes Baked 190 2, 4, 6 50

Boulangere Potatoes Bak e d 200 2, 4, 6 25

Bretonne P otatoes Baked 190 2, 4, 6 35

Page 13

Users Manual 211 EEO Dual Fuel

Page 13

VEGETABLES Cooking Method °C Shelves Time (mins)

Red Cabbage Braised 190 2, 4, 6 50

Parsnips Roast 200 2, 4, 6 25

Stuffed Whole Tomatoes Baked 190 2, 4, 6 10

Celery Braised 190 2, 4, 6 50

Stuffed Marrow Ba k e d 180 2, 4, 6 40

Whole Onions Roast 200 2, 4, 6 45

Whole Lettuce Braised 180 2, 4, 6 35

Whole Leeks Braised 190 2, 4, 6 20

Fennel Braised 190 2, 4, 6 40

Stuffed Peppers Bak e d 200 2, 4, 6 35

MISCELLANEOUS Cooking Method °C Shelves Time (mins)

Pizza Baked 200 2, 4, 6 12

Quiche Lorraine B a k ed 180 2, 4, 6 25

Pastry Shells (Blind) Baked 180 2, 4, 6 8

Yorkshire Pudding (Individual) Baked 220 2, 4, 6 20

Toad In The Hole Baked 220 2, 4, 6 25

BAKERY GOODS Cooking Method °C Shelves Time (mins)

Soda Bread Baked 200 2, 4, 6 25

French Bread Baked 200 2, 4, 6 25

Loaf Bread Baked 200 2, 4, 6 25

Dinner Rolls B a k ed 200 2, 4, 6 18

Chelsea Buns Baked 200 2, 4, 6 18

Vol-au-vent Cases Baked 200 2, 4, 6 14

Sausage Rolls Baked 200 2, 4, 6 15

Croissants Baked 200 2, 4, 6 18

Sultana Scones Baked 200 2, 4, 6 9

Meringue Shells Baked 100 2, 4, 6 180

Muffins Baked 200 2, 4, 6 25

Shrewsbury Biscuits Baked 150 2, 4, 6 20

Gingerbread Round Baked 160 2, 4, 6 30

Viennese Rosettes Baked 150 2, 4, 6 20

Apple Turnovers Baked 200 2, 4, 6 25

Chocolate Sponge Baked 170 2, 4, 6 20

Victoria Sponge Baked 170 2, 4, 6 20

Banana Loaf Baked 170 3, 6 45

Mincemeat Pies B a k e d 200 2, 4, 6 18

Fruit Slice Baked 180 2, 4, 6 30

Profiteroles Baked 210 2, 4, 6 20

Rich Fruit Cake Baked 140 3, 6 145

Cherry Cake Baked 150 3, 6 55

Shortbread Baked 150 2, 4, 6 25

SWEETS and DESSERTS Cooking Method °C Shelves Time (mins)

Eve’ s Pudding Bak e d 190 2, 4, 6 45

Bread and Butter Pudding Baked 170 2, 4, 6 40

Apple Tart Baked 190 2, 4, 6 30

Bakewell Tart Bake d 180 2, 4, 6 30

Queen of Puddings Bake d 190 2, 4, 6 18

Rice Pudding Baked 170 2, 4, 6 80

Rhubarb Crumble Baked 180 2, 4, 6 25

Stuffed Apples Baked 190 2, 4, 6 18

Pavlova Baked 100 2, 4, 6 125

Creme Caramel Baked 150 2, 4, 6 25

Jam Roll Baked 180 2, 4, 6 30

Page 14

Users Manual 211 EEO Dual Fuel

Page 14

Grill Operation

To Operate Grill

The two element grill allows the entire area to be heated or

alternatively for smaller portions,

right hand side may be used independently.

For full operation, turn switch knob

clockwise to Setting 3.

For half operation, turn switch

knob anti-clockwise to Setting 3.

This will activate the right hand element only .

The neon indicator light by the grill

control will come on.

Grill Operation

1 - LOW for Melba toast (Setting 1)

2 - MEDIUM for tomatoes, liver,

cauliflower au gratin. (Setting 2)

3 - HIGH for rare steak and toast.

(Setting 3)

USING THE GRILL

Reversible T oasting T rivet

a) Open door and remove pan from

storage position. Rest pan on

compartment door.

b) Select full or half operation and

switch to Low, Medium or High as

indicated above. Pre-heat the grill

for 5 minutes.

c) Load pan and position between the

side supports at desired level or

upon the base of the compartment. Ensure handle of grill pan

does not enter the compartment. The toasting trivet can be

turned over to give a further grilling position.

e) Depending on food type and

amount being prepared, it may be

necessary to turn food during

cooking

f) After use, turn control OFF.

g) Allow compartment to cool before

returning grill pan to storage posi-

tion.

ACCESSIBLE PARTS MAY BE HOT

WHEN THE GRILL IS IN USE.

IN USE

Grilling is a direct method of cooking

where heat radiates down on the

food. It is both quick and simple and

can be used to prepare a wide and

varied list of foods such as:

Whole Foods, Cuts of Meat or

Fish, Made-up Dishes, Tomatoes,

Herring, Lamb Chops, Salmon

Steaks, Kebabs

These may be cooked by placing

items on wire trivet or brander plate.

In addition to this, the grill can also

be used for the follo wing:

Browning (Duchess P otatoes)

Gratinating (Cauliflower au

Gratin)

Glazing (Fillets of Fish Bonne

Femme)

Toasting (Bread, Tea Cakes,

Melba T oast)

The heat is easily controlled and

cooking times are dependent upon

the following criteria:

Cut(s) of Meat or Fish (as applicable)

Freshness of Produce

Size and Weight of Produce

and perhaps most importantly, Personal Preference

Ultimately, it is experience that determines what type of food merits

which setting.

CHEFS TIPS for GRILLING

Always pre-heat the grill prior to

use.

Accessible parts may be hot

when using the grill. Never turn

grill on with the door closed or

with the pan in the storage position.

When in use, the grill pan must be

pushed to the compartment rear

at the required level (compartment bottom or grill pan

supports). The handle of the pan

should never enter the compartment.

After use, store grill pan on the

bottom of the grill compartment.

Page 15

Users Manual 211 EEO Dual Fuel

Page 15

The temperatures to be expected are as f ollo ws:

Food Item Condition Core Temp Range °C

Beef Rare 50-55

Beef Medium/Rare 55-60

Beef Medium 60-65

Beef Medium/W ell done 65-75

Beef Well done 75-80

Lamb Medium 65-70

Lamb Well Done 70-80

Chicken Cooked through 80-85

Duck Cooked through 70-75

Fish Cooked through 70-75

Gammon Cooked through 75-80

Goose Cooked through 70-75

Patés and Terrines Cooked through 75-80

Pork Cooked through 80-85

Turkey Cooked through 75-80

V eal Medium/Well done 65-75

Grill Cooking Chart

MEAT

Time (mins)

Back Bacon Rashers 2

Chicken Satay 6

Fillet Steak (170g) 10

Sirloin Steak (170g) 10

Hamburger (113g) 8

Lamb Chop 12

Lamb Kidneys 8-9

Lamb’s Liver 5

Pork Chops 1 2

Pork Sausage (57g) 8

Pork Kebabs 10

FISH

Time (mins)

Cod Fillet 7

Halibut Steaks 10-11

Herring Fillets in Oatmeal 7

Lemon Sole Fillets 5

Salmon Steaks 10

Whole Mackerel 11-12

Whole T rout 10

MISCELLANEOUS

Time (mins)

Mush rooms 3-4

Toasted Cheese 2

Whole T omatoes 4-5

Brander Plate

The combination of heat from the

element(s) above with that of the

plate directly below the food helps to

reduce conventional grilling times.

Seasoning The Brander

Plate

a) The brander must be seasoned

before use. When food begins to

stick, the process needs to be re-

peated.

b) Pre-heat the oven to 200°C

c) Lightly oil brander and cover sur-

face with cooking salt.

d) Place brander on a suitable baking

tray and insert into oven for ap-

proximately 30 minutes.

e) Remove brander when salt turns

light brown in colour.

f) Allow salt to cool before brushing

away.

g) Dress brander surface with oil and

burn on in oven for 5 minutes .

The plate is now ready for

use.

Using the Brander Plate

a) Open door and remove pan from

storage position. Sit br anding plate

in grill pan and lightly oil.

b) Select full or half operation and

switch to Low, Medium or High as

indicated above.

c) Insert grill pan within compartment

and pre-heat brander for 5 minutes.

d) Load brander and position be-

tween the side supports at desired

level or upon base of compartment.

Ensure handle of grill pan

does not enter compartment.

e) Turn food every 2 - 3 minutes to

ensure even cooking and to

achieve a branded effect.

f) After use, turn control OFF.

g) Allow compartment to cool before

returning grill pan to storage posi-

tion.

ACCESSIBLE PARTS MAY BE HOT

WHEN GRILL IS IN USE.

The Ambient Drawer

USING THE AMBIENT DRAWER

Located directly below the right

oven, this is not heated.

In normal circumstances, the drawer

condition will be ambient temperature. On occasion however, it will

absorb heat from the oven(s).

This provides an ideal condition in

which to prove yeast goods such as

croissants, bread and Chelsea

buns.

Alternatively the drawer is ideal for

the storage of roasting tins, baking

trays and other cooking utensils.

Do not store any flammable material

(e.g. pans with wooden handles).

Page 16

Users Manual 211 EEO Dual Fuel

Page 16

Cleaning

It is necessary to clean the unit

regularly to help maintain performance, efficiency, hygiene and

safety.

Whenever possible, wipe up

spillages as they occur to prevent

deposits becoming burnt-on. These

can be difficult to remove. Allow unit

to cool before commencing to clean

it.

NEVER USE PAINT SOLVENTS,

WASHING SODA, CAUSTIC

CLEANERS, BIOLOGICAL POWDERS, COARSE ABRASIVES OR

SALT.

Hob

It’s v ery easy to clean the Hob with a

recommended cleaner.

CAUTION — Do not use abrasive

cleaners or pads, oven aerosols or

pads or stain removers on the surface.

Daily care

First of all, be sure that all heat indicator lights are off and the cooking

surface is cool. Apply a small dab,

about the size of a 10p piece, of ceramic cooking cleaning cream in the

centre of each area to be cleaned.

Dampen a clean paper towel and

work the cleaning cream on the

cooking surface as if you were

cleaning a window. As a final step,

wipe the cooking surface with a

clean, dry paper towel.

Cleaning for spills

For spills and boil-overs that occur

while cooking, turn the unit off and

wipe the area surrounding the hot

zone with a clean paper towel. If a

spill (other than a sugary substance)

is on the hot zone, do not clean until

the unit is completely cooled down

and follow the instructions below

(“Cleaning for burned-on spills”). If

you accidentally melt anything on

the cooking or if you spill foods with

a high sugar content (preserves, tomato sauce, etc.), REMOVE the spill

IMMEDIATELY with a razor scraper,

while the unit is still hot. IMPORTANT: Use an oven glove to protect

your hand from potential burns.

Scrape the major spill or melted ma-

terial from the cooking zone and

push into a cold area. Then, turn the

unit “OFF” and allow to cool before

cleaning further. After the cooking

surface cools down and the heat indicator lights go off, use the daily

care procedure as outlined above.

Cleaning for burned-on spills

Be sure that the heat indicator lights

are off and the hob is cool. Remove

excess burned-on substance with a

single-edged razor scraper . Hold the

scraper at approximately a 30° angle to the surface and scrape off the

burned-on matter as you would

scrape paint off of a window .

IMPORTANT: Take care when using

a sharp scraper.

When you have removed as much

as possible with the scraper clean

using the daily care procedure as

described above.

To remove metal rub-off

Sliding pans on the hob - especially

aluminium or copper pans can leave

marks on the surface. These marks

often appear like scratches, but can

be easily removed using the procedure described above for cleaning

spills. If the rub-off marks are especially stubborn, use the cleaning

cream together with the razor

scraper, using the technique described above.

Grill Pan, Trivet and

Brander Plate

Remove stubborn particles from

trivet or brander using a stiff brush

or scouring pad. Clean in hot soapy

water. Having prepared meat or

foods that soil, leave to soak for a

few minutes immediately after use .

Vitreous Enamelled

Surfaces

Only use cleaners approved for use

on vitreous enamel.

It is advisable to clean such surfaces daily after use. Wipe clean

whilst still warm with a soft cloth

soaked in hot, soapy water.

Badly stained areas should be

cleaned by applying an approved

detergent to hot water and removed

using a nylon or Scotch Brite pad.

Oven

Cleaning is easier if carried out

whilst oven is still warm. F or remov al

and cleaning of roof, sides and rear

linings (these have a special enamel

finish) refer to cook and clean linings

section which follows.

Cook and Clean Oven

Linings

Coated with a special enamel, these

effect self cleaning to reduce soil

level.

The linings will be more effective if

fat splash is kept to a minimum. This

may be av oided b y :

Covering meat with foil or a roasting bag.

Drying meat before placing in

roasting tin

Lightly brush potatoes with fat

before placing around meat

Lining stains are removed by means

of oxidation when oven is heated.

These will not always disappear if

oven is only used at low temperatures.

If heavy splashing occurs, wipe linings with a lint free cloth and hot

soapy water .

Dry linings thoroughly and replace

before heating at 200°C for approximately one hour.

Removing shelves may cause a metallic rubbing on linings; this is

normal. Do not use abrasives,

scrapers, knives, scourers, paste,

bleach, steel wool, aerosol or proprietary pads on the linings.

It is not our claim that residue marks

will not appear on these parts, only

that they require the minimum of attention.

Page 17

Users Manual 211 EEO Dual Fuel

Page 17

Removing the Oven Linings

Some of the lining panels can be removed for cleaning and for cleaning

behind. Remove the shelves first.

The right hand fanned oven has a

removable oven roof - slide the roof

liner forward and remove .

The side panels of either oven can

be removed.

Each side of the oven is fixed with

four fixing screws.

You don’t have to remove the scre ws

to remove the oven linings. Lift each

side panel upwards and they will

slide off the screws. Then pull them

forwards.

Once the linings are removed, the

oven enamel interior can be

cleaned.

When replacing the linings fit the

side linings first.

Make sure you fit the oven roof with

the slot at the front.

Cleaning Brass

Components

Uncoated natural brass is

used as part of the authentic

unit finish and may tarnish

with age.

To regain a polished finish,

these areas should be

cleaned using a proprietary

cleaner such as Brasso.

Page 18

Users Manual 211 EEO Dual Fuel

Page 18

Troubleshooting

A crack has appeared in the Hob

surface

Disconnect the cooker immediately

from the power supply and arrange

for its repair. Don’t use the cooker

until after the repair. See the Customer care leaflet for how to contact

a service person.

My Hob is scratched

Have you used the correct cleaning

methods?

Pots and pans with rough bottoms,

or coarse particles (salt or sand) between the pan and the surface of the

hob may cause scratches.

Use the recommended cleaning

methods. Make sure pan bottoms

are smooth and clean. Tiny

scratches are not removable but will

become less visible in time as a result of cleaning.

Metal markings on the Hob

Do not slide aluminium or copper

pans across the surface. Marks from

aluminium and copper pans as well

as mineral deposits from water or

food can be remov ed with the cleaning cream.

Steam is coming from the oven

When cooking foods with a high water content (e.g. oven chips) there

may be some steam visible at the

rear grille. Take care when opening

the oven door as there ma y be a momentary puff of steam when the

oven door is opened. Stand well

back and allow any steam to disperse.

The oven fan is noisy

The note of the oven fan may

change as the oven heats up - this is

perfectly normal.

What cleaning materials are

recommended for the cooker?

See the ‘Cleaning’ section of the

Easy Guide for a full list of recommended cleaning materials. We do

not recommend Mr. Muscle, as it

contains chemicals that may damage the surfaces of your cooker.

The knobs get hot when I use the

oven or the grill, can I avoid this?

Yes, this is caused by heat rising

from the oven or the grill, and heating them up. Don’t leave the oven

door open. Make sure that the grill

pan is pushed right back to the ‘bac k

stop’ when grilling.

If there is an installation problem

and I don’t get my original installer

to come back to fix it who pays?

You do. Service organisations will

charge for their call outs if they are

correcting work carried out by your

original installer. It’s in your interest

to track down y our original installer .

Current Operated Earth Leakage

Breakers

Where the cooker installation is protected by a 30 milliamp sensitivity

residual current device (RCD), the

combined use of your cooker and

other domestic appliances may occasionally cause nuisance tripping.

In these instances the cooker circuit

may need to be protected by fitting

100mA device. This work should be

carried out by a qualified electrician.

Food is cooking too slowly, too

qui ckly, or burn i n g

Cooking times may differ from your

previous oven. Check that you are

using the recommended temperatures and shelf positions. See page

15. The oven control settings and

cooking times are intended to be

used only as a guide. Individual

tastes may require the temperature

to be altered either way, to get the

results you want. Try cooking at a

higher temperature setting. Is the

oven roof in?

The oven is not cooking evenly

Do not use a tin or tray larger than

320mm x 305mm.

If you are cooking a large item, be

prepared to turn it round during

cooking.

If two shelves are used, check that

space has been left for the heat to

circulate. When a baking tray is put

into the oven, make sure it is placed

centrally on the shelf.

Check that the door seal is not damaged and that the door catch is

adjusted so that the door is held

firmly against the seal.

A dish of water when placed on the

shelf should be the same depth all

over. (For example, if it is deeper at

the back, then the back of the

cooker should be raised up or the

front lowered). If the cooker is not

level arrange for your supplier to

lev el it f or you.

Oven not coming on when turned

on manually

Is the power on? Is the clock illuminated? If not there may be

something wrong with the power

supply. Is the cooker supply on at

the isolator switch? Is the clock

flashing 0.00? If so set it to the correct time of day. Has the Timer been

set to AUTO by mistake? If AUTO is

showing on the clock display, press

the ‘cook period’ button and reduce

any set cooking time showing to

0.00, with the (+) and (-) buttons.

Press the button twice. If this

does not solve the problem contact

a service person.

Oven not coming on when

automatic cooking

Timer set correctly but oven knob

left OFF by mistake?

Oven temperature getting hotter as

the cooker gets older

If turning the knob down has not

worked or only worked for a short

time then you may need a new thermostat. This should be fitted by a

service person.

Page 19

Users Manual 211 EEO Dual Fuel

Page 19

Grill not cooking properly

Are you using the pan and trivet

supplied with the cooker? Is the pan

being used on the runners, not the

floor of the compartment? Is the grill

tray pushed fully back to stop?

The oven light is not working

The bulb has probably blown. You

can buy a replacement bulb (which

is not covered under the guarantee)

from a good electrical shop. Ask for

an Edison screw fitting 15w 240v

lamp, FOR OVENS. It must be a

special bulb, heat resistant to 300

°C. See the Customer Care leaflet

for spares by mail order.

Open the oven door and remov e the

Handyrack (if fitted) and oven

shelves.

Turn off the power supply.

Unscrew the bulb cover by turning

anticlockwise. Unscrew the old bulb.

Screw in the new bulb, screw back

the bulb cover. Turn on the electricity

supply and check that the bulb now

lights.

Page 20

Users Manual 211 EEO Dual Fuel

Page 20

The cooker must be installed by a

qualified electrician in accordance

with the installation instructions. It

should be serviced by a qualified

service engineer and only approved spare parts used. Have the

installer show you the location of

the cooker control switch. Mark it

for easy reference. Always allow

the cooker to cool and then switch

off at the mains and before cleaning or carrying out any

maintenance work, unless specified otherwise in this guide.

All parts of the cooker become hot with use and will

retain heat even after you

have stopped cooking.

Take care when touching the hob

especially the marked cooking areas. The glass surface of the hob

will retain heat after the controls

have been turned off. To minimize

the possibility of burns, always be

certain that the hob controls are in

the OFF position and that the entire glass surface is cool before

attempting to clean the hob.

Use dry oven gloves when

applicable - using damp

gloves might result in steam

burns when you touch a hot

surface. Never operate the

cooker with wet hands.

Do not use a towel or other bulky

cloth in place of a glove. They

might catch fire if they touch a hot

surface.

Always turn the surface unit

controls off before removing

the pans.

Don’t place utensils on the hob

surface when it is in use. They may

become hot and could cause

burns.

Clean the hob with caution. If

a wet sponge or cloth is used

to wipe spills on a hot surface

unit, be careful to avoid steam

burns. Some cleansers can

produce noxious fumes if applied to a hot surface.

Do not use unstable saucepans and

position the handles away from the

edge of the hotplate.

Babies, toddlers and young

children should not be allowed

near the cooker at any time.

They should never be allowed

to sit or stand on any part of

the appliance. Teach them not

to play with controls or any

other part of the cooker.

Never store anything of interest to

children in cabinets above a cooker children climbing on the cooker to

reach them could be seriously injured.

Clean only parts listed in this

guide.

In the interests of hygiene and

safety the cooker should be kept

clean at all times as a build up in fats

and other food stuff could result in a

fire.

We recommend that you a void

wiping any surface unit areas

until they have cooled and the

indicator light has gone off.

Sugar spills are the exception

to this. Please see ‘Cleaning

your cooker’. When the hob is

cool, use only the recommended cleaning cream to

clean the hob.

To avoid possible damage to the

cooking surface, do not apply the

cleaning cream to the glass surface

when it is hot. Read and f ollo w all instructions and warnings on the

cleaning cream labels. After cleaning, use a dry cloth or paper towel to

remove any cleaning cream residue.

Avoid heating an empty pan.

Doing so may damage the

hob and the pan.

Always k eep combustib le wall cov erings or curtains etc. a safe distance

awa y from y our cooker.

Do not place or store items on

top of the glass hob surface

when it is not in use.

Do not spray aerosols in the vicinity

of the cooker while it is in on.

Do not store or use combustible materials, or flammable

liquids in the vicinity of this appliance.

Do not use water on grease fires.

Never pick up a flaming pan. Turn

the controls off. Smother a flaming

pan on a surface unit by covering

the pan completely with a well fitting

lid or baking tray. If available use a

multipurpose dry chemical or foamtype fire extinguisher .

Never leave the hob unattended at high heat settings.

Pans boiling over can cause

smoking and greasy spills

may catch on fire.

Never wear loose-fitting or hanging

clothes while using the appliance.

Be careful when reaching for items

stored in cabinets over the hob.

Flammable material could be ignited

if brought in contact with a hot surface unit and may cause severe

burns.

Take great care when heating

fats and oils, as they will ignite

if they get too hot.

Use a deep fat thermometer whenever possible to prevent overheating

fat bey ond the smoking point.

Never leave a chip pan unattended. Alw a ys heat f at slo wly,

and watch as it heats. Deep

fry pans should be only one

third full of fat. Filling the pan

too full of fat can cause spill

over when food is added. If

you use a combination of oils

or fats in frying, stir them to-

General Safety Instructions

Page 21

Users Manual 211 EEO Dual Fuel

Page 21

gether before heating, or as

the fats melt.

Foods for frying should be as dry as

possible. Frost on frozen foods or

moisture on fresh foods can cause

hot fat to bubble up and over the

sides of the pan. Carefully watch for

spills or overheating of foods when

frying at high or medium high temperatures. Never try to move a pan

of hot fat, especially a deep fat fryer.

Wait until the fat is cool.

When the grill is on, do not

use the top of the flue (the slot

along the back of the cooker)

for warming plates, dishes,

drying tea towels or softening

butter.

When using an electrical appliance

near the hob, be sure that the cord

of the appliance does not come into

contact with the surface area.

If you find a crack in the hob

surface immediately disconnect the appliance from the

supply and arrange for its repair.

Take care that no water seeps into

the appliance

Only certain types of glass,

glass-ceramic, earthenware or

other glazed containers are

suitable for hob cooking; others may break because of the

sudden change in temperature.

Use proper pan size-select pans

having flat bottoms large enough to

cover the surface unit’s heating

area. The use of undersized pans

will expose a portion of the surface

unit to direct contact and may result

in ignition of clothing. Proper relationship of pans to surface unit will

also improve efficiency.

Do not allow anyone to climb,

stand or hang on any part of

the cooker.

Do not use aluminium foil to cover

shelves, linings or the ov en roof .

Make sure that your kitchen is

well ventilated at all times. Use

extractor fans or hoods when

fitted.

Never heat unopened food containers. Pressure build up may make

container burst and cause injury .

The cooker is designed for

cooking foods only and must

not be used for any other purpose.

The oven should NOT be used for

heating the kitchen, not only does

this waste fuel but the control knobs

may become overheated.

When the oven is on DO NOT

leave the oven door open for

longer than necessary.

The specification of this cooker

should not be altered.

This appliance is heavy, take

care when moving it.

When the cooker is not in use ensure that the control knobs are in the

off position.

Do not slide pans across the

hob because this can scratch

the glass - the glass is scratch

resistant, not scratch proof.

Sharp instruments, rings or

other jewellery and rivets on

clothing could scratch the hob

surface.

Do not use the surface as a cutting

board.

Don’t store heavy items above

the hob. If they drop on the

hob, they could cause damage.

Page 22

Optional Extras - 211 EEO Dual Fuel

Page 22

Optional Extras

Splashback Fitting Instructions

The splashback should be positioned on the wall in line

with the unit bottom edge, 75mm below hob level. 4 x

5mm holes require to be drilled 7.5mm from the splashback edge at top and bottom.

Position panel against wall. Mark fixing locations through

existing holes.

Drill 6mm holes in the wall and push the rawlplugs provided fully home into these holes.

Position splashback and secure to wall using the fixings

provided.

Utensil Rack Fitting Instillation

UTENSIL RACK KIT CONTENTS

Item Description No. Off

A Brass Backing Plate 2

B Brass Rail End 2

C Countersunk Screw (M5) 4

D Stainless Steel Rail I

E Rawlplug 4

F Brass Countersunk Screw 4

Important Note

It is not advisable to install the utensil rack directly above the

appliance flue.

I. Secure the backing plates (A) to the rail ends (B) using

the fixings (C).

2. Slide both ends on to the rail.

3. Hold the assembled rack in the required position

against the wall and mark the location points through

the fixing holes.

4. If using the rawlplugs (E) provided, drill 4 x 6mm

holes and push the plugs fully home into these.

5. Secure the rack to the wall using the brass fixings (F)

Page 23

Optional Extras - 211 EEO Dual Fuel

Page 23

Flue Spacer Fitting Instructions

1. Working from the unit rear, remove the fixings that secure the flue capper to the hob. The centre fixing

should be removed last. When this has been removed,

the flue clamp plate will loosen. Allow the plate to rest

on the two flue box es .

2. Remove the flue capper.

3. Position the flue spacer on the hob and align the fixing

holes.

4. Starting with the centre fixing, secure the flue spacer to

the hob and tighten. Ensure that the flue clamp plate

has been repositioned.

Page 24

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 24

Installation and

Servicing Instructions

This appliance must be installed and serviced by a

competent person.

IMPORTANT

The unit shall be installed in accordance with the regulations

in force at the time. Read the instructions thoroughly before installation and subsequent use.

In the UK, regulations and standards are as follows -

BS 6891 :1988

Health And Safety At Work etc. Act

BS 7671 I.E.E. Regulations for Electrical Installations

Local and National Building Regulations

Electricity at Work Regulations

Fire Precautions Act

The appliance has been CE-marked on the basis of compliance with the Low

Voltage and EMC directives for the voltage stated on the data

plate.

WARNING - ALL APPLIANCES MUST BE EARTHED

On completion of the installation, this manual should be left

with the Engineer-in-Charge for reference during servicing.

Further to this, The Users Manual should be handed over to

the Owner, having had a demonstration of the operation and

cleaning of the unit.

IT IS IMPORTANT THAT THESE INSTRUCTIONS BE

CONSULTED PRIOR TO INSTALLING AND COMMISSIONING THIS APPLIANCE.

F AILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY RESULT IN DAMAGE OR THE NEED

FOR A SERVICE CALL.

SECTION 1 - INSTALLATION

UNLESS OTHERWISE STATED, PARTS WHICH HAVE

BEEN PROTECTED BY THE MANUFACTURER ARE

NOT TO BE ADJUSTED BY THE INSTALLER.

1.1 MODEL NUMBERS, NETT WEIGHTS AND

DIMENSIONS

Model Width Depth Height Weight

211-EEO 1100mm 600mm 935mm 140kg

1.2 SITING

1.2.1 Positioning the Appliance (see Figure 1)

Figure 1

The unit is supplied with two rear and one centre front roller for

movement purposes.

To position the range, first remove the kicking strip from the bottom front of the unit. Pull open the drawer to the fur thest point

and lift and pull it forward to remove. The screw that lowers the

front roller is positioned at the LH side of the drawer opening on

the centre support beam.

Place the flat end of the spanner over the square drive peg and

turn this clockwise until the front beam and feet are clear of the

floor. Use the hex end of the spanner to turn the two adjusting

nuts, positioned at either bottom front corner. Six complete turns

clockwise will lower the back rollers and raise the unit rear.

The unit may now be pushed into position.

THE APPLIANCE MUST NOT BE PUSHED, PULLED OR

LIFTED BY THE TOWEL RAIL OR DOOR HANDLES.

Page 25

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 25

Note

Ensure that the floor covering below the range is firmly fixed or

removed to prevent disturbance whilst positioning the appliance.

Figure 2

1.2.2 Levelling

The unit must be levelled following placement. The height at

the back is adjusted by using the hex end of the spanner on

the rear rollers. The front is levelled by initially turning the adjusting screw of the near roller clockwise until the desired

height is achieved. Following this, position the levelling feet by

screwing them down. When the unit is level, turn the front

roller adjuster anti-clockwise until the weight is transferred

from the roller to the feet.

1.2.3 APPLIANCE LOCATION

The unit may be installed in a kitchen/kitchen diner but not in a

room that contains a bath or shower.

1.2.4 Position of Appliance

The space required above the hotplate is indicated in Figure

1.

A width of 1115mm is required up to hotplate level to accom-

modate the additional width required when the doors are

opened fully.

A minimum overhead distance of 800mm is required above

the hob.

Curtains must not be fitted immediately behind the appliance.

Any extraction hood should be installed in accordance with

the manufacturer’s instructions.

1.3 ELECTRICAL SUPPLY

1.3.1 ELECTRICAL CONNECTION

This appliance must be installed by a qualified electrician to comply with the relevant Institute of

Electrical Engineers (I.E.E.) regulations and also local electricity supply company requirements.

WARNING - THIS APPLIANCE MUST BE EARTHED!

Note: The unit must be connected to the correct electrical supply as stated on the data label. A suitable control unit which

incorporates a double pole switch with contact separation of at

least 3mm in all poles must be fitted. This type of unit should

NEVER be connected to a regular power socket.

With diversity taken into consideration, we recommend the

use of a 40 - 45 amp cooker point.

Access to mains terminal is gained by removing electrical terminal cover box on back panel. Connect mains cable to

terminals as indicated below.

Fig. 4

The unit is Type X with regard to protection against the overheating of surrounding surfaces.

Current Operated Earth Leakage Breakers

In the event of an installation being protected by a 30mA sen-

sitivity residual current device (RCD), the combined use of the

unit and other domestic appliances may occasionally cause

nuisance tripping. In such instances , the cooker circuit may require to be protected by fitting a 100mA device. Such work

should be carried out by a qualified electrician.

1.4 ELECTRICAL RATINGS

1.4.1 Hob Element Ratings (230V - 50hz)

Hob Element Rating

Front Left 1.1kW

Rear Left 1.4kW

Rear Right 1.1kW

Front Right 1.1kW

Centre 2.7kW

1.4.2 ADDITIONAL ELECTRICAL RATINGS (230V

- 50HZ)

LH Oven - 2.0kW Browning Element 1.05kW

RH Oven - 2.3kW Grill Element 2.1kW

Page 26

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 26

SECTION 2 - ASSEMBLY and

COMMISSIONING

2.1 ASSEMBLY

After unpacking unit, check following parts -

Part No. Off

Oven Shelves 4

Grill Pan and Grid I

Ceramic Hob Scraper 1

Roasting Tin with T rivet 2

Cake Rack 2

Handy Rack 1

User’s Manual 1

2.2 CONNECTION TO THE ELECTRICITY SUPPLY

Refer to Section 1.3 of this manual.

2.4 PRE-COMMISSIONING CHECK

Check hob elements in turn. Turn control knob to full on

position and leave hob f or a f ew seconds bef ore checking

that heat is radiating from the element.

When check is complete, turn control off and repeat this

procedure for the remaining elements. Check also that

the residual heat indicator remains lit until the corresponding element cools.

SECTION 3 - SERVICING

3.1 SERVICING

Disconnect from electricity supply before commencing

servicing, par ticularly before removing any of the following:- control panel, side panels, ceramic hob or any

electrical components or covers.

Before restoring power, make connection checks as detailed in Section 1.3. Note - References to LH and RH

oven apply as view ed from the front.

3.2 TO REMOVE CONTROL PANEL

Disconnect appliance from electricity supply.

a) Remove control knobs from all taps.

b) Open grill and RH oven doors. Remove 3 fixings on top

front and 3 fixings on control panel underside.

c) Pull control panel forward. Remove connections from

rear of three neons. Disconnect earth lead and lift panel

clear of unit.

d) Replace all parts in reverse order.

e) When replacing any electrical connections refer to the

wiring diagram on Pages 16 and 17.

3.3 TO REMOVE CERAMIC HOB

Disconnect appliance from electricity supply. Pull unit forward

to gain access.

The ceramic hob material is much more sensitive to

scratches on the underside than the top.

Take care not to touch or scratch the underside of

the ceramic as this will weaken the material and

cause the top to shatter.

a) Remove control panel as detailed in Section 3.2.

b) Remove fixing screws on hob underside (2 - front, 4 -

rear).

c) Lift rear and slide ceramic hob forward.

d) Lift ceramic hob clear of appliance taking care not to

damage elements.

e) Replace in reverse order.

3.4 TO REMOVE AN OUTER SIDE PANEL

Disconnect the appliance from the electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove retaining screw on upper front edge and two

fixings on rear of the side panel. Undo lower retaining

screw situated below the edge at panel front corner.

c) Remove panel by pulling it away from unit. If this is diffi-

cult, it may be necessary to slacken the two closest hob

fixing screws

d) Replace parts in reverse order.

3.5 TO REMOVE A RESIDUAL HEAT

INDICATOR

Disconnect appliance from electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove ceramic hob as detailed in Section 3.3.

c) Disconnect the indicator leads.

d) Remove indicator from bracket.

c) Replace all parts in reverse order.

Ensure replacement indicator functions correctly.

Page 27

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 27

3.6 TO REMOVE OVEN/GRILL NEON

Disconnect appliance from electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove relevant connection and undo nut securing

neon to control panel.

c) Replace parts in reverse order. Ensure replacement

functions correctly.

3.7 TO REMOVE A THERMOSTAT

Disconnect appliance from electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove ceramic hob as detailed in Section 3.3.

c) Open appropriate oven door and remove shelves and

linings. For RH oven, slide roof liner away and remove

fixings securing thermostat phial cover.

d) Unclip thermostat phial from clips in oven back panel.

e) For LH oven, pull unit forward to access cover box at

rear. Remove cover fixings and lift clear.

f) Feed thermostat capillary clear of oven.

g) Disconnect wires from thermostat and undo fixings that

secure control to mounting plate.

h) Fit replacement and re-assemble in reverse order. En-

sure phial is clipped to oven rear and positioned

centrally between the clips. Check thermostat functions

correctly.

3.8 TO REPLACE A GRILL CONTROLLER

Disconnect appliance from electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove ceramic hob as detailed in Section 3.3.

c) Disconnect leads and undo fixings which secure device

to mounting plate.

d) Fit replacement and re-assemble in reverse order.

Check replacement functions correctly.

3.9 TO REMOVE AN OVEN CUT-OFF

THERMOSTAT

Disconnect appliance from electricity supply.

a) Pull unit forward to gain access to cover box. Undo cover

screws and lift clear.

b) Control is located on earth plate beside oven element

connections.

c) Disconnect thermostat wiring. Undo fixings that secure

thermostat to ear th plate and remove.

d) Fit replacement control and re-assemble parts in reverse

order.

3.10 TO REMOVE A HOB ELEMENT ENERGY

REGULATOR

Disconnect appliance from electricity supply.

a) Remove control panel as detailed in Section 3.2.

b) Remove ceramic hob as detailed in Section 3.3.

c) Disconnect regulator wiring and undo fixings that secure

device to mounting panel.

d) Fit replacement and re-assemble parts in reverse order.

Check replacement functions correctly

3.11 TO REMOVE A HOB ELEMENT

Disconnect appliance from electricity supply.

a) Remove ceramic hob as detailed in Section 3.3.

b) Disconnect element wiring.

c) Remove element spring from locating bracket by undo-

ing nut below bracket and lifting element directly upward.

d) Undo screws that secure spring to element.

e) Fit spring to new element using existing fixing holes.

f) Re-assemble parts in reverse order. Check replacement

functions correctly.

3.12 TO REMOVE OVEN DOOR

a) Open oven door and remove Handyrack (where fitted) by

removing one locating spar from bracket on the door.

Slide other spar free.

b) Support door and remove fixings that secure upper

hinge to unit front frame.

c) Remove door from lower hinge by lifting slightly and

moving it outward.

d) Re-assemble in reverse order.

3.13 TO REMOVE GRILL DOOR

a) Remove control panel as detailed in Section 3.2.

b) Remove ceramic hob as detailed in Section 3.3.

c) Remove LH side panel as detailed in Section 3.4.

d) Remove kick plate (4 screws).

e) Remove central vertical cover situated between ovens.

(5 screws).

f) Remove 2 countersunk scre ws (1 per side) which secure

hinge arms to front of grill chamber.

Note

The door hinge arms are spring tensioned. Carefully remove

grill door and retain the gaskets.

g) Re-assemb le in reverse order. Ensure gask et is fitted be-

tween hinge arm and front of grill chamber. Check door

operation.

3.14 TO REMOVE OVEN OUTER DOOR PANEL

a) Open the oven door.

b) Remove two screws ‘A’ and two screws ‘B’ from the door.

c) Remove the outer door panel.

d) Undo the nuts that secure the handle to the door panel.

Fit the handle to the replacement door panel.

e) Fit the replacement panel to the oven inner door.

f) Re-assemble in reverse order.

Page 28

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 28

3.15 TO REMOVE DOOR LATCH

a) Remove oven outer door panel as detailed in Section

3.14.

b) Remove fixings which secure latch assembly to inner

door panel. (See Figure 4).

c) Fit replacement catch and re-assemble in reverse order.

d) Check correct operation of door.

3.16 TO REMOVE OVEN DOOR SEAL

a) Remove outer door panel as detailed in Section 3.14.

b) Remove door bedding strip by sliding from clips on rear

face of inner door panel see Figure 5).

c) Fit replacement door seal and re-assemble in reverse

order.

3.17 TO ADJUST OVEN DOOR CATCH KEEPER

a) Open oven door and slacken locknut at keeper base.

b) Adjust keeper in or out as required, until desired door

operation is obtained.

c) Re-tighten locknut.

3.18 TO REMOVE OVEN LININGS

a) Open oven doors and remove shelves.

b) Slide oven roof lining forward to remove it. (RH oven

only)

c) Slide oven base forward and remove.

d) Lift oven side linings away from hanging screws and re-

move lining.

e) Replace all linings in reverse order.

3.19 TO REMOVE RH OVEN INNER BACK

a) Open RH oven door and remove fixings that secure in-

ner back to oven rear.

b) Lift removable panel away.

c) Re-assemble in reverse order. Ensure retaining fixings

are fully tightened.

3.20 TO REPLACE RH OVEN FAN

Disconnect appliance from electricity supply.

a) Pull unit f orw ard to access co v er boxes at appliance rear.

Remove fixings that secure cover and lift it clear.

b) Remove fan wiring, noting connection positions.

c) Remove inner back as detailed in Section 3.19.

d) Hold fan blades and undo centre nut (LH thread), brass

washers, fan blade and circlip.

e) Undo fixings that retain fan and remove it from the cavity

rear.

f) Fit replacement and re-assemble parts in reverse order.

Check oven operates satisfactorily.

3.21 TO REMOVE RH OVEN ELEMENT

Disconnect appliance from electricity supply.

a) Pull unit forward to access cover boxes at unit rear. Re-

move fixings that secure cover and lift it clear.

b) Undo terminal connections, noting their positions.

c) Remove inner back as detailed in Section 3.19.

d) Remove fixings that secure element within oven and lift

element away carefully.

e) Fit the replacement element and re-assemble parts in

reverse order.

f) Check oven operates correctly.

3.22 TO REMOVE LH OVEN ELEMENTS

Disconnect appliance from electricity supply.

3.22.1 Bottom Element

a) Pull unit forward to access cover boxes at unit rear. Re-

move fixings that secure cover and lift it clear.

b) Undo terminal connections, noting their positions.

c) Remove fixings that secure bottom element cover.

d) Undo terminal connections, noting their positions.

e) Remove the lower element support fixings.

f) Remove element bracket fixings and withdraw element.

g) Replace element and re-assemble parts in reverse or-

der.

3.22.2 Top Element

a) Open LH oven door and undo fixings that secure heat

shield.

b) Remove top element bracket fixings and withdraw ele-

ment.

c) Replace element and re-assemble parts in reverse or-

der. Check oven operates satisfactorily.

3.23 TO REMOVE GRILL ELEMENT

Disconnect appliance from electricity supply.

a) Pull unit forward to access the cover boxes at the appli-

ance rear. Remove fixings that secure cover and lift it

clear.

b) Undo terminal connections, noting their positions.

c) Remove grill pan.

d) Remove fixings that secure element front support from

within chamber.

e) Remove fixing from each element and withdraw ele-

ments from chamber.

f) Fit replacement element(s) and re-assemble parts in re-

verse order. Check grill operation.

Page 29

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 29

Page 30

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 30

Circuit Diagram Top

Page 31

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity supply before servicing. Check appliance is safe when you have finished.

Page 31

Circuit Diagram Bottom

Page 32

Loading...

Loading...