www.fairchildsemi.com

AN-6902

Applying SG6902 to Control a CCM PFC and

Flyback/PWM Power Supply

Summary

This application note shows a step-by-step design to a

120W/24V power adapter. The equations also can be

applied to different output voltages and wattages.

Features

Interleaved PFC/PWM Switching

Green-Mode PFC/PWM Switching

No PFC Switching at Light Loads for Power Saving

Innovative Switching Charge Multiplier-divider

Low Startup and Operating Current

Innovative Switching Charge Multiplier-divider

Multi-vector Control for Improved PFC Output

Transient Response

Average-Current-Mode Control for PFC

Programmable Two-Level PFC Output Voltage to

Achieve the Best Efficiency

PFC Over-voltage and Under-voltage Protections

PFC and PWM Feedback Open-loop Protection

Cycle-by-cycle Current Limiting for PFC/PWM

Slope Compensation for PWM

Maximum Power Limit for PWM

Brownout Protection

Over Temperature Protection

Power-on Sequence Control and Soft-start

20-Pin SOP and SSOP Packages

Description

SG6902 is designed for power supplies that consist of boost

PFC and flyback PWM. It requires few external

components to achieve green-mode operation and versatile

protections and compensations.

The proprietary interleave switching synchronizes the PFC

and PWM stages and reduces switching noise. At light

loads, PFC stage is turned off to save power and the PWM

switching frequency is decreased in response to the load.

For PFC stage, the proprietary multi-vector control scheme

provides a fast transient response in a low-bandwidth PFC

loop. The overshoot and undershoot of the PFC voltage are

clamped. If the feedback loop is broken, SG6902 shuts off

the switching to protect the power supply and its load.

For the flyback PWM stage, the synchronized slope

compensation ensures the stability of the current loop.

“Hiccup” operation limits a maximum output power during

the overload situations.

The difference between members of this family are shown

in the table below.

Parameter SG6902 SG6901A

Start Threshold Voltage

Minimum Operating Voltage

The Interval of OPFC Lags

Behind OPWM at Startup

PFC On/Off

OTP

Soft-Start

16V 12V

10V 10V

11.5ms 11.5ms

O X

O O

O O

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08

AN-6902 APPLICATION NOTE

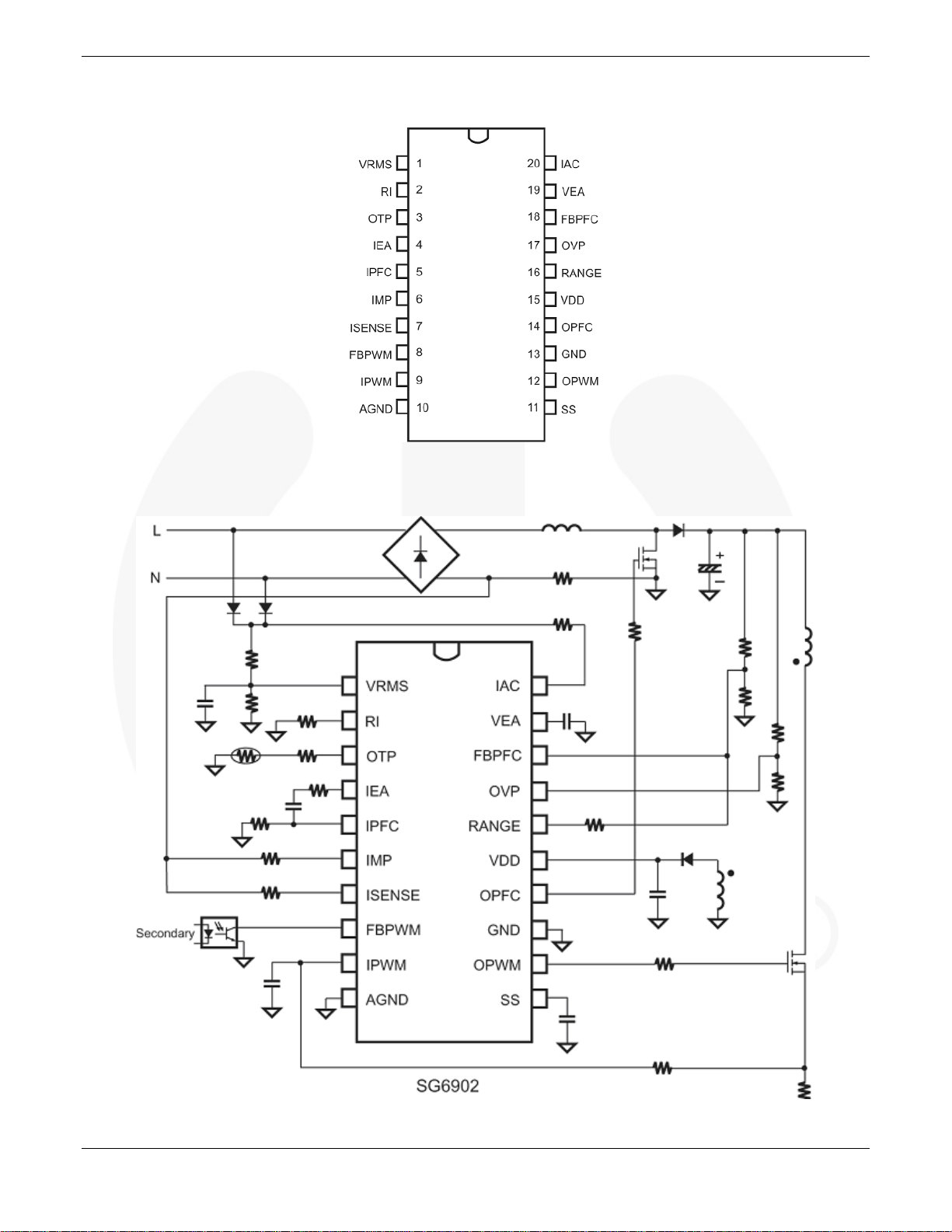

Pin Configuration

Figure 1. Pin Configuration

Typical Application

Figure 2. Typical Application

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 2

AN-6902 APPLICATION NOTE

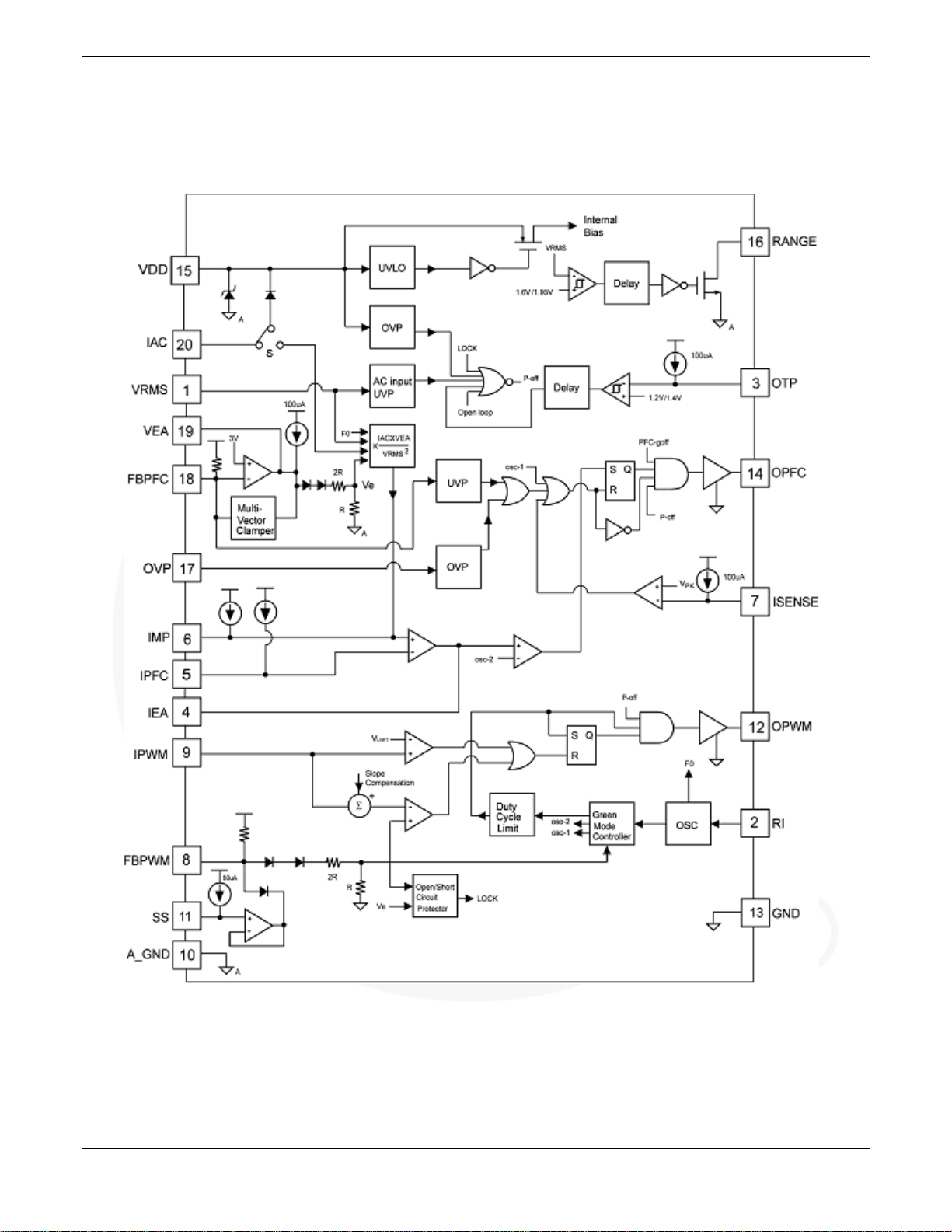

Block Diagram

Figure 3. Block Diagram

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 3

AN-6902 APPLICATION NOTE

PFC Section

Power-On Sequence

Because the capacitor includes ±20% variation, the

capacitor 100µF is chosen.

SG6902 is active when the line voltage is higher than the

brownout threshold. The PWM stage is switching first,

then, following an 11.5ms delay time after FBPWM

voltage is higher than a PFC turn-on threshold voltage,

the PFC stage is enabled.

PFC Inductor

The switching frequency fS, output power P

efficiency n, maximum ripple current ΔI, and minimum

input voltage V

should be defined before determining

IN.min

the inductance of PFC inductor. The following equations

are utilized to determine the inductance of the PFC

inductor. Normally the maximum ripple current is 20% ~

30% of maximum input current.

()

OUT

I×=Δ

V

3.0/P2

η

)MIN(IN

1D×−=

V

O

2V

min.IN

di

LV =

dt

max

fs/D

IN.min

L

××=2V

I

Δ

For a 120W adapter power, η= 0.85, V

= 65KHz, VO = 250V, ΔI = 0.66A, D = 0.49, L =

f

S

IN(MIN)

= 90V

0.4mH.

PFC Capacitor

An advantage of using interleaving switching of PFC and

PWM stage is to reduce the switching noise. The ESR

requirement of boost capacitor is relaxed. The boost

capacitor value is chosen to remain a hold-up time of

output voltage in the event line voltage is removed.

××

=

C

O

()

η

where V

is the minimum output voltage in accordance

O.min

with the requirement of the specification.

For a 120W power supply, the capacitor is determined as:

C

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 4

()

>

O

()

2

t)/(P2

up-holdPWMOUT

2

ripple)normal(O

ms1585.0/W1202

××

2

6020250

−−

2

VVV −−

min.O

F86

μ

=

(1)

(2)

(3)

(4)

AC,

(5)

(6)

OUT

,

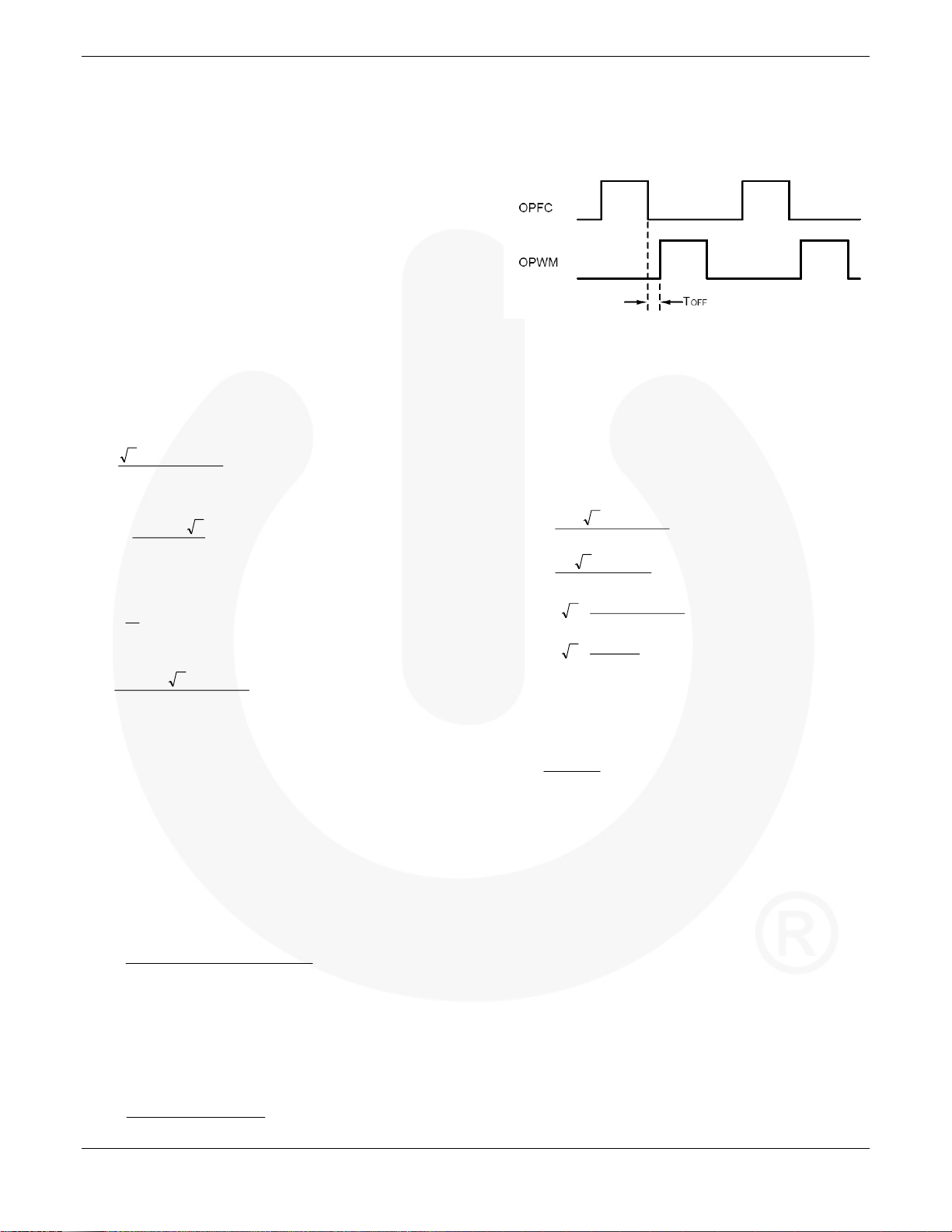

Figure 4. Interleaving Switching

Boost Rectifier and Switch

The fast reverse-recovery time of the boost diode is

required to reduce the power losses and the EMI. A 500V

voltage rating is chosen to withstand 400V boosts

potential. The average current and peak currents flow

through the boost diode and the switch, respectively, and

are given by:

η

/P22

××

I

AVG

I

AVG

PEAK

PEAK

=

π

×

=

2I

2I

OUT

V

××

π

75

×

×=

V

75

OUT

8.0/120

)Brownout(RMS

8.0/12022

A8.1

=

η

/P

)Brownout(RMS

A82.2

=×=

(7)

Oscillation and Green Mode

The resistor RI connected from the RI to GND pin

programs the switching frequency of SG6902.

1560

=

f

S

()

KR

Ω

I

For example, a 24kΩ resistor R

()

KHz

(8)

results in a 65kHz

I

switching frequency. The recommended range for the

switching frequency is 33kHz ~ 100kHz.

SG6902 provides an off-time modulation to reduce the

switching frequency in light-load and no-load conditions.

The feedback voltage of FBPWM pin is taken as

reference. When the feedback voltage is lower than about

2.1V, the switching frequency decreases accordingly.

Most of losses in a switching-mode power supply are

proportional to the switching frequency; therefore, the

off-time modulation reduces the power consumption of

the power supply in light-load and no-load conditions.

For a typical case of R

= 24KΩ, the switching frequency

I

is 65kHz at nominal load and decreases to 20kHz at light

load. The switching signal is disabled if the switching

frequency falls below 20KHz, which avoids acoustic noise.

For stability reasons, a capacitor connecting the RI pin to

GND is not suggested.

AN-6902 APPLICATION NOTE

f

F

s

20KHz

2.1

BPWM(V)

Figure 5. Switching Frequency vs. FB Voltage

To save power, the PFC stage is enabled only when the

feedback voltage of the FBPWM pin is higher than a

threshold voltage V

. The threshold voltage VTH is 2.1V

TH

to 2.45V at low line voltage input, 1.95V at high line

voltage. The threshold voltage V

determines an output

TH

power threshold to turn on/off the PFC stage for the

power saving. The output power P

can be expressed

OUT

as:

P

OUT

FB

where V

η

=

is a synchronized 0.5V ramp.

SL

ONIN

tL2

××

P

V

⎧

⎪

3V2.1V

⎨

⎪

⎩

)PEAK(IN

L

P

V

SL

tR

ONS

t

×+×××+=

t

ON

(9)

⎫

⎪

(10)

⎬

⎪

⎭

2

tV

××

()

Equation 10 shows that, through the feedback loop, the

on-time t

switching period t and/or the inductance L

changes in response to the change of the

ON

(the primary

P

inductance of the transformer) for providing a same

output power. Because the feedback voltage V

the on-time t

, a lower VFB causes a narrow on-time tON.

ON

controls

FB

Changing the switching frequency (the switching period

t) and the inductance L

, affects the output power

P

threshold to on/off the PFC stage.

IAC Signal

Figure 6 shows that the IAC pin is connected to the input

voltage via a resistor. A current I

multiplier.

I ≈

)PEAK(AC

V

)PEAK(IN

R

AC

For wide range input:

()

PEAKIN

=×=

is used for PFC

AC

V3742V264V

(11)

(12)

Figure 6. Linear Range

Line Voltage Detection (VRMS)

Figure 6 shows a resistive divider with low-pass filter

connected to the VRMS

The V

input is used for the PFC multiplier and

RMS

brownout protection.

For a sine wave input voltage, the voltage on the VRMS

pin is directly proportional to input voltage. To achieve

the brownout protection, the PFC stage is disabled after a

195ms delay once the V

The PWM stage is protected through the open-loop

detection on the FBPWM pin when the output voltage of

the PFC stage is too low. After that, SG6902 turns off.

When V

voltage is higher than 0.98V, the SG6902

RMS

restarts in accordance with power-on sequence of PFC

and PWM stages.

For example, a brownout protection is set as 75V

and RI can be determined as:

R

RMS

IN)MEAN(IN

V

RMS

=

1R

+

R1R

RMS

The threshold of V

V

= 75VAC, the value of R1 is 56.8KΩ.

IN

pin for line-voltage detection.

voltage drops below 0.8V.

RMS

2

2VV

××=

π

2

×××

2V

IN

= 0.8V. If R

RMS

π

= 4.8MΩ and

RMS

AC

. The

(13)

(14)

The linear range of I

suggested for a wide input range (90V

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 5

is 0~360µA. A 1.2M resistor is

AC

~ 264VAC).

AC

AN-6902 APPLICATION NOTE

(

PFC Operation

Cycle-by-cycle Current Limiting

SG6902 provides cycle-by-cycle current limiting for both

PFC and PWM stages. Figure 8 shows the peak current

limit for the PFC stage. The switching signal of PFC

stage is turned off immediately once the voltage on

ISENSE pin goes below the threshold voltage V

The voltage of V

. The correlation of the threshold voltage VPK and

V

PK

determines the threshold voltage

RMS

PK

.

VRMS is shown in Figure 8. The amplitude of the

shown in Figure 8 is determined by a

P

, in accordance with the following

T

Figure 7. Current Output

constant current I

reference current I

equation as:

The current source output from the switching charge

multiplier/divider can be expressed as:

MO

V

RMS

EAAC

2

KI

×=

)A(

μ

(15)

VI

×

According to Figure 7, the current output from IMP pin,

, is the summation of IMO and I

I

MP

equipped as same as R

is identical with I

. The constant current source I

3

. They are used to bias (pull HIGH)

MR2

. The resistor R2 is

MR1

MR1

Tp

Therefore, the peak current of the I

I

=

PEAK_S

V2.1

2I2I ×=×=

R

I

can be expressed as:

S

)

V2.0RI

−×

PP

R

S

(19)

(20)

the operating point of the IMP and IPFC pins since the

voltage across R

goes negative with respect to ground.

S

Through the differential amplification of the signal across

, a better noise immunity is acjoeved. The output of IEA

R

S

compared with an internal sawtooth generates a switching

signal for PFC. Through the feedback loop of the average

current control mode, the input current I

:

to I

MO

RIRI ×=×

SS2MO

According to this equation, the minimum value of R

maximum value of R

can be determined. The IMO should

S

be estimated under its specified maximum value.

A concern in determining the value of the sense resistor

includes low-resistance RS reduces the power

R

S

consumption, but high-resistance R

resolution to achieve low input current THD (total

harmonic distortion). Using a current transformer (CT)

instead of R

improves the efficiency for high-power

S

converters.For a 120W adapter, the power consumption of

= 0.36Ω is:

R

S

2

85.0/W120

90

⎞

⎟

⎠

=×

⎛

P

=

⎜

RS

⎝

R

and R3 can be determined as

2

(the brownout threshold is 75V):

120W/0.8

I

I

MO

MO

MAX

75V

IR

×

MAXS

=

R

2

2.830.36

×

=

3.3K

The results show that R

308μ0

=

2.83A2

=×=I

, R2, and R3 values are fit for

S

providing 120W output.

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 6

is proportional

S

provides high

S

W885.036.0

(16)

and

2

(17)

(18)

Figure 8. Current Limit

Multi-vector Error Amplifier

To achieve good power factor, the voltage for V

should be kept as DC-value according to Equation

V

EA

14. In other words, a low-pass RC filtering for V

narrow bandwidth (lower than the line frequency) of PFC

voltage loop are suggested to achieve better input current

shaping. The trans-conductance error amplifier has output

impedance R

(>90kΩ). A capacitor CEA (1µF ~ 10µF) is

O

suggested to connect from the output of the error

amplifier to ground (Figure 9). A dominant pole f

PFC voltage loop is shown as:

f××=

1

1

π

CR2

EAO

The average total input power can be expressed as:

IVP

×=

()()

IV

×∞

MORMS

V

×∞

RMS

V

V

RMS

R

×∞

V

RMS

IN

AC

V

VI

×

×

RMS

RMSINRMSININ

EAAC

2

V

EA

2

∞

V

EA

RMS

RMS

of the

1

and

and a

(21)

(22)

AN-6902 APPLICATION NOTE

Figure 9. Multi-vector Error Amplifier

Equation 22 shows the output of the voltage error

amplifier, V

, controls the total input power and the

EA

power delivered to the load.

Although the PFC stage has a low bandwidth voltage loop

for better input power factor, the innovative multi-vector

error amplifier provides a fast transient response to clamp

the overshoot and undershoot of PFC output voltage.

Figure 10 shows the block diagram of the multi-vector

error amplifier. When the variation of the feedback

voltage (FBPFC) exceeds ±5% of the reference voltage

(3V), the trans-conductance error amplifier programs its

output current to speed up the loop response. If R

A

is

open circuit, SG6902 is turned off immediately to prevent

over-voltage on the output capacitor.

Determine the resistor divider ratio R

V

R

O

A

R

B

1

−=

3

A/RB

:

(25)

250

R

A

R

B

=−=

3

33.821

(26)

Assume R

3MΩ, RB = 36.5KΩ, and R

A

= 60KΩ. Refer to

C

=

Figure 10. At high line input, maximum output voltage is:

)MAX(O

⎜

⎝

⎛

R

⎜

15.3V

⎞

A

⎟

+=×=

⎟

R//R

CB

⎠

V4201

=

(27)

Another circuit provides further over-voltage protection

to inhibit the PFC switching once the feedback voltage

exceeds the 3.25V the output voltage is clamped at:

)OVP(O

⎜

⎝

⎛

R

⎜

25.3V

⎞

A

⎟

+×=

⎟

R//R

CB

⎠

V4331

=

(28)

+

VEA

3V

FBPFC

RC

SG69XX

RANGE

(PFC)

VO

RA

RB

Two-level PFC Output voltage

Figure 10. Feedback Voltage of PFC

For universal input (90VAC ~ 264VAC), the output voltage

of PFC is usually designed to 250V at low line and 400V

at high line. This improves efficiency of the power

PWM SECTION

converter for low-line input. The RANGE pin (opendrain) is used for the two-level output voltage setting.

Figure 10 shows the RANGE output that programs the

PFC output voltage. The RANGE output is shorted to

ground when the V

high-impedance output (open) whenever the V

voltage exceeds 1.95V. It is a

RMS

voltage

RMS

drops below 1.6V. The output voltages can be determined

using below equations:

RR

+

BA

VOpenRange

=⇒=

O

R

V3

×

B

(23)

Soft-starting the PWM stage

The soft-start pin controls the rising time of the output

voltage and prevents the overshoot during power on. The

soft-start capacitor value for the soft-start period t

given by:

I

SS

V

OZ

is the zero-duty threshold of FBPWM voltage.

where V

tC ×=

SSSS

OZ

is

SS

(29)

()

R//RR

VGNDRange

O

+

=⇒=

()

CBA

V3

×

R//R

CB

(24)

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 7

AN-6902 APPLICATION NOTE

Leading-Edge Blanking (LEB)

A voltage signal develops on the current-sense resistor RS

represents the switching current of MOSFET. Each time

the MOSFET turns on, a spike, caused by the diode

reverse recovery time and by the parasitic capacitances of

the MOSFET, appears on the sensed signal. The SG6902

has a build-in leading-edge blanking time of about 350ns

to avoid premature termination of MOSFET by the spike.

Only a small-value RC filter (e.g. 100Ω + 47pF) is

required between the IPWM pin and R

negative spike into the IPWM pin. A non-inductive

resistor for the R

is recommended.

S

to prevent

S

Figure 12. Current Limit and Slope Compensation

SG6841

Gate

Blanking

Circuit

Figure 11. Turn-on Spike

Sense

Flyback PWM and Slope Compensation

As shown in Figure 12, peak-current-mode control is

utilized for flyback PWM. The SG6902 inserts a

synchronized 0.5V ramp at the beginning of each

switching cycle. This built-in slope compensation reduces

the current loop gain and ensures stable operation for

current-mode operation.

When the IPWM voltage, across the sense resistor,

reaches the threshold voltage, 0.65V or 0.7V selected by

RANGE, the OPWM turns off after a small propagation

delay, t

additional current proportional to T

is the output voltage of PFC and Lp is the

V

PFC

magnetized inductance of flyback transformer. Since the

propagation delay is nearly constant,

in a larger additional current and the output power limit is

higher than that of the low V

variation, the peak current threshold is modulated by the

RANGE output. When RANGE is shorted to GND, the

PFC output voltage is higher and the corresponding

threshold is 0.65V. When RANGE is opened, the PFC

output voltage is lower and the corresponding threshold is

0.7V. Increasing the inductance of transformer improves

this phenomenon.

. This propagation delay introduces an

PD-PWM

PD-PWM•VPFC

higher V

. To compensate for this

PFC

/Lp, where

results

PFC

Output Driver of OPFC and OPWM

SG6902’s OPFC and OPWM is fast totem-pole gate

driver that is able to directly drive external MOSFET. An

internal Zener diode clamps the driver voltage under 18V

to protect MOSFET from over-voltage damage.

VDD

ON/OFF

Driver

SG6841

18V

Gate

Figure 13. Gate Drive

Over-Current Protection (OCP) and ShortCircuit Protection (SCP)

OCP and SCP are based on detection of feedback signal

on FBPWM pin. Shown in Figure 14, if over-current or

short-circuit occurs, FBPWM is pulled HIGH through the

feedback loop. If the FB voltage is higher than 4.5V for

longer than 56ms debounce time, SG6902 is turned off.

Once V

such as 10V, SG6902 is UVLO (under-voltage lockout)

shut down. By the startup resistor, V

the turn-on threshold voltage 16V) until SG6902 is

enabled again. If the overloading condition still exists, the

protection takes place repeatedly. This prevents the power

supply from being overheated in overloading condition.

The 650ms time-out signal prevents SG6902 from being

latched off when the input voltage is fast on/off.

is lower than the turn-off threshold voltage,

DD

is charged (up to

DD

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 8

AN-6902 APPLICATION NOTE

(

s

p

Figure 14. Over-Current Protection or Short-Circuit Protection

Over-Temperature Protection (OTP)

SG6902 provides an OTP pin for over-temperature

protection. A constant current is output from this pin. If

RI is equal to 24kΩ, the magnitude of the constant current

is 100µA. An external NTC thermistor must be connected

from this pin to ground as shown in Figure 15. When the

OTP voltage drops below 1.2V, SG6902 is disabled until

OTP voltage exceeds 1.4V.

Figure 15. Over-Temperature Protection

Flyback Transformer Design

The turn ratio n = Np/Ns, is an important parameter for a

flyback power converter. It affects the maximum duty of

the switching signal when the input voltage is in

minimum value. It also influences the voltage stresses of

the MOSFET and the secondary rectifier.

Refer to Equations 30 and 31. If n increases, the voltage

stress of the MOSFET increases; however, the voltage

stress of the secondary rectifier decreases accordingly.

VVnVV +×+=

fOmax.INmax.DS

(30)

(31)

V +=

max.AK

where V

= 400V.

V

IN.max

()

xV

ma.IN

n

is the forward voltage of output diode and

f

V

O

Referring to the maximum duty cycle and minimum input

voltage at full load, the transformer inductance can be

calculated as:

)

VVn

+×

fO

D

=

max

η

L

=

P

where B

()

is how much percentage of the output power is

r

()

DV

××

maxmaxIN

BfP2

×××

into CCM in low line input voltage. Normally, the B

set as 30% ~ 50%. V

i

k

IN.min

i

av

d

VVnV

+×+

fOmin.IN

2

rSOUT

= 250V.

I

q

max

(32)

(33)

is

r

iΔ

p

1-d

max

Figure 16. Primary Current Waveform

Figure 16 shows the primary current waveform. Once the

inductor L

and average current I

is determined, the primary peak current Ipk

P

, at the full load and low line input

av

voltage, can be expressed as:

I××=

AV

η

V

I ××=Δ

P

O

max.IN

L

P

DV

maxmax.IN

TD

Smax

(34)

(35)

P

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 9

AN-6902 APPLICATION NOTE

I

Δ

P

I +

PK

I

=

AV

2

(36)

III Δ−=

PPKSQ

(37)

From Faraday’s law, the turns of primary side can be

expressed as:

IL

×

N ×

=

P

PKP

×

8

10

AB

emax

(38)

Figure 17 shows a transformer winding structure,

including primary winding (Np1), copper layer (shield),

secondary winding (Ns), auxiliary winding (AUX),

copper layer (shield), and primary winding (Np2).

Because the auxiliary winding is between secondary

winding and shield windings, it can alleviate the variation

voltage and avoid the VDD voltage reaching the

of V

DD

over-voltage threshold of 24.5V for normal operation.

The turns of auxiliary winding can be expressed as:

N

aux

where V

voltage of V

()()

=

is set to around 12V and Vfa is the forward

DD

rectifier diode.

DD

Transformer Winding Structure

D1VVN

−×+×

maxfaDDP

DV

×

maxmax.IN

(39)

Figure 17. Winding Structure

The auxiliary winding of the transformer is developed to

provide a power source (V

circuit. To produce a regulated V

voltage) to the control

DD

voltage, the reflected

DD

voltage of the auxiliary winding is designed to correlate

to the output voltage of secondary winding. A switching

voltage spike, caused by the leakage inductance of the

primary winding, would be coupled to the auxiliary

winding to increase the V

voltage in response to the

DD

increase of the load.

When the V

voltage is increased higher than the

DD

voltage of the over-voltage protection 24.5V, the control

circuit turns off the PWM and PFC stages to protect the

power supply. Therefore, the transformer windings

should prevent the auxiliary winding from primary

winding interference.

Lab Note

Before rework or solder/desolder on the power supply,

discharge primary capacitors by external bleeding

resistor. Otherwise, the PWM IC may be destroyed by

external high voltage during solder/desolder.

This device is sensitive to ESD discharge. To improve

production yield, the production line should be ESD

protected according to ANSI ESD S1.1, ESD S1.4, ESD

S7.1, ESD STM 12.1, and EOS/ESD S6.1

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 10

AN-6902 APPLICATION NOTE

Printed Circuit Board Layout

Note that SG6902 has two ground pins. Good highfrequency or RF layout practices should be followed.

Avoid long PCB traces and component leads. Locate

decoupling capacitors near the SG6902. A resistor (5 ~

20Ω) is recommended, connected in series from the

OPFC and OPWM to the gate of the MOSFET.

Isolating the interference between the PFC and PWM

stages is also important. Figure 18 shows an example of

the PCB layout. The ground trace connected from the

AGND pin of SG6902 to the decoupling capacitor, which

should be low impedance and as short as possible. The

ground trace 1 provides a signal ground. It should be

connected directly to the decoupling capacitor V

to the AGND pin of the SG6902. The ground trace 2

shows that the AGND pins should connect to the PFC

output capacitor C

independently. The ground trace 3 is

O

independently tied from the PGND to the PFC output

capacitor C

. The ground in the output capacitor CO is the

O

and/or

DD

To provide a good ground reference and reduce the

switching noise of both the PFC and PWM stages, the

ground traces 6 and 7 should be located very near and be

low impedance.

The IPFC pin is connected directly to R

through R3 to

S

improve noise immunity (beware that it may incorrectly

be connected to the ground trace 2). The IMP and

ISENSE pins should also be connected directly via the

resistors R

and RP to another terminal of RS. Due to the

2

ground trace 4 and 5 is PFC and PWM stages Current

loop, which should be as short as possible.

major ground reference for power switching.

Figure 18. PCB Layout

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 11

AN-6902 APPLICATION NOTE

Related Datasheets

SG6902 — Green Mode PFC / Flyback PWM Controller

SG6901A — Green Mode PFC / Flyback PWM Controller

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS

HEREIN TO IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE

APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS

PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, or (c) whose failure to perform

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in significant injury to the user.

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

© 2007 Fairchild Semiconductor Corporation www.fairchildsemi.com

Rev. 1.2.1 • 5/1/08 12

Loading...

Loading...