Page 1

*4270101871*

4270101871

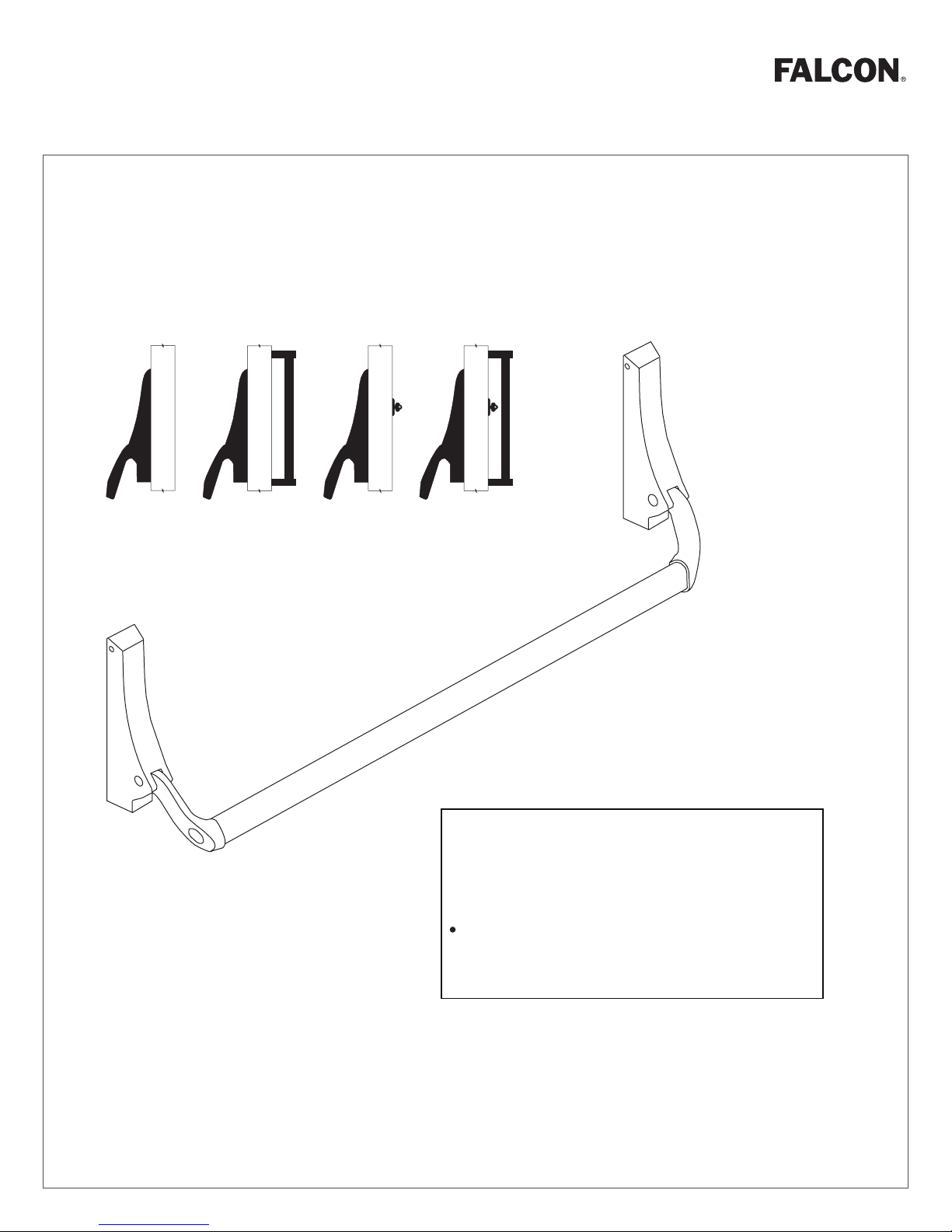

Concealed Vertical Rod Panic Device

1990 1991 1992 1993

with pull

with cylinder

1990

Installation Instructions

with pull

and cylinder

Index

• Before Installation....................................

• Installation ...............................................

• Series 1990 Parts List .............................

Head Jamb and Threshold Preparation ..

• Aluminum Door Preparation ....................

• Hollow Metal Door Preparation ...............

2

2

5

6

7

8

Page 2

Before Installation

1. Check “Series 1990 Parts List” (see page 5).

2. Prepare door, threshold, and head jamb: aluminum door page 7; hollow metal door page 8; threshold and head jamb page 6.

NOTES

1. Handing of device can be changed.

2. Latch mounting center lines need not be the same as the housing

center lines. The operating rod can work at an angle to permit

mounting of latches so they will clear projections inside the door.

3. Crossbar length equals the distance between the housing vertical

centerlines minus 1-3/4”.

INSTALLATION

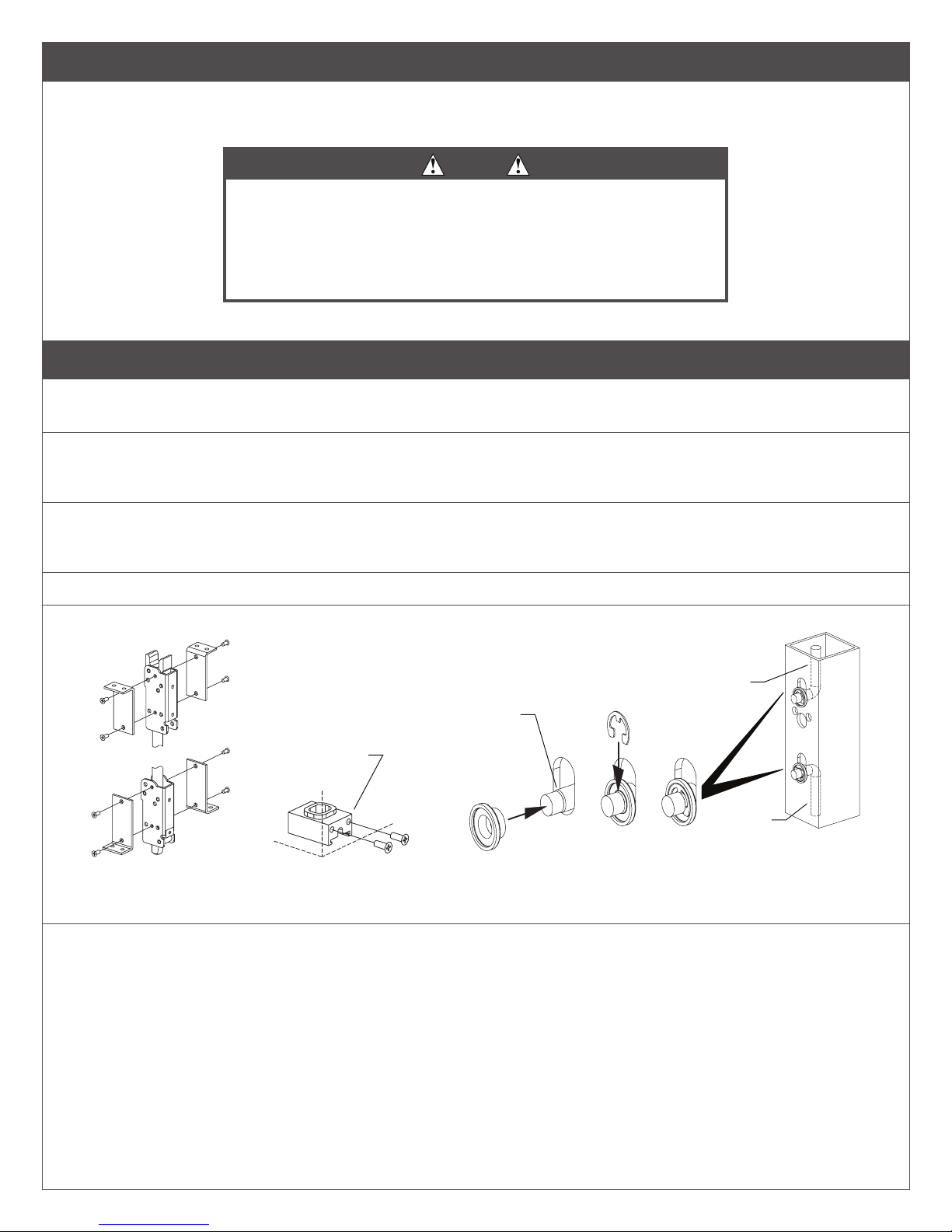

1 Install rod assemblies.

1a For hollow metal door, attach latch brackets to sides of top and bottom latches with #10-32 x 1/4” UFPH machine

screws (Figure 1-1).

1b Slide top rod assembly into door. Hollow metal door: Secure each latch bracket to door with two #10-32 x 3/8” FPH

machine screws. Aluminum door: Secure top latch to door with two #10-32 x 1/4” UFPH machine screws through face

of door into front mounting holes on latch.

1c Install bottom rod assembly into door. If using rod latch (RL) bottom rod assembly: For hollow metal door, secure each

latch bracket to door with two #10-32 x 3/8” FPH machine screws; for aluminum door, secure top latch to door with

two #10-32 x 1/4” UFPH machine screws through face of door into front mounting holes on latch.

1d For hex bottom rod, install hex rod guide in door with #10-24 x 3/8” UFPHTC screws (Figure 1-2).

1e Install rod bearing bushing over end of each rod and secure with retaining ring (Figure 1-3).

Retaining

ring

Groove

Hex rod guide

Rod

bearing

bushing

1 2 3

Figure 1-2

1f Check latch operation and rod length adjustment:

a. Place traveler over rod ends.

b. Slide traveler up. Top latch should release and hold rods in up position, and bottom latch should be completely retracted (ush

with bottom edge of door).

c. Move top latch back to locked position. Rods should drop down, locking top latch and extending bottom latch approximately 1/2”.

d. If necessary, adjust rod lengths for correct operation. Remove traveler after adjustment.

Figure 1-3Figure 1-1

Top rod

assembly

Bottom

rod

assembly

2

Page 3

2 Install cylinder

Install cylinder. If required, cut cylinder tailpiece as shown. Heads of cylinder mounting bolts must be ush with door surface.

3/64"

15/64" dia. drill

Tailpiece

3/16" from end of cylinder

tailpiece to surface of door

5/16" dia. c'sink

3 Install pinion cam and traveler.

Position flat spots on

pinion cam as shown

Cylinder

bushing

Traveler

Pinion

cam

!

Apply a light coating of

Duralub or equivalent

lubricant to prolong

pinion cam life.

Figure 3-1

NOTE

Figure 3-2

3

Page 4

4 Install retractor.

Install retractor over pinion cam (Figure 4-1). Position retractor as shown in Figure 4-2 for holdback (HB) or night latch (NL)

function.

Night latch (NL)Hold-back (HB)

Hold-back (HB): Turning key one

complete rotation retracts latch bolt. If

key is removed in this position, latch

bolt stays retracted. Returning key to

original position before removing allows

latch bolt to extend.

Night latch (NL) : Turning key as far as it

will go retracts latch bolt. Key must be

returned to original position to be

removed, leaving the door locked.

Figure 4-1

Install retractor with teeth to

right as shown for both RHR and

LHR doors; this makes all keys

function in the same direction

Figure 4-2

5 Install top strike.

Install top strike with four #8-32 x 1/4” at head Phillips undercut screws. The top strike is fabricated off center to permit pin

adjustment by rotating the strike 90°. Use strike shims (supplied with strike) as needed to adjust the projection of the strike

pin.

Shim

Strike

6 Install housing mounting studs, housings, and crossbar.

6a Install four housing mounting studs (Figure 6-1).

6b Install lock stile housing over mounting studs and secure with set screws (Figure 6-2). Test operation.

6c Install crossbar and hinge stile housing (Figure 6-3). Secure housing with set screws. Secure crossbar with

two 1/4-20 x 1” Taptite screws.

Studs

Studs

Figure 6-1

4

Figure 6-2

Figure 6-3

Page 5

SERIES 1990 PARTS LIST

Top Rod

Assembly

30

Hex

Bottom

Rod

Assembly

RL

Bottom

Rod

Assembly

24

22

19

18

20

29

25

28

17

26

31

1918

27

32

23

21

17

22

5

11

12

5

1

6

1

7

10

3

8

2

15

13

6

14

9

4

16

LHR shown

Item Qty. Description

1 2 Housing

2 1 Lever arm, LH

3 1 Lever arm, RH

4 1 Crossbar

5 4 Housing mounting stud

6 6 1/4-20 x 3/8" hex socket head set screw

7 1 1/8" Allen wrench

8 2 Axle pin

9 4 Retaining ring

10 4 Axle bushing

11 4 Tension spring

12 4 Spring retainer

13 2 7/16-14 x 3/4" hex socket head dogging screw

14 1 Dogging key

15 2 Spring pin

16 2 1/4-20 x 1" Taptite

Item Qty. Description

17 4 Latch bracket (hollow metal doors only)

18 8 #10-32 x 1/4" UFPHMS

19 8 #10-32 x 3/8" FPHMS

20 1 PB48 strike

21 3 PB48 strike shim

22 4 #8-32 x 1/2" UFPHTC

23 4 #10-32 x 1/4" UFPHMS

24 1 Hex rod guide

25 2 #10-24 x 3/8" UFPHTC

26 2 Rod bearing bushing

27 4 Retaining ring

28 1 Pinion cam

29 1 Cylinder bushing

30 1 Rim cylinder (optional; sold separately)

31 1 Traveler

32 1 Retractor

5

Page 6

PARTS LIST (CONTINUED)

TOP ROD

ASSEMBLY

ROD LATCH (RL) BOTTOM

ROD ASSEMBLY

SU latch

4270101806

Jam nut 3/8"-24

NUT.101 (Pkg of 10)

Top rod:

• Bent rod 35.125" long (7' door)

4270100017

(can be shortened by 5")

• Bent rod 47.125" long (8' door)

4270100018

(can be shortened by 13")

Optional ES (electric strike)

top latch (not shown)

4270100346

ROD ASSEMBLY

Bottom rod:

Bent rod 35.125" long

4270100017

(can be shortened by 5")

Jam nut 3/8"-24

NUT.101 (Pkg of 10)

RL bottom latch

4270100521

HEX BOTTOM

Bottom rod:

Bent rod 37.812" long

4270101825

(can be shortened by 6")

Jam nut 3/8"-24

NUT.101 (Pkg of 10)

Hex bolt

4270101830

Optional PL (pullman)

bottom latch (not shown)

4270101482

top latch

11/32"

Stop

21/32"

11/16"

11/16"

#29 (0.136") dia. drill

#8-32 tap, 4 places

Bottom plan view of head jamb

(looking up)

Upper Strike

Head Jamb Preparation

HEAD JAMB AND THRESHOLD PREPARATION

1-1/4"

29/32"

Stop

"E"

3/4" dia.; cut

strike opening

bottom

latch

Top plan view of threshold

for bottom latch

thru threshold

Rod Latch (RL) or Hex Bolt

Threshold Preparation

7/8"

7/16"

11/16"

1/8" R

Stop

"E"

Cut strike

opening for

bottom

latch

Top plan view of threshold

bottom latch

thru threshold

Pullman Latch

Threshold Preparation

6

Page 7

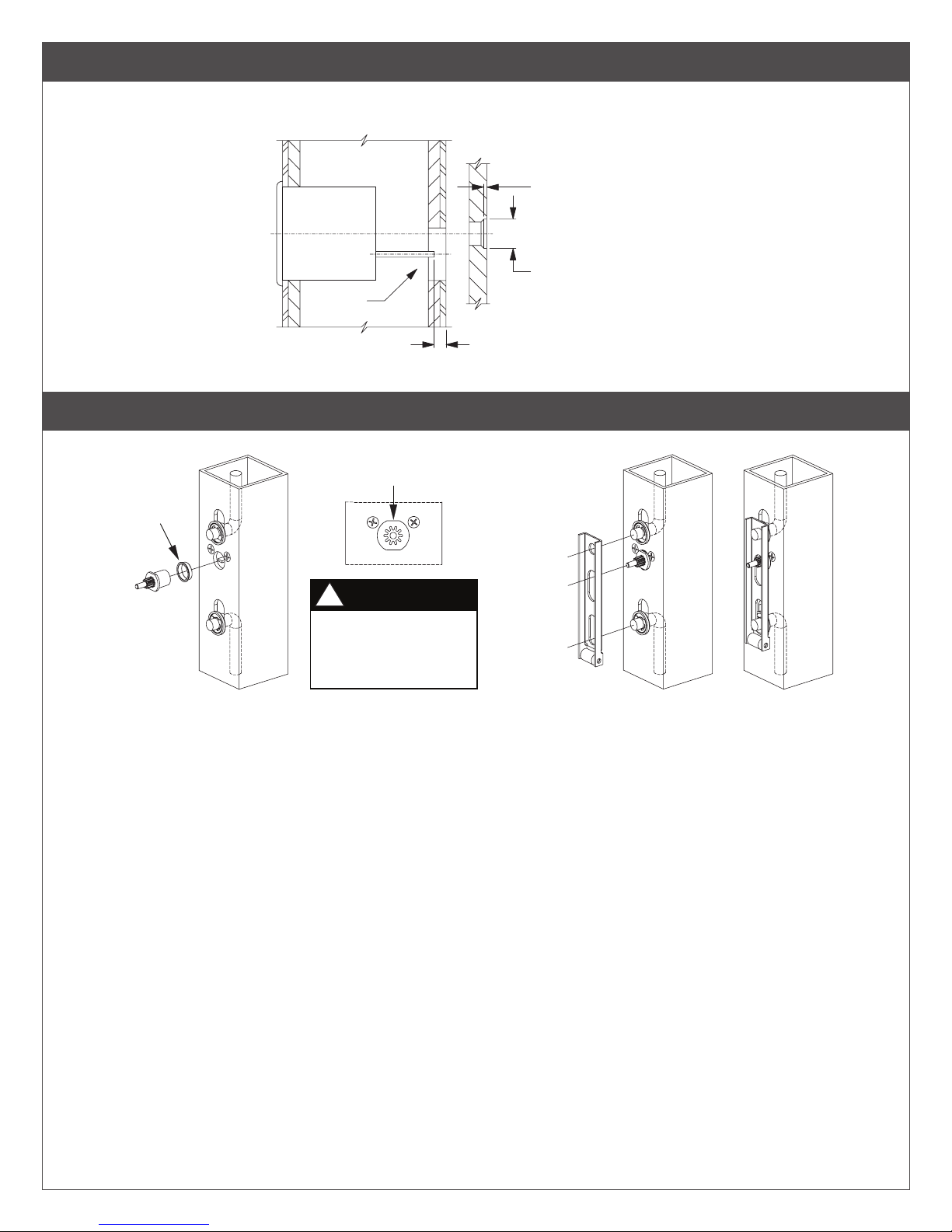

ALUMINUM DOOR PREPARATION

Hinge StileLock Stile

7/16"

1-3/8"

1-3/8"

Face of

door stop

7/16"

3"

1/8"

See

note

1-1/2"

13/16"

13/16"

1/2"

1-1/4"

7/8"

F

1-1/2"

Cutout on inside face only

See note

1/4" R

#9 (0.196" dia.)

thru inside face

c'sink 82˚

25/64" dia., 4 places

1-3/16" dia. thru

outside face for

rim cylinder

15/64" dia. c'sink

with 5/16" dia.

tool, 2 places

1/4"

9/16"

dia.

ream

3-13/16"

Face of

door stop

to

device

Surface Mounting

#9 (0.196" dia.)

thru inside face

1/4-20 tap, 2 places

Thru Bolting

1/4" dia. thru inside

face, 13/32" dia. thru

outside face, 2 places

D

!

D: Dimension from door stop face to

housing is 3/4" minimum for

medium and wide stiles.

E and F: Dimension from door stop face

to top or bottom latch can be the

same as "D" or can vary to suit door

conditions.

6-1/4"

NOTES

41-5/16"

to

bottom

of door

1-3/8"

7/8"

device

E

#9 (0.196" dia.)

thru inside face

1/4-20 tap, 2 places

See note

Face of

door stop

Pullman (PL) and Rod Latch (RL)

Door Preparation

E

Bottom of door

3/8"

9/16"

3/4"

#9 (0.196" dia.) thru

inside face, c'sink 82˚

to 25/64" dia., 2 places

Hex Bottom Bolt

Door Preparation

7

Page 8

HOLLOW METAL DOOR PREPARATION

Hinge StileLock Stile

1/8"

7/16"

See note

Face of

door stop

7/16"

3"

1-1/2"

13/16"

13/16"

1/2"

1-1/4"

7/8"

1/4" R

F

#9 (0.196" dia.)

thru inside face

1/4-20 tap, 2 places

1-1/2"

Cutout on inside face only

See note

3/16"

1/4"

door stop

1-3/16" dia. thru

outside face for

rim cylinder

15/64" dia. c'sink

with 5/16" dia.

tool, 2 places

device

1/4"

9/16"

dia.

ream

3-13/16"

Surface Mounting

#9 (0.196" dia.)

thru inside face

1/4-20 tap, 2 places

Thru Bolting

1/4" dia. thru inside

face, 13/32" dia. thru

outside face, 2 places

Face of

#10-32

D

6-1/4"

thru

4 places

(bottom view of door is typical)

!

D: Dimension from door stop face to

housing is 3/4" minimum for

medium and wide stiles.

E and F: Dimension from door stop face

to top or bottom latch can be the

same as "D" or can vary to suit door

conditions.

7/8"

7/8"

3/4"

1/2"

5/8"

5/8"

Top view of door

Top and Bottom

Latch Bracket

Door Preparation

NOTES

41-5/16"

to

bottom

of door

device

E

3/16"

Customer Service

1-877-671-7011 www.allegion.com/us

See note

Face of door stop

1/4"

E

Bottom of door

Reinforcing for

device to be

supplied by door

manufacturer as

shown

!

Reinforcement in head jamb for top

strike is 3/16" minimum. Reinforcement

in stile for panic device is 1/8" minimum.

NOTE

4270101871 Rev. 12/16-e

© Allegion 2016

Printed in U.S.A.

Loading...

Loading...