Page 1

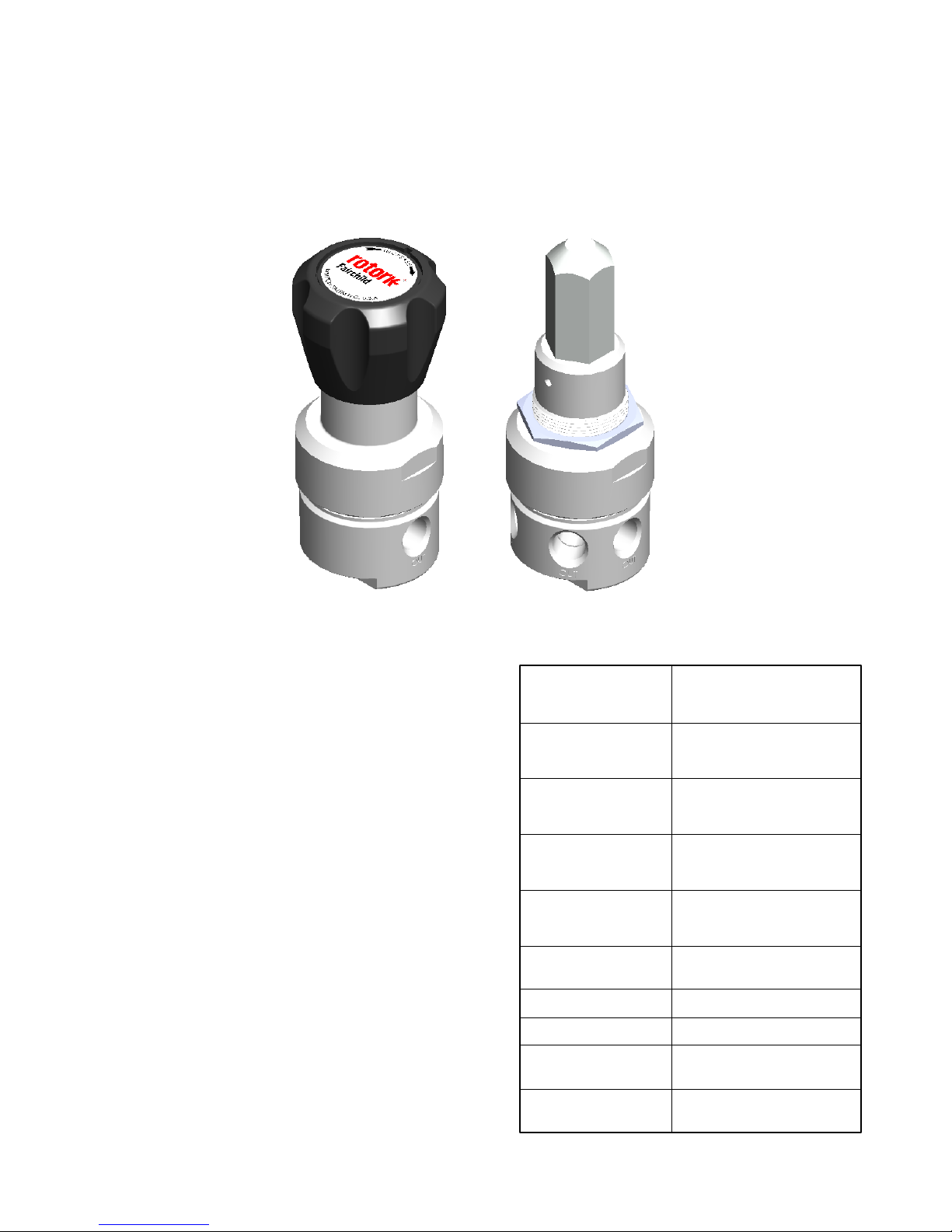

FAIRCHILD MODEL HPD

High Pressure Regulator

Installation, Operation and Maintenance Instructions

Introduction

The Fairchild HPD series pressure regulator is

a precision engineered, diaphragm sensing,

pressure reducing regulator designed to

regulate pressure of speciality gases and

liquids. This single stage,low to medium flow

capacity pressure regulator will fullfil pressure

control requirements in analytical, medical and

laboratory instrumentation. The 316 stainless

steel construction and engineered polymer

seals permit the use of both corrossive and non

corrosive media.

Features

Three polymer seat materials provide

•

media compatility and supply pressure

capability up to 6,000 psig.

Inconel diaphragm for corrosion

•

resistance and long life.

Five outlet pressrue ranges provide

•

optimum sensitivity

20 micron inlet filter

•

0.06 Cv flow coefficient

•

Relieving and non relieving designs

•

Tamperproof adjustment option

•

Table 1. Specifications & Limits

Maximum Supply

Pressure

(Seat Material)

3500 psig

CPTFE

PEEK

Vespel SP-1

Ambient

Temperature Limits

Supply Pressure

Effect

Connection Sizes

Connection Thread

Maximum Cv

Weight

240 Bar

24 MPa

6000 psig

410 Bar

41 MPa

6000 psig

410 Bar

41 MPa

-40º to +200ºF

-40º to +93ºC

< 2% of supply pressure

change

1/4" pipe

NPTF

Supply Valve 0.06

Exhaust Valve 0.02

2.21 lb

1.002kg

1

Page 2

FAIRCHILD MODEL HPD

Pressure Regulator

Installation, Operation and Maintenance Instructions

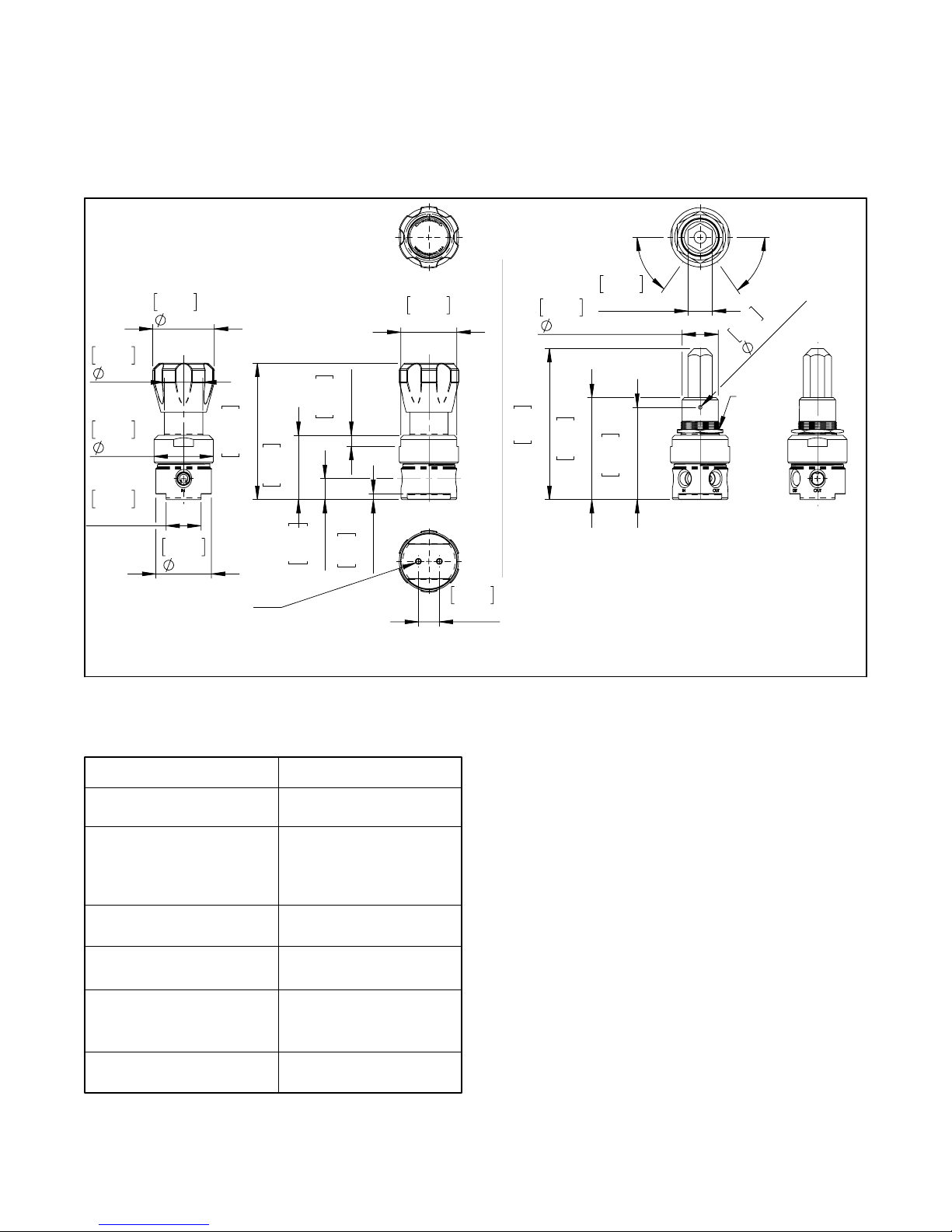

34.8

1.37

53.8

2.12

31.8

1.25

HPD1***A**K*N

1 Inlet & 1 Outlet Port

1/4 NPTF or BSPT

55.9

2.20

4.88

123.9

58.4

2.30

50.5

1.99

HPD1*2N******

2 x 10-32 UNF-2B X 0.36 dp

HPD1*2U******

2 x M5 x 1 X 0.36 dp

19.1

10.2

0.75

0.40

5.5

0.22

Figure 1.

50.8

2.00

Front

Model HPD Outline Dimensions

19.1

0.75

32.8

1.29

137

5.40

92.7

3.65

22.2

0.88

83.8

55°

Hex

3.2

Thread

1 3/8 -18

3.30

Front

HPD1***B**T*P

2 Inlet & 2 Outlet Ports

1/4 NPTF or BSPT

55°

Vent

0.13

Dimensions:

[mm]

inches

Table 2. Material of Construction

Valve Body & Bonnet

Supply & Exhaust Valves

Seats

Diaphragm

Seals

Springs

Supply Valve

Range Spring

External Finish

316 Stainless Steel

316 Stainless Steel

CPTFE

PEEK

Vespel SP-1

Inconel

PTFE

316 Stainless Steel

Music Wire

Passivated

Installation

You can mount the pressure regulator in any

position without affecting it's operation.

Clean all pipe fittings to remove contaminates

before installation.

Apply a minimum amount of pipe compound or

Teflon thread tape to the male threads of the fitting.

Start with the second thread back and work away

from the end of the fitting to avoid thread tape or

compound from contaminating the pressure

regulator.

The Inlet and Outlet are labeled "IN" and "OUT".

Tighten all connections securely. Avoid undersized

fittings that will limit the flow through the pressure

regulator

.

For more information, see Figure 1.

CAUTION

limit the supply pressure from the downstream

piping system. Employ properly sized pressure

limiting device to protect the piping system

downstream of the pressure regulator from the

effects of the supply pressure in the event of a

pressure regulator failure.

- Do not rely on the pressure regulator to

2

Page 3

FAIRCHILD MODEL HPD

Pressure Regulator

Installation, Operation and Maintenance Instructions

Panel Mounting

To panel mount the HPD, the knob must first be removed. To remove the knob, first using a small

screwdriver, pry up the insert in the top to expose the range screw and jam nut. Remove the jam nut and

then unscrew the knob from the range screw. Insert the HPD pressure regulator through the 1 3/8" hole in

the panel and fix it in place with the retaining nut. Reinstall the knob on the range screw and fix it in place

with the jam nut. Reinstall the knob cover

Knob adjustment

The knob on the HPD pressure regulator can be adjusted to limit the range of the output pressure. First

assure the pressure regulator has the intended operating supply pressure applied to the unit. Remove the

cover from the top of the knob and loosen the jam nut on the range screw. Insert a 3/16" hex wrench in the

range screw and adjust the pressure regulator to the desired maximum range. (Note, do not set the

pressure regulator to more than 110% of the rated range.) Adjust the knob so that it stops against the

bonnet. Tighten the jam nut to lock the knob to the range screw. Reinstall the knob cover.

Model

HPD

Analytical

Instrument

Process

Model

HPD

3 Way

Valve

Tank Change

Over System

Model

HPD

3

Page 4

MAINTENANCE

WARNING

Shutting off air supply to the pressure

regulator and adjacent equipment can create

dangerous system conditions.

To service the Model HPD, use the following steps:

Remove the Knob Cap and remove the Nut

1.

holding the Knob in place. Remove the Knob

from the Range Screw.

Remove the Bonnet from the Valve Body.

2.

Remove the Spring Seat, Range Spring and

3.

Diaphragm Assembly from the Valve Body.

Remove the Seat Retainer from the Valve Body.

4.

Remove the Valve , Valve Seat, Spring and

5.

Guide from the Valve Body.

Wash parts with instrument type cleaning

6.

solution, preferable in an ultrasonic cleaner.

Rinse and dry parts before reassembly.

Reassemble in reverse order.

7.

Torque Seat Retainer to 100 in.lb.

Torque Bonnet to 150 ft.lb.

Trouble Shooting

Problem

Leakage

High

Bleed

Source

Bonnet

• Relief Valve

• Supply Valve

• Supply Seat

• Diaphragm

Assembly

Solution

Tighten the Bonnet

• Clean all parts

including Valve

Body.

• If damaged, install

the service kit.

NOTE: If the standard maintenance procedure

does not correct the problem, install the

appropriate Service Kit per table below.

Service Kit Part No. 21916-

* * *

PSIG BAR

Pressure

Range

Seat

Material

Relief

0-25 0-1.7

0-50 0-3.5

1-100 0.07-7.0

2-250 0.15-17.0

PEEK

CTFE

Vespel SP-1

Non-Relieving

Relieving

3

4

5

7

P

T

V

N

R

Cap

Nut

Knob

Option

Bonnet

Range Screw

Spring Seat

Diaphragm

Assembly

Non-Relieving

Option

Spring

Diaphragm

Assembly

Relieving

Option

Seat

Retainer

Valve Seat

Valve

Spring

Guide

Snap

Ring

Spacer

2 Port

Valve Body

Filter

Option

LEGAL NOTICE:

The information set forth in the foregoing

Installation, Operation and Maintenance

Instructions shall not be modified or amended

in any respect without prior written consent of

Fairchild Industrial Products Company. In

addition, the information set forth herein shall

be furnished with each product sold incorporating Fairchild's unit as a component thereof.

Cap

Tamperproof

Option

Nut &

Bonnet

Panel

Mounting

Option

4 Port

Valve

Body

Option

FAIRCHILD INDUSTRIAL PRODUCTS CO.

REGISTERED TO ISO 9001:2008

10002346 QM08

Fairchild Products Company

3920 West Point Blvd. • Winston-Salem, NC 27103

phone: (336) 659-3400 • fax: (336) 659-9323

sales@fairchildproducts.com • www.fairchildproducts.com

IS-10000HPD

Litho in USA

Rev - 10/12

4

Loading...

Loading...