Fairchild T5220, T5220 Series, TXPD5220 Installation, Operation And Maintenance Instructions

Page 1

FAIRCHILD T5220 SERIES

ELECTRO-PNEUMATIC TRANSDUCER

Installation, Operation and Maintenance Instructions

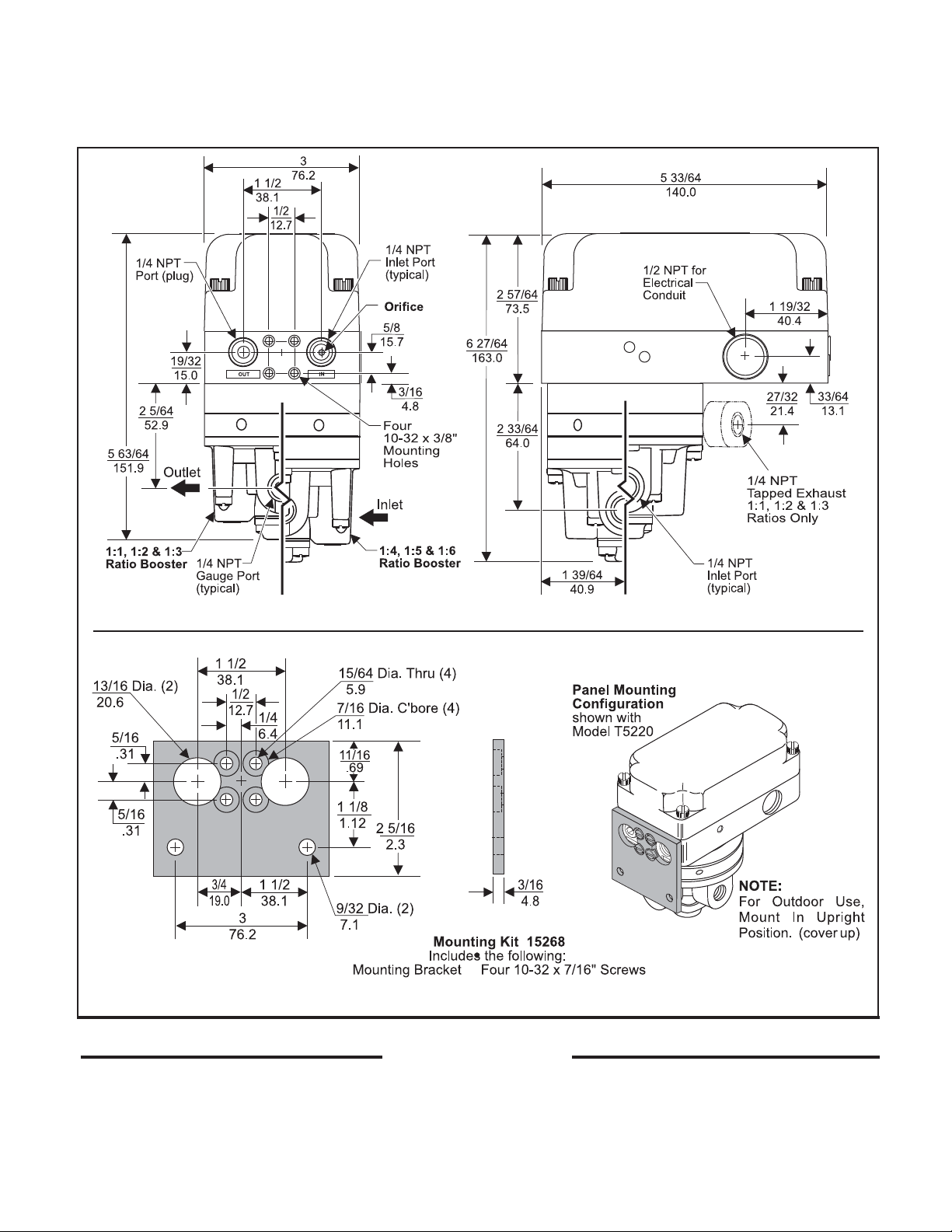

Figure 1. Model T5220 Outline Dimensions

Figure 2. Mounting Kit 15268. (Sold Separately)

INST ALLATION

The Model T5220 can be mounted directly onto a flat surface

using the two 10-32 tapped mounting holes in the base of the

housing. For more information, see Figure 1. “T5220 Outline

Dimensions” above.

The Model T5220 can be Panel Mounted using the

mounting bracket supplied in Mounting Kit 15268. For

more information, see Figure 2. above.

1

Page 2

Installation (Continued)

NOTE:

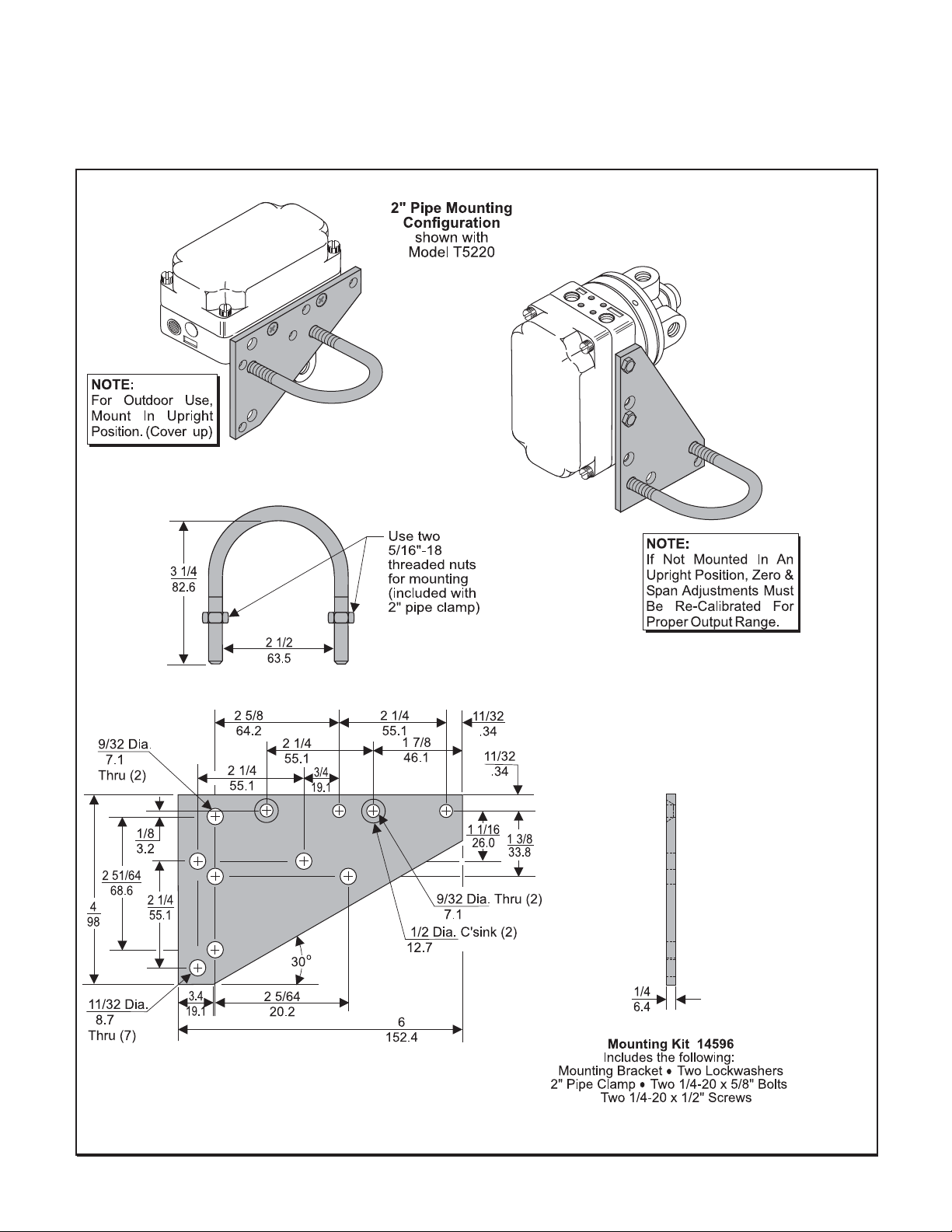

The Model T5420 can be mounted on a 2" pipe using the

Optional Mounting Kit 14596. For more information, see

Figure 3. below.

For outdoor use, mount the T5220 in an upright

position. This will help prevent rain water from

entering into the unit. For more information, see

Figure 3. “Mounting Kit 14596” below.

Figure 3. Optional Mounting Kit 14596. (Sold Separately)

2

Page 3

INSTALLATION

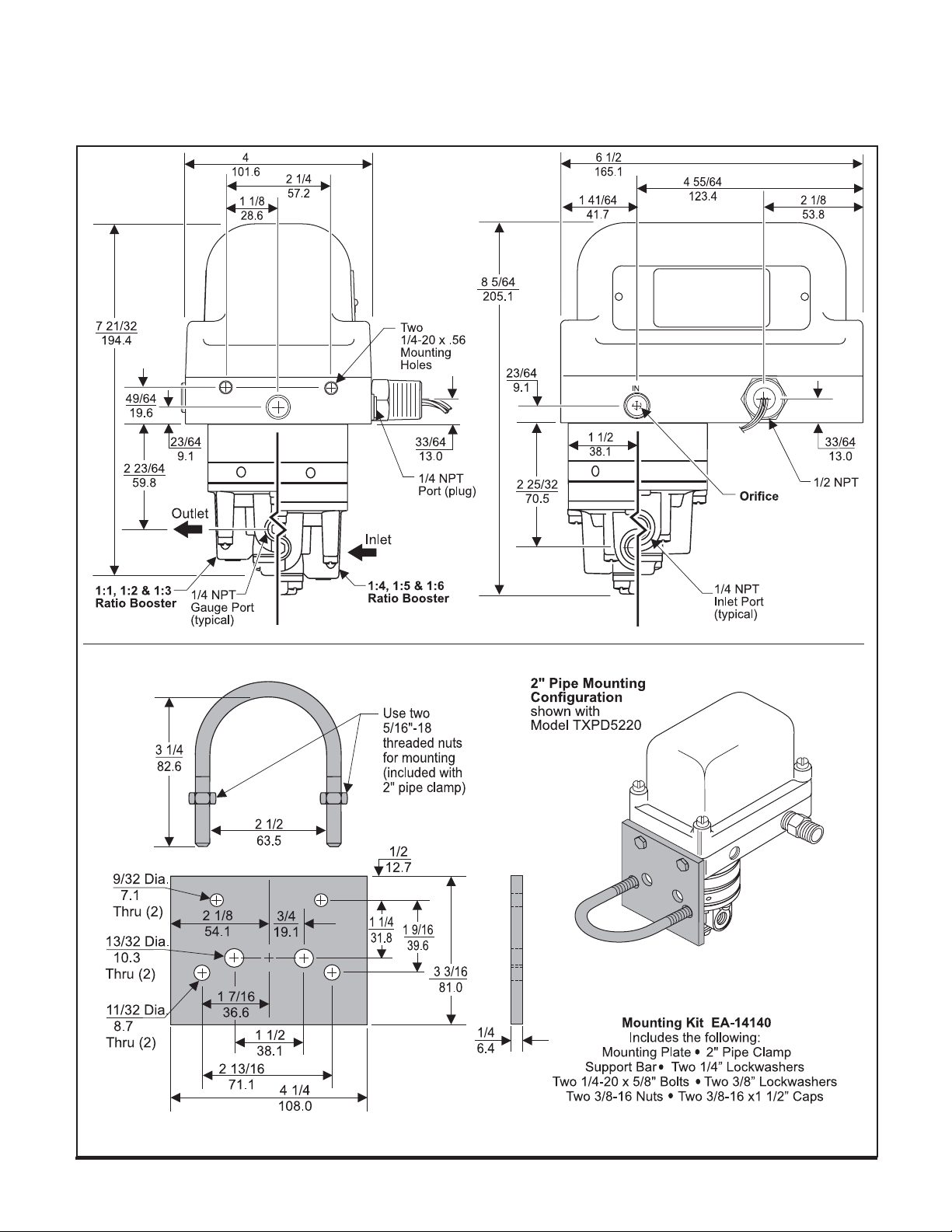

The Model TXPD5220 can be mounted directly onto a flat

surface using the four 1/4-20 x 7/16 tapped mounting holes

in the base of the housing . For more information, see Figure

4. “TXPD5220 Outline Dimensions” below.

14140 is available for Panel or 2" Pipe Mounting. For

more information, see Figure 5 below.

Mounting Kit

Figure 4. TXPD5220 Outline Dimensions.

Figure 5. Mounting Kit 14140. (Sold Separately)

3

Page 4

Pneumatic Connections

Electric Connection

Clean all pipelines to remove dirt and scale before installation.

Apply a minimum amount of pipe compound to the male

threads of the fitting only. Do Not use teflon tape as a

sealant. Start with the third thread back and work away

from the end of the fitting to avoid the possibility of

contaminating the transducer. Install the transducer in the

air line.

NOTES:

Instrument quality air, per ISA Standards

D7.3-1981, is required. Use a filter to remove dirt and liquid in the air line ahead of

the transducer for correct performance. If

an air line lubricator is used, it MUST be

located downstream, beyond the transducer.

The user is responsible for insuring that the

environment in which the unit will be

installed, and the operating gas, are compatible with the materials in the trans-

WARNING:

To prevent possible ignition of hazardous

atmosphere, DO NOT REMOVE COVER from

the TXPD5220 Transducer while current is

on.

To maintain Explosion-Proof capability, DO

NOT DAMAGE mating surfaces between

cover and base. NEVER ADD GASKETS.

For the T5220 Transducer, make connections to the Terminal Block through a 1/2 NPT Conduit Connector (not

supplied) and a plastic sleeve as shown below in Figure 7.

“Electrical Connections”.

For the TXPD5220 Transducer, make connections from the

Sealed Connector Wires to an external Terminal Block. The

TXPD5220 Transducer has an additional ground wire that is

used. For more information, see Figure 7. “Electrical

Connections” below.

NOTE: The T5220 & TXPD5220 should be wired in

accordance with the wiring diagram inside of

cover.

Wiring in Hazardous Areas

Wiring in hazardous areas should be performed in accordance with the Table 1. and any local codes that apply.

Table 1. Hazardous Location Wiring Practices.

Country

U.S.

Canada

Agency

FM

CSA

Code

ANSI/ISA RP 12.6 & ANSI/NFPA 70

CEC Part 1

Intrinsically Safe Connections

Refer to the latest revision of the indicated drawing.

Table 2. Intrinsically Safe Installation Drawings.

Underwriting Group Drawing Number

FM (Factory Mutual)

CSA (Canadian Standards)

EC-14007

EC-16097

Figure 6. Electrical Connections.

4

Page 5

CALIBRATIONS / ADJUSTMENTS

Equipment Required for Calibration:

• Pneumatic Supply capable of delivering up to 150 psig.

• Current Supply capable of delivering up to 50 mA.

• Voltage Supply capable of delivering up to 10 VDC.

• Pressure Gage capable of a digital readout up to 50 psig

with an accuracy of .1%.

• Digital Volt Meter capable of a readout up to 30 mA or

10 VDC with an accuracy of .02%.

The following adjustments are provided:

Full Range Operation

Forward/Reverse Mode

Calibration - Zero and Span

FULL RANGE OPERATION

Forward Acting Mode Adjustment

NOTE:

1.

• Forward Acting Calibration-Zero

Air Supply must be on before adjustments are

made.

Connect the input signal to the transducer as shown

in Figure 6. “Electrical Connections.”

2.

Apply the minimum input signal and adjust the Zero

screw for minimum output pressure. Turn screw

counterclockwise to increase pressure and clockwise to decrease pressure.

• Forward Acting Calibration-Span

3.

Apply the maximum input signal and adjust the Span

screw on the potentiometer for maximum output

pressure. Turn screw clockwise to increase pressure and counterclockwise to decrease pressure.

Repeat steps 2-3 until the desired output range is

4.

obtained. For more information, see Figure 7. “T5220/

TXPD5220 Calibration Configuration.”

Reverse Acting Mode Adjustment

NOTE:

5.

• Reverse Acting Calibration-Zero

• Reverse Acting Calibration-Span

Intrinsically safe units cannot be set for reverse acting mode in field.

Connect the input signal to the transducer as shown

in Figure 6. “Electrical Connections.”

6.

Apply the minimum input signal and adjust the Zero

screw for maximum output pressure. Turn screw

counterclockwise to increase pressure and clockwise to decrease pressure.

7.

Apply the maximum input signal and adjust the Span

screw on the potentiometer for minimum output pressure. Turn screw counterclockwise to increase pressure and clockwise to decrease pressure.

Repeat steps 6-7 until the desired output range is

8.

obtained. For more information, see Figure 8. “T5200/

TXPD5200 Calibration Configuration.”

Figure 7. T5220 / TXPD5220 Calibration Configuration.

5

Page 6

MAINTENANCE

To clean the Orifice, use the following procedure:

Turn off the air supply to the transducer. If the

1.

transducer is a common supply unit, remove the Pipe

Plug from the In Port located on the rectangular base.

If the transducer is a separate supply unit, remove the

Air Line Fitting from the In Port.

2.

Remove the Orifice Assembly (9) from the unit by

threading a 1/4-20" Screw into the orifice housing and

pulling it out through the inlet port. For more informa-

tion, see Figure 8. “Exploded Drawing” below.

Clean with alcohol and dry with compressed air.

3.

NOTE:

To clean the Inner Valve Assembly, use the following

procedure:

1.

2.

3.

4.

NOTE:

Parts must be completely dry before reassembling.

Shut off the valve that is supplying air to transducer. It

is not necessary to remove the Transducer from air

line.

Remove Screws (7) holding the Retainer Cap (6) and

Plate (5) to Booster (1).

Pull out Inner Valve Assembly (4) and wash the seat

carefully.

Wipe off any particles that may be attached to rubber

Seat Ring Assembly (2). For more information, see

Detail A, below.

Avoid such solvents as acetone, carbon tetrachloride and trichlorethylene.

To clear probblems caused by Magnet malfunction,

use the following procedure:

1.

Shut off the valve that is supplying air to transducer. It

is not necessary to remove the Transducer from air

line.

2.

Remove three Screws (12) holding Magnet (11) to

Transducer (8).

3. Remove Magnet (11) and clean gap of any foreign

material with masking tape. For more information, see

View B, below.

4.

Place Magnet (11) over Coil (10) and tighten with three

Screws (12).

5.

Using a non-matalic rod, Raise up on the arm to make

sure Coil (10) is not sticking in Magnet (11).

NOTE:

To replace PC Board, use the following procedure:

1.

2.

3.

4.

If Coil is sticking, loosen Screws and reposition Magnet. Tighten Screws and repeat

step 5.

Disconnect wires from Terminal Block on PC Board (14).

Unsolder Red (+) and Black (-) Leads on PC Board (14).

Remove four Screws (13) holding PC Board (14) to

Transducer (8). For more information, see Figure 8.

“Exploded Drawing” below.

Replace PC Board (14) with the appropriate PC Board

from Table 3. on page 7.

Figure 8. Exploded Drawing.

6

Page 7

Maintenance (continued)

TROUBLE-SHOOTING

Table 3. T5220 Series Components.

Item

Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14

14

14

14

14

14

14

1

2

1

1

1

1

1

1

2

1

1

4

1

1

1

1

1

1

1

1

3

1

1

For T5220, TFI5220, TFN5220, TFNI5220, TXPD5220,

& TXPDI5220 Units Only.

For TCI5220 Only.

Part No.

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

13744-2

15638-2

13745-2

15483-2

14639-2

15640-2

13746-2

15639-2

Description

Transducer

Orifice

Coil

Magnet

Screw

Screw

Booster

Seat Ring Assembly

Screen

Inner Valve Assembly

Retainer Plate

Retainer Cap

Screw

1

1-5 mA PC Board

2

1-5 mA PC Board

1

4-20,10-50 mA PC Board

2

4-20,10-50 mA PC Board

1

1-5 VDC PC Board

2

1-5 VDC PC Board

1

1-9 VDC PC Board

2

1-9 VDC PC Board

NS: (Not Serviceable) In the Part No. column, NS indicates that the part is not available for field replacement.

Table 4. Trouble-Shooting.

Problem

No Output

Solution (check)

Supply Pressure

Clogged Orifice

Power Supply

Leakage

Low or Improper

Span Adjust

Pneumatic Connections

Zero and SpanAdjust

Supply Pressure Low

Output Leakage

Erratic Operation

DC Signal

Loose Wires or Connections

Liquid in Air Supply

Dirt in Magnet Gap

Unit Does Not

Replace PC Board

Operate

NOTE: Booster Repair Kits are available for the T5220.

Ratio

1:1

1:2

1:3

1:4

1:5

1:6

Kit Number

15288-1

15288-2

15288-3

15656-4

15656-5

15656-6

7

Page 8

IS-500T5220

Litho in USA

Rev. M 06/07

Loading...

Loading...