Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

FEATURES

High-voltage start-up

Low operating current (4mA)

Linearly decreasing PWM frequency to 22KHz

Frequency jittering to reduce EMI emission

Fixed PWM frequency (65KHz)

Peak-current-mode control

Cycle-by-cycle current limiting

Leading-edge blanking

Synchronized slope compensation

To minimize standby power consumption, a proprietary

green-mode function provides off-time modulation to

linearly decrease the switching frequency at light-load

conditions. To avoid acoustic noise problems, the

minimum PWM frequency is set above 22KHz. This

green-mode function enables the power supply to meet

international power conservation requirements. With the

internal high-voltage start-up circuitry, the power loss due

to bleeding resistors is eliminated. To further reduce power

consumption, SG6742 is manufactured using the BiCMOS

process, which allows an operating current of 4mA.

Internal open-loop protection

GATE output maximum voltage clamp (18V)

V

V

under-voltage lockout (UVLO)

DD

over voltage protection (OVP)

DD

Programmable over-temperature protection (RT)

Internal latch circuit (OVP, RT)

Constant power limit (full AC input range)

Internal OTP sensor with hysteresis

SG6742 integrates a frequency a hopping function that

helps reduce EMI emission of a power supply with

minimum line filters. Also, its built-in synchronized slope

compensation achieves stable peak-current-mode control.

The proprietary internal line compensation ensures

constant output power limit over a wide AC input voltages,

from 90V

to 264VAC.

AC

SG6742 provides many protection functions. In addition

APPLICATIONS

General-purpose switch-mode power supplies and

flyback power converters, including:

Power Adapters

Open-Frame SMPS

DESCRIPTION

to cycle-by-cycle current limiting, the internal open-loop

protection circuit ensures safety should an open-loop or

output short-circuit failure occur. PWM output is disabled

until V

controller starts up again. As long as V

drops below the UVLO lower limit when the

DD

exceeds about

DD

26V, the internal OVP circuit is triggered.

SG6742 is available in an 8-pin DIP or SOP package.

The highly integrated SG6742 series of PWM controllers

provides several features to enhance the performance of

flyback converters.

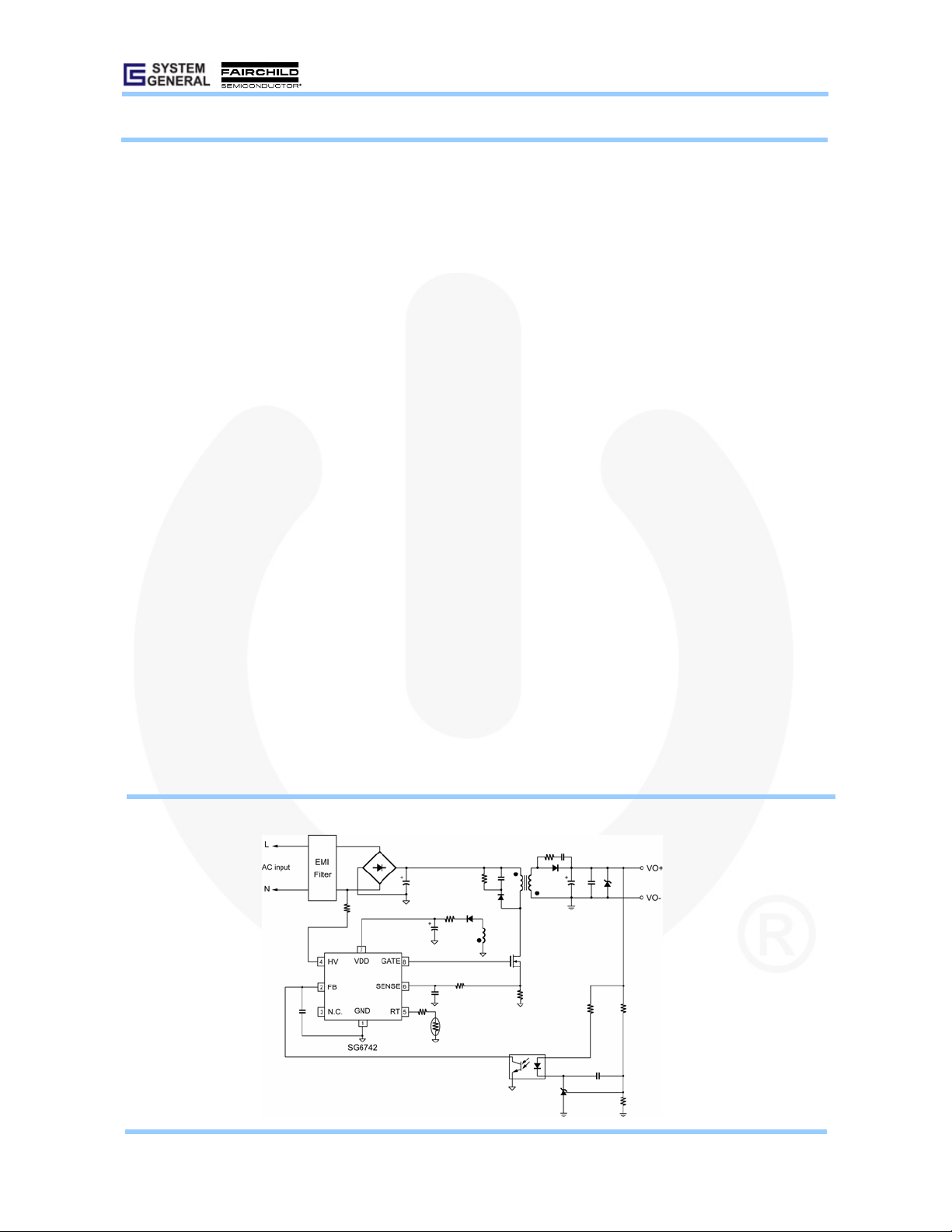

TYPICAL APPLICATION

© System General Corp. - 1 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

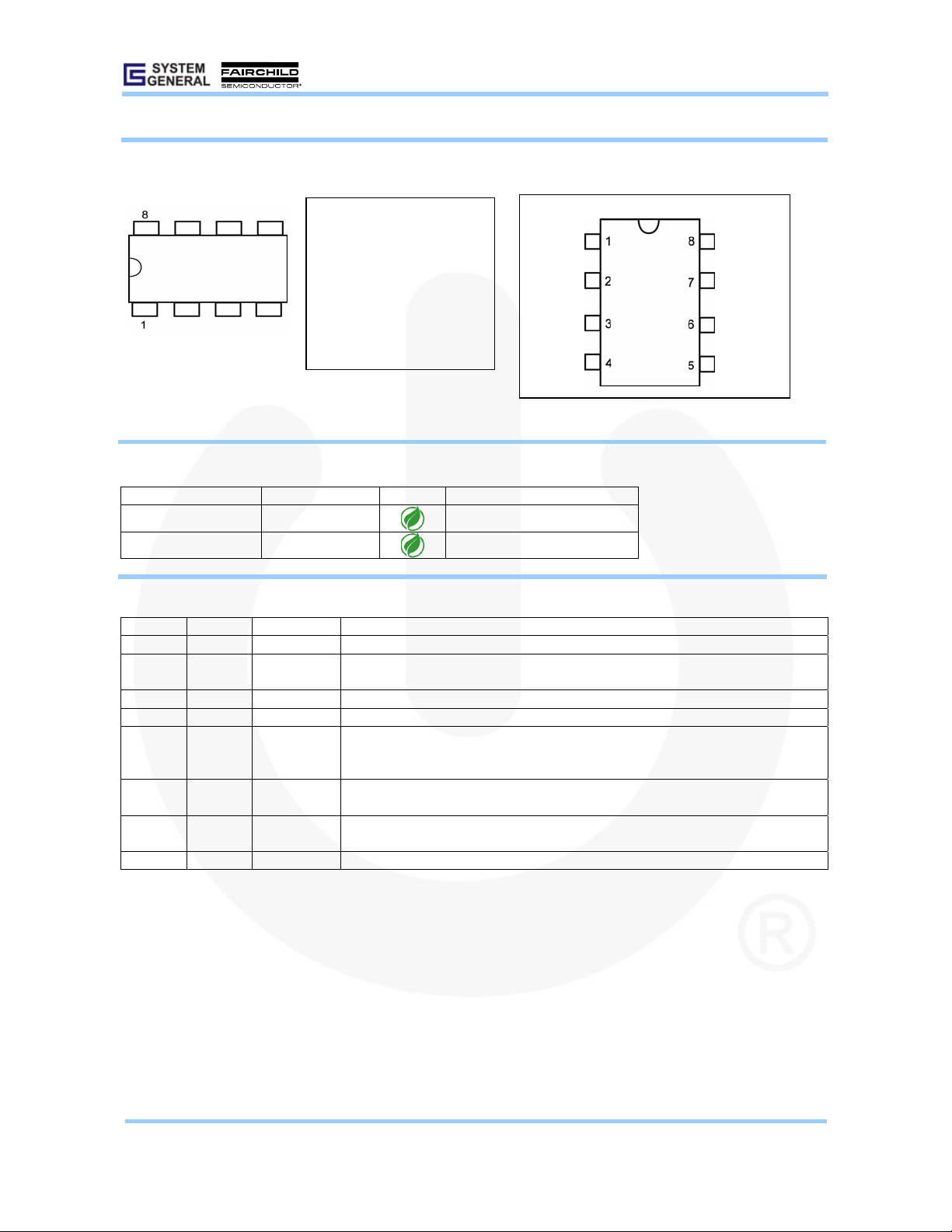

MARKING INFORMATION PIN CONFIGURATION

T: D = DIP, S = SOP

SG6742

XXXXXXXXYWWV

TP

P: Z =Lead Free

Null=regular package

XXXXXXXX: Wafer Lot

Y

: Year; WW: Week

V

: Assembly Location

GND

FB

GATE

VDD

NC

HV

SENSE

RT

ORDERING INFORMATION

Part Number PWM Frequency Pb-Free Package

SG6742SZ 65KHz

SG6742DZ (Preliminary) 65KHz

SOP-8

DIP-8

PIN DESCRIPTIONS

Pin No. Symbol Function Description

1 GND Ground Ground.

2 FB Feedback

3 NC NA NC pin.

4 HV Start-up Input For start-up, this pin is pulled high to the line input or bulk capacitor via resistors.

5 RT

6 SENSE Current Sense

7 VDD Power Supply

8 GATE Driver Output The totem-pole output driver. Soft driving waveform is implemented for improved EMI.

Temperature

Detection

The signal from the external compensation circuit is fed into this pin. The PWM duty cycle is

determined in response to the signal on this pin and the current-sense signal on SENSE pin.

For over-temperature protection, an external NTC thermistor is connected from this pin to GND

pin. The impedance of the NTC decreases at high temperatures. Once the voltage of the RT

pin drops below a fixed limit, PWM output is disabled.

Current sense. The sensed voltage is used for peak-current-mode control and cycle-by-cycle

current limiting.

Power supply. The internal protection circuit disables PWM output as long as VDD exceeds the

OVP trigger point.

© System General Corp. - 2 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

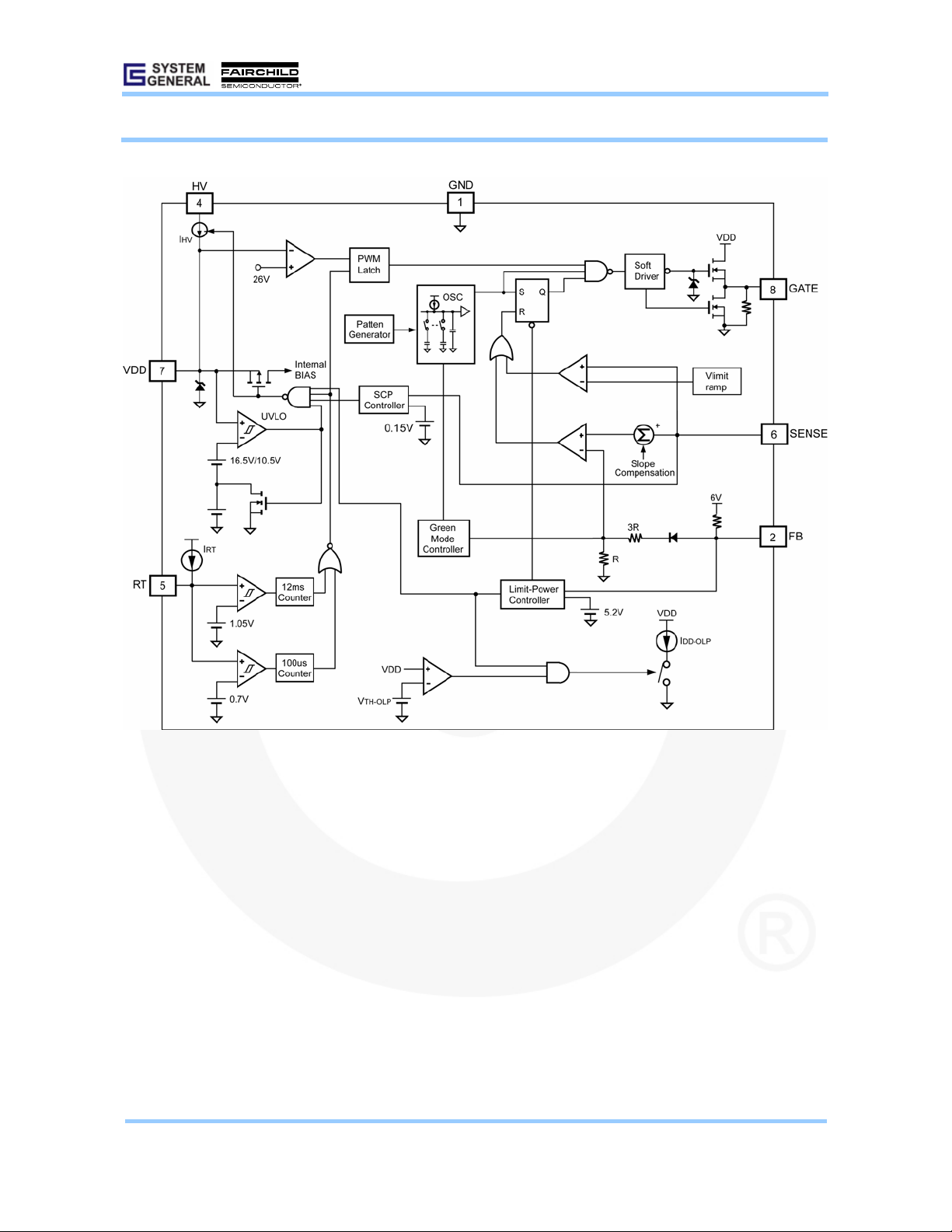

BLOCK DIAGRAM

© System General Corp. - 3 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

VDD Supply Voltage 30 V

VHV Input Voltage to HV Pin 500 V

VL Input Voltage to FB, SENSE, CS Pin -0.3 to 7.0 V

PD Power Dissipation TA < 50°C

Thermal Resistance (Junction-to-Air)

R

Θ

JA

DIP

SOP 400

DIP 82.5

SOP 141.0

TJ Operating Junction Temperature -40 to +125 °C

T

Storage Temperature Range -55 to +150 °C

STG

T

L

ESD

Lead Temperature (Wave Soldering or Infrared, 10 Seconds) 260 °C

Electrostatic Discharge Capability, Human Body Model All pins except HV pin 4 KV

Electrostatic Discharge Capability, Machine Model All pins except HV pin 400 V

* All voltage values, except differential voltages, are given with respect to the GND pin.

* Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device.

800

mW

°C/W

ELECTRICAL CHARACTERISTICS

VDD 15V; TA 25°C, unless otherwise noted.

VDD Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

Continuously Operating Voltage 22 V

DD-OP

V

Start Threshold Voltage 15.5 16.5 17.5 V

DD-ON

V

Minimum Operating Voltage 9.5 10.5 11.5 V

DD-OFF

I

Start-up Current V

DD-ST

I

Operating Supply Current VDD = 15V, GATE open 4 5 mA

DD-OP

I

Internal Sink Current V

DD-OLP

V

I

TH-OLP

V

VDD Over-Voltage Protection 25 26 27 V

DD-OVP

t

VDD Over-Voltage Protection Debounce Time 75 125 200 µs

D-VDDOVP

Off Voltage 6.5 7.5 8.0 V

DD-OLP

– 0.16V 30 µA

DD-ON

+0.1V 50 70 90 µA

TH-O LP

HV Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

IHV Supply Current Drawn from HV Pin

I

Leakage Current After Start-up

HV-LC

VAC=90V (VDC=120V)

V

=10µF

DD

HV = 500V,

VDD = V

DD-OFF

+1V

1.2

mA

1 20 µA

© System General Corp. - 4 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

Oscillator Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

F

Frequency in Nominal Mode

OSC

t

Hopping Period 4.4 ms

HOP

F

Green-Mode Frequency 18 22 25 KHz

OSC-G

FDV Frequency Variation vs. VDD Deviation VDD=11V to 22V 5 %

FDT Frequency Variation vs. Temp. Deviation TA=-20 to 85°C 5 %

* Hopping off at green-mode.

Center Frequency 62 65 68

Hopping Range ±3.7 ±4.2 ±4.7

KHz

Feedback Input Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

AV Input Voltage to Current-Sense Attenuation 1/4.5 1/4.0 1/3.5 V/V

ZFB Input Impedance 4 7 kΩ

V

Output High Voltage FB pin open 5.5 V

FB-OPEN

V

FB Open-Loop Trigger Level

FB-OLP

t

Delay Time of FB Pin Open Loop Protection 53 56 59 ms

D-OLP

V

Green-Mode Entry FB Voltage 1.9 2.1 2.3 V

FB-N

V

Green-Mode Ending FB Voltage V

FB-G

5.0 5.2 5.4 V

-0.5 V

FB-N

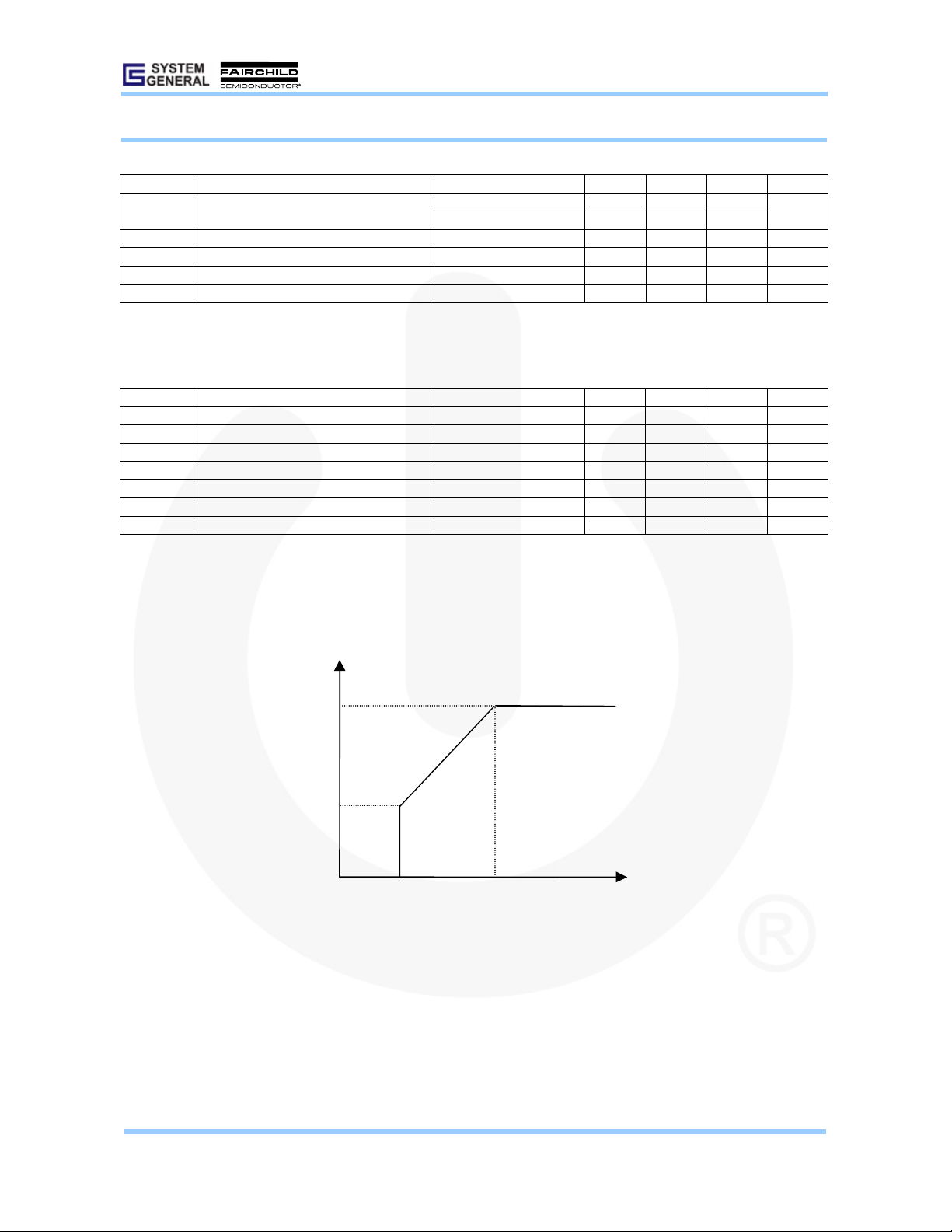

PWM Frequency

F

OSC

F

OSC-G

V

V

FB-G

V

FB-N

FB

© System General Corp. - 5 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

Current-Sense Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

Z

Input Impedance 12 KΩ

SENSE

V

Current Limit Flatten Threshold Voltage 0.87 0.90 0.93 V

STHFL

V

Current Limit Valley Threshold Voltage V

STHVA

STHFL–VSTHVA

0.18 0.22 0.26 V

tPD Delay to Output 100 200 ns

t

Leading-Edge Blanking Time 275 350 425 ns

LEB

V

S-SCP

t

D-SSCP

Threshold Voltage for SENSE Short-circuit

Protection

Delay Time for SENSE Short-circuit

Protection

0.10 0.15 0.20 V

V

< 0.15V 100 150 200 µs

SENSE

GATE Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

DCY

Maximum Duty Cycle 60 65 70 %

MAX

V

Gate Low Voltage VDD=15V, IO=50mA 1.5 V

GATE-L

V

Gate High Voltage VDD=12V, IO=50mA 8 V

GATE-H

tr Gate Rising Time VDD=15V, CL=1nF 150 250 350 ns

tf Gate Falling Time VDD=15V, CL=1nF 30 50 90 ns

I

GATE-SOURCE

V

GATE-CLAMP

Gate Source Current VDD=15V, GATE=6V 250 mA

Gate Output Clamping Voltage VDD=22V 18 V

RT Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

IRT Output Current from the RT Pin 92 100 108 µA

V

RTTH1

V

RTTH2

t

D-OTP1

t

D-OTP2

Over-Temperature Protection Threshold

Voltage

Over-Temperature Protection Threshold

Voltage

Over-Temperature Latch-off Debounce V

Over-Temperature Latch-off Debounce VRT < V

0.7V VRT 1.05V, after

12ms latch off

0.7V, after 100µs

V

RT

latch off

V

RTTH2

V

RT

60 100 140 µs

RTTH2

8 12 16 ms

RTTH1

1.015 1.050 1.085 V

0.65 0.70 0.75 V

Over Temperature Protection (OTP)

Symbol Parameter Test Condition Min. Typ. Max. Unit

T

Protection Junction Temperature* 135 °C

OTP

T

Restart Junction Temperature** T

Restart

* When activated, the output is disabled and the latch is turned off.

** This is the threshold temperature for enabling the output again and resetting the latch after over-temperature protection has

been activated.

-25 °C

OTP

© System General Corp. - 6 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

TYPICAL CHARACTERISTICS

Start-u p Current (I

25

20

15

(uA)

10

DD_ST

I

5

0

-40 -30 -15 0 25 50 75 8 5 100 125

) vs Temperature

DD-S T

Temperature (℃)

Start Threshold Voltage (V

20

19

18

(V)

DD-ON

17

V

16

) vs Temperature)

DD-ON

Operating Supply Current (I

5

4

3

(mA)

2

DD-OP

I

1

0

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

) vs Temperature

DD-OP

Minimum Operating Voltage (V

13

12

11

(V)

DD-OFF

10

V

9

) vs Temperature

DD-OFF

15

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

Supply current drawn from pin HV (IHV) vs Temperature

5

4

3

(mA)

HV

I

2

1

0

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

8

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

HV pin Leakage Current after Start-up (I

10

8

6

(uA)

4

HV-LC

I

2

0

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

) vs Temperature

HV-LC

© System General Corp. - 7 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

Frequency in nominal mode (F

70

) vs Temperature

OSC

Maximum Duty Cycle (DCY

70

) vs Temperature

MAX

68

66

(kHz)

OSC

64

F

62

60

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

Outpu t Current fro m the RT pin (IRT) vs Temperature

104

102

100

(uA)

RT

I

98

96

94

-40 -30 -15 0 25 50 75 8 5 100 125

Temperature (℃)

68

66

(%)

MAX

64

DCY

62

60

-40 -30 - 15 0 25 50 75 85 100 125

Temperature (℃)

© System General Corp. - 8 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

OPERATION DESCRIPTION

Start-up Current

For start-up, the HV pin is connected to the line input or

bulk capacitor through an external diode and resistor R

HV

,

which are recommended as 1N4007 and 100KΩ. Typical

start-up current drawn from the HV pin is 1.2mA and it

charges the hold-up capacitor through the diode and

resistor. When the V

start-up current switches off. At this moment, the V

capacitor level reaches V

DD

DD-ON

, the

DD

capacitor only supplies the SG6742 to keep the VDD

before the auxiliary winding of the main transformer to

carry on provide the operating current.

Operating Current

Operating current is around 4mA. The low operating

current enables better efficiency and reduces the

requirement of V

hold-up capacitance.

DD

Green-Mode Operation

The patented green-mode function provides an off-time

modulation to reduce the switching frequency in

light-load and no-load conditions. The on-time is limited

for better abnormal or brownout protection. VFB, which is

derived from the voltage feedback loop, is taken as the

reference. Once V

is lower than the threshold voltage,

FB

switching frequency is continuously decreased to the

minimum green mode frequency, around 22KHz.

Current Sensing / PWM Current Limiting

Peak-current-mode control is utilized to regulate output

voltage and provide pulse-by-pulse current limiting. The

switch current is detected by a sense resistor into the

SENSE pin. The PWM duty cycle is determined by this

current sense signal and V

the voltage on the SENSE pin reaches around V

(V

–1.2)/4, a switch cycle is terminated immediately.

FB

V

is internally clamped to a variable voltage around

COMP

, the feedback voltage. When

FB

COMP

=

0.85V for output power limit.

Leading-Edge Blanking

Each time the power MOSFET is switched on, a turn-on

spike occurs on the sense-resistor. To avoid premature

termination of the switching pulse, a leading-edge

blanking time is built in. During this blanking period, the

current-limit comparator is disabled and it cannot switch

off the gate driver.

Under-Voltage Lockout (UVLO)

The turn-on and turn-off threshold are fixed internally at

16.5V/10.5V. During start-up, the hold-up capacitor must

be charged to 16.5V through the start-up resistor so that

IC is enabled. The hold-up capacitor continues to supply

V

before the energy can be delivered from auxiliary

DD

winding of the main transformer. V

must not drop

DD

below 10.5V during this start-up process. This UVLO

hysteresis window ensures that hold-up capacitor is

adequate to supply V

during start-up.

DD

Gate Output / Soft Driving

The SG6742 BiCMOS output stage is a fast totem pole

gate driver. Cross conduction is avoided to minimize heat

dissipation, increases efficiency, and enhances reliability.

The output driver is clamped by an internal 18V Zener

diode to protect power MOSFET transistors against

undesirable gate over voltage. A soft driving waveform is

implemented to minimize EMI.

Built-in Slope Compensation

The sensed voltage across the current-sense resistor is

used for peak-current-mode control and pulse-by-pulse

current limiting. Built-in slope compensation improves

stability or prevents sub-harmonic oscillation. SG6742

inserts a synchronized positive-going ramp at every

switching cycle.

Constant Output Power Limit

When the SENSE voltage, across the sense resistor Rs,

reaches the threshold voltage, around 0.9V, the output

GATE drive is turned off after a small delay, t

delay introduces additional current, proportional to

t

/ LP. Since the delay is nearly constant, regardless

PD•VIN

of the input voltage V

, higher input voltage results in a

IN

larger additional current and the output power limit is

higher than under low input line voltage. To compensate

this variation for wide AC input range, a sawtooth

power-limiter is designed to solve the unequal

power-limit problem. The power limiter is designed as a

positive ramp signal and is fed to the inverting input of the

OCP comparator. This results in a lower current limit at

high-line inputs than at low-line inputs.

. This

PD

© System General Corp. - 9 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

VDD Over-Voltage Protection

VDD over-voltage protection has been built in to prevent

damage due to abnormal conditions. Once the V

voltage is over the over-voltage protection voltage

(V

disabled until the V

then start-up again. Over-voltage conditions are usually

caused by open feedback loops.

) and lasts for t

DD-OVP

D-VDDOVP

voltage drops below the UVLO,

DD

, the PWM pulses are be

When VDD goes below the turn-off threshold (eg, 10.5V)

the controller is totally shut down. V

the turn-on threshold voltage of 16V through the start-up

DD

resistor until PWM output is restarted. This protection

is charged up to

DD

feature is activated as long as the over-loading condition

persists. This prevents the power supply from overheating

due to over loading conditions.

Noise Immunity

Thermal Protection

An NTC thermistor R

be connected from pin RT to ground. A constant current

I

is output from pin RT. The voltage on RT pin can be

RT

expressed as V

(1.3V / R

such that V

(V

), the PWM is turned off after 12ms (t

RTTH1

V

is less than 0.7V (V

RT

= IRT × (R

RT

). At high ambient temperature, R

I

decreases. When VRT is less than 1.05V

RT

immediately after 100µs (t

in series with a resistor RA can

NTC

+ Ra), in which IRT = 2 x

NTC

is smaller,

NTC

D-OTP1

), PWM should be turned off

RTTH2

).

D-OTP2

). If

Limited Power Control

The FB voltage increases every time the output of the

power supply is shorted or over-loaded. If the FB voltage

remains higher than a built-in threshold for longer than

t

, PWM output is turned off. As PWM output is

D-OLP

turned off, the supply voltage V

begins decreasing.

DD

Noise on the current sense or control signal may cause

significant pulse width jitter, particularly in

continuous-conduction mode. Slope compensation helps

alleviate this problem. Good placement and layout

practices should be followed. Avoiding long PCB traces

and component leads, locating compensation and filter

components near the SG6742, and increasing the power

MOS gate resistance improves performance.

© System General Corp. - 10 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

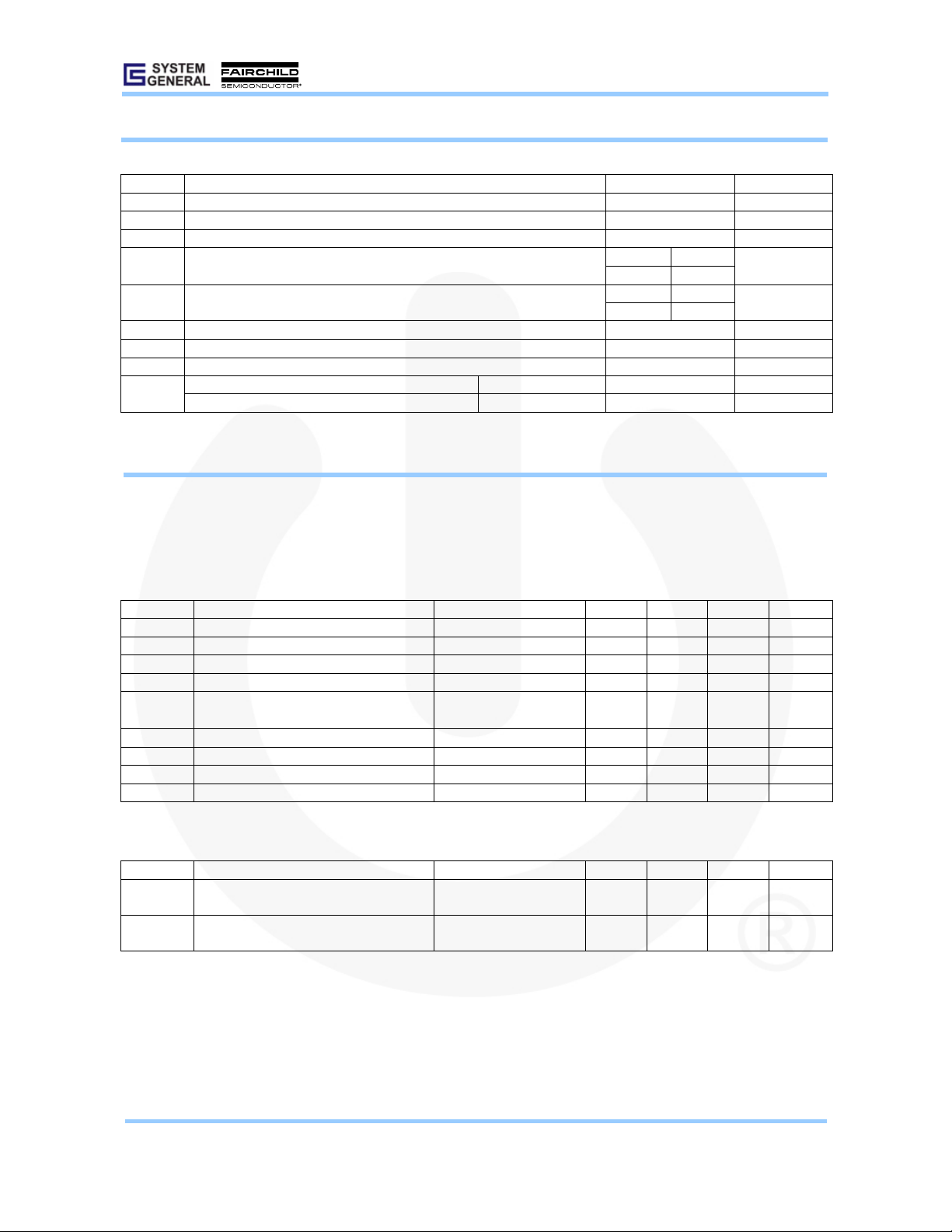

REFERENCE CIRCUIT (12V/5A)

F1

CN1

1

2

3

CN1

L1

1 2

3 4

T1

C1

1 2

3 4

VZ1

C2

21

D4

2

BD1

4

C3

1

21

+

3

R1

C5

C4

D2

2 1

T2

4

5

6

2

3 7

8

C6R2

1

2

3

Q1

21

+

1 2

C7

VO+

L2

21

+

C8

1 2

VO+

L3

D1

3 4

2 1

VO-

R3

R4

D3

21

21

SG6742

U1

1

2

C12

3

GND

FB

NC

HV4RT

8

GATE

7

VDD

6

SENSE

5

+

C9

R6

C10

THER1

43

23

Q2

1

R5

R7

12

R8

U2

R9

R

U3

A K

VO+

R10

C11

R11

BOM

Reference Component Reference Component

BD1 BD 4A/600V Q1 STP20-100CT

C1 XC 0.68µF/300V Q2 MOS 7A/600V

C2 XC 0.1µF/300V R1 R 100Kohm 1/2W

C3 YC 222pF/Y1 R2 R 47ohm 1/4W

C4 EC 120µF/400V R3 R 100Kohm 1/2W

C5 CC 0.01µF/500V R4 R 20ohm 1/8W

C6 CC 102pF/100V R5 R 100ohm 1/8W

C7 EC 1000µF/25V R6 R 4.7Kohm 1/8W

C8 EC 470µF/25V R7 R 0.3ohm 2W

C9 EC 22µF/50V R8 R 680ohm 1/8W

C10 CC 470pF/50V R9 R 4.7Kohm 1/8W

C11 CC 222pF/50V R10 R 150Kohm 1/8W

C12 CC 103pF/50V R11 R 39Kohm 1/8W

D1 Zener Diode 15V 1/2W (option) THER1 Thermistor TTC104

D2 BYV95C T1 10mH

D3 FR103 T2 600µH(PQ2620)

D4 1N4007 U1 IC SG6742

F1 FUSE 4A/250V U2 IC PC817

L1 Inductor (900µH) U3 IC TL431

L2 Inductor (2µH) VZ1 VZ 9G

L3 Inductor (900µH)

© System General Corp. - 11 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

PACKAGE INFORMATION

8PINS-DIP(D)

D

¢X

85

Θ

Dimensions

E1

1

4

A2

A1

L

b1

e

b

Symbol

A 5.334 0.210

A1 0.381 0.015

A2 3.175 3.302 3.429 0.125 0.130 0.135

b 1.524 0.060

b1 0.457 0.018

D 9.017 9.271 10.160 0.355 0.365 0.400

E 7.620 0.300

E1 6.223 6.350 6.477 0.245 0.250 0.255

e 2.540 0.100

L 2.921 3.302 3.810 0.115 0.130 0.150

eB 8.509 9.017 9.525 0.335 0.355 0.375

θ˚ 0˚ 7˚ 15˚ 0˚ 7˚ 15˚

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E

A

eB

© System General Corp. - 12 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

yp

A

A

Highly Integrated Green-Mode PWM Controller SG6742

8PINS-SOP(S)

8

5

C

Dimensions

E

1

b

4

e

D

H

F

Θ

A

A1

Symbol

1.346 1.752 0.053 0.069

1 0.101 0.254 0.004 0.010

b 0.406 0.016

c 0.203 0.008

D 4.648 4.978 0.183 0.196

E 3.810 3.987 0.150 0.157

e 1.016 1.270 1.524 0.040 0.050 0.060

F 0.381X45° 0.015X45°

H 5.791 6.197 0.228 0.244

L 0.406 1.270 0.016 0.050

θ˚ 0° 8° 0° 8°

Millimeter Inch

Min. T

.Max.Min. Typ.Max.

L

© System General Corp. - 13 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Product Specification

Highly Integrated Green-Mode PWM Controller SG6742

© System General Corp. - 14 - www.sg.com.tw • www.fairchildsemi.com

Version 1.0.1 (IAO33.0083.B0) September 24, 2007

Loading...

Loading...