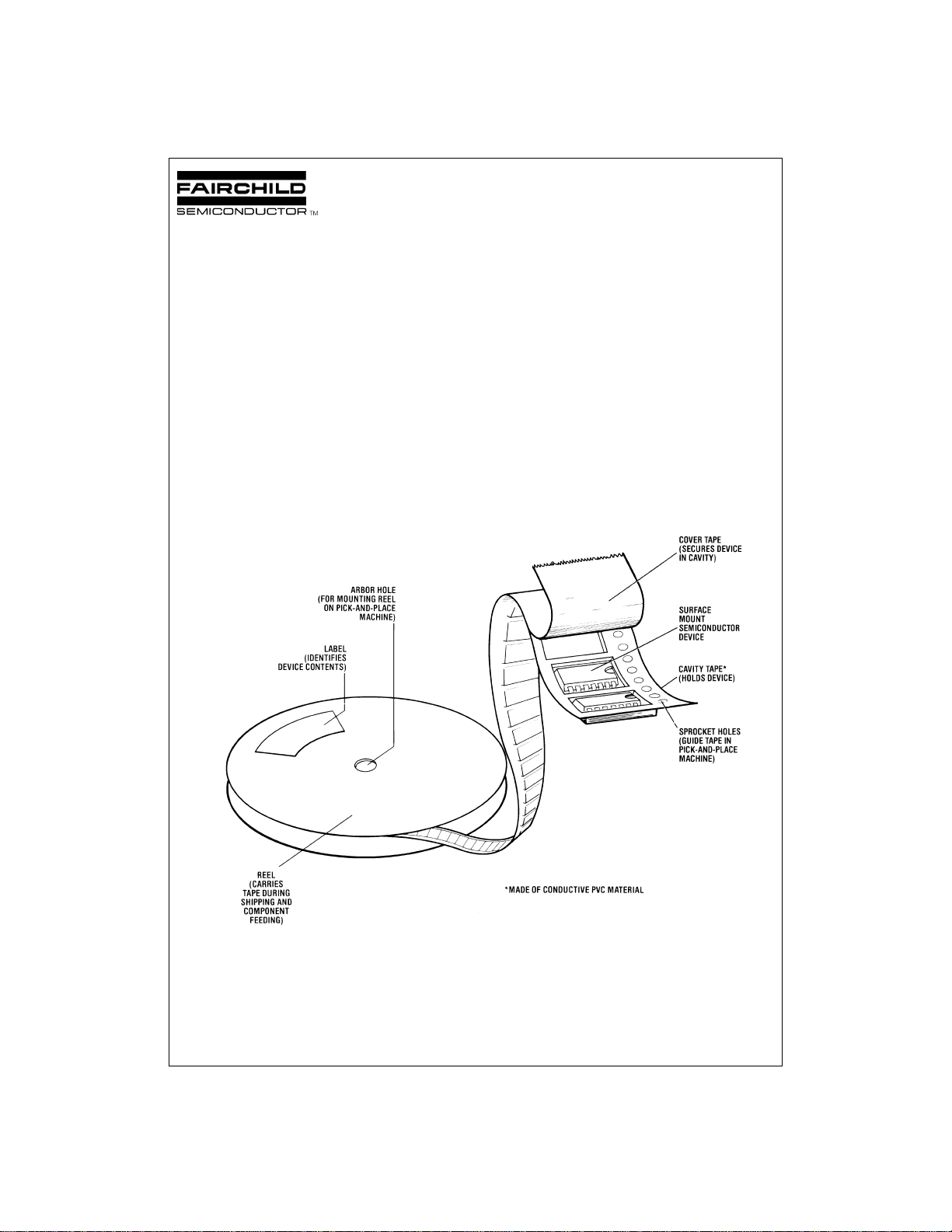

Surface Mount Tape and Reel Specification

General Description

Tape-and-Reel is a method for shipment of surface mount

devices. This approach simplifies the handling of semiconductors for automated circuit board assembly systems. A

Tape-and-Reel holds hundreds-to-thousands of surface

mount devices(as compared with less than 100 devices in a

rail), so that pick-and-place machines have to be reloaded

less frequently. This savings in labor will further reduce

manufacturing costs for automated circuit board assembly.

Features

Conductive PVC material reduces static charge buildup

•

Fully meets proposed EIA standard RS-481A (taping of

•

surface-mounted components for automatic placing)

Tape-and-Reel Diagram

April 1998

Fully compatible with Fairchild’s surface mount package

•

types

Variable code density code 39 bar code label for Auto-

•

mated Inventory Management availability

Mechanical samples of surface mount packages avail-

•

able in Tape-and-Reel for automated assembly process

development

Single Tape-and-Reel holds hundreds-to-thousands of

•

surface mount semiconductors for additional labor savings

Conductive cover Tape-and-Reel availability

•

Reels individually packed

•

Surface Mount Tape and Reel Specification

MS500145-1

© 1998 Fairchild Semiconductor Corporation MS500145 www.fairchildsemi.com

Tape-and-Reel Overview

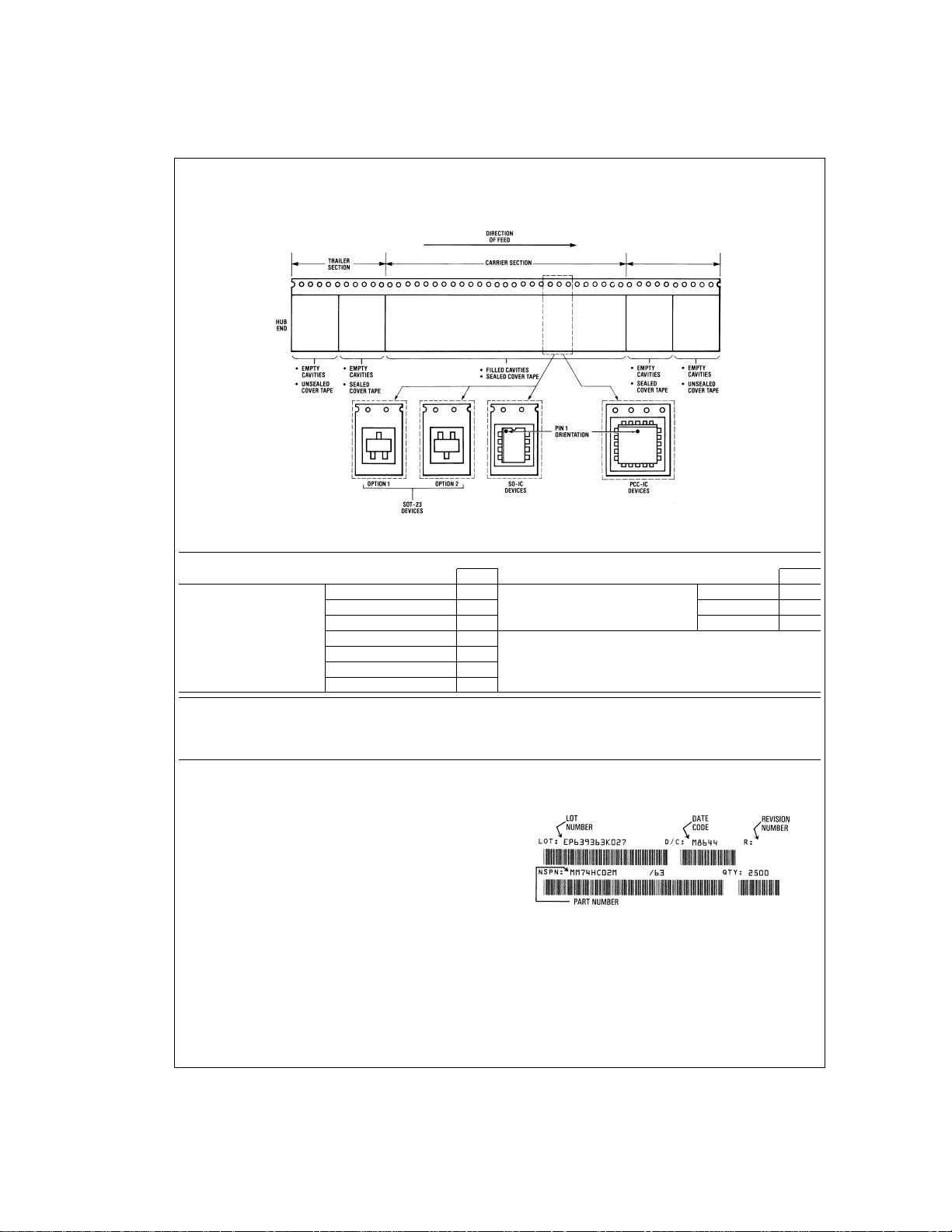

TAPE FORMAT AND DEVICE ORIENTATION

MS500145-2

Small Outline IC (SO-IC) SO-8 (Narrow) 4 Plastic Chip Carrier IC (PLCC-IC) PLCC-20 11

SO-14 (Narrow) 5 PLCC-28 12

SO-14 (Wide) 6

SO-16 (Narrow) 7

SO- 16 (Wide) 8

SO-20 (Wide) 9

SO-24 (Wide) 10

MATERIALS

Cavity Tape: Conductive PVC (less than 10

Cover Tape: Polyester 2. Conductive Fibregboard available

1. Conductive Cover available 3. Conductive Plastic (PVC) available

Page Page

5

Ω/Sq) Reel: 1. Solid 80 pt. Fibreboard (standard)

LABEL

Human and machine readable label is provided on reel. A

variable (C.P.I.)densitycode 39 is available. FSC STD Label

(7.6 C.P.I.).

Field

Lot Number

Date Code

Revision Level

MS500145-3

Fairchild Part No. I.D.

Quantity

Fields are separated by at least one blank space.

Future Tape-and-Reel packs will also include a smaller-size

bar code label (high-density code 39) at the beginning of the

tape. (This tape label is not available on current production.)

Fairchild Semiconductor will also offer additional labels containing information per your specific specification.

www.fairchildsemi.com 2

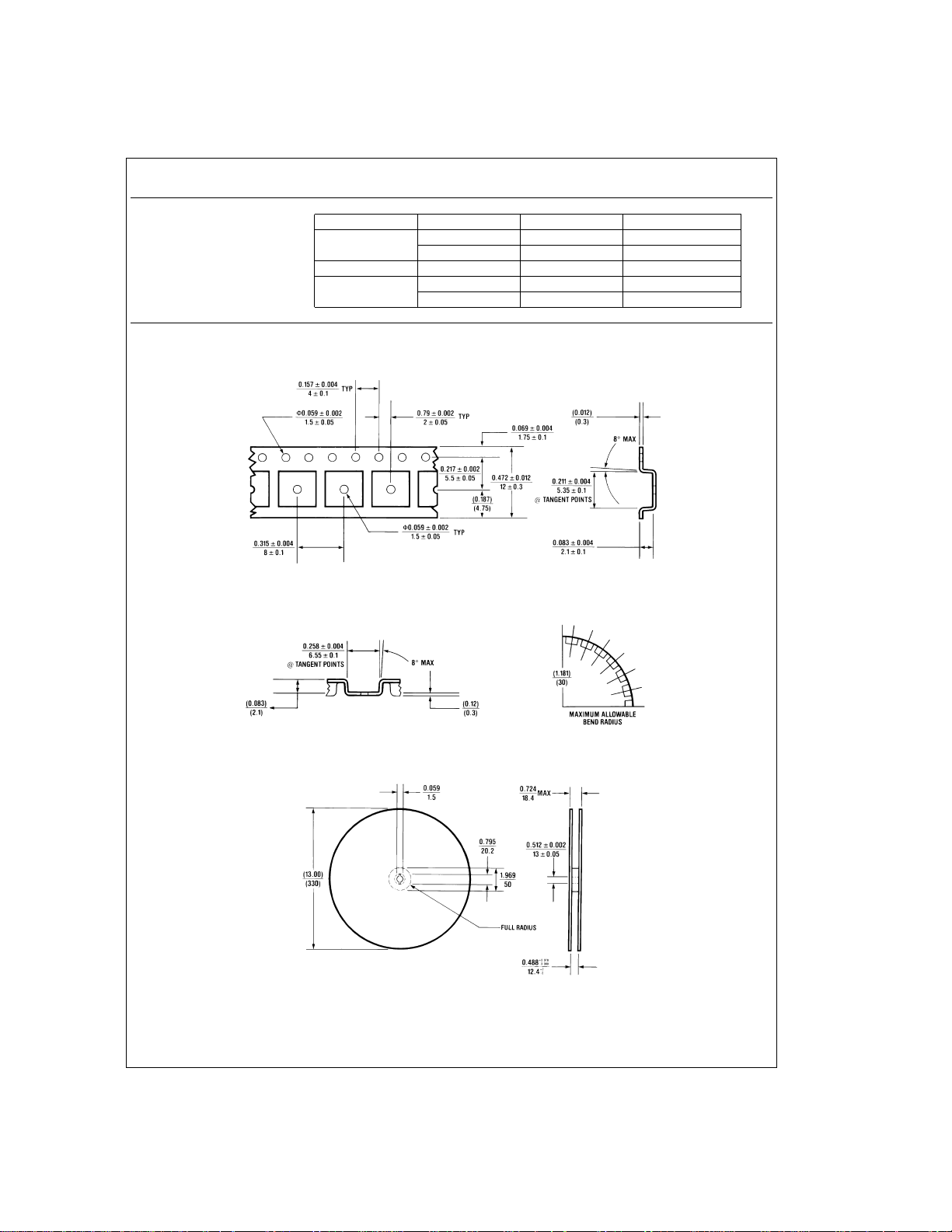

SO-8 (Narrow)

TAPE FORMAT

Direction (Start End) 5 (min) Empty Sealed

Tape Section # Cavities Cavity Status Cover Tape Status

Leader 5 (min) Empty Unsealed

of

Feed Trailer 2 (min) Empty Sealed

Carrier 2500 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

3 www.fairchildsemi.com

MS500145-6

MS500145-7

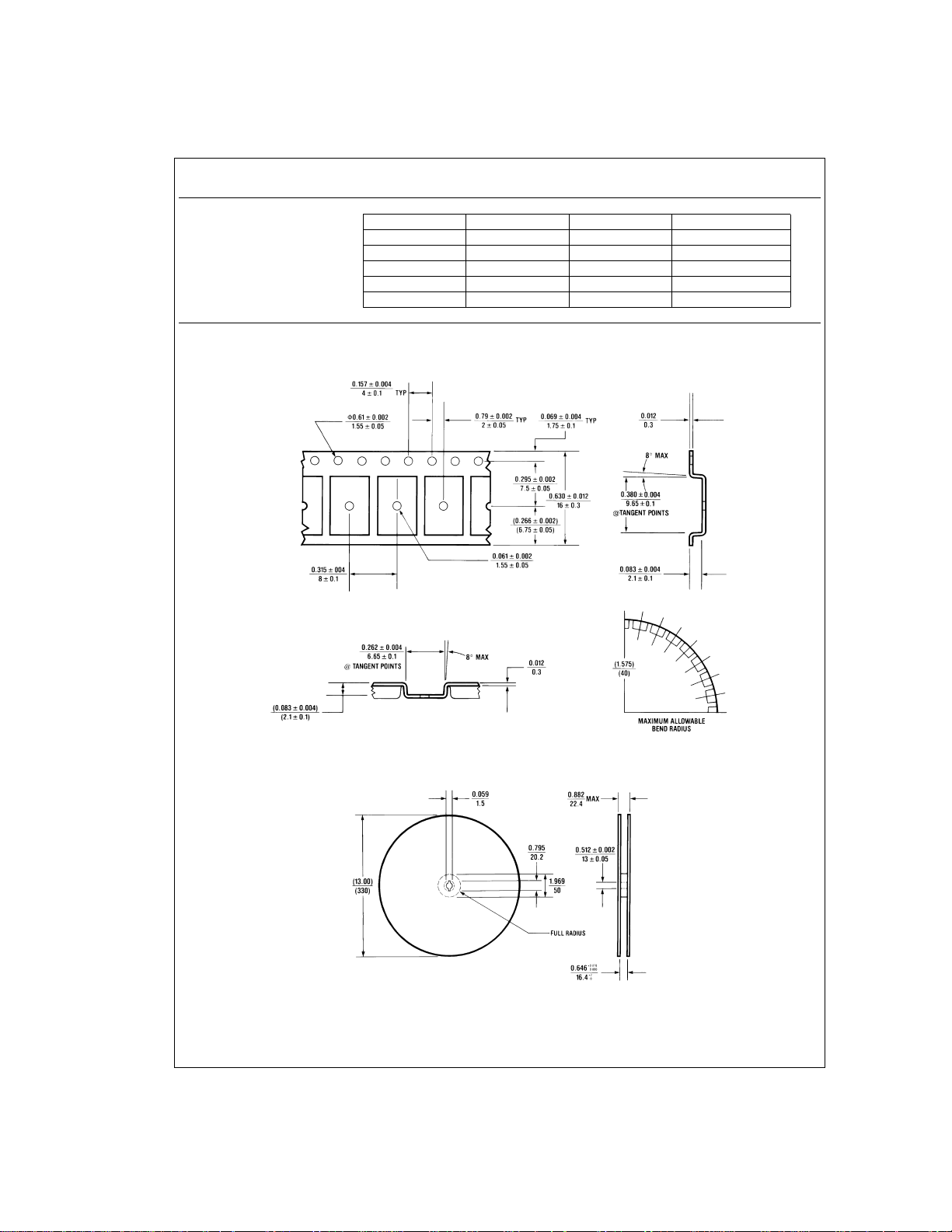

SO-14 (Narrow)

TAPE FORMAT

Direction (Start End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Tape Section # Cavities Cavity Status Cover Tape Status

Leader 5 (min) Empty Unsealed

Carrier 2500 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

www.fairchildsemi.com 4

MS500145-8

MS500145-9

SO-14 (Wide)

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Start End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 2500 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

5 www.fairchildsemi.com

MS500145-10

MS500145-11

SO-16 (Narrow)

TAPE FORMAT

Direction (Start End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Tape Section # Cavities Cavity Status Cover Tape Status

Leader 5 (min) Empty Unsealed

Carrier 2500 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

www.fairchildsemi.com 6

MS500145-12

MS500145-13

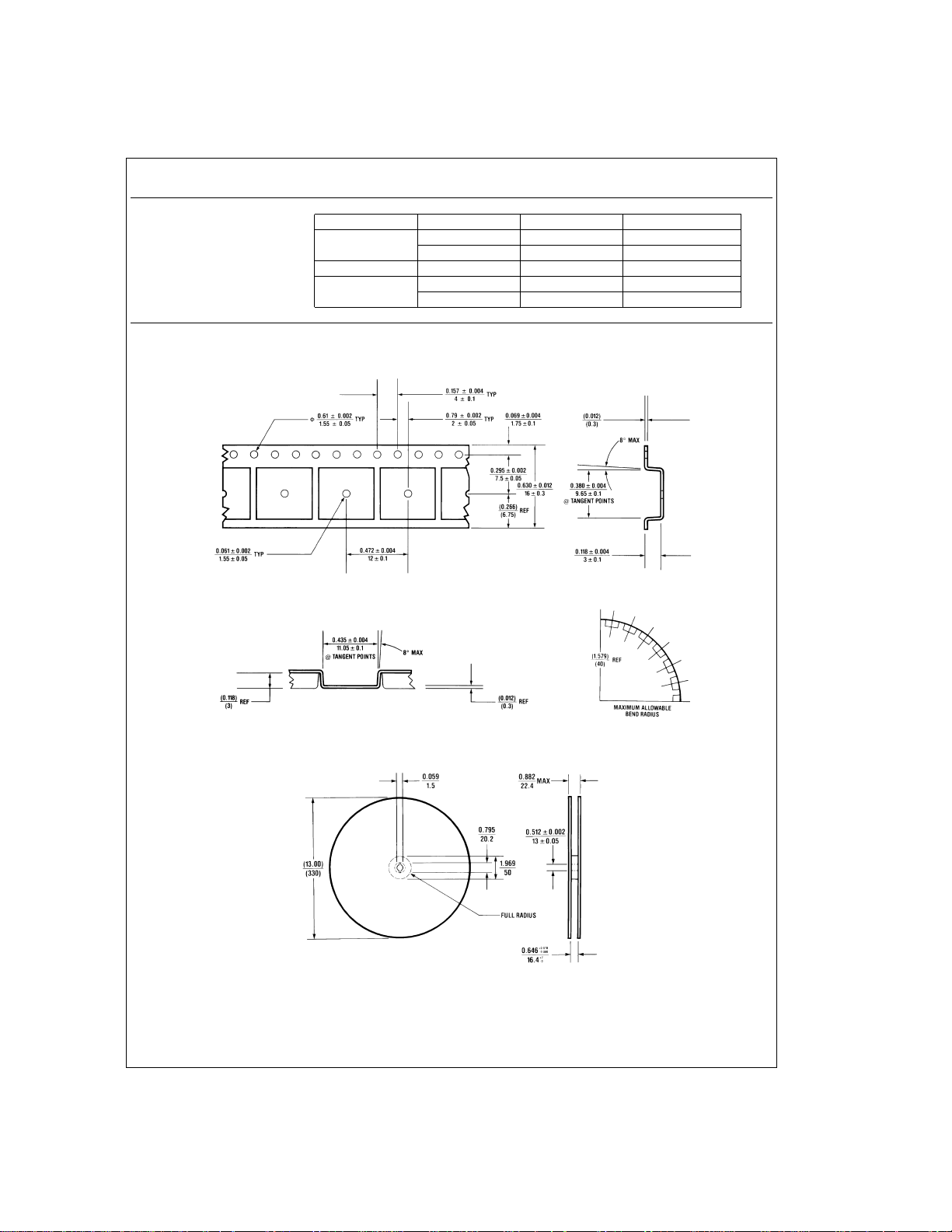

SO-16 (Wide)

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Start End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 1000 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

7 www.fairchildsemi.com

MS500145-14

MS500145-15

SO-20 (Wide)

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Start End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 1000 Filled Sealed

↑

(Hub End) 2 (min) Empty Unsealed

TAPE DIMENSIONS

REEL DIMENSIONS

www.fairchildsemi.com 8

MS500145-16

MS500145-17

SO-24 (Wide)

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Starter End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 1000 Filled Sealed

↑

(Hub End) 2 (min) Empty Sealed

TAPE DIMENSIONS

REEL DIMENSIONS

9 www.fairchildsemi.com

MS500145-18

MS500145-19

PLCC-20

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Starter End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 1000 Filled Sealed

↑

(Hub End) 2 (min) Empty Sealed

TAPE DIMENSIONS

REEL DIMENSIONS

www.fairchildsemi.com 10

MS500145-20

MS500145-21

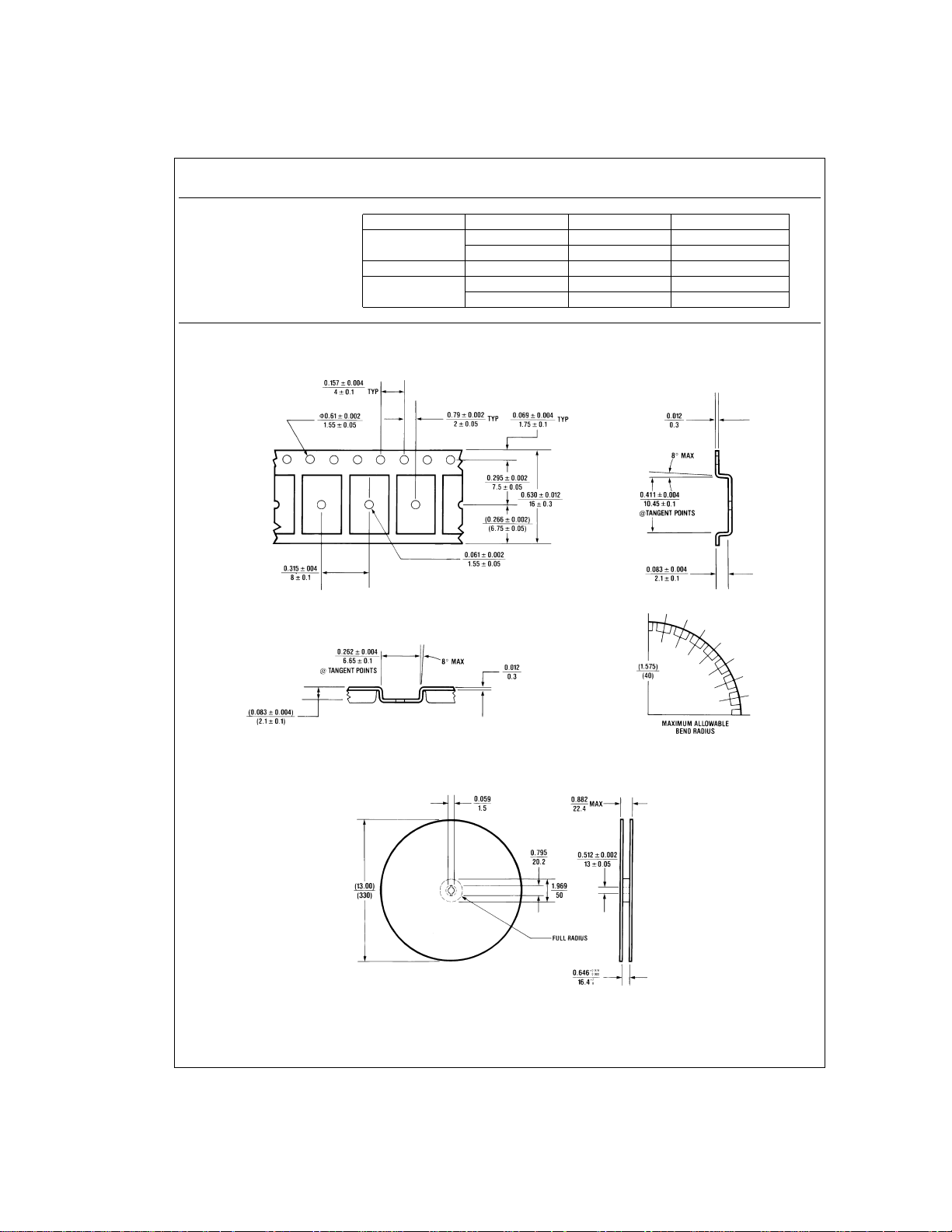

PLCC-28

TAPE FORMAT

Tape Section # Cavities Cavity Status Cover Tape Status

Direction (Starter End) 5 (min) Empty Sealed

of

Feed Trailer 2 (min) Empty Sealed

Leader 5 (min) Empty Unsealed

Carrier 750 Filled Sealed

↑

(Hub End) 2 (min) Empty Sealed

TAPE DIMENSIONS

REEL DIMENSIONS

MS500145-23

11 www.fairchildsemi.com

MS500145-22

Application-Total System Saving

Cost pressures today are forcing many electronics manufacturers to automate their production lines. Surface mount

technology plays a key role in this cost-savings trend because:

The mounting of devices on the PC board surface elimi-

•

nates the expense of drilling holes;

The use of pick-and-place machines to assemble the PC

•

boards greatly reduces labor costs;

The lighter and more compact assembled products re-

•

sulting from the smaller dimensions of surface mount

packages mean lower material costs.

Production processes now permit both surface mount and

insertion mount components to be assembled on the same

PC board.

MS500145-32

Automated manufacturers can improve their cost savings by

using Tape-and-Reel for surface mount devices. Simplified

handling results because hundreds-to-thousands of semiconductors are carried on a single Tape-and-Reel pack (see

the “Ordering Information” section for the exact quantities).

With this higher device count per reel (when compared with

less than 100 devices per rail), pick-and-place machines

have to be re-loaded less frequently and lower labor costs

result.

With Tape-and-Reel, manufacturers save twice — once from

using surface mount technology for automated PC board assembly and again form less device handling during shipment

and machine set-up.

www.fairchildsemi.com 12

Ordering Information

When you order a surface mount semiconductor, it will be in

one of the available surface mount package types (see Appendix II for the physical dimensions of the surface mount

packages). Specifying the Tape-and -Reel method of shipment ((Note 1)) means that you will receive your devices in

the following quantities per Tape-and-Reel pack:

Small Outline IC SO-8 (Narrow) 2500

Plastic Chip Carrier IC PLCC-20 1000

Note 1: For surface mount integrated circuits, your order will automatically be shipped in conductive rails unless you indicate “Tape-and-Reel” after the device de-

scription on your purchase order.

SO-14 (Narrow) 2500

SO-14 (Wide) 1000

SO-16 (Narrow) 2500

SO-16 (Wide) 1000

SO-20 (Wide) 1000

SO-24 (Wide) 1000

PLCC-28 750

Device Quantity

Example: You order 5,000 74AC14SC ICs shipped in

Tape-and-Reel.

All 5,000 devices have the same date code

•

You receive 2 SO-14 (Narrow) Tape-and-Reel packs,

•

each having 2500 74AC14SC ICs

13 www.fairchildsemi.com

Appendix I—Short-Form Procurement Specification

TAPE FORMAT

Trailer (Hub End) Carrier Leader (Start End)

Empty Cavities, Empty Cavities, Filled Cavities Empty Cavities, Empty Cavities,

min min min min

(Unsealed (Sealed (Sealed (Sealed (Unsealed

Cover Tape) Cover Tape) Cover Tape) Cover Tape) Cover Tape)

SMALL OUTLINE IC

SO-8 (Narrow) 2 2 2500 5 5

SO-14 (Narrow) 2 2 2500 5 5

SO-14 (Wide) 2 2 1000 5 5

SO-16 (Narrow) 2 2 2500 5 5

SO-16 (Wide) 2 2 1000 5 5

SO-20 (Wide) 2 2 1000 5 5

SO-24 (Wide) 2 2 1000 5 5

PLASTIC SHIP CARRIER IC

PLCC-20 2 2 1000 5 5

PLCC-28 2 2 750 5 5

→

Direction of Feed

www.fairchildsemi.com 14

Appendix I—Short-Form Procurement Specification (Continued)

TAPE DIMENSIONS (24 Millimeter Tape or Less)

MS500145-33

WPFEP

2

P

0

DTA

SMALL OUTLINE IC

±

SO-8

(Narrow)

SO-14

(Narrow)

SO-14

(Wide)

SO-16

(Narrow)

SO-16

(Wide)

SO-20

(Wide)

SO-24

(Wide)

.30 8.0±.10 5.5±.05 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 6.4±.10 5.2±.10 2.1±.10 1.55±.05 30

12

±

.30 8.0±.10 7.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 6.5±.10 9.0±.10 2.1±.10 1.5±.05 40

16

±

.30 12.0±.10 7.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 10.9±.10 9.5±.10 3.0±.10 1.55±.05 40

16

±

.30 8.0±.10 7.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 6.5±.10 10.3±.10 2.1±.10 1.55±.05 40

16

±

.30 12.0±.10 5.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 10.9±.10 10.76±.10 3.0±.10 1.55±.05 40

16

±

.30 12.0±.10 11.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 10.9±.10 13.3±.10 3.0±.10 2.05±.05 50

24

±

.30 12.0±.10 11.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 10.9±.10 15.85±.10 3.0±.10 2.05±.05 50

24

PLASTIC CHIP CARRIER IC

±

PLCC-20 16

PLCC-28 24

Note A: A0,B0and K0dimensions are measured 0.3 mm above the inside wall of the cavity bottom.

Note B: Tape with components shall pass around a mandril radius R without damage.

Note C: Cavity tape material shall be PVC conductive (less than 10

Note D: Cover tape material shall be polyester (30–65 grams peel-back force).

Note E: D

Note F: All dimensions are in millimeters.

.30 12.0±.10 7.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 9.3±.10 9.3±.10 4.9±.10 1.55±.05 40

±

.30 16.0±.10 11.5±.10 1.75±.10 2.0±.05 4.0±.10 1.55±.05 .30±.10 13.0±.10 13.0±.10 4.9±.10 2.05±.05 50

5

Ω/Sq).

Dimension is centered within cavity.

1

0

B

0

K

0

D

1

R

15 www.fairchildsemi.com

Appendix I—Short-Form Procurement Specification (Continued)

REEL DIMENSIONS

MS500145-35

12 mm Tape SO-8 (Narrow)

16 mm Tape SO-14

24 mm Tape SO-20 (Wide)

(Narrow)

SO-14 (Wide)

SO-16

(Narrow)

SO-16 (Wide)

PLCC-20

SO-24 (Wide)

PLCC-28

A (Max) B (Min) C D (Min) N (Min) G T (Max)

±

(13.00) 0.059 0.512

(330) 1.5 13

(13.00) 0.059 0.512

(330) 1.5 13

(13.00) 0.059 0.512

(330) 1.5 13

Units:

0.002 0.795 1.969 0.488

±

0.05 20.2 50 12.4

±

0.002 0.795 1.969 0.646

±

0.05 20.2 50 16.4

±

0.002 0.795 1.969 0.960

±

0.05 20.2 50 24.4

Inches

Millimeters

+0.045

−0.000

+2

−0

+0.078

−0.000

+2

−0

+0.078

−0.000

+2

−0

0.724

18.4

0.882

22.4

1.197

30.4

Material: Paperboard (Non-Flaking)

www.fairchildsemi.com 16

Appendix II—Physical Dimensions of Surface Mount Packages

SO-14 (Wide)

SO-16 (Narrow)

17 www.fairchildsemi.com

Appendix II—Physical Dimensions

of Surface Mount Packages

SO-16 (Wide)

(Continued)

SO-20 (Wide)

www.fairchildsemi.com 18

Appendix II—Physical Dimensions

of Surface Mount Packages

SO-24 (Wide)

PLCC-20

(Continued)

19 www.fairchildsemi.com

Appendix II—Physical Dimensions

of Surface Mount Packages

PLCC-28

Surface Mount Tape and Reel Specification

(Continued)

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and (c)

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life

support device or system, or to affect its safety or

effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

Fairchild Semiconductor

Corporation

Americas

Customer Response Center

Tel: 1-888-522-5372

Fax: 972-910-8036

www.fairchildsemi.com

Fairchild does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and Fairchild reserves the right at any time without notice to change said circuitry and specifications.

Fairchild Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 8 141-35-0

English Tel: +44 (0) 1 793-85-68-56

Italy Tel: +39 (0) 2 57 5631

Fairchild Semiconductor

Hong Kong Ltd.

8/F Room 808 Empire Centre

68 Mody Road, Tsimshatsui East

Kowloon, Hong Kong

Tel: 852-2722-8338

Fax: 852-2722-8383

Fairchild Semiconductor

Japan Ltd.

4F, Natsume BI,

2-18-6 Yushima, Bunkyo-ku,

Tokyo 113-0034, Japan

Tel: 81-3-3818-8840

Fax: 81-3-3818-8450

Loading...

Loading...