Page 1

FPF2300/02/03

Dual-Output Current Limit Switch

FPF2300/02/03 — Dual-Output Current Limit Switch

June 2009

Features

! 1.8 to 5.5V Input Voltage Range

! Typical R

! 1.3A Current Limit (Typical)

! Slew Rate Controlled

! Reversed Current Blocking when Disabled

! ESD Protected, Above 4000V HBM

! Independent Thermal Shutdown

! UVLO

! RoHS Compliant

= 75mΩ at IN = 5.5V

ON

Applications

! Notebook Computing

! Peripheral USB Ports

! Networking / USB Based Equiptment

Description

The FPF2300/02/03 are dual-channel load switches of

IntelliMAX™ family. The FPF2300/02/03 consist of dual,

independent, current-limited, slew rate controlled, Pchannel MOSFET power switches. Slew rated turn-on

prevents inrush current from glitching supply rails. The

input voltage range operates from 1.8V to 5.5V to fulfill

today's USB device supply requirements. Switch control

is accomplished by a logic input (ON) capable of

interfacing directly with low-voltage control signal.

For the FPF2302, if the constant current condition persists after 10ms, these parts shut down the switch and

pull the fault signal pin (FLAGB) LOW. The FPF2300 has

an auto-restart feature that turns the switch on again

after 504ms if the ON pin is still active. For the FPF2303,

a current limit condition immediately pulls the fault signal

pin LOW and the part remains in the constant-current

mode until the switch current falls below the current limit.

For the FPF2300 through FPF2303, the current limit is

typically 1.3A for each switch to align with notebook

computing applications. FPF2300/02/03 is available in

both SO8 and MLP 3X3mm 8-lead packages.

Figure 1. 8-Lead SOP Figure 2. 8-Lead MLP (3x3mm)

Ordering Information

Eco

Status

Auto

Restart

ON Pin

Activity

Mode Package

Constant

Current

Constant

Current

8-Lead SO8

8-Lead Molded Leadless Package (MLP)

8-Lead Molded Leadless Package (MLP)

8-Lead Molded Leadless Package (MLP)

Minimum

Part Number

Current

Limit

FPF2300MX 1100mA 10ms RoHS 504ms Active LOW Restart 8-Lead SO8

FPF2302MX 1100mA 10ms RoHS N/A Active LOW Latch Off 8-Lead SO8

FPF2303MX 1100mA 0ms RoHS N/A Active LOW

FPF2300MPX 1100mA 10ms Green 504 Active LOW Restart

FPF2302MPX 1100mA 10ms Green N/A Active LOW Latch Off

FPF2303MPX 1100mA 0ms Green N/A Active LOW

For Fairchild’s definition of Eco Status, please visit: http://www.fairchildsemi.com/company/green/rohs_green.html.

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3

Current Limit

Blanking Time

Page 2

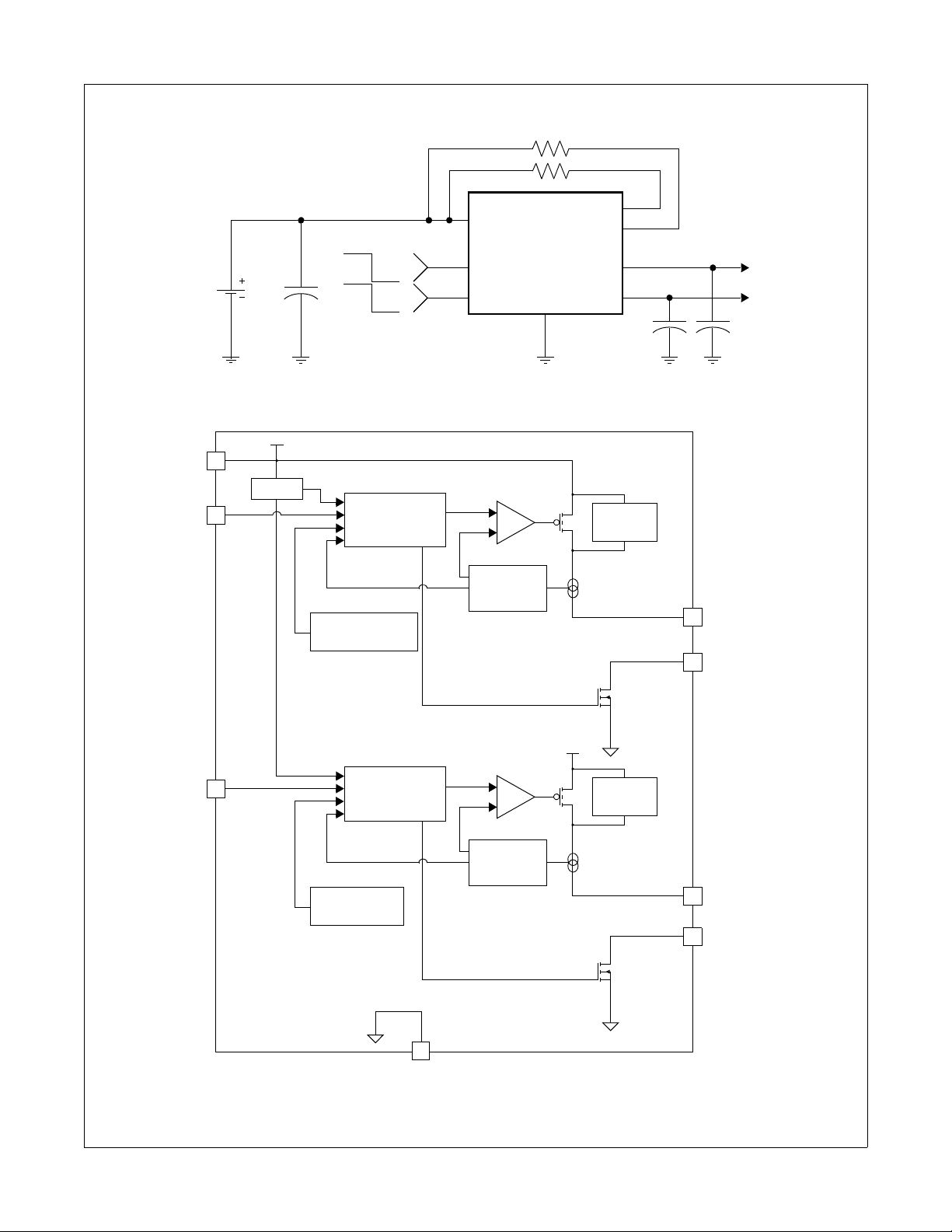

Application Circuit

FPF2300/02/03 — Dual-Output Current Limit Switch

IN = 1.8V-5.5V

C

IN

Functional Block Diagram

IN

UVLO

ONA

PROTECTION A

IN

ONOFF

ONOFF

ONA

ONB

Figure 3. Typical Application

CONTROL

LOGIC A

THERMAL

FPF2300/2/3

GND

CURRENT

LIMIT A

FLAGB(A)

FLAGB(B)

OUTA TO LOAD A

OUTB

REVERSE

CURRENT

BLOCKING

C

OUTB

TO LOAD B

C

OUTA

OUTA

FLAGB(A)

ONB

CONTROL

LOGIC B

THERMAL

PROTECTION B

CURRENT

LIMIT B

REVERSE

CURRENT

BLOCKING

OUTB

FLAGB(B)

GND

Figure 4. Block Diagram

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 2

Page 3

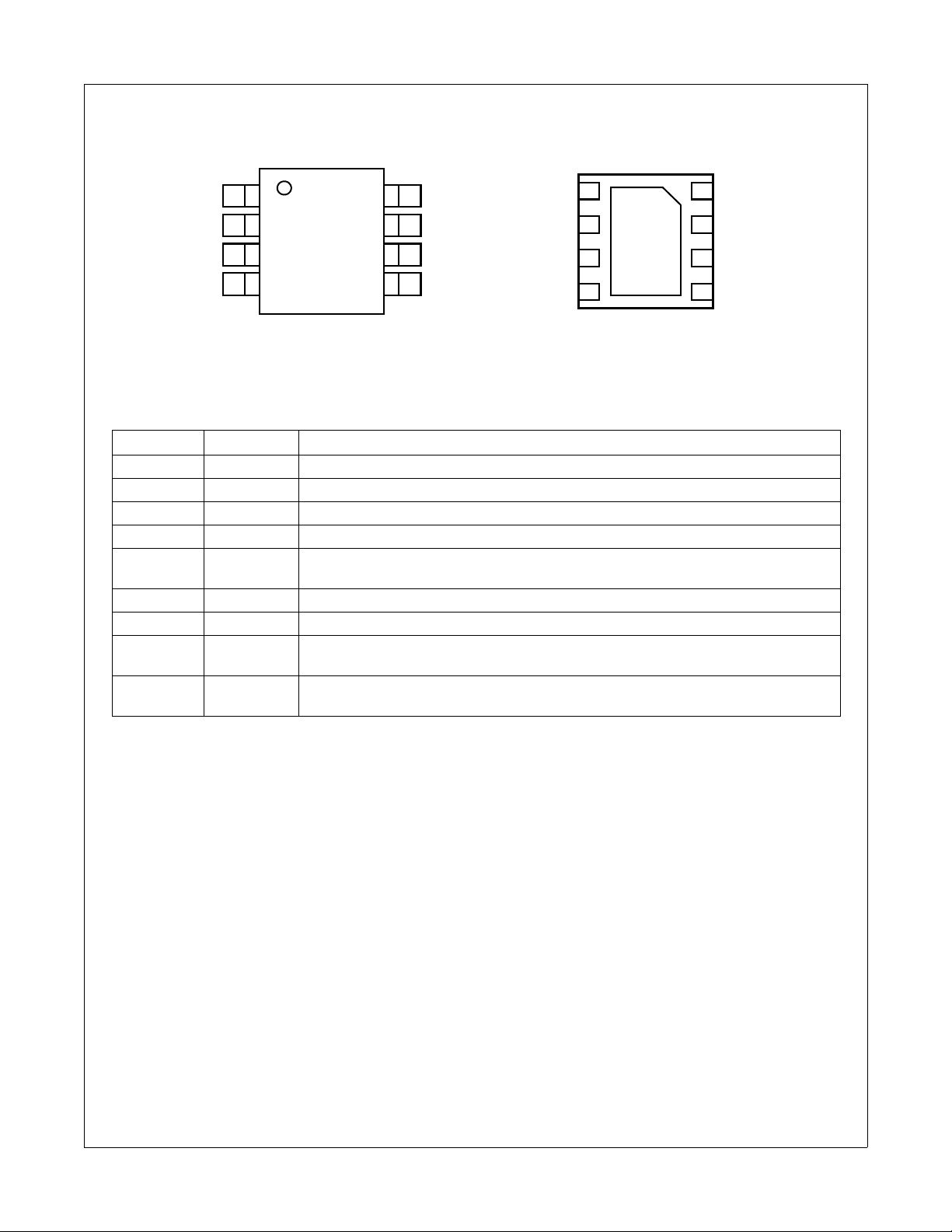

Pin Configuration

FPF2300/02/03 — Dual-Output Current Limit Switch

GND

ONA

ONB

FLAGB(A)

1

IN

2

3

4

SO8

8

OUTA

7

OUTB

6

FLAGB(B)

5

FLAGB(A)

FLAGB(B)

8

OUTA

7

9

63

5

MLP 3X3mm 8-Lead Bottom View

Figure 5. Pin Configurations

Pin Description

Pin # Name Function

1 GND Ground

2 IN Supply Input: Input to the power switch and the supply voltage for the IC.

3 ONA ON / OFF control input of power switch A. Active LOW

4 ONB ON / OFF control input of power switch B. Active LOW

5FLAGB(B)

6 OUTB Switch Output: Output of the power switch B

7 OUTA Switch Output: Output of the power switch A

8FLAGB(A)

9(MLP) Thermal Pad

Fault Output B, Active LO, open drain output which indicates an over supply, UVLO

and thermal shutdown.

Fault Output A, Active LO, open drain output which indicates an over supply, UVLO

and thermal shutdown.

IC Substrate, which can be connected to GND for better thermal performance. Do not

connect to other pins.

GND

1

2

IN

ONAOUTB

4

ONB

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 3

Page 4

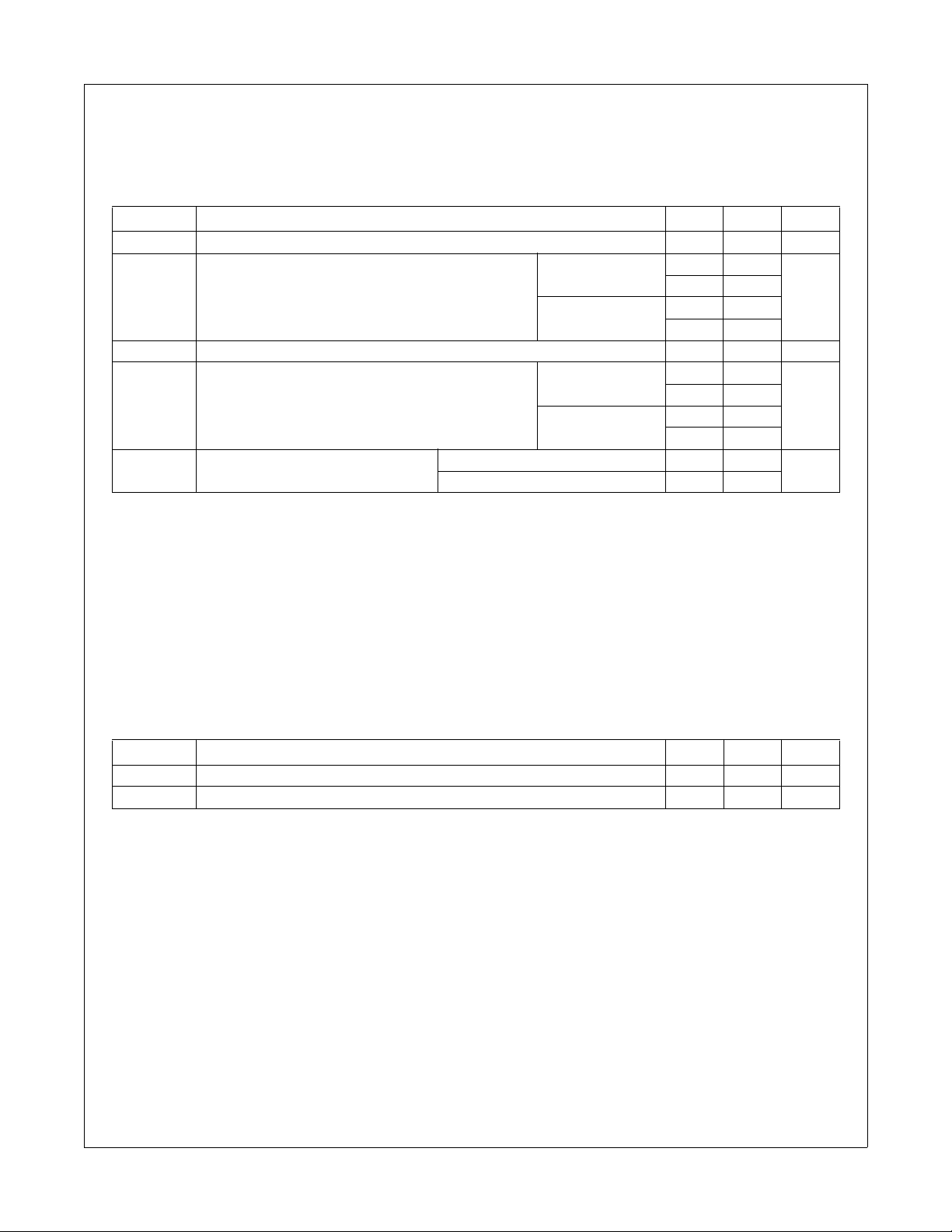

Absolute Maximum Ratings

Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be operable above the recommended operating conditions and stressing the parts to these levels is not recommended. In addition, extended exposure to stresses above the recommended operating conditions may affect device reliability. The

absolute maximum ratings are stress ratings only

Symbol Parameter Min. Max. Unit

IN, OUTA, OUTB, ONA, ONB, FLAGB(A), FLAGB(B) to GND -0.3 6.0 V

P

T

STG

Θ

JA

ESD Electrostatic Discharge Protection

Notes:

1. Two-layer PCB of 2s0p from JEDEC STD 51-3.

2. Four-layer PBD of 2s0p from JEDEC STD 51-7.

3. Soldered thermal pad on a two-layer PCB without vias based on JEDEC STD 51-3.

4. Soldered thermal pad on a four-layer with two vias connected with GND plane base on JEDEC STD 51-5, 7.

Power Dissipation

D

Storage Temperature -65 +150 °C

Thermal Resistance, Junction-to-Ambient

.

SO8

MLP

SO8

MLP

Human Body Model, JESD22-A114 4000

Charged Device Model, JESD22-C101 2000

0.8

1.4

0.6

2.2

158

92

216

57

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

W

°C/W

V

FPF2300/02/03 — Dual-Output Current Limit Switch

Recommended Operating Range

The Recommended Operating Conditions table defines the conditions for actual device operation. Recommended

operating conditions are specified to ensure optimal performance to the datasheet specifications. Fairchild does not

recommend exceeding them or designing to absolute maximum ratings.

Symbol Parameter Min. Max. Unit

IN Supply Input 1.8 5.5 V

T

Ambient Operating Temperature -40 +85 °C

A

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 4

Page 5

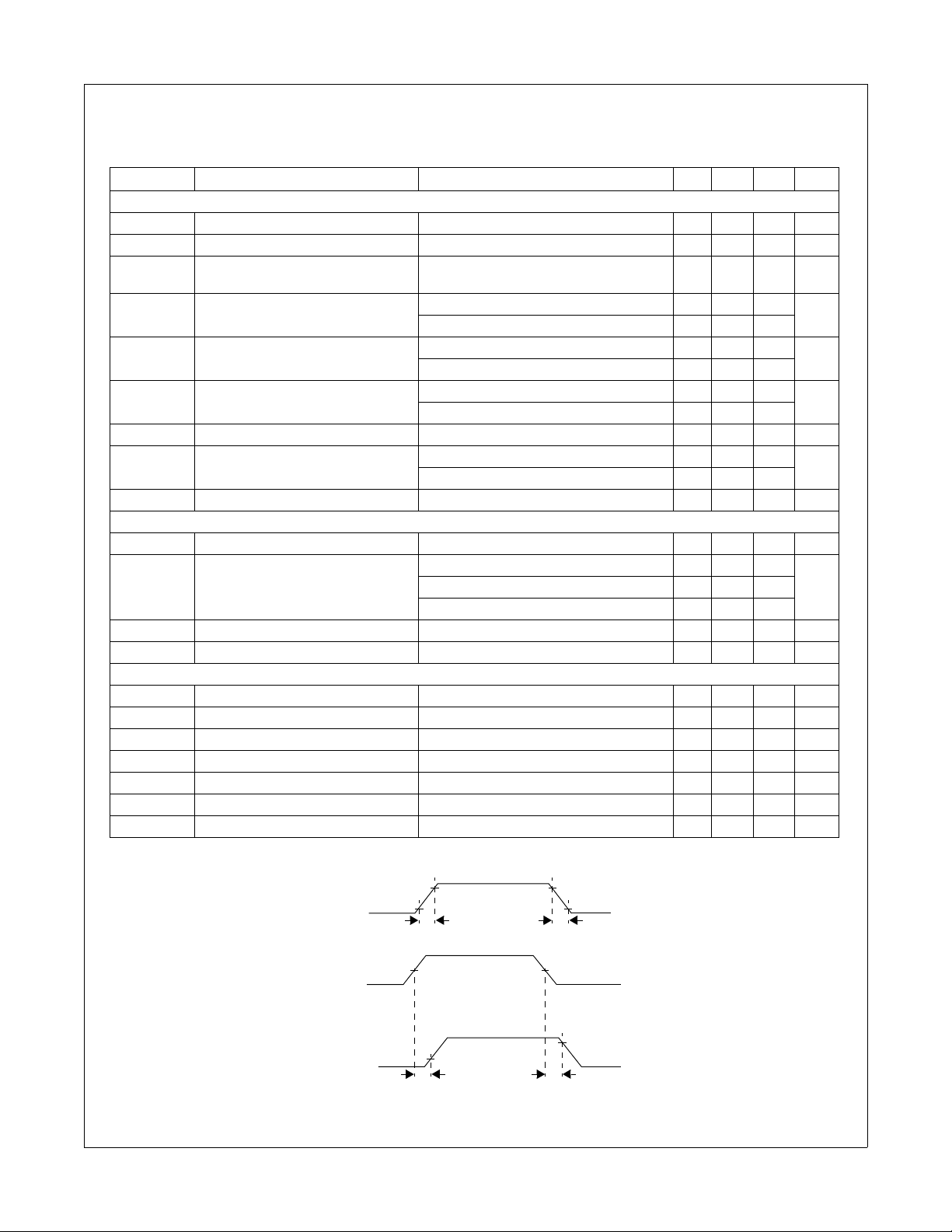

Electrical Characteristics

IN = 1.8 to 5.5V, TA = -40 to +85°C unless otherwise noted. Typical values are at IN = 3.3V and TA = 25°C.

Symbol Parameter Conditions Min. Typ. Max. Units

Basic Operation

V

IN

I

Q

I

SD

R

ON

V

IH

V

IL

I

ON

Protections

I

LIM

TSD Thermal Shutdown

V

UVLO

V

UVLO_HYS

Dynamic

t

ON

t

OFF

t

R

t

BLANK

t

RSTRT_BLANK

t

RSRT

t

CLR

Note:

5. FPF2303 has a 10ms startup FLAGB blanking time when the part is turned on via the ON pin to ensure transient load currents settle.

Operating Voltage 1.8 5.5 V

Quiescent Current IN = 5.5V, V

V

= V

IN Shutdown Current

On Resistance

ON Input Logic High Voltage (ON)

ON Input Logic Low Voltage

ONA

OUTA = OUTB = Short to GND,

IN = 5.5V, I

IN = 5.5V, I

IN = 1.8V 0.8

IN = 5.5V 1.4

IN = 1.8V 0.5

IN = 5.5V 0.9

= V

ONA

= 5.5V, IN = 5.5V

ONB

= 200mA, TA = 25°C 75 140

OUT

= 200mA, TA = -40°C to 85°C 90

OUT

ONB

= 0V, I

= 0mA 52.5 94.5 μA

OUT

3 μA

mΩ

V

V

ON Input Leakage VON = IN or GND -1 1 μA

FLAGB Output Logic Low Voltage

FLAGB Output High Leakage Current IN = V

IN = 5.5V, I

IN = 1.8V, I

ON

Current Limit IN = 3.3V, V

= 1mA 0.1 0.2

SINK

= 1mA 0.15 0.30

SINK

= 5V 1 μA

OUTA

= V

= 3V, TA = 25°C 1.1 1.3 1.5 A

OUTB

V

Shutdown Threshold 140

°CReturn from Shutdown 130

Hysteresis 10

Under-Voltage Shutdown IN Increasing 1.55 1.65 1.75 V

Under-Voltage Shutdown Hysteresis 50 mV

Turn-On Time RL = 500Ω, CL = 0.1μF 113.5 μs

Turn-Off Time RL = 500Ω 6 μs

OUTA, OUTB Rise Time RL = 500Ω, CL = 0.1μF13.5μs

Over-Current Blanking Time FPF2300, FPF2302 5 10 20 ms

Startup FLAGB Blanking Time FPF2303

(5)

51020ms

Auto-Restart Time FPF2300 504 ms

Current Limit Response Time IN = 3.3V, Moderate Over-Current Condition 20 μs

OUT

10%

90%

t

R

90%

10%

t

F

FPF2300/02/03 — Dual-Output Current Limit Switch

ON

OUT

50% 50%

10%

t

DON

t

ON

= tR + t

DON

t

OFF

= tF + t

t

DOFF

90%

DOFF

Figure 6. Timing Diagram

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 5

Page 6

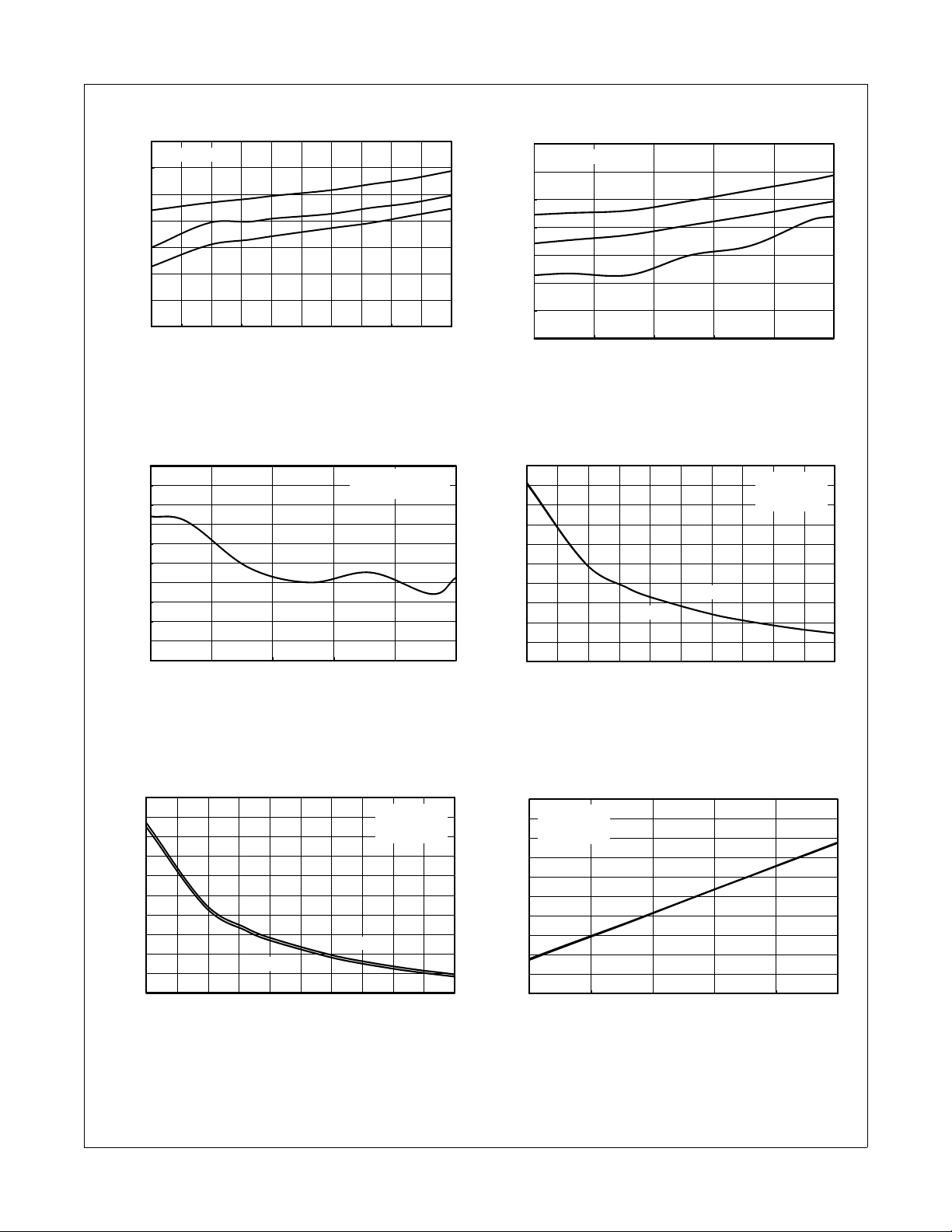

Typical Characteristics

5

)

SUPPLY

CURRENT

(

A)

85°C

C

5

5

)

V

5

5

)

5

A

70.00

ONA = ONB = 0V

60.00

u

50.00

40.00

30.00

20.00

10.00

0.00

1.8 2. 2 2.5 2. 9 3.3 3. 7 4.0 4. 4 4.8 5.1 5.

SUPPLY VOLTAGE (V

25°C

-40°

Figure 7. Quiescent Current vs. Supply Voltage Figure 8. Quiescent Current vs. Temperature

70.00

ONA = ONB = 0V

60.00

50.00

IN = 5.5V

40.00

IN = 3.3V

IN = 1.8V

CURRENT (uA)

Q

I

30.00

20.00

10.00

0.00

-40 -15 10 35 60 8

TJ, JUNCTI ON TEMPERATURE ( °C)

FPF2300/02/03 — Dual-Output Current Limit Switch

5.00

4.50

IN = ONA = ONB = 5.5V

OUT = 0 V

4.00

3.50

3.00

2.50

2.00

1.50

1.00

IN SHUTDOWN CURRENT (uA)

0.50

0.00

-40 -15 10 35 60 8

TJ, J UNCTION TEMPERATURE (° C)

Figure 9. IN Shutdown Current vs. Temperature

160

150

140

130

120

110

100

90

80

ON RESISTANCE (mOhms)

70

R

A

ON

60

1.82.22.52.93.33.74.04.44.85.15.

SUPPLY VOLTAGE (V

R

B

ON

ONA = ONB = 0

I

= 200mA

OUT

T

= 25°C

A

160

150

140

ONA = ONB = 0V

I

= 200mA

OUT

T

= 25°C

A

130

120

110

100

90

80

ON RESISTANCE (mOhms)

R

R

B

ON

A

ON

70

60

1.82.22.52.93.33.74.04.44.85.15.

SUPPLY VOLTAGE (V

Figure 10. RON vs. Supply Voltage (MLP)

100

IN = 5.5V

95

I

= 200mA

OUT

ONA = ONB = 0V

90

85

80

75

70

65

60

ON RESISTANCE ( mOhm)

55

50

-40 -15 10 35 60 8

TJ, JUNCTION TEMPERATURE (°C)

R

B

ON

R

ON

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

Figure 11. RON vs. Temperature (SO8) Figure 12. R

vs. Temperature (MLP)

ON

FPF2300/02/03 • Rev. 1.1.3 6

Page 7

Typical Characteristics

5

A

5

)

L

5

5

5

)

5

A

B

FPF2300/02/03 — Dual-Output Current Limit Switch

90

IN = 5.5V

I

= 200mA

OUT

85

ONA = ONB = 0V

80

75

70

65

60

ON RESISTANCE ( mOhm)

55

50

-40 - 15 10 35 60 8

TJ, JUNCTI ON TEMPERATURE ( °C)

R

B

ON

R

ON

1.5

TA = 25°C

1.3

V

1.0

0.8

0.5

0.3

ON THRESHOLD VOLTAGE (V)

0.0

1.8 2.2 2. 5 2. 9 3.3 3.7 4. 0 4.4 4.8 5. 1 5.

I

V

IH

SUPPLY VOLTAGE (V

Figure 13. RON vs. Temperature (SO8) Figure 14. ON Threshold Voltage vs. Supply Voltage

1.2

IN = 5.5V

1.0

IN = 3.3V

0.8

IN = 1.8V

0.6

0.4

1.2

IN = 5.5V

1.0

0.8

0.6

0.4

IN = 3.3V

IN = 1.8V

0.2

ON THRESHOLD VOLTAGE ( V)

0.0

-40 -15 10 35 60 8

TJ, JUNCTION TEMPERATURE (°C)

Figure 15. ON High Voltage vs. Temperature

1350

TA = 25°C

1340

1330

1320

1310

1300

1290

1280

CURRENT LIMI T (mA)

1270

1260

1250

1.8 2.2 2.5 2.9 3.3 3.7 4.0 4.4 4.8 5.1 5.

ILIM(Typ)A

ILIM(Typ)B

SUPPLY VOLTAGE (V

0.2

ON THRESHOLD VOLTAGE ( V)

0.0

-40 - 15 10 35 60 8

TJ, JUNCTI ON TEMPERATURE ( °C)

Figure 16. ON Low Voltage vs. Temperature

1350

IN = 3.3V

1340

OUTA = OUTB = 3V

ONA = ONB = 0V

1330

1320

1310

1300

1290

1280

CURRENT LIMI T (mA)

1270

1260

1250

-40 - 15 10 35 60 8

ILIM(Typ)

ILIM(Typ)

TJ, JUNCTION TEMPERATURE (°C)

Figure 17. Current Limit vs. Supply Voltage Figure 18. Current Limit vs. Temperature

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 7

Page 8

Typical Characteristics

5

s

s

5

s

s

5

V

5

)

V

5

V

FPF2300/02/03 — Dual-Output Current Limit Switch

1000

IN = 3.3V

t

DON

100

10

t

DOFF

TURN ON/OFF DELAY TIME (us)

1

-40 - 15 10 35 60 8

TJ, JUNCTION TEMPERATURE (°C)

Figure 19. t

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

OVER CURRENT BLANKING TIME (ms)

7.0

-40 - 15 10 35 60 8

/ t

DON

TJ, J UNCTION TEMPERATURE (° C)

vs. Temperature Figure 20. t

DOFF

FLAGB( B)

FLAGB( A)

R

CL = 0.1 uF

IN = 3.3V

R

FPF2300/ 2

IN = 3.3V

ONA = ONB = 0

= 500 Ohm

L

= 500 Ohm

L

20

18

16

14

12

10

8

6

RISE/FALL TIME (us)

4

2

0

-40 - 15 10 35 60 8

TJ, JUNCTION TEMPERATURE (°C)

RISE

10.0

9.5

9.0

8.5

8.0

7.5

STARTUP FLAGB BLANKI NG TIME ( ms)

7.0

-40 - 15 10 35 60 8

TJ, J UNCTION TEMPERATURE (° C)

t

R

t

F

/ t

vs. Temperature

FAL L

FLAGB( A

FLAGB( B)

IN = 3.3V

R

= 500 Ohm

L

CL = 0.1 uF

IN = 3.3V

R

= 500 Ohm

L

FPF2303

IN = 3.3V

ONA = ONB = 0

620.0

600.0

vs. Temperature

BLANK

FPF2300

IN = 3.3V

ONA = ONB = 0

Figure 22. t

IN

RSTRT_BLANK

vs. TemperatureFigure 21. t

2V/DIV

580.0

560.0

540.0

RESTART TIME (ms)

520.0

500.0

-40 -15 10 35 60 8

TJ, J UNCTION TEMPERATURE (° C)

Figure 23. t

OUTA

OUTB

vs. Temperature Figure 24. tON Response

RSTRT

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 8

ON

2V/DIV

OUT

2V/DIV

IN = 5V

ON = 3.3V

C

= 0.1μF

OUT

R

= 500Ω

L

200μs/DIV

Page 9

Typical Characteristics

IN

2V/DIV

ON

2V/DIV

t

BLANK

IN = 5V

C

OUT

R

= 2.8Ω

L

FPF2300/02/03 — Dual-Output Current Limit Switch

= 10μF

ON

2V/DIV

IN = 5V

OUT

2V/DIV

ON = 3.3V

C

= 0.1μF

OUT

R

= 500Ω

L

200μs/DIV

ON

2V/DIV

Figure 25. t

t

Response Figure 26. Over-Current Blanking Time (FPF2300/2)

OFF

C

= 10μF

OUT

R

= 3.3Ω

L

START_BLANK

FLAGB

2V/DIV

I

OUT

1A/DIV

OUT

2V/DIV

2ms/DIV

Figure 27. Startup FLAGB Blanking Time (FPF2303)

FLAGB

2V/DIV

I

OUT

1A/DIV

OUT

5V/DIV

2ms/DIV

ON

2V/DIV

t

RSTRT

FLAGB

2V/DIV

I

OUT

1A/DIV

OUT

5V/DIV

100ms/DIV

Figure 28. Auto-Restart Time (FPF2300)

IN = 5V

C

= 10μF

OUT

R

= 2.8Ω

L

IN

5V/DIV

ON

5V/DIV

I

OUT

1A/DIV

C

OUT

= 47μF

C

OUT

= 100μF

C

C

OUT

OUT

IN = 5V

ON = 3.3V

R

= 5Ω

L

= 470μF

= 220μF

200μs/DIV

Figure 29. Current Limit at Startup with

Different Output Capacitor

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 9

IN

5V/DIV

ON

5V/DIV

OUT

5V/DIV

= 47μFC

OUT

C

= 100μFC

OUT

OUT

= 220μF

OUT

C

200μs/DIV

Figure 30. Output Voltage at Startup with

Different Output Capacitor

IN = 5V

ON = 3.3V

R

= 5Ω

L

= 470μF

Page 10

Typical Characteristics

FPF2300/02/03 — Dual-Output Current Limit Switch

IN

5V/DIV

ON

2V/DIV

IN = 5V

ON = 3.3V

C

OUTA

C

OUTB

R

= RLB = 1Ω

LA

OUTA

2V/DIV

OUTB

2V/DIV

400μs/DIV

Figure 31. Current Limit Response Time Both

Channels are in OC

IN

5V/DIV

ON

5V/DIV

I

OUT

500mA/DIV

IN = 5V

C

OUT

C

= 470μF

L

R

= 5Ω

L

= 100μF

= 100μF

= 47μF

IN

5V/DIV

ON

2V/DIV

FLAGB(A)

2V/DIV

FLAGB(B)

2V/DIV

10ms/DIV

Figure 32. Startup FLAGB Blanking Time

IN

5V/DIV

ON

5V/DIV

I

OUT

2A/DIV

IN = 5V

ON = 3.3V

C

= 100μF

OUTA

C

= 100μF

OUTB

R

= RLB = 1Ω

LA

IN = 5V

C

= 10μF

IN

C

= 100μF

OUT

C

= 47μF

L

OUT

5V/DIV

1ms/DIV

Figure 33. Inrush Response During Capacitive Load

Hot Plug-In Event

OUT

5V/DIV

200μs/DIV

Figure 34. Inrush Response During Capacitive and

Resistive Load Hot Plug-In Event

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 10

Page 11

Description of Operation

The FPF2300, FPF2302, and FPF2303 are dual-output currentlimit switches designed to meet notebook computer, peripheral

USB port, and point-of-load (POL) application power requirements.

Dual-output current can be used where dual or quad USB ports are

powered by hosts or self-powered hubs. The FPF230X family

offers control and protection while providing optimum operation

current for a safe design practice. The core of each switch is a

typical 75mΩ (IN = 5.5V) P-channel MOSFET and a controller

capable of functioning over an input operating range of 1.8-5.5V.

The FPF230X family offers current limiting, UVLO (under-voltage

lockout), and thermal shutdown protection per each switch. In the

event of an over-current condition, the load switch limits the load to

current limit value. The minimum current limit is set to 1100mA.

On/Off Control

The ON pin is active LOW for FPF2300/2/3 and controls the state

of the switch. Pulling the ON pin continuous to LOW holds the

switch in the ON state. The switch moves into the OFF state when

the ON pin is pulled HIGH or if a fault is encountered. For all

versions, an under-voltage on input voltage or a junction

temperature in excess of 140°C overrides the ON control to turn off

the switch. In addition, excessive currents cause the switch to turn

off in the FPF2300 and FPF2302 after a 10ms blanking time. The

FPF2300 has an auto-restart feature that automatically turns the

switch ON again after 504ms. For the FPF2302, the ON pin must

be toggled to turn on the switch again. The FPF2303 does not turn

off in response to an over-current condition, but remains operating

in a constant-current mode as long as ON is enabled and the

thermal shutdown or UVLO is not activated. The ON pin does not

have a pull-down or pull-up resistor and should not be left floating.

Current Limiting

The current limit ensures that the current through the switch

doesn't exceed a maximum value, while not limiting at less than a

minimum value. FPF230X family has dual-output load switches

being housed in one package. The minimum current at which both

switches start limiting the load current is set to 1100mA. The

FPF2300 and FPF2302 have a blanking time of 10ms (typical),

during which the switch acts as a constant current source. At the

end of the blanking time, the switch is turned off. The FPF2303 has

no current limit blanking period, so it remains in a constant current

state until the ON pin of the affected switch is deactivated or the

thermal shutdown turns off the switch.

Fault Reporting

Over-current, input under-voltage, and over-temperature fault

conditions are signaled out by the FLAGB pin going LOW. A UVLO

fault is reported on both FLAGB(A) and FLAGB(B) simultaneously,

while over-current and over-temperature condition faults are

reported independently. FPF2300 and FPF2302 have a current

fault blanking feature that prevents over-current faults shorter than

the blanking time (t

signal (FLAGB) output.

BLANK(Typ)

If the over-current condition persists beyond the blanking time, the

FPF2300 pulls the FLAGB pin LOW and shuts the switch off. If the

ON pin is kept active, an auto-restart feature releases the FLAGB

pin and turns the switch on again after a 504ms auto-restart time

(t

). If the over-current condition persists beyond the blanking

RSTRT

time, the FPF2302 has a latch-off feature that pulls the FLAGB pin

LOW and shuts the switch off. The switch is kept off and the

FLAGB pin kept LOW until the ON pin is toggled. The FPF2303

responds to an overload condition by immediately pulling the

FLAGB pin LOW and the switch remains in constant current mode

until the output overload condition is removed. The FPF2303 has a

= 10ms) from triggering the fault

startup blanking feature that prevents current faults related to startup transients from triggering the FLAGB output. The startup blanking feature is effective for the first 10ms (typical) following device

turn-on via ON pin.

The FLAGB outputs are two open-drain MOSFETs that require a

pull-up resistor on each FLAGB pin. FLAGB can be pulled HIGH to

a voltage source other than input supply with maximum 5.5V. A

100KΩ pull-up resistor is recommended. When the ON pin is inactive, the FLAGB is disabled to reduce current draw from the supply.

If the FLAGB is not used, the FLAGB can be connected to ground

on the PCB.

.

ON

device wakeup

IN

device wakeup

FLAGB

RISE

TIME

90% V

OUT

I

LOAD

Figure 35. FLAGB Assertion in Under-Voltage Fault

10% V

I

LIMIT

OUT

OUT

ON

VIN

VOUT

ILOAD

Over

current

condt ion

FLAGB

tBLANK

RL*

ILMIT

ILIMIT

tRSTRT

Figure 36. FPF2300 FLAGB Reports While Entering

into an Over-Current Condition

Note:

6. An over-current condition signal loads the output with a

heavy load current larger than I

LIM

value.

FPF2300/02/03 — Dual-Output Current Limit Switch

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 11

Page 12

FPF2300/02/03 — Dual-Output Current Limit Switch

ON

VIN

VOUT

ILOAD

ILIMIT

Over

current

condtion

FLAGB

Start up

tBLANK

Thermal Shutdown

Device Cools Off

Figure 37. FPF2300 FLAGB While and Over-Current

Condition is Applied

Note:

7. An over-current condition signal loads the output with a

heavy load current larger than I

LIMIT

value.

Under-Voltage Lockout (UVLO)

The under-voltage lockout feature turns off the switch if the

input voltage drops below the under-voltage lockout threshold.

With the ON pin active (ON pin pulled LOW), the input voltage

rising above the under-voltage lockout threshold causes a

controlled turn-on of the switch and limits current overshoot. If a

device is in UVLO condition, both FLAGBs go LOW and indicate

the fault condition. The device detects the UVLO condition when

input voltage goes below UVLO voltage, but remains above

1.3V (typical).

Reverse Current Blocking

Each switch of FPF2300/2/3 has an independent reverse

current blocking feature that protects input source against

current flow from output to input. For a standard USB power

design, this is an important feature that protects the USB host

from being damaged due to reverse current flow on V

activate the reverse current blocking, the switch must be in OFF

BUS

. To

state (ON pins inactivated) so that no current flows from the

output to the input. The FLAGB operation is independent of the

reverse current blocking and does not report a fault condition if

this feature is activated.

Thermal Shutdown

The thermal shutdown protects the device from internally or

externally generated excessive temperatures. Each switch has

an individual thermal shutdown protection function and operates

independently as adjacent switch temperatures increase above

140°C. If one switch is in normal operation and shutdown

protection of second switch is activated, the first channel

continues to operate if the affected channel's heat stays

confined. The over-temperature in one channel can shut down

both switches due to rapidly generated excessive load currents

resulting in very high power dissipation. Generally, a thermally

improved board layout can provide heat sinking and allow heat

to stay confined and not affect the second switch operation.

During an over-temperature condition, the FLAGB is pulled

LOW and the affected switch is turned off. If the temperature of

the die drops below the threshold temperature, the switch

automatically turns on again. To avoid unwanted thermal

oscillations, a 10°C (typical) thermal hysteresis is implemented

between thermal shutdown entry and exit temperatures.

If output of both switches are connected together and an

excessive load current activates thermal protection of both, the

controller can shut down the switches after both FLAGB outputs

go LOW and turn on both channels again. This provides

simultaneous switch turn on. Thermal protection is for device

protection and should not be used as regular operation.

Input Capacitor

To limit the voltage drop on the input supply caused by transient

inrush currents when the switch is turned on into discharged

load capacitors or a short-circuit; an input capacitor, C

recommended between IN and GND. The FPF2310/2/3/3L

, is

IN

features a fast current limit response time of 20μs. An inrush

current (also known as surge current) could occur during the

current limit response time while the switch is responding to an

over-current condition caused by large output capacitors. A

10μF ceramic capacitor, C

the inrush current and prevent input voltage drop at turn on.

Higher values of C

IN

, is required to provide charges for

IN

can be used to further reduce voltage drop.

Output Capacitor

A 0.1μF to 1μF capacitor, C

OUT and GND pins. This capacitor prevents parasitic board

inductances from forcing output voltage below GND when the

switch turns off. This capacitor should have a low dissipation

factor. An X7R MLCC (Multilayer Ceramic Chip) capacitors is

recommended.

For the FPF2300 and FPF2302, the total output capacitance

needs to be kept below a maximum value, C

prevent the part from registering an over-current condition

beyond the blanking time and shutdown. The maximum output

capacitance for a giving input voltage can be determined from

the following:

C

OUT(MAX)

For example, in a 5V application, C

as:

C

OUT(MAX)(IN = 5V)

, should be placed between the

OUT

I

x t

=

LIM(MIN)

BLANK(MIN)

V

IN

OUT(MAX)

can be determined

1.1A x 5ms

=

1.1mF

=

5

OUT(MAX)

, to

(1)

(2)

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 12

Page 13

Application Information

FPF2300/02/03 — Dual-Output Current Limit Switch

Host

IN

5V

1μF

FPF230X is designed to simplify USB port power design based

on self-powering USB host/hub applications. A self-powering

USB port is powered by a local 5V power supply, not by an

upstream port. Each port should supply at least 500mA to each

downstream function based on USB 2.0 specification. Implementation can depend on the number of USB ports and current

OFF ON ONA

OFF ON ONB OUTB

Figure 38. Self Powered 4-Port USB Hub Using a Single FPF230X

10KΩ

10KΩ

FLAGB(A)

FLAGB(B)

33μF

33μF

Downstream

USB Port

Downstream

USB Port

FPF2300/2/3

OUTA

GND

33μF

33μF

capability per port required in actual power designs. FPF230X

has 1.1A minimum current limit per output, which can cover two

ports, as shown in Figure 38. Four USB ports can be implemented with a single FPF230X part and current limiting is provided based on a two-port basis for a cost-effective solution.

10KΩ

10KΩ

Downstream

USB Port

Downstream

USB Port

Host

5V

1μF

1μF

Figure 39. Individual Port Power Management for Self-Powered 4-Port USB Hub

In Figure 39, each USB port is connected with each output.

Four USB ports can be implemented with two FPF230X parts.

Current limiting and control are provided based on a single port.

OFF ON ONA

OFF ON ONB OUTB

OFF ON ONA

OFF ON ONB OUTB

IN

FLAGB(A)

FLAGB(B)

33μF

Downstream

USB Port

FPF2300/2/3

OUTA

Downstream

USB Port

Downstream

USB Port

IN

GND

10KΩ

10KΩ

FLAGB(A)

FLAGB(B)

33μF

33μF

FPF2300/2/3

OUTA

GND

33μF

Current capability per port has more headroom; up to a minimum of 1.1A per port.

Downstream

USB Port

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 13

Page 14

10KΩ

10KΩ

FPF2300/02/03 — Dual-Output Current Limit Switch

Host

IN

5V

1μF

High current, over 2A, is sometimes required to supply enough

power to downstream functions. As shown in Figure 40, a 2.2A

OFF ON ONA

OFF ON ONB OUTB

Figure 40. Self-Powered USB Port for High Current Demand

Power Dissipation

During normal operation as a switch, the power dissipation of

the device is small and has little effect on the operating

temperature of the part. The maximum power dissipation for

both switches while the switch is in normal operation occurs just

before both channels enter into current limit. This may be

calculated using the formula:

P

D_MAX(Normal Operation)

For example, for a 5V application, maximum normal operation

power loss while both switches delivering output current up to

1.1A, can be calculated as:

P

D_MAX(Normal Operation)(IN = 5V)

The maximum junction temperature should be limited to 125°C

under normal operation. Junction temperature can be calculated using the formula below:

T

= PD x R

J

θJA

where:

T

is junction temperature;

J

P

is power dissipation across the switch;

D

R

is thermal resistance junction to ambient of the package;

θJA

T

is ambient temperature.

A

For the example, T

with T

=25°C while both switches are delivering up to 1.1A is

A

calculated as:

T

J(MAX)(NormalOperation)

= P

D_MAX(Normal Operation)(IN = 5V)

= 78.4°C

= 2 x (I

LIM(MIN)

= 2 x (1.1)2 x 0.14

=

+ T

A

J(MAX)(Normal operation)

)2 x R

ON(MAX)

(3)

(4)

338mW

(5)

for an SO8 package

x 125 + 25

(6)

FLAGB(A)

FLAGB(B)

FPF2300/2/3

OUTA

GND

33μF

minimum load current can be achieved by tying dual outputs

together.

If the part goes into current limit, the maximum power

dissipation occurs when the output of switch is shorted to

ground. For the FPF2300 the power dissipation scales with the

auto-restart time, t

t

. In this case, the maximum power dissipated for the

BLANK

FPF2300 is::

P

D_MAX(CurrentLimit)

, and the over-current blanking time,

RSTRT

t

t

BLANK

BLANK

+ t

=

2 x x IN

which results in:

P

D_MAX(CurrentLimit)

=

10 + 504

10

2 x

Note that this is below the maximum package power dissipation

and the thermal shutdown feature protection provides additional

safety to protect the part from damage due to excessive

heating. The junction temperature is only able to increase to the

thermal shutdown threshold. Once this temperature has been

reached, toggling ON has no affect until the junction

temperature drops below the thermal shutdown exit

temperature. For the FPF2303, a short on both outputs causes

both switches to operate in a constant current state and

dissipate a worst-case power of:

MAX

= 2 x IN

(MAX)

x I

LIM(MAX)

= 2 x 5.5 x1.5 = 16.5 W

As both FPF2303 outputs are connected to GND.

This power dissipation is significant and activates both thermal

shutdown blocks and the part can cycle in and out of thermal

shutdown as long as the ON pin is activated (pulled LOW) and

the output short is present.

Downstream

USB Port

RSTRT

(MAX)

x 5.5 x 1.5 = 321mW

x I

LIM(MAX)

(7)

(8)

(9)P

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 14

Page 15

PCB Layout Recommendations

For the best performance, all traces should be as short as

possible. To be most effective, the input and output capacitors

should be placed close to the device to minimize the effects that

parasitic trace inductances may have on normal and shortcircuit operation. Using wide traces for IN, OUTs, and GND pins

helps minimize parasitic electrical effects and the case-toambient thermal impedance.

Improving Thermal Performance

Improper layout could result in higher junction temperature and

triggering the thermal shutdown protection feature. This concern

is particularly significant for the FPF2303, where both channels

operate in constant current mode in the overload conditions and

during fault condition the outputs are shorted, resulting in large

voltage drop across switches. In this case, power dissipation of

the switch (P

maximum absolute power dissipation of part.

The following techniques improve the thermal performance of

this family of devices. These techniques are listed in order of

the significance of impact.

1. Thermal performance of the load switch can be improved

by connecting the DAP (Die Attach Pad) of MLP 3x3mm

package to the GND plane of the PCB.

2. Embedding two exposed through-hole vias into the DAP

(pin 9) provides a path for heat to transfer to the back GND

plane of the PCB. A drill size of round, 15 mils (0.4mm),

with 1-ounce copper plating is recommended to create

appropriate solder reflow. A smaller size hole prevents the

solder from penetrating into the via, resulting in device liftup. Similarly, a larger via hole consumes excessive solder

and may result in voiding of the DAP.

= (VIN - V

D

OUT

) x I

) could exceed the

LIM(MAX)

FPF2300/02/03 — Dual-Output Current Limit Switch

Figure 42. Proper Layout of Output and Ground

Copper Area

15mil

25mil

Figure 41. Two Through-Hole Open Vias Embedded

in DAP

3. The IN, OUTs, and GND pins dissipate most of the heat

generated during a high load current condition. Figure 42

illustrates a proper layout for devices in MLP 3x3mm

packages. IN, OUTs, and GND pins are connected to

adequate copper so heat may be transferred as efficiently

as possible out of the device. The low-power FLAGB and

ON pin traces may be laid out diagonally from the device to

maximize the area available to the ground pad. Placing the

input and output capacitors as close to the device as

possible also contributes to heat dissipation, particularly

during high load currents.

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 15

Page 16

FPF230X Evaluation Board

The FPF230X evaluation board has components and circuitry to

demonstrate FPF2300/2/3 load switch functions and features,

accommodating both the MLP 3x3mm and SO8 packages. The

state of the each channel can be configured using J1 and J2

jumpers. In addition, both channels can be controlled by ONA

and ONB test pints. Thermal performance of the board is

improved using techniques in the layout recommendations

section. R3 and R4 resistors are used on the board to sink a

light load current when switches are activated.

FPF2300/02/03 — Dual-Output Current Limit Switch

Figure 44. Bottom and ASB Layers

Figure 43. Top, SST and AST Layers

(MLP 3x3mm and SO8)

Figure 45. Zoom-In to Top Layer

Releated Resources

FPF2300/02/03 Evaluation Board User Guide; Power Switch for USB Applications

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 16

Page 17

Dimensional Outline and Pad Layout

FPF2300/02/03 — Dual-Output Current Limit Switch

Figure 46. 8-Lead SO8 Package

Package drawings are provided as a service to customers considering Fairchild components. Drawings may change in any manner

without notice. Please note the revision and/or date on the drawing and contact a Fairchild Semiconductor representative to verify or

obtain the most recent revision. Package specifications do not expand the terms of Fairchild’s worldwide terms and conditions,

specifically the warranty therein, which covers Fairchild products.

Always visit Fairchild Semiconductor’s online packaging area for the most recent package drawings:

http://www.fairchildsemi.com/packaging/

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 17

.

Page 18

Dimensional Outline and Pad Layout

FPF2300/02/03 — Dual-Output Current Limit Switch

Figure 47. 8-Lead Molded Leadless Package (MLP)

Package drawings are provided as a service to customers considering Fairchild components. Drawings may change in any manner

without notice. Please note the revision and/or date on the drawing and contact a Fairchild Semiconductor representative to verify or

obtain the most recent revision. Package specifications do not expand the terms of Fairchild’s worldwide terms and conditions,

specifically the warranty therein, which covers Fairchild products.

Always visit Fairchild Semiconductor’s online packaging area for the most recent package drawings:

http://www.fairchildsemi.com/packaging/

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 18

.

Page 19

TRADEMARKS

The following includes registered and unregistered trademarks and service marks, owned by Fairchild Semiconductor and/or its global subsidianries, and is

not intended to be an exhaustive list of all such trademarks.

Auto-SPM™

Build it Now™

CorePLUS™

CorePOWER™

CROSSVOLT™

CTL™

Current Transfer Logic™

EcoSPARK

EfficentMax™

EZSWITCH™*

®

™*

®

Fairchild

Fairchild Semiconductor

FACT Quiet Series™

®

FACT

®

FAST

FastvCore™

FETBench™

FlashWriter

®

*

FPS™

F-PFS™

®

FRFET

Global Power Resource

Green FPS™

Green FPS™ e-Series™

Gmax™

GTO™

IntelliMAX™

ISOPLANAR™

MegaBuck™

MICROCOUPLER™

MicroFET™

MicroPak™

MillerDrive™

®

MotionMax™

Motion-SPM™

OPTOLOGIC

OPTOPLANAR

®

®

SM

®

PDP SPM™

PowerTrench

PowerXS™

Programmable Active Droop™

QFET

QS™

Quiet Series™

RapidConfigure™

Saving our world, 1mW/W/kW at a time™

SmartMax™

SMART START™

SPM

STEALTH™

SuperFET™

SuperSOT™-3

SuperSOT™-6

SuperSOT™-8

SupreMOS™

SyncFET™

Sync-Lock™

Power-SPM™

®

®

™

®

®

*

The Power Franchise

TinyBoost™

TinyBuck™

®

TinyLogic

TINYOPTO™

TinyPower™

TinyPWM™

TinyWire™

TriFault Detect™

TRUECURRENT™*

μSerDes™

®

UHC

Ultra FRFET™

UniFET™

VCX™

VisualMax™

XS™

®

* Trademarks of System General Corporation, used under license by Fairchild Semiconductor.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE

RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY

PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

THESE SPECIFICATIONS DO NOT EXPAND THE TERMS OF FAIRCHILD°ØS WORLDWIDE TERMS AND CONDITIONS, SPECIFICALLY THE WARRANTY

THEREIN, WHICH COVERS THESE PRODUCTS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE

EXPRESS WRITTEN APPROVAL OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a) are

intended for surgical implant into the body or (b) support or sustain life,

and (c) whose failure to perform when properly used in accordance with

instructions for use provided in the labeling, can be reasonably

expected to result in a significant injury of the user.

2. A critical component in any component of a life support, device, or

system whose failure to perform can be reasonably expected to cause

the failure of the life support device or system, or to affect its safety or

effectiveness.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing counterfeiting of

their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation, substandard performance,

failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to protect ourselves and our customers

from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts either directly from Fairchild or from Authorized

Fairchild Distributors who are listed by country on our web page cited above. Products customers buy either from Fairchild directly or from Authorized Fairchild

Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for handling and storage and provide access to Fairchild's full range of

up-to-date technical and product information. Fairchild and our Authorized Distributors will stand behind all warranties and will appropriately address any

warranty issues that may arise. Fairchild will not provide any warranty coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is

committed to combat this global problem and encourage our customers to do their part in stopping this practice by buying direct or from authorized distributors.

FPF2300/02/03 — Dual-Output Current Limit Switch

PRODUCT STATUS DEFINITIONS

Definition of Terms

Datasheet Identification Product Status Definition

Advance Information Formative / In Design

Preliminary First Production

No Identification Needed Full Production

Obsolete Not In Production

Datasheet contains the design specifications for product development. Specifications may change

in any manner without notice.

Datasheet contains preliminary data; supplementary data will be published at a later date. Fairchild

Semiconductor reserves the right to make changes at any time without notice to improve design.

Datasheet contains final specifications. Fairchild Semiconductor reserves the right to make

changes at any time without notice to improve the design.

Datasheet contains specifications on a product that is discontinued by Fairchild Semiconductor.

The datasheet is for reference information only.

Rev. I40

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 19

Loading...

Loading...