www.fairchildsemi.com

AN-9066

UniFET™ — Optimized Switch for Discontinuous Current

Mode Power Factor Correction

Abstract

This application note discusses merits of planar technology

power MOSFET in discontinuous current mode power

factor correction application. In most test conditions it is

cost competitive and gives performance benefits compared

to a super-junction technology device. The benefits are

verified through the mathematical simulation and systemlevel experiments. A new planar technology power

MOSFET from Fairchild shows faster switching

characteristics that contribute to higher efficiency and lower

device temperature.

Introduction

Switch-mode power supplies are increasingly being

designed with an active power factor correction at the input

stage to meet international regulations for harmonics. The

boost topology in discontinuous current mode (DCM) is

most suitable power factor correction (PFC) method for

converters with less than 300W power rating[1]. In this

topology, the switching-on power loss of boost switch is

negligible, and the major power losses are the switching-off

losses and conduction losses. After the super-junction

devices have been introduced, they are often considered as

optimized switches for active power factor correction

because of extremely low on-resistance and highly nonlinear capacitance curves. In the discontinuous current mode

power factor correction, however, the conventional planar

devices can compete against the powerful super-junction

family. This article shows that Fairchild’s UniFET™ power

MOSFET can provide performance superior to the superjunction devices in the discontinuous current mode power

factor correction applications.

Power MOSFET Technologies

The super-junction technology utilizes deep P-type pillar

structure in the body of the power MOSFET. The effect of

the pillars is to confine the electric field in the lightly doped

epitaxial region of the power MOSFET. Thanks to this Ppillar, the resistivity of N-epi can be reduced compared to

the conventional planar technology, while maintaining the

same breakdown voltage. Therefore, typical on-resistance of

the super-junction MOSFETs is only one third of the

conventional planar power MOSFETs at the same chip size.

Most commercially available super-junction devices adopt

multiple epi-layers to build the deep P-pillar structure. The

multi-epi process, however, has some disadvantages, such

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09

as increased process steps and higher manufacturing cost. In

contrast, the UniFET™ power MOSFET utilizes a planar

double-diffused metal-oxide semiconductor (DMOS)

process that is very mature and highly cost competitive.

Moreover, it has improved ring terminations and optimized

active cell structures compared to the conventional planar

power MOSFETs. The resulting specific on-resistance of

the UniFET is even close to some super-junction devices at

500V of breakdown voltage range.

The planar power MOSFETs also have higher reliability

than the super-junction MOSFETs under unclamped

inductive switching (UIS) condition, which can occur

during power supply power-up or AC line transient. The

devices can enter breakdown, and even be destroyed, in the

worst situations. Typically, the planar MOSFETs are much

better than the super-junction devices in UIS mode. The

newest super-junction technology enabled equivalent UIS

rating to the planar MOSFETs at unit area; however, its

practical rating as a single device is still inferior to planar

MOSFETs because of smaller die size. The UIS ruggedness

of UniFET is also far better than previous generations of

planar technology. For an example, a 265mΩ, 500V

UniFET shows more than 80A of avalanche current under

low coil UIS test. Moreover, it does not fail at all in the test.

On the contrary, a conventional planar MOSFET with same

on-resistance failed at around 40A. The improved

ruggedness ensures enhanced reliability. In terms of

switching performance, a gate charge is one of the

benchmarks to compare different devices. The UniFET has

a smaller gate charge, faster switching characteristics, and

reduced switching power losses than the conventional

planar MOSFETs. Some typical electric characteristics

benchmarks are shown in

Table 1. Gate Charge and Parasitic Capacitance

Benchmark Data

Q

FDB12N50 22nC 140pF 985Pf 12pF

FQB12N50 39nC 220pF 1550pF 25pF

FDA16N50 32nC 235pF 1495pF 20pF

FQA16N50 60nC 325pF 2300pF 35pF

Note:

1. FDB12N50 and FDA16N50 are UniFET™. FQB12N50

and FQA16N50 are QFET

planar power MOSFET.

Table 1.

G

C

OSS

®

, is a previous generation of

C

ISS

C

RSS

AN-9066 APPLICATION NOTE

Discontinuous Current Mode Power

Factor Correction

Generally, power factor correction circuits have used a

boost topology because it is simple and low costs. There are

two modes of the power factor correction boost circuit

operation. One is continuous current mode (CCM) that has

continuous inductor current. This mode has many benefits,

like lower core loss and ripple current and a smaller input

filter; but it requires very fast reverse recovery diode as the

boost diode since the boost switch in being switched on

while the inductor current is not zero. The discontinuous

current mode switches on the boost switch when the

inductor current is zero, allowing less expensive diodes to

be used. The turn-on loss of the boost switch is also

negligible. Usually, the discontinuous current mode is used

for small power supplies, 300W or less, that have relatively

small inductor current, but are very sensitive to cost

constraints.

450

Simulation and Experimental

Results

Conduction loss is easy to evaluate because the R

is clearly stated in datasheets, but the switching loss varies

greatly by the circuit conditions. To compare the switching

performance in the system, one UniFET and one superjunction device are selected and evaluated. An inductive

switching test board was used to measure switching loss at

turn-off transient. In this way, it is possible to keep the

important test variables, like drain current and external

series gate resistor, under control.

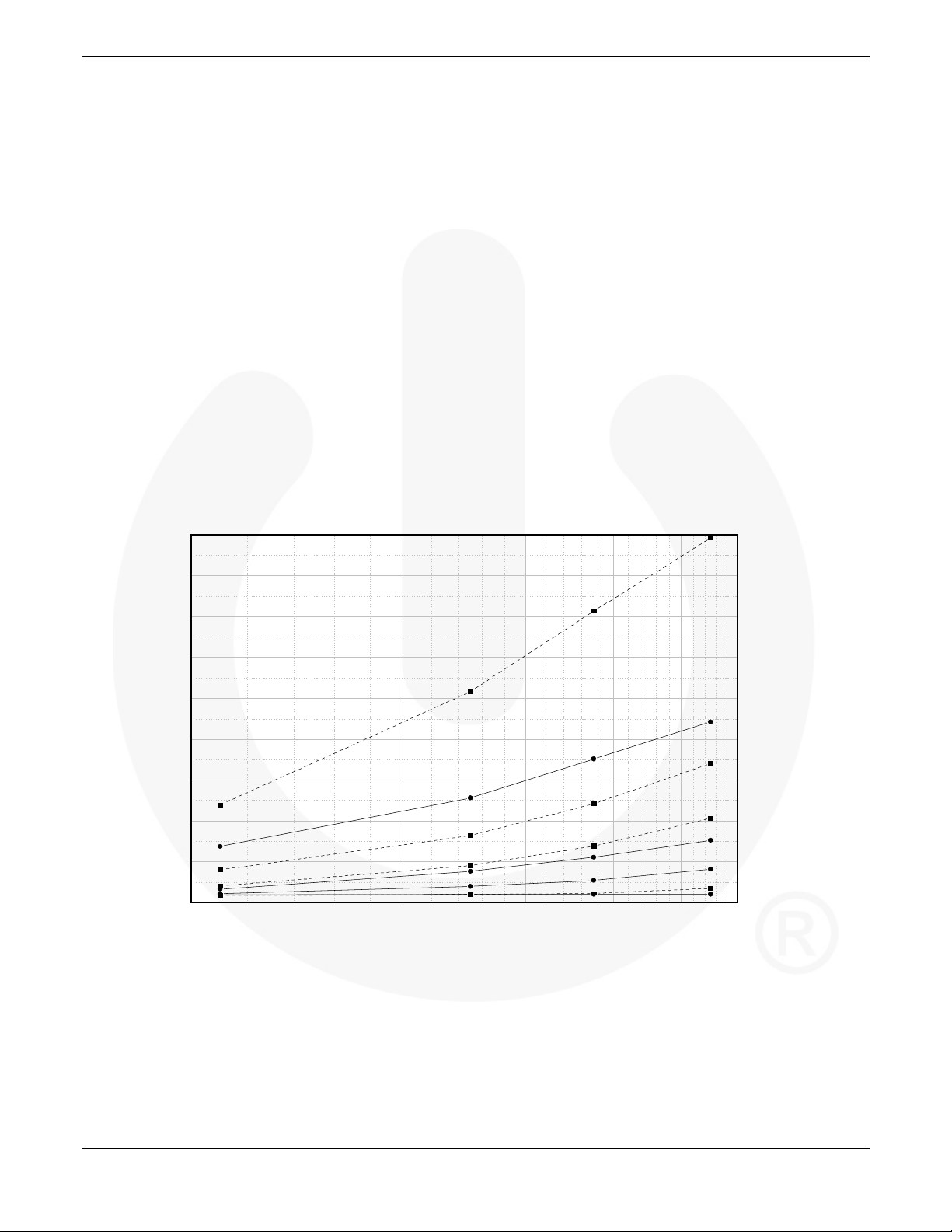

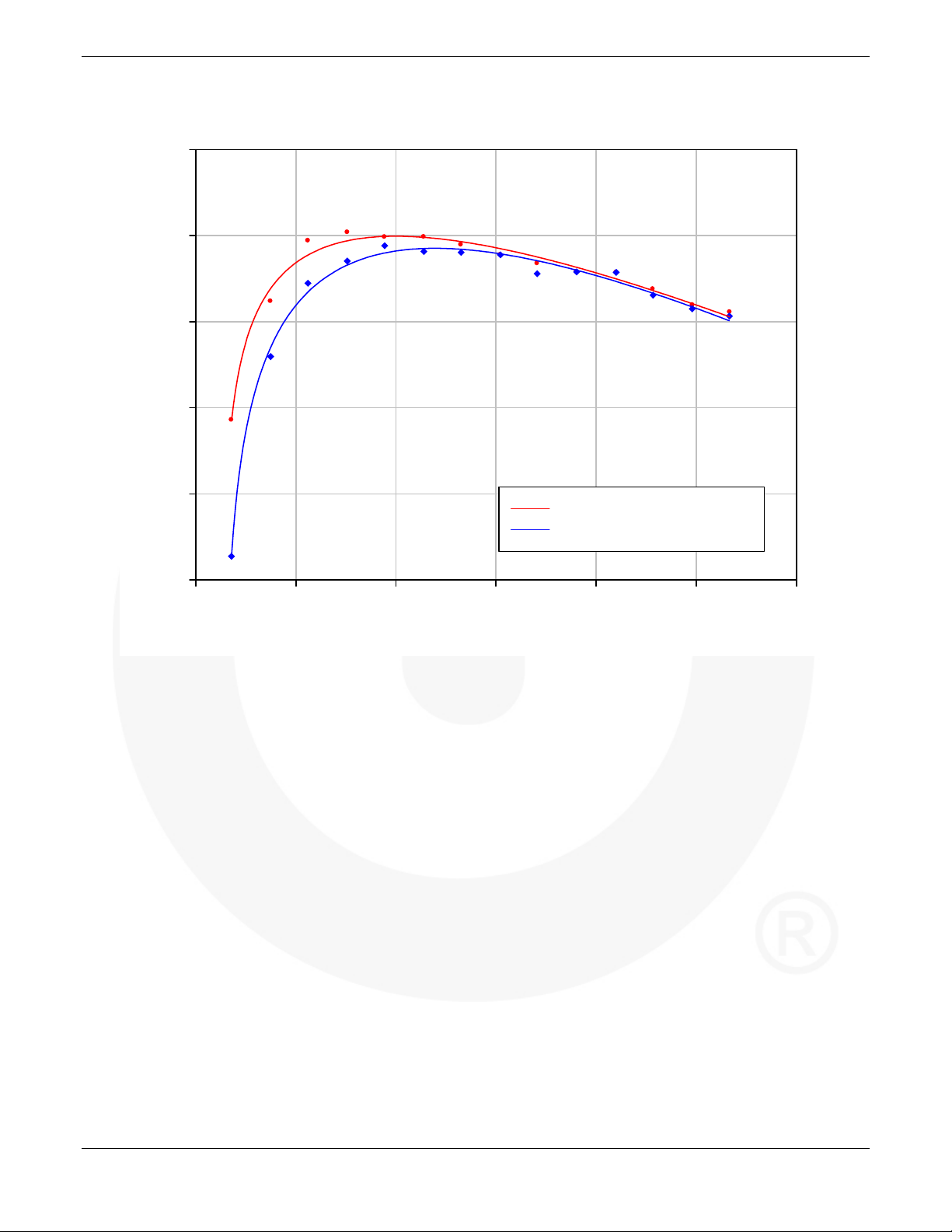

Figure 1 shows the energy loss curves with different

conditions of the series gate resistor and the drain-current.

The solid traces indicate the losses of the UniFET and the

dotted traces are losses of the super-junction device. There

are four different lines per device, according to the pre-set

drain current levels. The drain current levels are 20A, 10A,

6.5A, and 1.8A from top to bottom.

DS(on)

value

400

350

300

250

200

150

100

S wit c hin g- o ffE n er g yLos s [ µJ ]

50

0

4 8 12 16 20 24

External Series Gate Resistance [Ω]

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 2

450

400

350

300

250

200

150

100

Switching-Off Enery Loss [µJ]

50

0

4 8 12 16 20 24

External Series Gate Resistance[Ω]

Figure 1. Energy Losses During Switching-Off Transition

www.fairchildsemi.com

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09

AN-9066 APPLICATION NOTE

It is obvious that the UniFET has far less energy loss than

the super-junction device at high current condition. Also,

the UniFET outperforms the super-junction device as gate

resistance becomes larger. The only test point where the

super-junction device does better than the UniFET is at the

lowest current and the smallest gate resistor. The power loss

during switching-on transition has not been evaluated

because it is negligible in the DCM PFC. Based on the

switching performance evaluation results, a simulation was

preformed to analyze system-wide performance. A 200Wrated DCM PFC was assumed for the simulation and

simulation time has set to a single cycle of AC input.

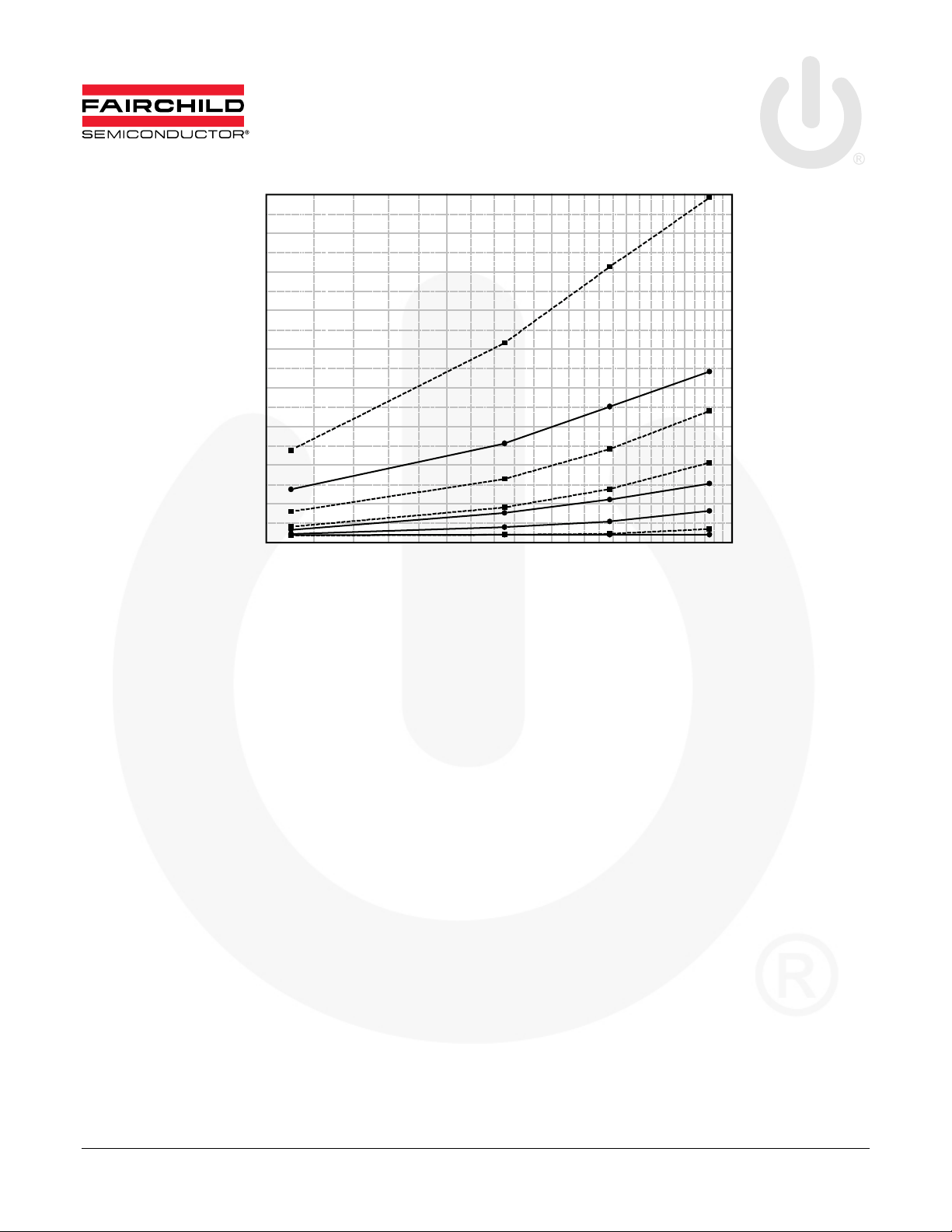

The simulated conduction losses are shown in

lower R

low R

junction devices.

makes the less conduction loss. Clearly, the

DS(on)

is the most significant benefit of the super-

DS(on)

Figure 3 shows combined loss curves at

external series gate resistance of 15Ω. In

Figure 2. The

Figure 3, the

estimated performance of the UniFET is better than the

super-junction device due to its fast switching

characteristics. The distortion at zero-crossing current

regions is due to convergence error of the simulation. With

more switching energy loss data, the convergence error can

be reduced.

When lowered to 4.4Ω gate resistor, the super-junction

device is slightly better than the UniFET in

shown in

Figure 1, there are not much difference in

Figure 4. As

switching-off power losses with small resistor and low drain

current conditions.

To verify simulation results, both devices are evaluated

using a state-of-the-art game console power supply. The

devices are applied to DCM PFC block of the power supply

and the test conditions are set as V

P

OUT

=225W, R

=22Ω, and R

G(on)

G(off)

=3.3Ω.

=110VAC/60Hz,

IN

Figure 2. Simulated Conduction Losses In Watt

Figure 3. Simulated Combined Losses with RG=15Ω

Figure 4. Simulated Combined Losses with RG=4.4Ω

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 4

AN-9066 APPLICATION NOTE

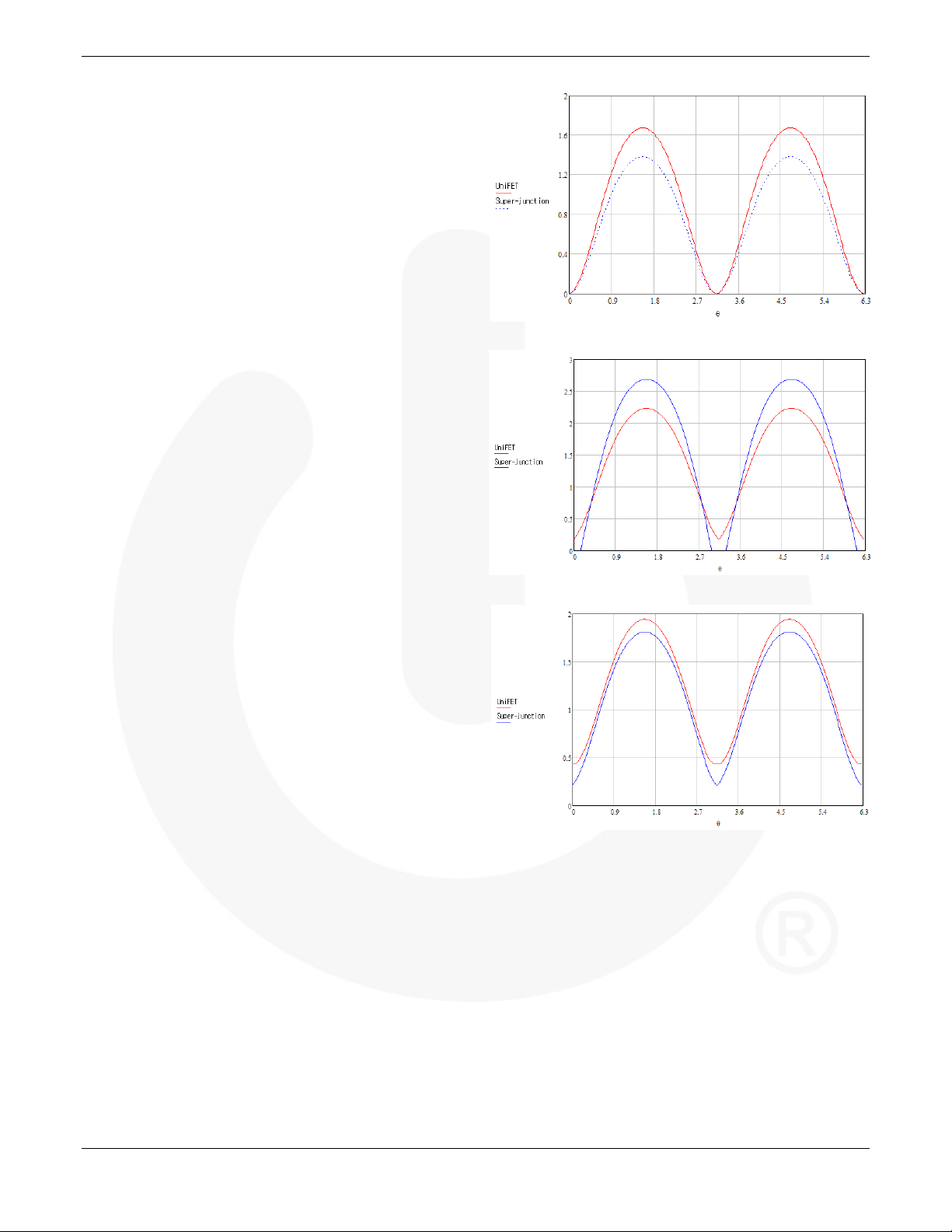

Figure 5, an IR camera was used to measure device

In

temperature. Three measurement points are a PFC diode and

two paralleled PFC MOSFETs. Even with small gate

resistor, the UniFET temperature is lower than the superjunction device by around 10 degrees. The reason for this

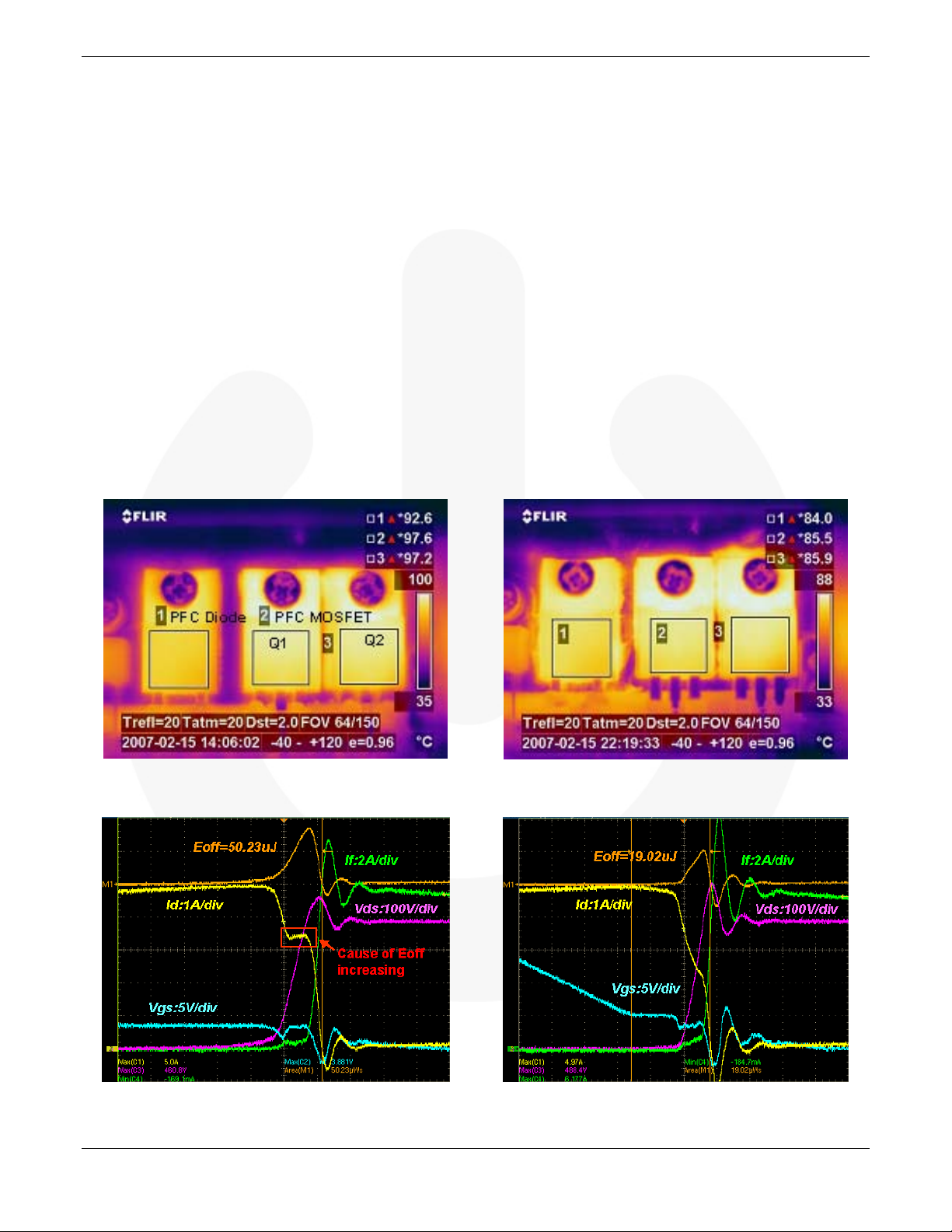

lower temperature is smaller switching losses, as shown in

Figure 6. The UniFET switching-off energy loss at the peak

of AC input voltage is less than a half of the super-junction

device switching loss. There is a little plateau in the drain

current of the super-junction that makes switching-off loss

bigger. There was no such waveform in the bench test.

Perhaps it is due to different gate drive circuitry and printed

circuit board layout.

Recently, dedicated controllers for the interleaved

discontinuous current mode power factor correction were

introduced to the market. The interleaved CRM PFC

technique is a good alternative solution to implement highdensity, cost-effective converters with an extended input

power range. It quickly became mainstream topology in

switching power supplies for flat panel displays because the

interleaving technique can reduce the total system cost

compared to CCM topology. Although it requires a pair of

boost inductors, boost switches, and rectifiers, it can use

small-sized filters, smaller high-voltage aluminum

electrolytic capacitor, a less-expensive 500V-rated boost

switches, and slower rectifiers. In addition, making the flat

panel TV slim is a trend and the smaller components are a

crucial requirement for a low-profile switching power

supply.

As the interleaving PFC is also operated in discontinuous

current mode, the UniFET can be quite competitive with the

super-junction device. To compare system performance, the

UniFET and the super-junction device were tested with an

interleaved DCM PFC evaluation board. The evaluation was

done using an interleaved CRM controller with phase

management. Two RURP860 ultrafast rectifiers are applied

as boost diodes. The test conditions are set as

=115VAC/60Hz,R

V

IN

=10Ω, R

G(on)

=3.9Ω, room

G(off)

temperature without fan, and an external bias for controller

supply voltage.

(a) Super-Junction Device (b) UniFET

Figure 5. Device Temperature (Not Same Scale)

™

(a) Super-Junction Device (b) UniFET

Figure 6. Switching-Off Energy Loss

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 5

™

AN-9066 APPLICATION NOTE

98

97

96

95

Efficiency [%]

94

93

0 100 200 300 400 500 600

Output Power [W]

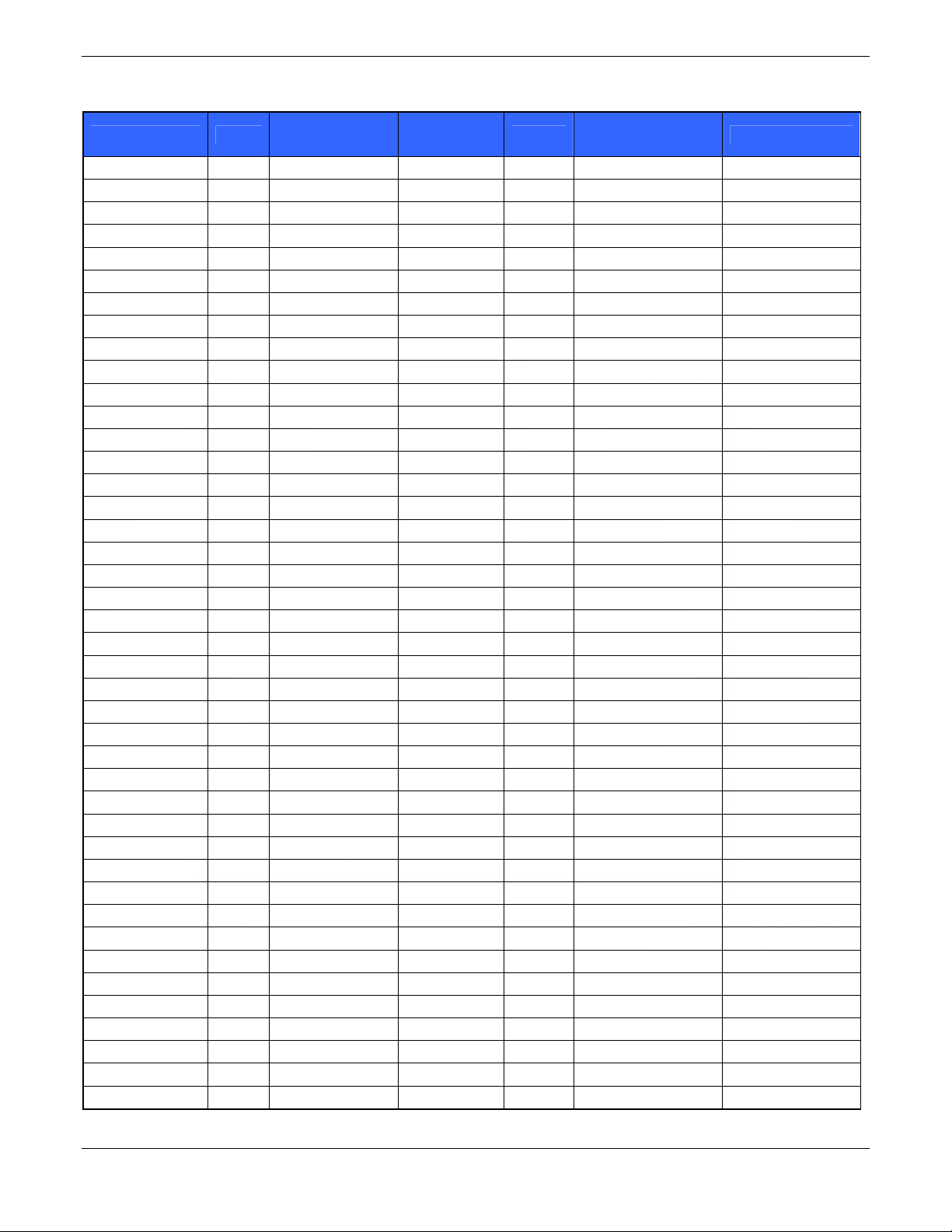

Figure 7. Efficiency Curves with 115V AC Input

The efficiency results are shown in

much difference in efficiency when in heavy load.

Basically, the super-junction device has lower R

the UniFET at same drain current rating and therefore will

have more conduction loss advantage as the load becomes

heavier. The smaller switching loss of the UniFET

compensates its higher R

DS(on)

the UniFET shows slightly better performance. In the lightload area, the switching loss dominates the power losses

and the UniFET surpasses the super-junction device.

Figure 7. There is not

than

DS(on)

well in heavy load area and

UniFET, 20A/500V

Super-juncti on, 21A/500V

Conclusion

The performance of the UniFET™ was evaluated at both

device level and system level. It showed good results

against the super-junction device and can be an optimum

solution in DCM PFC application as long as required

breakdown voltage of the boost switch is 500V. The

interleaved DCM PFC is gaining attention recently and this

is another application where the UniFET can be considered

as a high-performance, cost-effective boost switch.

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 6

AN-9066 APPLICATION NOTE

Table 2. 500V UniFET™ Line-up

Part Number BV

DSS

R

DS(ON)

Max (W)

at VGS = 10V

Qg Typ. (nC)

at VGS = 5V

ID (A)

QRR Typ. (nC)

at diF/dt=100A/µs

Package

FDD5N50U 500 2.000 11.0 3.00 33 TO-252(DPAK)

FDD5N50F 500 1.550 11.0 3.50 120 TO-252(DPAK)

FDD5N50 500 1.400 11.0 4.00 1800 TO-252(DPAK)

FDPF5N50FT 500 1.550 11.0 4.50 120 TO-220F

FDP5N50 500 1.400 11.0 5.00 1800 TO-220

FDPF5N50T 500 1.400 11.0 5.00 1800 TO-220F

FDD6N50F 500 1.150 15.0 5.50 150 TO-252(DPAK)

FDU6N50 500 0.900 12.8 6.00 1700 TO-251(IPAK)

FDD6N50 500 0.900 12.8 6.00 1700 TO-252(DPAK)

FDPF7N50F 500 1.150 15.0 6.00 150 TO-220F

FDP7N50 500 0.900 12.8 7.00 1700 TO-220

FDPF7N50 500 0.900 12.8 7.00 1700 TO-220F

FDB12N50U 500 0.800 21.0 10.00 100 TO-263(D2PAK)

FDB12N50F 500 0.700 21.0 11.50 370 TO-263(D2PAK)

FDPF12N50FT 500 0.700 21.0 11.50 370 TO-220F

FDB12N50 500 0.650 22.0 11.50 3500 TO-263(D2PAK)

FDP12N50 500 0.650 22.0 11.50 3500 TO-220

FDPF12N50T 500 0.650 22.0 11.50 3500 TO-220F

FDPF13N50FT 500 0.540 30.0 12.00 450 TO-220F

FDB15N50 500 0.380 33.0 15.00 5000 TO-263(D2PAK)

FDP15N50 500 0.380 33.0 15.00 5000 TO-220

FDH15N50 500 0.380 33.0 15.00 5000 TO-247

FDP16N50 500 0.390 32.0 16.00 5000 TO-220

FDPF16N50T 500 0.380 32.0 16.00 5000 TO-220F

FDA16N50 500 0.380 32.0 16.50 5000 TO-3P

FDP18N50 500 0.265 45.0 18.00 5400 TO-220

FDPF18N50 500 0.265 45.0 18.00 5400 TO-220F

FDPF18N50T 500 0.265 45.0 18.00 5400 TO-220F

FDA18N50 500 0.265 45.0 19.00 5400 TO-3P

FDP20N50F 500 0.260 50.0 20.00 500 TO-220

FDPF20N50FT 500 0.260 50.0 20.00 500 TO-220F

FDA20N50F 500 0.260 50.0 22.00 500 TO-3P

FDP20N50 500 0.230 45.6 20.00 7200 TO-220

FDPF20N50T 500 0.230 45.6 20.00 7200 TO-220F

FDA20N50 500 0.230 45.6 22.00 7200 TO-3P

FDA24N50 500 0.190 65.0 24.00 8100 TO-3PN

FDA24N50F 500 0.200 65.0 24.00 1400 TO-3PN

FDA28N50 500 0.155 80.0 28.00 8000 TO-3PN

FDA28N50F 500 0.175 80.0 28.00 1380 TO-3PN

FDH44N50 500 0.120 90.0 44.00 14000 TO-247

FDH45N50F 500 0.120 105.0 45.00 640 TO-247

FDA50N50 500 0.105 105.0 48.00 10000 TO-3P

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 7

AN-9066 APPLICATION NOTE

Reference

[1] Fairchild application note, AN-42047 Power Factor Correction Basics

Author

Won-suk Choi and Sung-mo Young, Application Engineer.

HV PCIA PSS Team / Fairchild Semiconductor

Phone +82-32-680-1839

Fax +82-32-680-1823

Email wonsuk@fairchildsemi.co.kr

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS

HEREIN TO IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE

APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS

PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, or (c) whose failure to perform

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in significant injury to the user.

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.0.1 • 4/3/09 8

Loading...

Loading...