Fairchild ILC6363 service manual

查询ILC6363供应商

www.fairchildsemi.com

ILC6363

Step-Up DC-DC Converter for One-Cell Lithium-Ion

Batteries

Features

• ILC6363CIR-50: Fixed 5.0V output; custom voltages are

available upon request

• ILC6363CIR-ADJ: Adjustable output to 6V maximum

• Capable of 500mA output current

• Peak efficiency: > 90% at V

V

= 3.6V

IN

OUT

= 3.6V, I

= 300mA,

OUT

• No external diode is required (synchronous rectification)

• Battery input current of 300µA at no load

• True load disconnect from battery input in shutdown

(1µA)

• Oscillator frequency: 300kHz ±15%

• Low battery detector with 100ms transient rejection delay

• Power good output flag when V

is in regulation

OUT

• MSOP-8 package

Applications

• Cellular phones

• Palmtops, PDAs and portable electronics

• Equipment using single Lithium-Ion batteries

Description

The ILC6363 step-up/step-down DC-DC converter is a

switch mode converter, capable of supplying up to 500mA

output current, at a fixed or user selectable output voltage.

The range of input, and output voltage options makes the

ILC6363 ideal for Lithium-ion (Li-ion), or any other battery

application, where the input voltage range spans above and

below the regulated output voltage. When ILC6363’s input

voltage exceeds the output voltage by more than 800mV, the

output will begin to track the input linearly.

The ILC6363 is a direct replacement for ILC6360, in applications where SYNC pin is not used. The PFM or PWM

operating mode is user selectable through SEL pin connected

to ground or left open, respectively. The choice should be

dependent upon the current to be delivered to the load: PFM

is recommended for better efficiency at light load,while

PWM is recommended for more than 50mA load current.

In shutdown mode, the device allows true load disconnect

from battery input.

Configured as a 300kHz, fixed frequency PWM/PFM boost

converter , the ILC6363 can perform a limited b uck operation

in PFM mode, when the input voltage is up to 0.8V higher

than the output voltage.

The ILC6363 is unconditionally stable with no external

compensation; the sizes of the input and output capacitors

influence input and output ripple voltages, respectively.

Since the ILC6363 has an internal synchronous rectifier, the

standard fixed voltage version requires minimal external

components: an inductor, an input capacitor, and an output

capacitor. If a tantalum output capacitor is used, then an

additional 10µF ceramic output capacitor will help reduce

output ripple voltage.

Other features include a low battery input detector with a

built-in100ms transient rejection delay and a power good

indicator useful as a system power on reset.

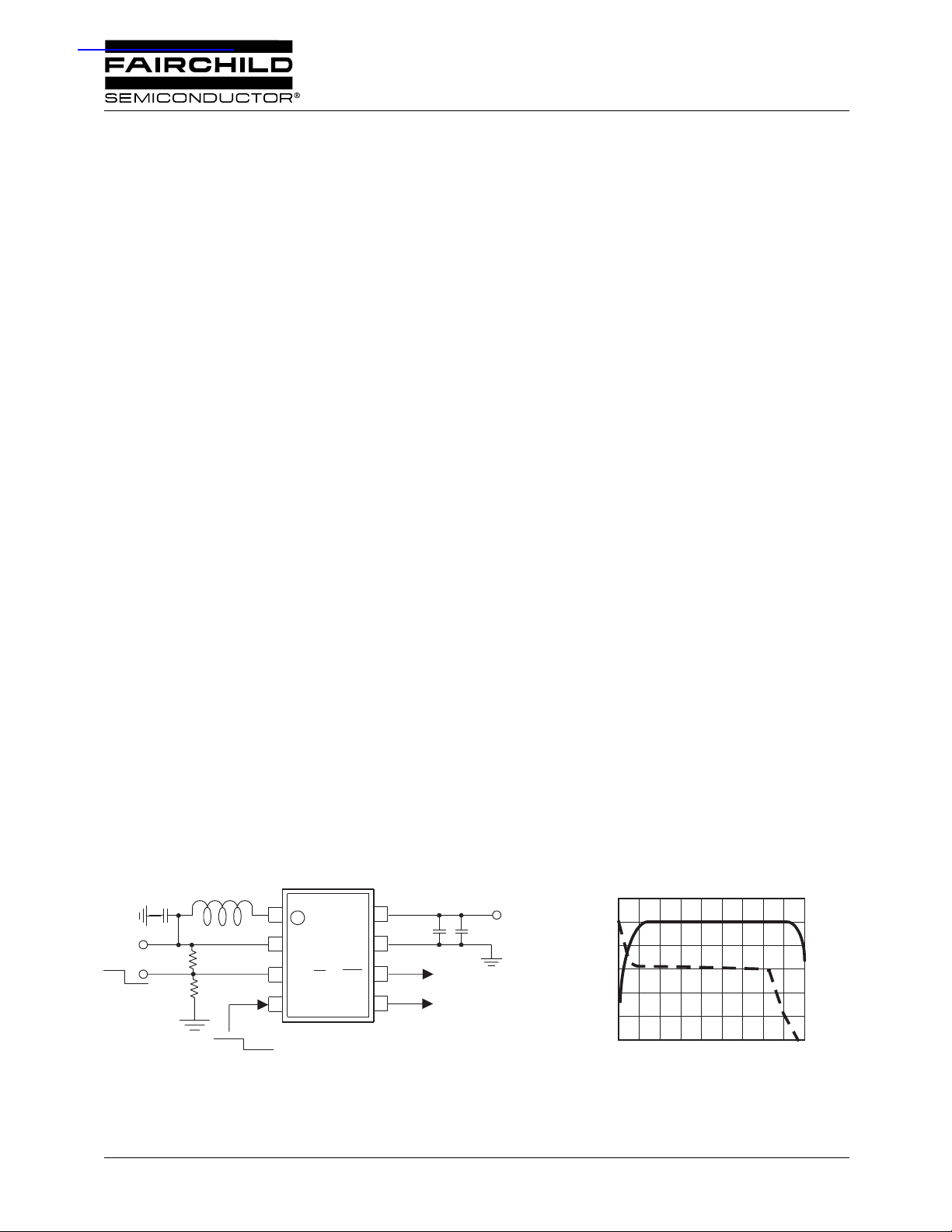

Typical Circuit

IN

V

IN

2.7V to 4.2V

ON

OFF

C

100µF

+

L

15µH

R5

R6

PWM

PFM

ILC6363CIR-XX

1

X

L

2

V

IN

3

LBI/SD

4

SEL

MSOP-8

Figure 1.

V

OUT

GND

LBO

POK

C

OUT

8

7

6

5

10µF 100µF

+

+

Low Battery

Detector Output

Power Good Output

(Fixed V

OUT

V

only)

OUT

Optimized to Maximize Battery Life

90

80

70

ILC6363 Efficiency (%)

Time

4.2

3.6

3.0

REV. 1.3.5 5/21/02

Battery Voltage (V)

ILC6363 PRODUCT SPECIFICATION

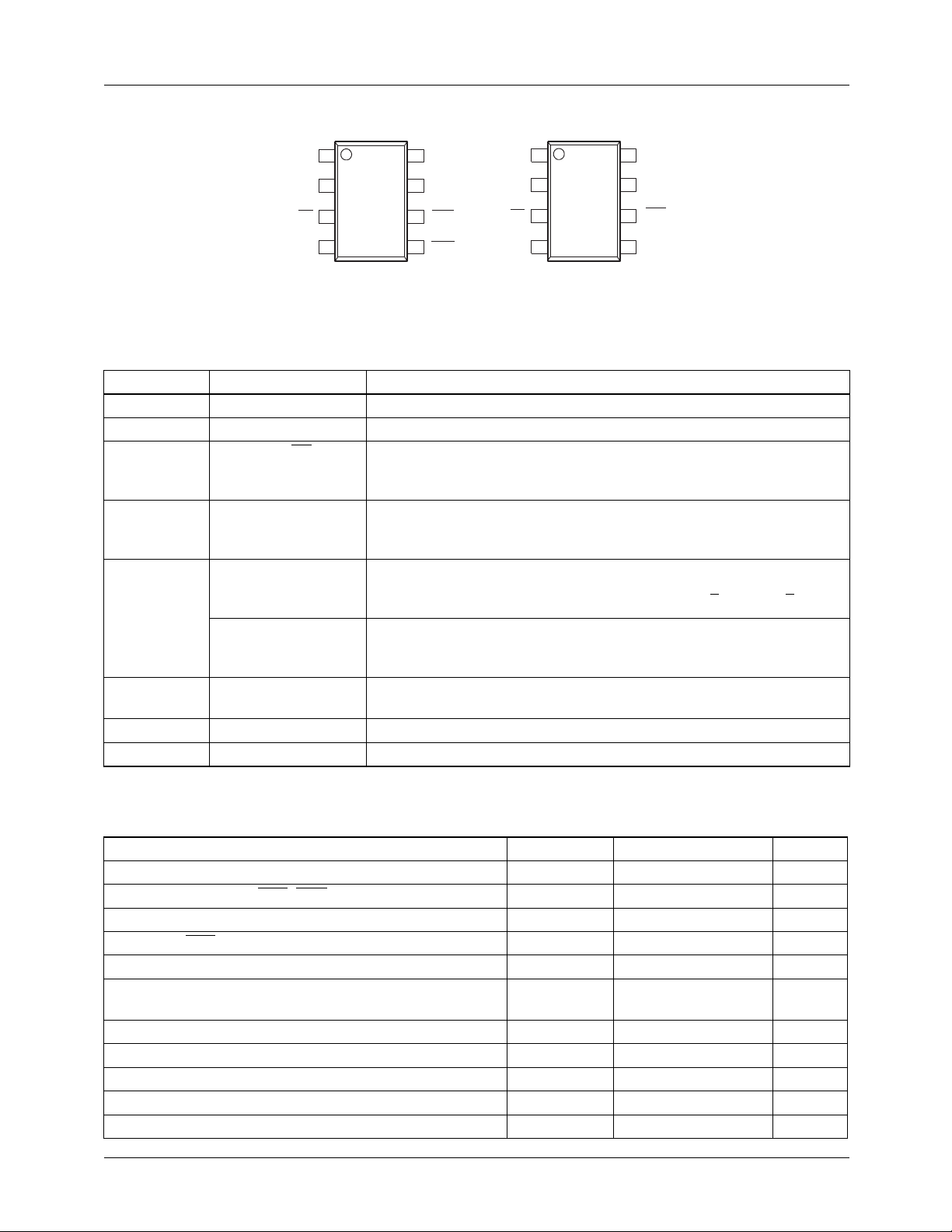

Pin Assignments

V

OUT

L

X

1

8

V

OUT

L

X

1

8

V

LB/SD

SEL

IN

2

3

4

(TOP VIEW)

ILC6363CIR-XX

MSOP

7

GND

LBO

6

5

POK

V

LB/SD

SEL

2

IN

3

4

MSOP

(TOP VIEW)

ILC6363CIR-ADJ

7

GND

LBO

6

5

V

FB

Pin Definitions

Pin Number Pin Name Pin Function Description

1L

2V

X

IN

3 LBI/SD

4 SEL

POK

(ILC6363CIR-XX

5

V

FB

(ILC6363CIR-ADJ)

6 LBO

7 GND

8V

OUT

Inductor input . Inductor L connected between this pin and the battery

Input Voltage . Connect directly to battery

Low battery detect input and shutdown . Low battery detect threshold

is set with this pin using a potential divider. If this pin is pulled to logic low

then the device will shutdown.

Select Input .

A low logic level signal applied to this pin selects PFM

operation mode. If the pin is left open or high logic level is applied, PWM

mode is selected.

Power Good Output . This open drain output pin will go high when

output voltage is within regulation, 0.92•V

0.98•V

OUT(NOM)

OUT(NOM)

Feedback Input . This pin sets the adjustable output voltage via an

external resistor divider network. The formula for choosing the resistors

is shown in the “Applications Information” section.

Low Battery Output . This open drain output will go low if the battery

voltage is below the low battery threshold set at pin 3.

Ground of the IC . Connect this pin to the battery and system ground

Regulated output voltage .

< V

threshold

<

Absolute Maximum Ratings

Parameter Symbol Ratings Units

Voltage on V

Voltage on LBI, Sync, LBO, POK, V

Peak switch current on L

Current on LBO pin I

Continuous total power dissipation at 85°C P

Short circuit current I

Operating ambient temperature T

Maximum junction temperature T

Storage temperature T

Lead temperature (soldering 10 sec.) 300 °C

Package thermal resistance

2

pin V

OUT

, L

and V

FB

X

pin IL

X

pins -0.3 to 7 V

IN

OUT

X

SINK(LBO)

D

SC

A

J(MAX)

stg

θ

JA

-0.3 to 7 V

1A

5mA

315 mW

Internally protected

(1 sec. duration)

-40 to 85 °C

150 °C

-40 to 125 °C

206 °C/W

REV. 1.3.5 5/21/02

A

≥

η

≥

η

PRODUCT SPECIFICATION ILC6363

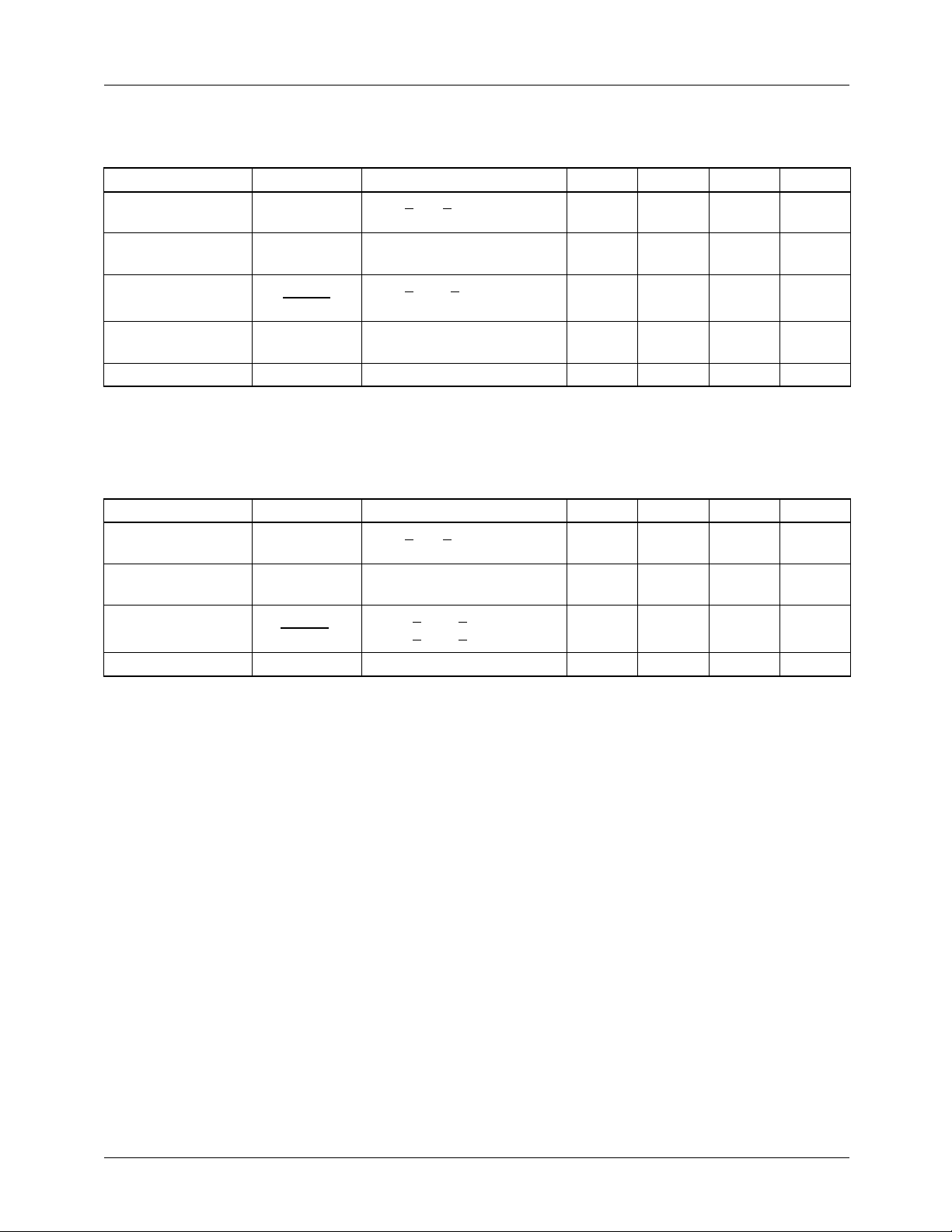

Electrical Characteristics ILC6363CIR-50 in PFM Mode

Unless otherwise specified, all limits are at V

IN

= V

= 3.6V, I

LBI

= 1mA and T

OUT

(SEL in LOW State)

= 25°C, test circuit Figure 1.

A

BOLDFACE type indicate limits over the specified operating temperature range. (Note 2)

Parameter Symbol Conditions Min. Typ. Max. Units

Output Voltage V

Maximum Output

Current

Load Regulation

No Load Battery

OUT(nom)

I

OUT

∆∆

∆∆

V

OUT

V

OUT

I

IN (no load)

2.7V <

V

OUT

V

= 2.7V

IN

1mA <

I

OUT

<

V

4.2V 4.875

IN

4.825

0.96V

OUT(nom)

I

50mA 1 %

<

OUT

,

5.0 5.125

5.175

250 mA

= 0mA 300 µA

Input Current

Efficiency

Electrical Characteristics ILC6363CIR-50 in PWM Mode

Unless otherwise specified, all limits are at V

I

= 20mA 85 %

OUT

(SEL Open)

= V

IN

= 3.6V, I

LBI

= 100mA and T

OUT

= 25°C, test circuit Figure 1.

A

BOLDFACE type indicate limits over the full operating temperature range. (Note 2)

Parameter Symbol Conditions Min. Typ. Max. Units

Output Voltage V

Maximum Output

OUT(nom)

I

OUT

2.7V < V

V

OUT

< 4.2V 4.850

IN

0.92V

OUT(nom)

4.800

5.0 5.150

5.200

500 mA

Current

Load Regulation

Efficiency

∆∆

∆∆

V

V

OUT

OUT

50mA < I

50mA < I

I

= 300mA 92 %

OUT

OUT

OUT

< 200mA

< 300mA

3

4

V

V

%

REV. 1.3.5 5/21/02

3

ILC6363 PRODUCT SPECIFICATION

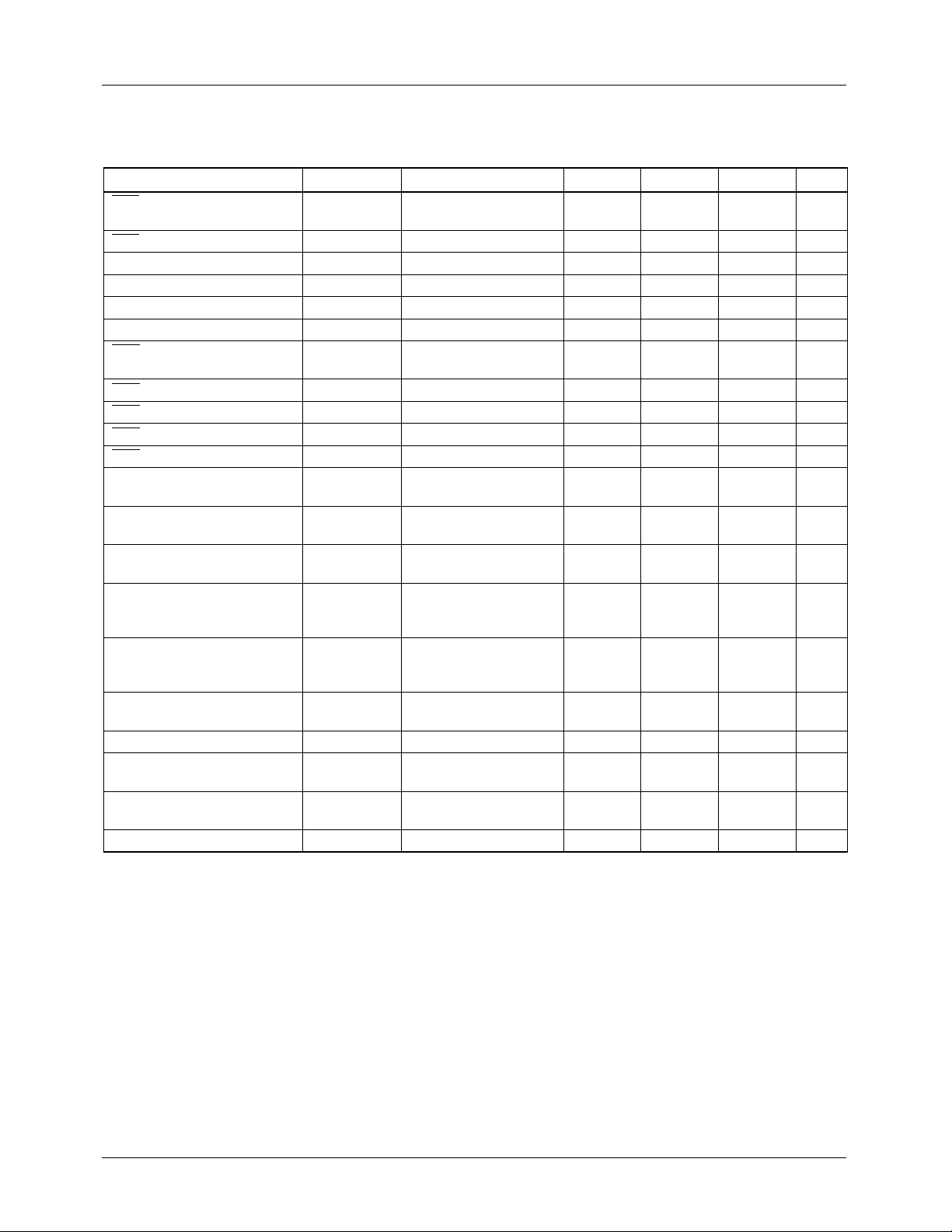

General Electrical Characteristics

T

= 25°C, V

A

BOLDFACE indicate limits over the specified operating temperature range. (Note 2).

output voltage low V

LBO

output leakage current I

LBO

Shutdown input voltage low V

Shutdown input voltage high V

SEL input voltage high V

SEL input voltage low V

output voltage low V

POK

output voltage high V

POK

output leakage Current I

POK

threshold V

POK

hysteresis V

POK

Feedback voltage

(ILC6363CIR-ADJ only)

Output voltage adjustment

range (ILC6363CIR-ADJ only)

Minimum startup voltage V

Input voltage range V

Battery input current in load

disconnect mode

Switch on resistance R

Oscillator frequency f

LBI input threshold V

Input leakage current I

LBI hold time t

Notes:

1. Absolute maximum ratings indicate limits which, when exceeded, may result in damage to the component. Electrical

specifications do not apply when operating the device outside its rated operating conditions.

2. Specified min/max limits are production tested or guaranteed through correlation based on statistical control methods.

Measurements are taken at constant junction temperature as close to ambient temperature as possible using low duty cycle

pulse testing.

3. Guaranteed by design

4. In order to get a valid low-battery-output (LBO) signal, the input voltage must be lower than the low-battery-input (LBI)

threshold for a duration greater than the low battery hold time (Hold(LBI)). This feature eliminates false triggering due to

voltage transients at the battery terminal.

= V

IN

= 3.6V, I

LBI

= 50mA, unless otherwise specified.

OUT

Parameter Symbol Conditions Min. Typ. Max. Units

I

LBO(low)

LBO(hi)

SD(low)

SD(hi)

SEL(hi)

SEL(low)

POK(low)

POK(hi)

L(POK)

TH(POK

HYST

V

FB

V

OUT(ADJ) min

V

OUT(ADJ) max

I

IN(start)

IN

I

IN(SD)

ds(on)

osc

REF

LEAK

HOLD(LBI)

= 2mA, open drain

SINK

output, V

V

LBO

= 1V

LBI

= 5V 1

16

1.5 V

I

= 2mA, open drain

SINK

output

6V at pin 5 2 µA

0.92xV

OUT

0.95xV

OUT

50 mV

1.225

1.250 1.275

1.212

VIN = 0.9V, I

V

= 3V, I

IN

= 10mA, PWM

OUT

OUT

OUT

= 50mA

= 50mA

2.5

6

0.9 1 V

mode

V

OUT

± 4%

I

OUT

V

LBI/SD

V

OUT

= V

OUT(nominal)

= 10mA

< 0.4V,

= 0V

0.9

1

1 10 µA

(short circuit)

N-Channel MOSFET

P-Channel MOSFET

400

750

255 300 345 kHz

1.175

1.250 1.325

1.150

Pins LB/SD,SEL and

VFB, (Note 3)

(Note 4) 100 120 mS

0.4

0.4

0.4 V

0.4 V

6 V

0.98xV

OUT

1.288

V

OUT(nomi-

+ 0.8V

nal)

1.350

200 nA

V

µA

V

V

V

V

V

V

mΩ

V

2

4

REV. 1.3.5 5/21/02

PRODUCT SPECIFICATION ILC6363

Application Information

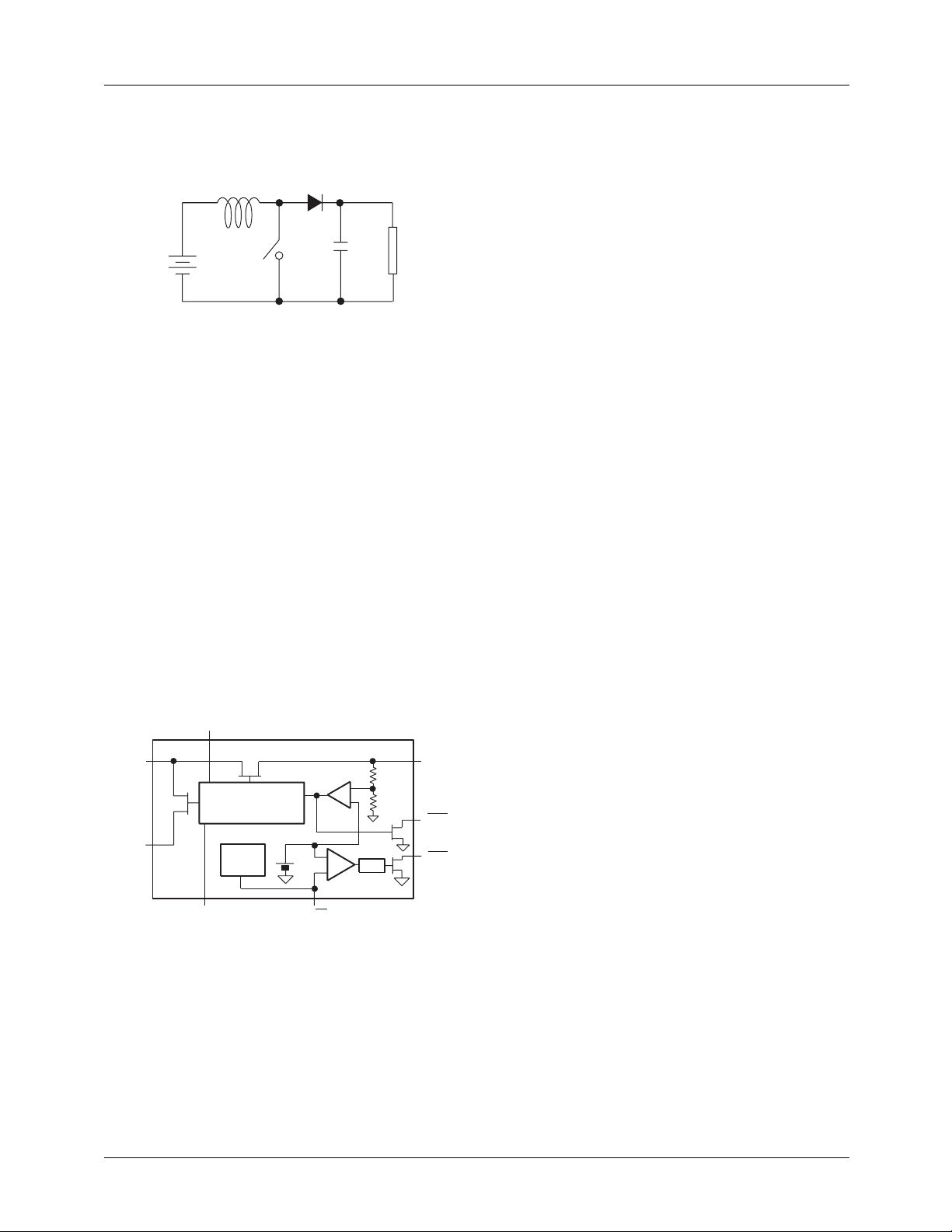

The ILC6363 performs boost DC-DC conversion by controlling the switch element as shown in the simplified circuit in

Figure 3 below.

Figure 3. Basic Boost Circuit

When the switch is closed, current is built up through the

inductor. When the switch opens, this current is forced

through the diode to the output. As this on and off switching

continues, the output capacitor voltage builds up due to the

charge it is storing from the inductor current. In this way, the

output voltage is boosted relative to the input.

In general, the switching characteristic is determined by the

output voltage desired and the current required by the load.

The energy transfer is determined by the power stored in the

coil during each switching cycle.

PL = ƒ(tON, VIN)

Synchronous Rectification

The ILC6363 also uses a technique called “synchronous

rectification” which removes the need for the external diode

used in other circuits. The diode is replaced with a second

switch or in the case of the ILC6363, an FET as shown in

Figure 4 below.

V

IN

ILC6363

-

+

+

DELAY

-

V

OUT

POK

LBO

PWM/PFM

CONTROLLER

SHUTDOWN

CONTROL

SEL

SW2

V

REF

LB/SD

L

X

SW1

GND

Figure 4. Simplified ILC6383 block diagram

The two switches now open and close in opposition to each

other, directing the flow of current to either char ge the inductor or to feed the load. The ILC6363 monitors the voltage on

the output capacitor to determine how much and how often

to drive the switches.

PWM Mode Operation

The ILC6363 uses a PWM or Pulse Width Modulation

technique. The switches are constantly driven at typically

300kHz. The control circuitry varies the power being

delivered to the load by varying the on-time, or duty cycle,

of the switch SW1 (see Figure 5). Since more on-time

translates to higher current build-up in the inductor, the

maximum duty cycle of the switch determines the maximum

load current that the device can support. The minimum value

of the duty cycle determines the minimum load current that

can maintain the output voltage within specified values.

There are two key advantages of the PWM type controllers.

First, because the controller automatically varies the duty

cycle of the switch's on-time in response to changing load

conditions, the PWM controller will always have an optimized waveform for a steady-state load. This translates to

very good efficiency at high currents and minimal ripple on

the output. Ripple is due to the output cap constantly accepting and storing the charge received from the inductor, and

delivering charge as required by the load. The “pumping”

action of the switch produces a sawtooth-shaped voltage as

seen by the output.

The other key advantage of the PWM type controllers over

pulse frequency modulated (PFM) types is that the radiated

noise due to the switching transients will always occur at

(fixed) switching frequency. Many applications do not care

much about switching noise, but certain types of applications, especially communication equipment, need to minimize the high frequency interference within their system as

much as possible. Use of the PWM converter in those cases

is desirable.

PFM Mode Operation

For light loads the ILC6363 can be switched to PFM. This

technique conserves power by only switching the output if

the current drain requires it. As shown in the Figure 5, the

waveform actually skips pulses depending on the power

needed by the output. This technique is also called “pulse

skipping” because of this characteristic.

In the ILC6363, the switchover from PWM to PFM mode is

determined by the user to improve efficiency and conserve

power.

The Dual PWM/PFM mode architecture was designed specifically for applications such as wireless communications,

which need the spectral predictability of a PWM-type

DC-DC converter, yet also need the highest efficiencies

possible, especially in Standby mode.

REV. 1.3.5 5/21/02 5

Loading...

Loading...