Page 1

www.fairchildsemi.com

Application Note 50

Implementing the RC5050 and RC5051 DC-DC

Converters on Pentium

®

Pro Motherboards

Introduction

This document describes how to implement a switching voltage regulator using an RC5050 or an RC5051 high speed

controller, a power inductor, a Schottky diode, appropriate

capacitors, and external power MOSFETs. This regulator

forms a step down DC-DC converter that can deliver up to

14.5A of continuous load current at voltages ranging from

1.3V to 3.5V. A specific application circuit, design considerations, component selection, PCB layout guidelines, and performance evaluations are covered in detail.

In the past 10 years, microprocessors have ev olved at such an

exponential rate that a modern chip can rival the computing

power of a mainframe computer. Such evolution has been

possible because of the increasing numbers of transistors that

processors integrate. Pentium CPUs, for example, integrate

well over 5 million transistors on a single piece of silicon.

To integrate so many transistors on a piece of silicon, their

physical geometry has been reduced to the sub-micron level.

As a result of each geometry reduction, the corresponding

operational voltage for each transistor has also been reduced.

The changing CPU voltage demands the design of a programmable power supply—a design that is not completely

re-engineered with every change in CPU voltage.

The voltage range of the CPU has shown a downw ards trend

for the past 5 years: from 3.3V for the Pentium, to 3.1V for

the Pentium Pro, and to 1.8V for future processors. With this

trend in mind, Raytheon Electronics has designed the

RC5050 and RC5051 controllers. These controllers integrate

the necessary programmability to address the changing

power supply requirements of lower voltage CPUs.

Previous generations of DC-DC converter controllers were

designed with fixed output voltages adjustable only with a

set of external resistors. In a high volume production environment (such as with personal computers), however, a CPU

voltage change requires a CPU board re-design to accommodate the new voltage requirement. The 5-bit DAC in the

RC5050 and the RC5051 reads the voltage ID code that is

programmed into modern processors and provides the appropriate CPU voltage. In this manner, the PC board does not

have to be re-designed each time the CPU voltage changes.

The CPU can thus automatically configure its own required

supply voltage.

Intel Pentium Pro Processor Power

Requirements

Refer to Intel’s AP-523 Application Note, Pentium® Pro

Processor Power Distribution Guidelines, November 1995

(order number 242764-001), as a basic reference. The specifications contained in this document have been modified

slightly from the original Intel document to include updated

specifications for more recent processors. Please contact

Intel Corporation for specific details.

Input V oltages

A v ailable inputs are +12V ±5% and +5V ±5%. Either one or

both of these inputs can be used by the DC-DC converter.

The input voltage requirements for Raytheon’s RC5050

and RC5051 DC-DC converters are listed in Table 1.

Table 1. Input Voltage Requirements

MOSFET

Part # Vcc for IC

RC5050

RC5051

+5V ±5% +5V ±5% 12V ±5% or

Drain

Pentium Pro DC Power Requirements

Refer to Table 2, Intel Pentium Pro and OverDrive® Processor Power Specifications. For a motherboard designs without

a standard VRM (Voltage Regulator Module) socket, the

on-board DC-DC converter must supply a minimum of

13.9A of current @2.5V and 12.4A of current @3.3V. For a

Flexible Motherboard design, the on-board DC-DC converter must supply 14.5A maximum ICCP.

DC V oltage Regulation

As indicated in Table 2, the voltage level supplied to the

CPU must be within ±5% of its nominal setting. Voltage regulation limits must include:

• Output load ranges specified in Table 2

• Output ripple/noise

• DC output initial voltage set point

• Temperature and w arm up drift (Ambient +10°C to +50°C

at full load with a maximum rate of change of 5°C per 10

minutes minimum but no more than 10°C per hour)

• Output load transient with:

Slew rate >30A/µs at converter pins

Range: 0.3A - ICCP Max (as defined in Table 2).

MOSFET

Gate Bias

+5V ±5%

Rev. 1.1.0

Page 2

AN50 APPLICATION NOTE

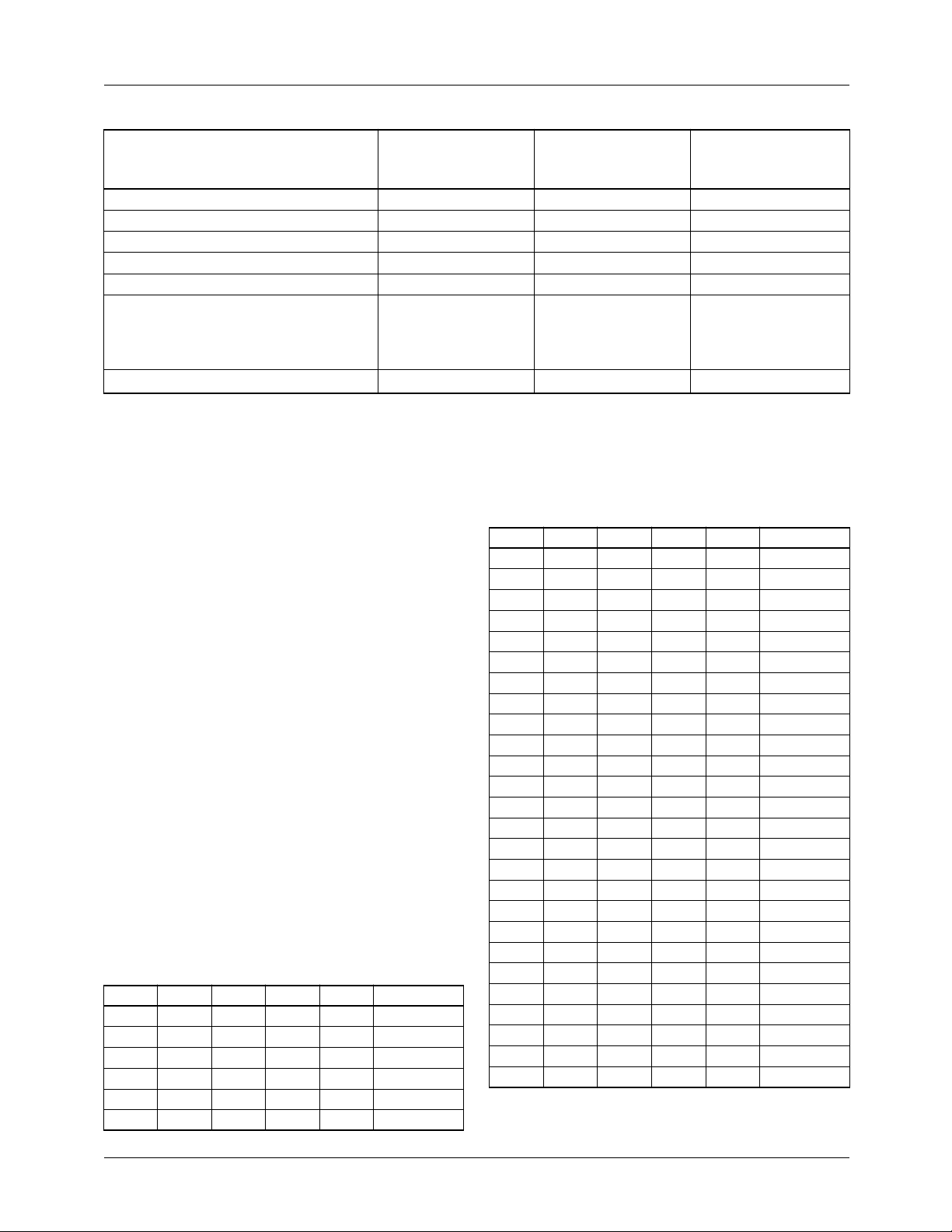

Table 2. Intel Pentium Pro and OverDrive® Processor Power Specifications

Voltage

Specification,

CPU Model, Features

VCCP (VDC)

150MHz, 256K L2 Cache 3.1 ±5% 9.9 29.2

166MHz, 512K L2 Cache 3.3 ±5% 11.2 35.0

180MHz, 256K L2 Cache 3.3 ±5% 10.1 31.7

200MHz, 256K L2 Cache 3.3 ±5% 11.2 35.0

200MHz, 512K L2 Cache 3.3 ±5% 12.4 37.9

OverDrive Processors

150Mhz

2.5 ±5% 11.2

180Mhz

200Mhz

Flexible Motherboard

Notes:

1. Maximum power values are measured at typical V

2. Flexible motherboard specifications are recommendations only. Actual specifications are subject to change.

2

2.4-3.5 ±5% 14.5 45.0

P to take into account the thermal time constant of the CPU package.

CC

Maximum

Current,

ICCP (A)

12.5

13.9

Maximum Thermal

Design power

1

(W)

26.7

29.7

32.9

Output Ripple and Noise

Ripple and noise are defined as periodic or random signals

over the frequency band of 20Mhz at the output pins. Output

ripple and noise requirements of ±13mV must be met

throughout the full load range and under all specified input

voltage conditions.

Efficiency

The efficiency of the DC-DC converter must be greater than

80% at maximum output current and greater than 40% at low

current draw.

Processor Voltage Identification

There are four voltage identification Pins, VID3-VID0, on

the Pentium Pro processor package which can be used to

support automatic selection of the power supply voltage.

These pins are internally unconnected or are shorted to

ground (VSS). The logic status of the VID pins defines the

voltage required by the processor. In order to address future

low voltage microprocessors, the RC5050 and RC5051

include a VID4 input bit to extend the output voltage range

as low as 1.3V. The output voltage programming codes are

presented in Table 3. A “1” refers to an open pin and a ‘0’

refers to a short to ground.

Table 3. Output Voltage Programming

Codes

VID4 VID3 VID2 VID1 VID0 V

0 1 1 1 1 1.30V

0 1 1 1 0 1.35V

0 1 1 0 1 1.40V

0 1 1 0 0 1.45V

0 1 0 1 1 1.50V

0 1 0 1 0 1.55V

OUT

to CPU

Table 3. Output Voltage Programming

Codes

Note:

1. 0 = processor pin is tied to GND

(continued)

VID4 VID3 VID2 VID1 VID0 V

OUT

0 1 0 0 1 1.60V

0 1 0 0 0 1.65V

0 0 1 1 1 1.70V

0 0 1 1 0 1.75V

0 0 1 0 1 1.80V

0 0 1 0 0 1.85V

0 0 0 1 1 1.90V

0 0 0 1 0 1.95V

0 0 0 0 1 2.00V

0 0 0 0 0 2.05V

1 1 1 1 1 No CPU

1 1 1 1 0 2.1V

1 1 1 0 1 2.2V

1 1 1 0 0 2.3V

1 1 0 1 1 2.4V

1 1 0 1 0 2.5V

1 1 0 0 1 2.6V

1 1 0 0 0 2.7V

1 0 1 1 1 2.8V

1 0 1 1 0 2.9V

1 0 1 0 1 3.0V

1 0 1 0 0 3.1V

1 0 0 1 1 3.2V

1 0 0 1 0 3.3V

1 0 0 0 1 3.4V

1 0 0 0 0 3.5V

1 = processor pin is open.

to CPU

2

Page 3

APPLICATION NOTE AN50

I

L

VINV

OUT

–( )T

ON

L1

-----------------------------------------------=

V

OUT

V

IN

T

ON

T

S

-----------

=

I/O Controls

In addition to the Voltage Identification, there are several signals that control the DC-DC converter or provide feedback

from the DC-DC converter to the CPU. They are PowerGood (PWRGD), Output Enable (OUTEN), and Upgrade

Present (UP#). These signals will be discussed later.

RC5050 and RC5051 Description

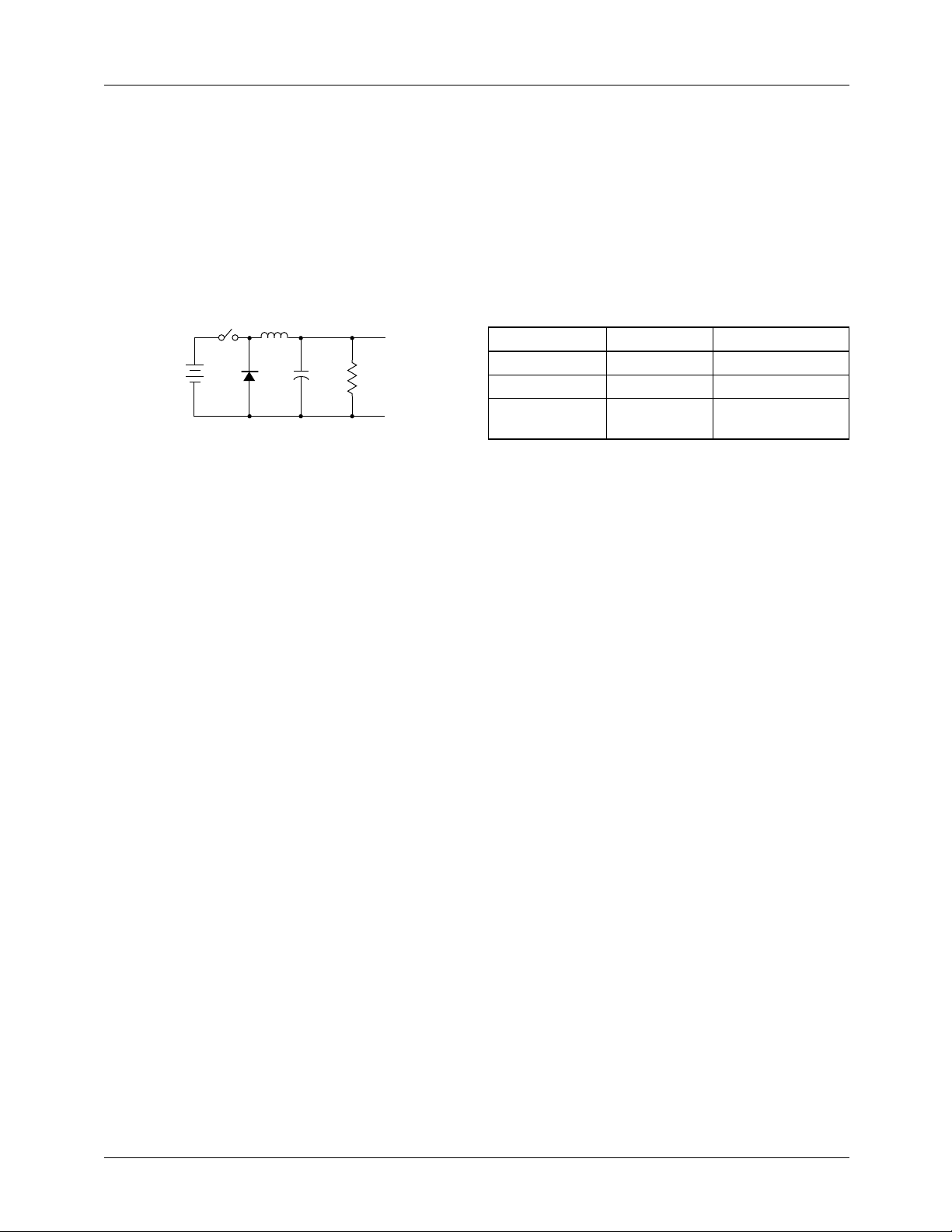

Simple Step-Down Converter

S1

V

IN

Figure 1. Simple Buck DC-DC Converter

Figure 1 illustrates a step-down DC-DC converter with no

feedback control. The derivation of the basic step-down converter is the basis for the design equations for the RC5050

and RC5051. Referring to Figure 1, the basic operation

begins by closing the switch S1. When S1 is closed, the input

voltage V

is impressed across inductor L1. The current

IN

flowing in this inductor is given by the following equation:

where T

is the duty cycle (the time when S1 is closed).

ON

When S1 opens, the diode D1 conducts the inductor

current and the output current is delivered to the load according to the following equation:

V

-------------------------------------------=

I

L

–( )

OUTTSTON

L1

whereTS is the overall switching period and (TS - TON) is the

time during which S1 is open.

D1

L1

C1 RL Vout

65-5050-06

+

–

The RC5050 and RC5051 Controllers

The RC5050 is a programmable non-synchronous DC-DC

controller IC. The RC5051 is a synchronous version of the

RC5050. When designed around the appropriate external

components, either of these devices can be configured to

deliver more than 14.5A of output current. The RC5050 and

RC5051 utilize both current-mode and voltage-mode PWM

control to create an integrated step-down voltage regulator.

The key differences between the RC5050 and RC5051 are

listed in Table 4.

Table 4. RC5050 and RC5051 Differences

RC5051 RC5050

Operation Synchronous Non-Synchronous

Package 20-SOIC 20-SOIC

Output Enable/

Yes Yes

Disable

Main Control Loop

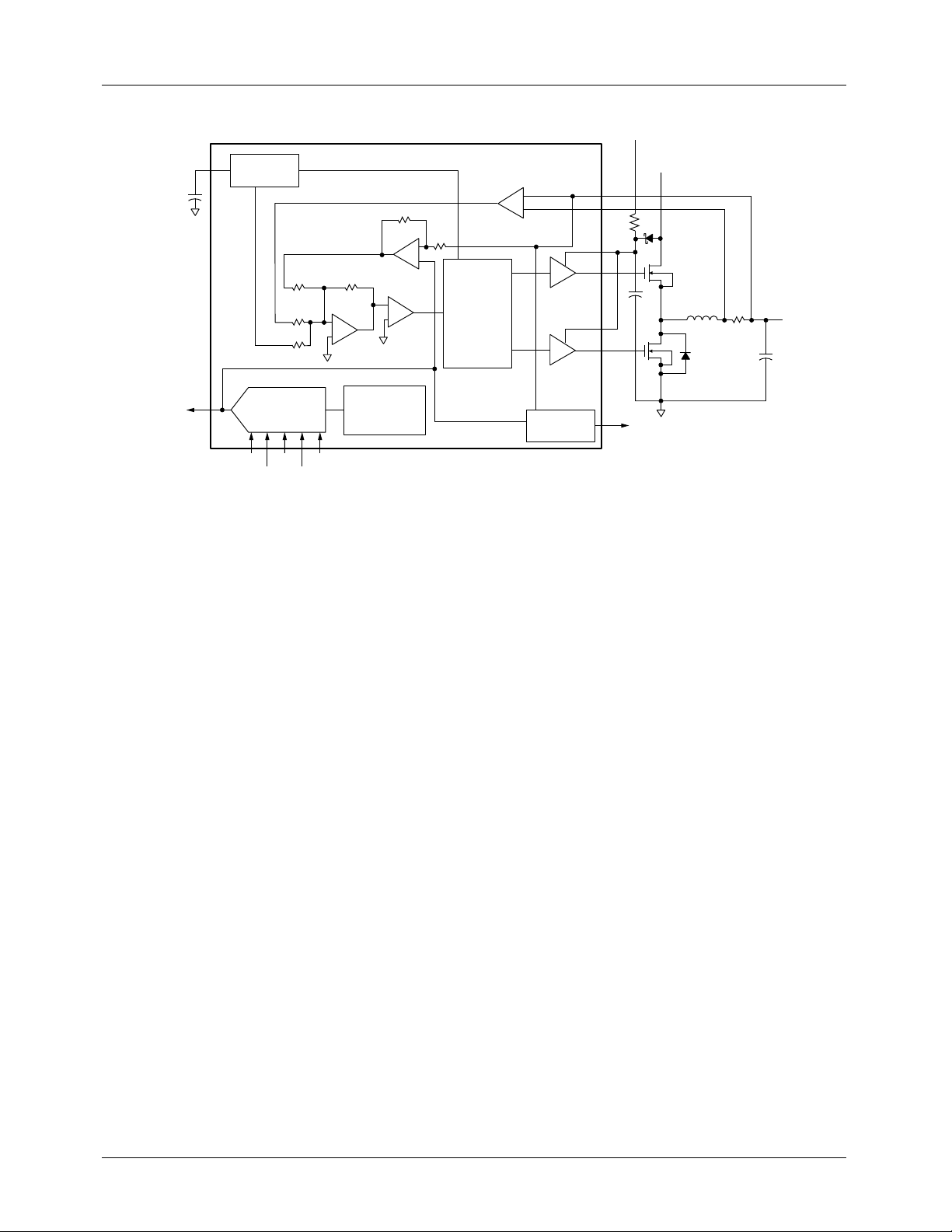

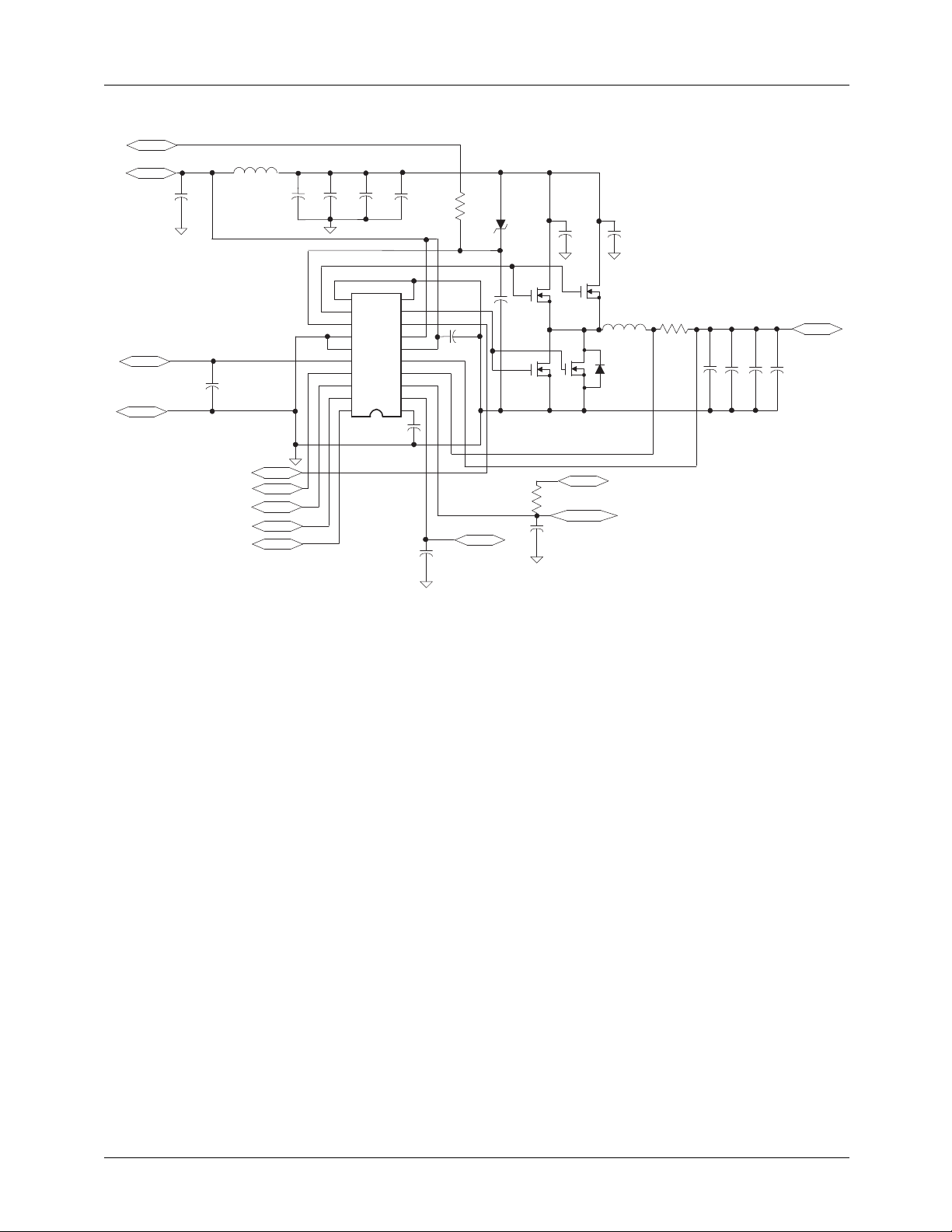

Refer to the RC5051 Block Diagram illustrated in Figure 2.

The control loop of the regulator contains two main sections;

the analog control block and the digital control block. The

analog section consists of signal conditioning amplifiers

feeding into a set of comparators which provide the inputs to

the digital control block. The signal conditioning section

accepts inputs from the IFB (current feedback) and VFB

(voltage feedback) pins and sets up two controlling signal

paths. The voltage control path amplifies the VFB signal and

presents the output to one of the summing amplifier inputs.

The current control path takes the difference between the

IFB and VFB pins and presents the resulting signal to

another input of the summing amplifier. These two signals

are then summed together with the slope compensation input

from the oscillator. This output is then presented to a

comparator, which provides the main PWM control signal to

the digital control block.

The additional comparators in the analog control section set

the point at which the current limit comparator disables the

output drive signals to the external power MOSFETs.

By solving these two equations, we can arrive at the basic

relationship for the output voltage of a step-down con v erter:

In order to obtain a more accurate approximation for V

we must also include the forward voltage VD across diode

D1 and the switching loss, VSW. After taking into account

these factors, the new relationship becomes:

T

ON

-----------

V

OUT

VINVDVSW–+( )

V

–=

D

T

S

where VSW= MOSFET switching loss

= IL • R

DS,ON

OUT

The digital control block takes the comparator inputs and the

main clock signal from the oscillator to provide the appropriate pulses to the HIDRV and LODRV output pins. These

pins control the external power MOSFETs. The digital section utilizes high speed Schottky transistor logic, allowing

the RC5050 and the RC5051 to operate at clock speeds as

,

high as 1MHz.

High Current Output Drivers

The RC5051 contains two identical high current output

drivers that utilize high speed bipolar transistors in a

push-pull configuration. Each driver is capable of

delivering 1A of current in less than 100ns. Each driver’s

power and ground are separated from the chip’s power and

ground for additional switching noise immunity.

3

Page 4

AN50 APPLICATION NOTE

+12V

RC5051

OSC

–

+

–

+

+5V

–

+

VREF

VID0

5-BIT

DAC

VID2 RSEL

VID1

VID3

1.24v

REFERENCE

Figure 2. RC5051 Block Diagram

The HIDRV driver has a power supply, VCCQP, supplied

from a 12V source as illustrated in Figure 2. The resulting

voltage is sufficient to provide the gate to source voltage to

the external MOSFET that is required to achieve a low

R

. Since the low side synchronous FET is referenced

DS,ON

to ground, there is no need to boost the gate drive voltage,

and its VCCP power pin can be tied to VCC.

Internal Voltage Reference

The reference included in the RC5050 and RC5051 is a precision band-gap voltage reference. The internal resistors are

precisely trimmed to provide a near zero temperature coefficient (TC). Added to the reference input is the resulting output from an integrated 5-bit DAC—provided in accordance

to the Pentium Pro specification guidelines. These guidelines

require the DC-DC converter output to be directly programmable via a 4-bit voltage identification (VID) code. This

code scales the reference voltage from 2.0V (no CPU) to

3.5V in 100mV increments. To target future generations of

low-voltage processors, the RC5050 and RC5051 incorporate a VID4 pin to allo w additional programmability between

1.3V and 2.05V. For guaranteed stable operation under all

operating conditions, a 0.1µF of decoupling capacitance

should be connected to the VREF pin. No load should be

imposed on this pin.

Power Good (PWRGD)

The RC5050 and RC5051 Power Good function is designed

in accordance with the Pentium Pro DC-DC converter specification to provide a constant voltage monitor on the VFB

pin. The circuit compares the VFB signal to the VREF volt-

–

+

DIGITAL

CONTROL

POWER

GOOD

PWRGD

VO

65-5051-01

age and outputs an active-low interrupt signal to the CPU

when the power supply voltage exceeds ±12% of nominal.

The Power Good flag provides no other control function to

the RC5050 or the RC5051.

Output Enable (OUTEN)

The DC-DC converter accepts an open collector signal for

controlling the output voltage. The low state disables the output voltage. When disabled, the PWRGD output is in the lo w

state.

Upgrade Present (UP#)

Intel specifications state that the DC-DC converter should

accept an open collector signal, used to indicate the presence

of an upgrade processor. The typical state is high (that is, a

standard processor is in the system). When in the low or

ground state (an OverDrive processor is present), the output

voltage must be disabled unless the conv erter can supply the

requirements of the OverDrive processor . When disabled, the

PWRGD output must be in the low state. Because the

RC5050 and RC5051 can supply the requirements of the

OverDrive processor, the #UP signal is not required.

Over-Voltage Protection

The RC5050 and RC5051 constantly monitor the output

voltage for protection against over voltage conditions. If the

voltage at the VFB pin e xceeds 20% of the selected program

voltage, an over-voltage condition is assumed and the chip

disables the output drive signal to the external MOSFET(s).

4

Page 5

APPLICATION NOTE AN50

Short Circuit Protection

A current sense methodology is implemented to disable the

output drive signal to the MOSFET(s) when an over-current

condition is detected. The voltage drop created by the output

current flowing across a sense resistor is presented to an

internal comparator. When the voltage developed across the

sense resistor exceeds the comparator threshold voltage, the

chip reduces the output drive signal to the MOSFET(s).

The DC-DC converter returns to normal operation after the

fault has been removed, for either an over-voltage or a short

circuit condition.

Oscillator

The RC5050 and RC5051 oscillator section uses a fixed current capacitor charging configuration. An external capacitor

(C

) is used to preset the oscillator frequency between

EXT

200KHz and 1MHz. This scheme allows maximum flexibility in setting the switching frequency and in choosing external components.

In general, a lower operating frequency decreases the peak

ripple current flowing in the output inductor, thus allowing

the use of a smaller inductor value. Unfortunately, operation

at lower frequencies increases the amount of energy storage

that must be provided by the bulk output capacitors during

load transients due to slower loop response of the controller.

In addition, the efficiency losses due to switching of the

MOSFETs increase as the operating frequency is increased.

Thus, efficiency is optimized at lower operating frequencies.

An operating frequency of 300 kHz was chosen to optimize

efficiency while maintaining excellent regulation and transient performance under all operating conditions.

Design Considerations and

Component Selection

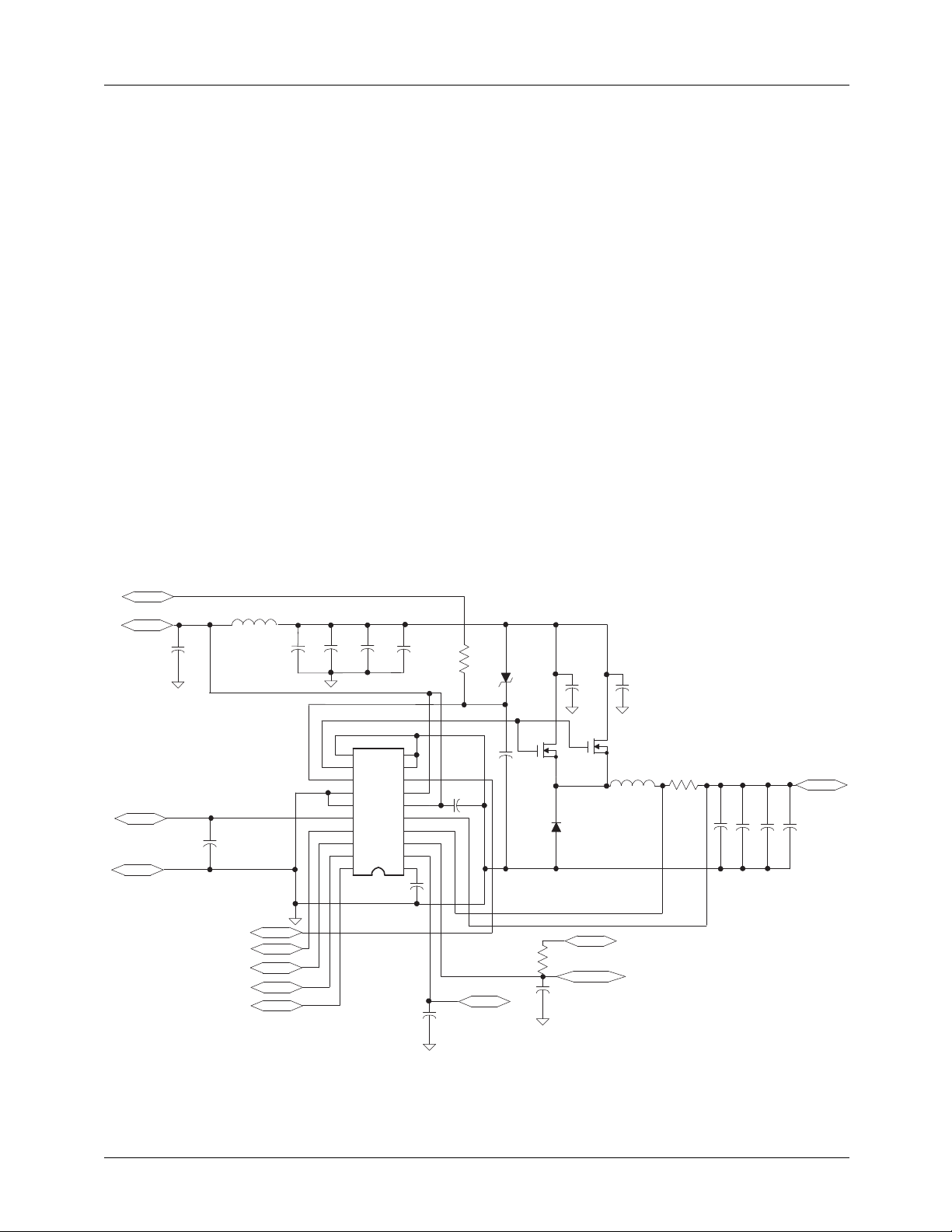

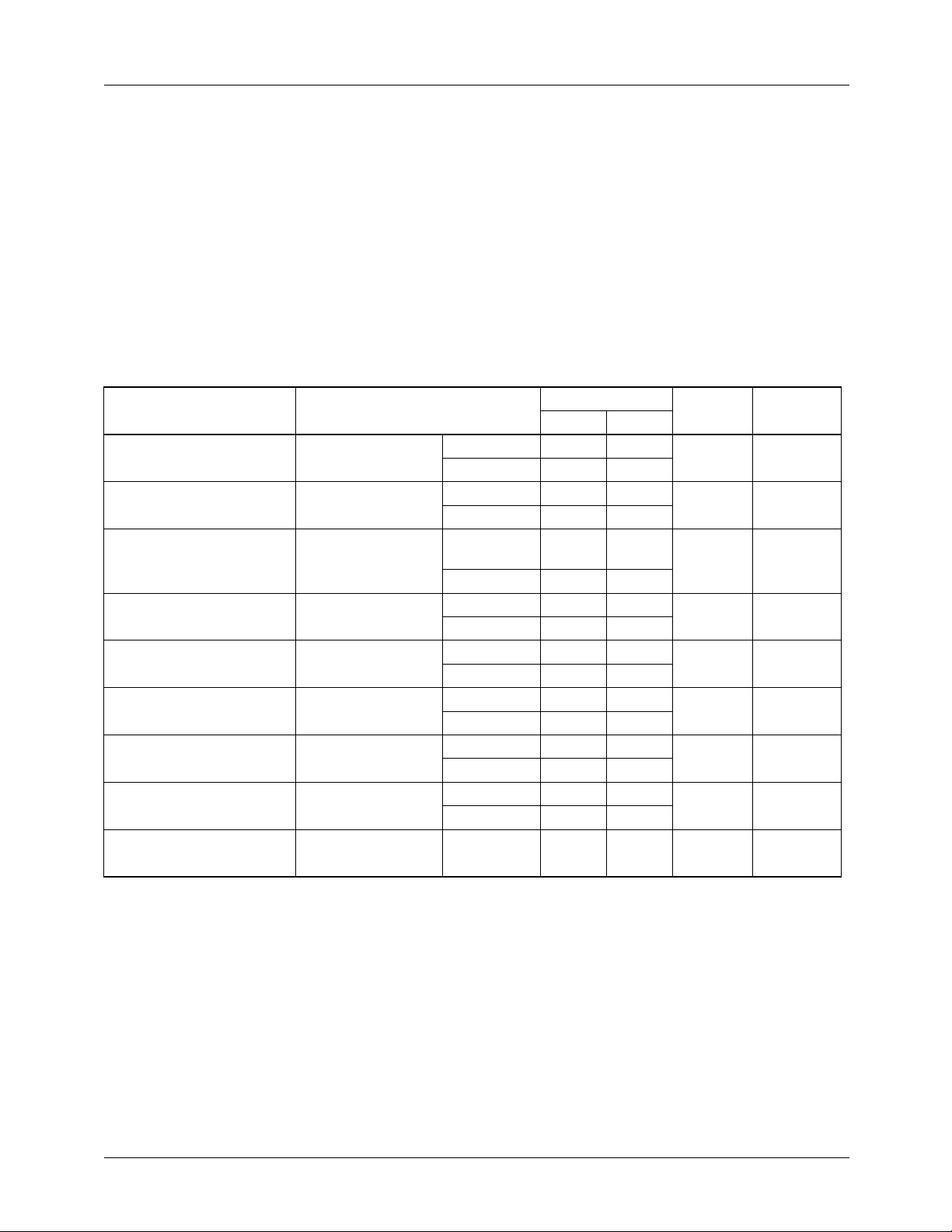

Figure 3 shows a typical non-synchronous application using

the RC5050. Figure 4 illustrates the synchronous application using the RC5051.

VREF

GND

+12V

+5V

C4

0.1µF

C7

0.1µF

L2

2.5µH

VID4

VID3

VID2

VID1

VID0

C1

1000 µF

C2

1000 µF

12

13

14

15

16

17

18

19

20

C3

1000µF

RC5050

C

EXT

100pF

C5

0.1µ F

1011

9

8

7

6

5

4

3

2

1

C10

0.1µ F

R5

47

C6

4.7µF

ENABLE

C12

1µF

D1

1N4691

IRF7413

R6

10K

M1

C11

0.1µ F

C8

0.1µ F

DS1

MBR2015CTL

VCC

PWRGD

M2

IRF7413

C9

0.1µF

L1

1.3µ H

R

6mΩ

SENSE

F

µ

1500

C13

1500 µF

C14

C15

VO

1500µF

1500µF

C16

Figure 3. Non-Synchronous DC-DC Converter Application Schematic Using the RC5050

5

Page 6

AN50 APPLICATION NOTE

+12V

+5V

C4

0.1µF

VREF

GND

C7

0.1µF

L2

2.5µH

VID4

VID3

VID2

VID1

VID0

C1

1000 µF

C2

1000 µF

12

13

14

15

16

17

18

19

20

C3

1000µF

RC5051

C

100pF

C5

R5

0.1µ F

47

1011

9

8

7

6

5

4

3

2

1

EXT

C10

0.1µ F

C6

4.7µF

ENABLE

C12

1µF

D1

1N4691

IRF7413

10K

IRF7413

M3

R6

M1

C11

0.1µ F

C8

0.1µ F

VCC

PWRGD

M2

M4

IRF7413

0.1µF

IRF7413

1.3µ H

DS1

1N5817

C9

R

L1

6mΩ

SENSE

F

µ

1500

C13

1500 µF

C14

C15

VO

1500 µF

1500µF

C16

Figure 4. Synchronous DC-DC Converter Application Schematic Using the RC5051

6

Page 7

APPLICATION NOTE AN50

MOSFET Selection Cosiderations

• Power package with low Thermal Resistance

• Drain current rating of 20A minimum

MOSFET Selection

• Drain-Source voltage > 15V.

This application requires N-channel Logic Level Enhancement Mode Field Effect Transistors. Desired characteristics

are as follows:

The on-resistance (R

) is the primary parameter for

DS,ON

MOSFET selection. It determines the power dissipation

within the MOSFET and, therefore, significantly affects the

• Low Static Drain-Source On-Resistance,

R

< 37 mΩ (lower is better)

DS,ON

efficiency of the DC-DC converter. Table 5 is a selection

table for MOSFETs.

• Low gate drive voltage, VGS ≤ 4.5V

Table 3. MOSFET Selection Table

R

Manufacturer & Model # Conditions

Fuji

V

= 4V, ID = 17.5A TJ = 25°C 25 37 TO-220 Φ

GS

2SK1388

Siliconix

V

= 4.5V, ID = 5A TJ = 25°C 16.5 20 SO-8

GS

SI4410DY

National Semiconductor

V

= 5V, ID = 40A TJ = 25°C 13 15 TO-220 Φ

GS

1

TJ = 125°C 37 —

TJ = 125°C 28 34

NDP706AL

NDP706AEL TJ = 125°C 20 24

National Semiconductor V

NDP603AL T

National Semiconductor V

= 4.5V, ID = 10A TJ = 25°C 31 40 TO-220 Φ

GS

= 125°C 42 54 ΦJC= 2.5

J

= 5V, ID = 24A TJ = 25°C 22 25 TO-220 ΦJA= 62.5

GS

NDP606AL TJ = 125°C 33 40 Φ

Motorola V

= 5V, ID = 37.5A TJ = 25°C 6 9 TO-263 Φ

GS

MTB75N03HDL TJ = 125°C 9.3 14 (D2 PAK) Φ

Int. Rectifier V

= 5V, ID = 31A TJ = 25°C — 28 TO-220 Φ

GS

IRLZ44 TJ = 125°C — 46 Φ

Int. Rectifier V

= 4.5V, ID = 28A TJ = 25°C — 19 TO-220 Φ

GS

IRL3103S TJ = 125°C — 31 Φ

Intl Rectifier V

IRF7413 SMD

= 4.5V,

GS

ID = 3.7A

TA = 25°C 18 SO-8 Φ

DS, ON

(mΩ)

Package

(SMD)

Thermal

ResistanceTyp. Max.

= 75

JA

Φ

= 50

JA

= 62.5

JA

Φ

= 1.5

JC

= 62.5

JA

= 1.5

JC

= 62.5

JA

= 1.0

JC

= 62.5

JA

= 1.0

JC

= 62.5

JA

= 1.0

JC

= 50

JA

Note:

1. R

values at Tj = 125°C for most devices were extrapolated from the typical operating curves supplied by the

DS,ON

manufacturers and are approximations only.

7

Page 8

AN50 APPLICATION NOTE

Two MOSFETs in parallel.

We recommend two MOSFETs used in parallel instead of

one single MOSFET. The following significant advantages

are realized using two MOSFETs in parallel:

• Significant reduction of Power dissipation.

Maximum current of 14A with one MOSFET:

P

MOSFET

= (I2 R

)(Duty Cycle) =

DS,ON

(14)2(0.050*)(3.3+0.4)/(5+0.4-0.35) = 7.2 W

With two MOSFETs in parallel:

P

MOSFET

= (I2 R

)(Duty Cycle) =

DS,ON

(14/2)2(0.037*)(3.3+0.4)/(5+0.4-0.35) = 1.3W/FET

* Note: R

25°C. R

using a single MOSFET. When using two MOSFETs in parallel, the

temperature effects should not cause the R

listed maximum value of 37mΩ.

increases with temperature. Assume R

DS,ON

can easily increase to 50mΩ at high temperature when

DS,ON

DS,ON

DS,ON

to rise above the

• Less heat sink required.

With power dissipation down to around one watt and with

MOSFETs mounted flat on the motherboard, considerable

less heat sink is required. The junction-to-case thermal

resistance for the MOSFET package (TO-220) is typically

at 2°C/W and the motherboard serves as an excellent heat

sink.

• Higher current capability.

With thermal management under control, this on-board

DC-DC converter is able to deliver load currents up to

14.5A with no performance or reliability concerns.

MOSFET Gate Bias

MOSFET can be biased by one of two methods: Charge

Pump and 12V Gate Bias.

• Method 1. Charge pump (or Boostrap) method.

Figure 5 employs a charge pump to provide gate bias.

Capacitor CP is the charge pump deployed to boost the

voltage of the RC5050 output driver. When the MOSFET

switches off, the source of the MOSFET is at -0.6V.

VCCQP is charged through the Schottky diode to 4.5V.

Thus, the capacitor CP is charged to 5V. When the MOSFET turns on, the source of the MOSFET voltage is equal

to 5V. The capacitor voltage follows, and hence provides a

voltage at VCCQP equal to 10V. The Schottky diode is

required to provide the charge path when the MOSFET is

off, and reverses bias when the VCCQP goes to 10V. The

charge pump capacitor, CP, needs to be a high Q, high frequency capacitor. A 1µF ceramic capacitor capacitor is

recommended here.

= 25mΩ at

+5V

DS2

PWM/PFM

Control

VCCQP

HIDRV

CP

M1

DS1

L1

RS

VO

CB

65-AP50-01

Figure 5. Charge Pump Configuration

• Method 2. 12V Gate Bias.

Figure 6 illustrates how a 12V source can be used to bias

the VCCQP. A 47 Ω resistor is used to limit the transient

current into the VCCQP pin and a 1µF capacitor filter is

used to filter the VCCQP supply. This method provides a

higher gate bias voltage (VGS) to the MOSFET, and therefore reduces the R

of the MOSFET and reduces the

DS,ON

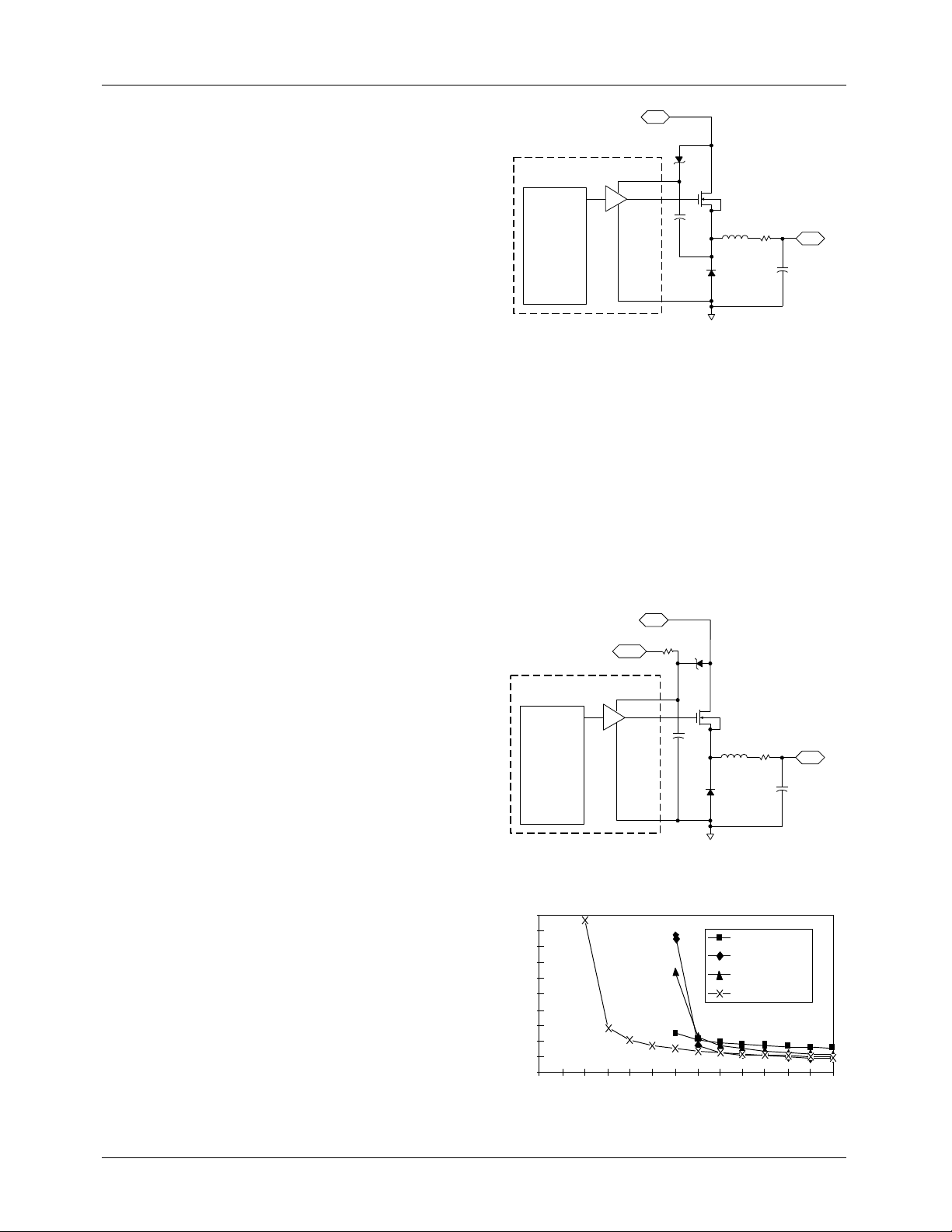

power loss due to the MOSFET. Figure 7 shows how

R

reduces dramatically with VGS increases. A 6.2V

DS,ON

Zener diode (D1) is placed to clamp the voltage at VCCQP

to a maximum of 12V and ensure that the absolute maximum voltage of the IC will not be exceeded

+5V

47Ω

+12V

D1

1µF

6.2V

M1

L1

RS

DS1

R(DS)Fuji

R(DS)7060

R(DS)706A

R(DS)-706AEL

(V)

GS

VO

CB

65-AP50-02

0.1

0.09

0.08

0.07

0.06

(Ω)

0.05

DS,ON

0.04

R

0.03

0.02

0.01

VCCQP

HIDRV

PWM/PFM

Control

Figure 6. 12V Gate Bias Configuration

0

1.5 2 2.5 3 3.5 4 5 6 7 8 9 10 11

Gate-Source Voltage, V

Figure 7. R

vs. VGS for Selected MOSFETs

DS,ON

8

Page 9

APPLICATION NOTE AN50

Converter Efficiency

Losses due to parasitic resistance in the switches, coil, and

sense resistor dominate at high load-current level. The major

loss mechanisms under heavy loads, in usual order of importance, are:

• MOSFET I2R Losses

• Coil Losses

• Sense Resistor Losses

Calculation of Converter Efficiency Under Heavy Loads

• gate-charge losses

• diode-conduction losses

• transition losses

• Input Capacitor losses

• losses due to the operating supply current of the IC.

P

Efficiency

P

LOSS

where , where

PD

COILIOUT

PD

SENSERIOUT

PD

GATEqGATE

PD

DIODE

PD

TRAN

PD

CAPIRMS

PD

IC

OUT

------------p

IN

PD

MOSFET

PD

MOSFETIOUT

2

×=

VfID× 1 Dutycycle–( )=

2

V

C

× I

IN

-------------------------------------------------------------=

2

ESR×=

VCCICC×=

R

2

I

×

OUTVOUT

--------------------------------------------------------= =

I

OUTVOUTPLOSS

PD

+ + + + + + +=

COIL

2

× DutyCycle×= DutyCycle

COIL

R

×=

SENSE

, where q

f 5V××=

R

PD

DS,ON

+×

SENSER

GATE

PD

GATE

is the gate charge and f is the switching frequency

× f×

RSS

I

DRIVE

LOAD

, where C

is the reverse transfer capacitance of the high-side MOSFET.

RSS

PD

DIODE

PD

TRAN

PD

CAP

V

+

OUTVD

------------------------------------------=

V

–+

INVDVSW

PD

Example

DutyCycle

3.3 0.5+

------------------------------ 0.73= =

5 0.5 0.3–+

IC

PD

MOSFET

PD

COIL

PD

SENSER

PD

GATE

PD

DIODE

PD

TRAN

PD

CAP

PD

IC

PD

LOSS

Efficiency

1020.030× 0.73× 2.19W= =

1020.010× 1W= =

1020.0065× 0.65W= =

CV f× 5V× 1.75nf 9 1–( )V 285Khz 5V××× 0.019W= = =

0.5 10 1 0.73–( )× 1.35W= =

52400pf× 10× 285khz×

----------------------------------------------------------------

0.7A

0.010W∼=

7.5 2.5–( )20.015× 0.37W= =

0.2W=

2.19W 1.0W 0.65W 0.019W 1.35W 0.010W 0.37W 0.2W+ + + + + + + 5.789W= =

3.3 10×

---------------------------------------

3.3 10 5.815+×

85%≈=∴

9

Page 10

AN50 APPLICATION NOTE

Selecting the Inductor

The inductor is one of the most critical components to be

selected for a DC-DC converter application. The critical

parameters are inductance (L), maximum DC current (IO),

and DC coil resistance (Rl). The inductor core material is a

crucial factor in determining the amount of current the

inductor is able to withstand. As with all engineering

designs, tradeoffs exist between various types of core materials. In general, Ferrites are popular due to low cost, low EMI

properties, and high frequency (>500KHz) characteristics.

Molypermalloy powder (MPP) materials exhibit good saturation characteristics, low EMI, and low hysteresis losses,

but tend to be expensive and more effectively utilized at

operating frequencies below 400KHz. Another critical

parameter is the DC winding resistance of the inductor. This

value should typically be reduced as much as possible, as the

power loss in the DC resistance degrades the efficiency of

the converter by the relationship: P

loss

of the inductor is a function of the oscillator duty cycle

(TON) and the maximum inductor current (IPK). IPK can be

calculated from the relationship:

VINVSW– VD–

I

PKIMIN

-----------------------------------------

+=

L

T

ON

Where TON is the maximum duty cycle and VD is the

forward voltage of diode DS1.

2

= I

x Rl. The value

O

When designing the external current sense circuitry, pay

careful attention to the output limitations during normal

operation and during a fault condition. If the short circuit

protection threshold current is set too low, the DC-DC converter may not be able to continuously deliver the maximum

CPU load current. If the threshold level is too high, the output driver may not be disabled at a safe limit and the resulting power dissipation within the MOSFET(s) may rise to

destructive levels.

The following is the design equation used to set the short circuit threshold limit:

V

th

R

SENSE

I

SCIinductor

Where I

I

load, max

You must also take into account the current (Ipk -I

--------

, where: I

I

SC

≥ I

and I

pk

min

Load, max

= Output short circuit current=

SC

IpkI

----------------------------+=

are peak ripple current and

= maximum output load current.

–( )

min

2

), or the

min

ripple current flowing through the inductor under normal

operation. Figure 8 illustrates the inductor current waveform

for the RC5050 DC-DC converter at maximum load.

Ipk

Then the inductor value can be calculated using the

relationship:

L

I

–

PKIMIN

Where VSW (R

DS,ON

T

ON

x IO) is the drain-to-source voltage of

– VO–

V

INVSW

-----------------------------------------

=

M1 when it is switched on.

Implementing Short Circuit Protection

Intel currently requires all power supply manufacturers to

provide continuous protection against short circuit conditions that may damage the CPU. T o address this requirement,

Raytheon Electronics has implemented a current sense methodology to limit the power delivered to the load in the event

of overcurrent. The voltage drop created by the output current across a sense resistor is presented to one terminal of an

internal comparator with hysterisis. The other comparator

terminal has the threshold voltage, nominally of 120mV.

Table 6 states the limits for the comparator threshold of the

Switching Regulator.

Table 6. RC5050 Short Circuit Comparator

Threshold Voltage

Short Circuit Comparator

V

threshold

Typical 120

Minimum 100

Maximum 140

(mV)

I

(Ipk-I

)/2

min

I

Imin

T

ON

T=1/f

Figure 8. Typical DC-DC Converter

Inductor Current Waveform

T

OFF

s

LOAD, MAX

t

The calculation of this ripple current is as follows:

IpkI

–( )

min

---------------------------2

V

– V

INVSW

-----------------------------------------------------

–( )

L

OUT

V

+( )

OUTVD

----------------------------------------------V

– VD+( )

INVSW

T×=

where:

V

= input voltage to converter,

IN

V

= voltage across switcher MOSFET = I

SW

LOAD

x R

DS,ON

VD = Forward Voltage of the Schottky diode,

T = the switching period of the converter = 1/fS, and

fS = switching frequency.

For an input voltage of 5V, output voltage of 3.3V, L equals

1.3µH and a switching frequency of 285KHz (using

C

= 100pF), the inductor current can be calculated at

EXT

approximately 1A:

I

–( )

pkImin

---------------------------2

3.3 0.5+( )

---------------------------------------------------------

5.0 14.5 0.037×– 0.5+

5.0 14.5 0.037×– 3.3–( )

--------------------------------------------------------------

1.3 10

6–

×

1

-----------------------

× 2A=

285 10

3

×

×=

,

10

Page 11

APPLICATION NOTE AN50

Therefore, for load current of 14.5A, the peak current

through the inductor, Ipk, is found to be approximately

15.5A:

IPKI

–( )

min

ISCI

≥ I

inductor

Load, max

-----------------------------+ 14.5 2+ 16.5A= = =

2

Therefore, the short circuit detection threshold must be at

least 16.5A.

Table 7. Comparison of Sense Resistors

Discrete Iron

Motherboard

Description

Tolerance

Trace Resistor

±29% ±5%

Factor (TF)

Size

(L x W x H)

2" x 0.2" x 0.001"

(1 oz Cu trace)

Power capability >50A/in 1 watt

Temperature

+4,000 ppm +30 ppm ±75 ppm ±30 ppm ±20 ppm

Coefficient

Cost

@10,000 piece

Low included in

motherboard

Alloy

Resistor (IRC)

(±1% available)

0.45" x 0.065" x

0.200"

(3W and 5W

available)

$0.31 $0.47 $0.09 $0.09

The next step is to determine the value of the sense resistor.

Including sense resistor tolerance, the sense resistor value

can be approximated as follows

R

SENSE

V

th,min

---------------I

SC

1 TF–( )×

V

th,min

-----------------------------------

1.0 I

+

Load,max

1 TF–( )×= =

Where TF = Tolerance Factor for the sense resistor.

Table 7 describes tolerance, size, power capability, temperature coefficient and cost of various type of sense resistors.

Discrete Metal

Strip Surface

Mount Resistor

(Dale)

Discrete MnCu

Alloy Wire

Resistor

Discrete

CuNi Alloy

Wire Resistor

(Copel)

±1% ±10% ±10%

0.25" x 0.125" x

0.025"

0.200" x 0.04" x

0.160"

0.200" x 0.04" x

0.100"

1 watt 1 watt 1 watt

Refer to Appendix A for Directory of component suppliers

Based on the Tolerance Factor in the above table, for an

embedded PC trace resistor and for I

V

th,min

R

SENSE

100mV

---------------------------------

2.0A 14.5A+

----------------------------------------

2.0A I

+

Load, max

1 29%–( )× 4.3mΩ=

For a discrete resistor and for I

V

th,min

R

SENSE

100mV

---------------------------------

2.0A 14.5A+

----------------------------------------

2.0A I

+

Load, max

1 5%–( )× 5.8mΩ=

1 TF–( )× = =

load, max

1 TF–( )× = =

load,max

= 14.5A:

= 14.5A:

For user convenience, Table 8 lists the recommended values

for sense resistors for various load currents using embedded

PC trace resistors and discrete resistors.

Table 8. R

I

Load,max

(A)

for Various Load Currents

sense

R

SENSE

PC Trace

Resistor (mΩ)

R

SENSE

Discrete

Resistor (mΩ)

10.0 5.9 7.9

11.2 5.4 7.2

12.4 4.9 6.6

13.9 4.5 6.0

14.0 4.4 5.9

14.5 4.3 5.8

Discrete Sense Resistor

Discrete Iron Alloy resistors come in variety of tolerances

and power ratings, and are most ideal for precision implementation. MnCu Alloy wire resistors or CuNi Alloy wire

resistors are ideal for low cost implementations.

11

Page 12

AN50 APPLICATION NOTE

R ρ

L

W t

×

-------------

×=

Embedded Sense Resistor (PC Trace Resistor)

Embedded PC trace resistors have the advantage of near zero

cost implementation. However, the value of the PC trace

resistor has large variations. Embedded resistors have 3

major error sources: the sheet resistivity of the inner layer,

the mismatch due to L/W, and the temperature variation of

the resistor. All three error sources must be considered for

laying out embedded sense resistors.

• Sheet resistivity.

For 1 ounce copper, the thickness variation is typically

1.15 mil to 1.35 mil. Therefore error due to sheet resistivity is (1.35 - 1.15)/1.25 = 16%

• Mismatch due to L/W.

Percent error in L/W is dictated by geometry and the

power dissipation capability of the sense resistor. The

sense resistor must be able to handle the load current and

therefore requires a minimum width which is calculated as

follows.

I

L

----------=

W

0.05

where: W = minimum width required for proper power

dissipation (mils) and I

= Load Current in Amps.

L

For 15A of load current, minimum width required is

300mils, which reflects a 1% L/W error.

• Thermal Consideration.

Due to I2R power losses the surface temperature of the

resistor will increase leading to a higher value. In addition,

ambient temperature

variation will add the change in resistor value:

R R

where: R20 is the resistance at 20°C,

1 α20T 20–( )]+[=

20

α

= 0.00393/ °C, T

20

is the operating temperature, and R is the desired value.

where:

ρ = Resistivity(µΩ-mil),

L = Length(mils),

W = Width(mils), and

W

L

t

t = Thickness(mils).

For 1oz copper, t = 1.35 mils, ρ = 717.86 µΩ-mil,

1 L/1 W = 1 Square ( ■ ).

For example, you can layout a 5.30mΩ embedded sense

resistor using the equations above:

I

10

L

----------

W

L

0.05

R W× t×

------------------------

ρ

---------- 200mils= = =

0.05

0.00530 200× 1.35×

--------------------------------------------------- 2000mils= = =

717.86

L/W = 10 ■

Therefore, to model 5.30mΩ embedded sense resistor, you

need W = 200 mils and L = 2000 mils. Refer to Figure 9.

1 1 1 1 1 1 1 1 1 1

W = 200 mils

L = 2000

Figure 9. 5.30mΩ Sense Resistor (10 ■)

You can also implement the sense resistor in the following

manner. Each corner square is counted as 0.6 square since

current flowing through the corner square does not flow

uniformly and it is concentrated towards the inside edge, as

shown in Figure 10.

1 1 1 1 1 1

.6 .6

1 1

.8

For temperature T = 50°C, the %R change = 12%.

Table 9 is the summary of the tolerance for the Embedded

PC Trace Resistor.

Table 9. Summary PC Trace Resistor Tolerance

Tolerance due to Sheet Resistivity variation 16%

Tolerance due to L/W error 1%

Tolerance due to temperature variation 12%

Total Tolerance for PC Trace Resistor 29%

Design Rules for Using an Embedded Resistor

The basic equation for laying an embedded resistor is:

12

Figure 10. 5.30mΩ Sense Resistor (10 ■)

A Design Example Combining an Embedded Resistor

and a Discrete Resistor

For low cost implementation, the embedded PC trace resistor

is most desirable. However, its wide tolerance (29%) presents a challenge. In addition, requirements for the CPU

change frequently, and, thus, the maximum load current may

be subject to change. Combining embedded resistors with

discrete resistors may be a desirable option. Figure 11 shows

a design that provides flexibility with a solution to address

wide tolerances.

In this design, you have the option to choose an embedded

or a discrete MnCu sense resistor. To use the discrete sense

resistor, populate R21 with a shorting bar (zero Ohm resistor) for proper Kelvin connection and add the MnCu sense

resistor. To use the embedded sense resistor, on the other

hand, populate R22 with a shorting bar for Kelvin connec-

Page 13

APPLICATION NOTE AN50

Embedded Sense Resistor

IFBH

MnCu Discrete

Resistor

IFBL

Figure 11. Short Circuit Sense Resistor Design Using a PC Trace Resistor and an Optional Discrete Sense Resistor

R21 R22

Output Power

Plane (Vout)

R-∆r

R

R+∆r

tion. The embedded sense resistor allo ws the user to choose a

plus or a minus delta resistance tap to offset any large sheet

resistivity change. In this design, the center tap yields 6mΩ,

the left tap yields 6.7mΩ, and the right tap yields 5.3mΩ.

RC5050 and RC5051 Short Circuit Current

Characteristics

The RC5050 and RC5051 short circuit current characteristic

includes a hysteresis function that prevents the DC-DC converter from oscillating in the event of a short circuit. Figure

12 shows the typical characteristic of the DC-DC converter

circuit with a 6mΩ sense resistor. The converter exhibits a

normal load regulation characteristic until the voltage across

the resistor exceeds the internal short circuit threshold of

120mV. At this point, the internal comparator trips and

signals the controller to turn off the gate drive to the power

MOSFET. This causes a drastic reduction in output voltage

as the load regulation collapses into the short circuit control

mode. The output voltage does not return to its nominal

value the output current is reduced to a value within the safe

range for the DC-DC converter.

3.5

3.0

2.5

2.0

1.5

1.0

Output Voltage

0.5

0

0 5 10 15 20 25

Output Current

Power Dissipation Consideration During a

Short Circuit Condition

The RC5050 and RC5051 controllers respond to an output

short circuit by drastically changing the duty cycle of the

gate drive signal to the power MOSFET. In doing this, the

power MOSFET is protected from stress and from eventual

failure. Figure 13A shows the gate drive signal of a typical

RC5050 operating in continuous mode with a load current of

10A. The duty cycle is set by the ratio of the input voltage to

the output voltage. If the input voltage is 5V, and the output

voltage is 3.1V, the ratio of Vout/ Vin is 62%. Figure 13B

shows the result of a RC5050 going into its short circuit

mode with a duty cycle approximately of 20%. Calculating

the power in the MOSFET at each condition on the graph

(Figure 12) shows how the protection works. The power dissipated in the MOSFET at normal operation for a load current of 14.5A, is given by:

2

14.5

P

I2RON× DutyCycle

D

----------

2

for each MOSFET.

The power dissipated in the MOSFET at short circuit

condition for a peak short current of 20A, is given by:

P

D

2

.037× .2 × 0.74W==

2

20

------

for each MOSFET.

These calculations show that the MOSFET is not being

over-stressed during a short circuit condition.

× .62 1.2W=×=×=

˙

.037

Figure 12. RC5050 Short Circuit Characteristic

13

Page 14

AN50 APPLICATION NOTE

Figure 13A. V

Operation Condition with V

Output Waveform for Normal

CCQP

= 3.3V@10A

out

P

D Diode,

14 0.45× 0.8× 5W≈

I

VF× 1 DutyCycle–( )× = =

F ave,

Thus, for the Schottky diode, the thermal dissipation during

a short circuit is greatly magnified. This requires that the

thermal dissipation of the diode be properly managed by an

appropriate heat sink. To protect the Schottky from being

destroyed in the event of a short circuit, you should limit the

junction temperature to less than 130°C. You can find the

required thermal resistance using the equation for maximum

junction temperature:

T

–

J max( )TA

-------------------------------=

P

D

R

ΘJA

Assuming that the ambient temperature is 50°C,

T

–

ΘJA

------------------------------P

D

R

J max( )TA

130 50–

--------------------- 16°C W⁄= = =

5

Thus, you need to provide a heat sink that gives the Schottky

diode a thermal resistance of 16°C/W or lower to protect the

device during an indefinite short.

In summary, with proper heat sink, the Schottk y diode is not

over-stressed during a short circuit condition.

Figure 13B. V

Output Shorted to Ground

Power dissipation on the Schottky diode during a short circuit condition must also be considered. During normal operation, the Schottky diode dissipates power while the power

MOSFET is off. The power dissipated in the diode during

normal operation, is given by:

P

D Diode,

14.5 0.5V× 1 0.62–( ) 2.75W=×

IFVF× 1 DutyCycle–( )× = =

During a short circuit, the duty cycle dramatically reduces to

around 20%. The forward current in the short circuit condition decays exponentially through the inductor. The power

dissipated in the diode during short circuit condition, is

approximately given by:

1

-----------–

I

F ending,

F ave,

20A 7.9A+( ) 2⁄ 14A≈ ≈

I

L R⁄

Isce

× 20A e

Output Waveform for

CCQP

1.5µs

--------------–

1.3µs

× 7.9A≈==

Schottky Diode Selection

The application circuit diagram of Figure 3 shows a Schottky

diode, DS1. In non-synchronous mode, DS1 is used as a flyback diode to provide a constant current path for the inductor

when M1 is turned off. Table 10 shows the characteristics of

several Schottky diodes. Note that MBR2015CTL has a v ery

low forward voltage drop. This diode is ideal for applications

where the output voltage is required to be less than 2.8V.

Table 10. Schottky Diode Selection Table

Manufacturer

Model # Conditions

Philips

PBYR1035

Motorola

MBR2035CT

Motorola

MBR1545CT

Motorola

MBR2015CTL

IF = 20A; Tj = 25°C

IF = 20A; Tj = 125°C

IF = 20A; Tj = 25°C

IF = 20A; Tj = 125°C

IF = 15A; Tj = 25°C

IF = 15A; Tj = 125°C

IF = 20A; Tj = 25°C

IF = 20A; Tj = 150°C

Forward Voltage

V

F

< 0.84v

< 0.72v

< 0.84v

< 0.72v

< 0.84v

< 0.72v

< 0.58v

< 0.48v

Output Filter Capacitors

Output ripple performance and transient response are functions of the filter capacitors. Since the 5V supply of a PC

motherboard may be located several inches away from the

DC-DC converter, the input capacitance may play an important role in the load transient response of the RC5050 and

RC5051. The higher input capacitance, the more charge storage is available for improving current transfer through the

14

Page 15

APPLICATION NOTE AN50

FET. Low Equiv alent Series Resistance (ESR) capacitors are

best suited for this type of application. Incorrect selection

can hinder the converter's overall performance. The input

capacitor should be placed as close to the drain of the FET as

possible to reduce the effect of ringing caused by long trace

lengths.

The ESR rating of a capacitor is a difficult number to

quantify. ESR is defined as the resonant impedance of the

capacitor. Since the capacitor is actually a complex impedance device having resistance, inductance, and capacitance,

it is natural for this device to have a resonant frequenc y. As a

rule, the lower the ESR, the better suited the capacitor is for

use in switching power supply applications. Many capacitor

manufacturers do not supply ESR data. A useful estimate of

the ESR can be obtained using the following equation:

ESR

DF

-------------=

2πfC

where DF is the dissipation factor of the capacitor, f is the

operating frequency, and C is the capacitance in farads.

With this in mind, correct calculation of the output capacitance is crucial to the performance of the DC-DC converter.

The output capacitor determines the overall loop stability,

output voltage ripple, and load transient response. The calculation is as follows:

I

∆T×

O

C µF( )

--------------------------------------=

∆V I

ESR×–

O

For I

= 12.2A (0-13A load step) and ∆V = 100mV, the bulk

O

capacitance required can be approximated as follows:

C µF( )

∆T×

O

-------------------------------------∆V I

ESR×–

O

12.2A 2µs×

--------------------------------------------------------------- 2870µF= = =

100mV 12.2A 7.5mΩ×–

I

Because the control loop response of the controller is not

instantaneous, the initial load transient must be supplied

entirely by the output capacitors. The initial voltage deviation

is determined by the total ESR of the capacitors used and the

parasitic resistance of the output traces. For a detailed analysis

of capacitor requirements in a high-end microprocessor

system, please refer to Application Bulletin 5.

Input Filter

The DC-DC converter should include an input inductor

between the system +5V supply and the converter input as

described below. This inductor serves to isolate the +5V

supply from the noise in the switching portion of the

DC-DC converter, and to limit the inrush current into the

input capacitors during power up. A value of 2.5µH is rec-

ommended, as illustrated in Figure 14.

5V Vin

0.1µF

2.5µH

1000µF, 10V

Electrolytic

65-AP42-17

where ∆V is the maximum voltage deviation due to load

Figure 14. Input Filter

transients, ∆T is the reaction time of the power source (loop

response time for the RC5050 and RC5051 isapproximately

2µs), and I

is the output load current.

O

Bill of Material

Table 11 is the Bill of Material for the Application Circuits

of Figure 3 and Figure 4.

Table 11. Bill of Materials for a 13A Pentium Pro Klamath Application

Quantity Reference Manufacturer Part

Order #

7 C4, C5, C7,

C8, C9, C10,

Panasonic

ECU-V1H104ZFX

0.1µF 50V capacitor

C11

1 C6 Panasonic

4.7µF 16V capacitor

ECSH1CY475R

1 Cext Panasonic

120pF capacitor

ECU-V1H121JCG

1 C12 Panasonic

1µF 16V capacitor

ECSH1CY105R

3 C1, C2, C3 United Chemi-con

LXF16VB102M

4 C13, C14,

C15, C16

1 DS1

(note 1)

Sanyo

6MV1500GX

Motorola

MBR2015CT

1000µF 6.3V electrolytic

capacitor 10mm x 20mm

1500µF 6.3V electrolytic

capacitor 10mm x 20mm

Shottky diode, 15A Vf < 0.52V @ I

1 D1 Motorola 1N4691 6.2V Zener Diode

Description Requirements and

Comments

ESR < 0.047 Ω

ESR < 0.047 Ω

= 10A

f

15

Page 16

AN50 APPLICATION NOTE

Table 11. Bill of Materials for a 13A Pentium Pro Klamath Application (continued)

Quantity Reference Manufacturer Part

Order #

1 L1 Pulse Engineering

1.3µH inductor

Description Requirements and

Comments

PE-53680

1 L2* Pulse Engineering

PE-53681

2-4

(note 2)

M1-M4 International Rectifier

IRF7413

1 Rsense Coppel

2.5µH inductor *Optional—helps

reduce ripple on 5v line

N-Channel Logic Level

Enhancement Mode MOSFET

R

DS,ON

V

= 4.5V, ID = 5A

GS

6 mΩ, 1W

CuNi Wire resistor

1 R5 Panasonic

47Ω 5% resistors

ERJ-6GEY050Y

1 R6 Panasonic

10KΩ 5% resistor

ERJ-6ENF10.0KY

U1 Raytheon

RC5050M or RC5051M

Refer to Appendix A for Directory of component suppliers.

Notes:

1. When used in synchronous mode, a 1A schottky diode such as the 1N5817 should be substituted for the MBR2015CT.

2. A target R

value of 10mΩ should be used for each output driver switch. Refer to Table 3 for alternative MOSFETs.

DS,ON

PCB Layout Guidelines and

Considerations

PCB Layout Guidelines

• Placement of the MOSFETs relative to the RC5050 is

critical. Place the MOSFETs (M1 & M2) so that the trace

length of the HIDRV pin from the RC5050 to the FET

gates is minimized. A long lead length on this pin would

cause high amounts of ringing due to the inductance of the

Programmable DC-DC

converter

trace and the large gate capacitance of the FET. This noise

radiates all throughout the board, and, because it is

switching at such a high voltage and frequency, it is very

difficult to suppress.

Figure 15 shows an example of good placement for the

MOSFETs in relation to the RC5050. In addition, this figure shows an example of problematic placement for the

MOSFETs.

< 18mΩ

16

M1

M2

Good layout

RC5050

11

12

13

14

15

16

17

18

19

20

10

9

8

7

6

5

4

3

2

1

“Quiet" Pins=

Figure 15. Placement of the MOSFETs

Bad layout

RC5050

11

12

13

14

15

16

17

18

19

20

10

9

8

7

6

5

4

3

2

1

M1

M2

Page 17

APPLICATION NOTE AN50

In general, all of the noisy switching lines should be kept

away from the quiet analog section of the RC5050. That is,

traces that connect to pins 12 and 13 (HIDRV and

VCCQP) should be kept far away from the traces that connect to pins 1 through 5, and pin 16.

• Place the 0.1µF decoupling capacitors as close to the

RC5050 pins as possible. Extra lead length negates their

ability to suppress noise.

• Each VCC and GND pin should have its own via to the

appropriate plane. This helps to provide isolation between

pins.

• Surround the CEXT timing capacitor with a ground trace.

Be sure to place a ground or power plane under the

capacitor for further noise isolation to provide additional

shielding to the oscillator pin 1 from the noise on the

PCB. In addition, place this capacitor as close to the

RC5050 pin 1 as possible.

• Place the MOSFETs, inductor and Schottky as close

together as possible for the same reasons on the first bullet

above. Place the input bulk capacitors as close to the

drains of MOSFETs as possible. In addition, placement of

a 0.1µF decoupling capacitor right on the drain of each

MOSFET helps to suppress some of the high frequency

switching noise on the input of the DC-DC converter.

• Place the output bulk capacitors as close to the CPU as

possible to optimize their ability to supply instantaneous

current to the load in the event of a current transient.

Additional space between the output capacitors and the

CPU allows the parasitic resistance of the board traces to

degrade the DC-DC conv erter’ s performance under se vere

load transient conditions, causing higher voltage

deviation. For more detailed information regarding

capacitor placement, refer to Application Bulletin AB-5.

• The traces that run from the RC5050 IFB (pin 4) and VFB

(pin 5) pins should be run next to each other and Kelvin

connected to the sense resistor. Running these lines

together prevents some of the common mode noise that is

presented to the RC5050 feedback input. Try, as much as

possible, to run the noisy switching signals (HIDRV &

VCCQP) on one layer, but use the inner layers for power

and ground only. If the top layer is being used to route all

of the noisy switching signals, use the bottom layer to

route the analog sensing signals VFB and IFB.

Example of a PC Motherboard Layout and

Gerber File.

This section shows a reference design for motherboard

implementation of the RC5050 along with the Layout Gerber

File and Silk Screen. The actual PCAD Gerber File can be

obtained from Raytheon Electronics local Sales Office or

from the Semiconductor Division Marketing department at

415-966-7819.

17

Page 18

AN50 APPLICATION NOTE

Guidelines for Debugging and

Performance Evaluations

Debugging Your First Design Implementation

1. Note the setting of the VID pins to know what voltage is

to be expected.

2. Do not connect any load to the circuit. While monitoring

the output voltage, apply power to the part with current

limiting at the power supply. This ensures that no catastrophic shorts are present.

3. If proper voltage is not achieved go to "Procedures "

below.

4. When you have proper voltage, increase the current limiting of the power supply to 16A.

5. Apply load at 1A increments. An active load (HP6060B

or equivalent) is suggested.

6. In case of poor regulation refer to "Procedures" below.

Procedures

1. If there is no voltage at the output and the circuit is not

drawing current look for openings in the connections,

check the circuitry versus schematic, and check the

power supply pins at the device to make sure that voltage(s) are applied.

2. If there is no voltage at the output and the circuit is

drawing excessive current (>100mA) with no load,

check for possible shorts. Determine the path of the

excessive current and which devise is drawing it—this

current may be drawn by peripheral components.

3. If the output voltage comes close to the expected value,

check the VID inputs at the device pins. The part is factory set to correspond to the VID inputs.

4. Premature shut down can be caused by an inappropriate

value of the sense resistor. See the “Sense Resistor” section.

5. Poor load regulation can be due to many causes. Check

the voltages and signals at the critical pins.

6. The VREF pin should be at the voltage set by the VID

pins. If the power supply pins and the VID pins are

correct the VREF should have the correct voltage.

7. Next check the oscillator pin. You should see a saw tooth

wave at the frequency set by the external capacitor.

8. When the VREF and CEXT pins are checked and

correct and the output voltage is incorrect, look at the

waveform at VCCQP. This pin should be swinging from

ground to +12V (in the +12V application), and from

slightly below +5V to about +10V (charge pump application). If the VCCQP pin is noisy, with ripples/overshoots riding on it this may make the converter not to

function correctly.

9. Next, look at HIDRV pin. This pin directly drives the

gate of the FET. It should provide a gate drive (Vgs) of

about 5V when turning the FET on. A careful study of

the layout is recommended. Refer to the “PCB Layout

Guidelines” section.

10. Past experience shows that the most frequent errors are

incorrect components, improper connections, and poor

layout.

Performance Evaluation

This section shows a sample ev aluation results as a reference

guide for evaluating a DC-DC Converter using the RC5050

on a Pentium Pro motherboard.

Load Regulation

VID I

10100 0.5 3.0904

Load Regulation 0.5A – 9.9A 0.70%

VID I

10010 0.5 3.2805

Load Regulation 0.5A – 12.4A 0.64%

(A) V

load

1.0 3.0825

2.0 3.0786

3.0 3.0730

4.0 3.0695

5.0 3.0693

6.0 3.0695

7.0 3.0695

8.0 3.0694

9.0 3.0694

9.9 3.0691

(A) V

load

1.0 3.2741

2.0 3.2701

3.0 3.2642

4.0 3.2595

5.0 3.2597

6.0 3.2606

7.0 3.2611

8.0 3.2613

9.0 3.2611

10.0 3.2607

11.0 3.2599

12.0 3.2596

12.4 3.2596

out

out

(V)

(V)

18

Page 19

APPLICATION NOTE AN50

VID I

(A) V

load

out

(V)

11010 0.5 2.505

1.0 2.504

2.0 2.501

3.0 2.496

4.0 2.493

5.0 2.493

6.0 2.492

7.0 2.492

8.0 2.491

9.0 2.490

10.0 2.989

11.0 2.488

12.0 2.486

13.0 2.485

13.9 2.484

Load Regulation 0.5A – 13.9A 0.84%

Note:

Load regulation is expected to be typically around 0.8%. The

load regulation performance for this device under evaluation

is excellent.

Output Voltage Load Transients Due to Load Current Step

This test is performed using Intel P6.0/P6S/P6T Voltage

Transient Tester.

Low to High

Current Step

0.5A-9.9A -76.0mV Refer to

Attachment

A for Scope

Picture

High to Low

Current Step

9.9A-0.5A +70mV Refer to

Attachment

B for Scope

Picture

Low to High

Current Step

0.5A-12.4A -97.6mV Refer to

Attachment

C for Scope

Picture

High to Low

Current Step

12.4A-0.5A +80.0mV Refer to

Attachment

D for Scope

Picture

Low to High

Current Step

0.5A-13.9A -99.2mV Refer to

Attachment

E for Scope

Picture

High to Low

Current Step

13.9A-0.5A +105.2mV Refer to

Attachment

F for Scope

Picture

Note:

Transient voltage is recommended to be less than 4% of the

output voltage. The performance of the device under evaluation is significantly better than a typical VRM.

19

Page 20

AN50 APPLICATION NOTE

Input Ripple and Power on Input Rush Current

Power on Input Rush Current was not measured on the motherboard because we did not want to cut the 5V trace and

I

= 9.9A Input Ripple

load

Voltage = 15mV

Refer to Attachment G for Scope

Picture

Note:

Excellent input ripple voltage. Input ripple voltage is recom-

mended to be less than 5% of the output voltage.

Component Case Temperature

Case Temperature

I

load

Device Description

Q3A MOSFET

insert a current probe in series with the supply. However,

with the input filter design, the Input Rush Current is well

within specification.

Case Temperature

= 9.9A

(°C)

I

load

= 12.4A

(°C)

57 63 66.3

K1388

Q3B MOSFET

58 64 66.6

K1388

L1 Inductor,

53 56 61.2

Unknown

Q2 Schottky Diode

66 70 87

2048CT

IC Raytheon’s RC5050 52 54 58

Cin Input Cap. 1000µF 38.2 36.8 39

Cout Output Cap.

35 34.8 38.2

1500µF

Case Temperature

I

= 13.9A

load

(°C)

Note:

The values for case temperatures are within guidelines. That is, case temperatures for all components should be below

105°C @25°C Ambient.

Evaluation Summary

The on-board DC-DC converter is fully functional. It has

excellent load regulation, transient response, and input voltage ripple.

Attachment A

Attachment B

20

Page 21

APPLICATION NOTE AN50

Attachment C

Attachment D

Attachment E

Attachment F

Attachment G

21

Page 22

AN50 APPLICATION NOTE

Summary

This application note covers many aspects of the RC5050

and RC5051 for implementation of a DC-DC converter a on

Pentium Pro motherboard. A detailed discussion includes

the processor power requirements, a description of the

RC5050 and RC5051, design considerations and components selection, layout guidelines and considerations, guidelines for debugging, and performance evaluations.

RC5050 Evaluation Board

Raytheon Electronics provides an evaluation board to verifying system level performance of the RC5050. The e v aluation

board serves as a guide to performance expectations when

using the supplied external components and PCB layout.

Call Raytheon Electronics local Sales Office or the Marketing department at 415-966-7819 for an evaluation board.

22

Page 23

APPLICATION NOTE AN50

Appendix A

Directory of Component Suppliers

Dale Electronics, Inc.

E. Hwy. 50, PO Box 180

Yankton, SD 57078-0180

PH: (605) 665-9301

National Semiconductor

2900 Semiconductor Drive

Santa Clara, CA 95052-8090

PH: (800) 272-9959

Fuji Electric

Collmer Semiconductor Inc.

14368 Proton Rd.

Dallas, Texas 75244

PH: (214)233-1589

General Instrument

Power Semiconductor Division

10 Melville Park Road

Melville, NY 11747

PH: (516) 847-3000

Hoskins Manufacturing Co.

(Copel Resistor Wire)

10776 Hall Road

Hamburg, MI 48139-0218

PH: (313) 231-1900

Intel Corp.

5200 NE Elam Young Pkwy.

Hillsboro, OR. 97123

PH: (800) 843-4481 Tech. Support

for Power Validator

International Rectifier

233 Kansas St.

El Segundo, CA 90245

PH: (310) 322-3331

IRC Inc.

PO Box 1860

Boone, NC 28607

PH: (704) 264-8861

Motorola Semiconductors

PO Box 20912

Phoenix, Arizona 85036

PH:(602) 897-5056

Nihon Inter Electronics Corp.

Quantum Marketing Int’l, Inc.

12900 Rolling Oaks Rd.

Caliente, CA 93518

PH: (805) 867-2555

Panasonic Industrial Co.

6550 Katella Avenue

Cypress, CA 90630

PH: (714) 373-7366

Pulse Engineering

12220 World Trade Drive

San Diego, CA 92128

PH: (619) 674-8100

Sanyo Energy USA

2001 Sanyo Avenue

San Diego, CA 92173

PH: (619) 661-6620

Siliconix

Temic Semiconductors

2201 Laurelwood Road

Santa Clara, CA 95056-1595

PH: (800) 554-5565

Sumida Electric USA

5999 New Wilke Road Suite #110

Rolling Meadows, IL 60008

PH: (708) 956-0702

Xicon Capacitors

PO Box 170537

Arlington, Texas 76003

PH:(800) 628-0544

23

Page 24

AN50 APPLICATION NOTE

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

instructions for use provided in the labeling, can be

reasonable expected to result in a significant injury of the

user.

Fairchild Semiconductor

Corporation

Americas

Customer Response Center

Tel:1-888-522-5372

www.fairchildsemi.com

Fairchild Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 8 141-35-0

English Tel: +44 (0) 1 793-85-68-56

Italy Tel: +39 (0) 2 57 5631

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

Fairchild Semiconductor

Hong Kong Ltd.

13th Floor, Straight Block,

Ocean Center, 5 Canto Rd.

Tsimshatsui, Kowloon

Hong Kong

Tel:+852 2737-7200

Fax:+852 2314-0061

National Semiconductor

Japan Ltd.

Tel:81-3-5620-6175

Fax:81-3-5620-6179

2/98 0.0m

1998 Fairchild Semiconductor Corporation

Stock#AN30000050

Loading...

Loading...