Page 1

User Guide for

FEBFMT1030_MEMS01

Evaluation Board

Motion Tracking Module with MT Software

Suite

Featured Fairchild Products:

FEBFMT1030, FMT1030, FMT1020,

FMT1010

For technical support, please contact

Fairchild Semiconductor

or your local sales team

Fairchild Sales Offices

© 2015 Fairchild Semiconductor Corporation FEBFMT1030_MEMS01 • Rev. 1.0

Page 2

Table of Contents

1. Introduction ............................................................................................................................... 3

1.1. Description ....................................................................................................................... 3

1.2. Features ............................................................................................................................ 3

1.3. Ordering Information ....................................................................................................... 3

2. Photographs............................................................................................................................... 4

3. Getting Started .......................................................................................................................... 5

3.1. Installing MT Software Suite ........................................................................................... 5

3.2. Displaying Data in MT Manager ..................................................................................... 6

3.3. Configuring the FMT with MT Manager ......................................................................... 7

3.4. Other Functionality of MT Manager ................................................................................ 8

3.5. Embedded Examples ........................................................................................................ 8

3.6. Frames of Reference used in FMT ................................................................................... 8

4. Package and Handling............................................................................................................. 10

4.1. Evaluation Kit ................................................................................................................ 10

4.1. Pin Descriptions ............................................................................................................. 13

4.2. Schematics ...................................................................................................................... 14

4.3. Physical Dimensions ...................................................................................................... 16

4.4. Electrical Specifications ................................................................................................. 16

4.5. Absolute Maximum Ratings........................................................................................... 17

5. Revision History ..................................................................................................................... 18

© 2015 Fairchild Semiconductor Corporation 2 FEBFMT1030_MEMS01 • Rev. 1.0

Page 3

1. Introduction

Part Number

Description

Packing Method

FEBFMT1030_MEMS01

Evaluation Kit for FMT1030 AHRS

Single unit

This user guide describes the Evaluation Kit for the FMT1030. The FMT1030 Evaluation

Kit is designed to support the evaluation of the FMT1000-series, in particular the

FMT1030 Attitude and Heading Reference System.

1.1. Description

The FMT1000-series is a module outputting 3D orientation, 3D rate of turn, 3D

acceleration and 3D magnetic field. It is specifically designed for industrial applications

featuring vibration rejection, a robust sensor fusion algorithm and a high update rate. The

FMT1000-series can be configured for any application.

The FMT1000-series Evaluation Kit is an excellent tool to start working with the

FMT1000-series. It has a pre-mounted FMT1030 AHRS and comes with the extensive

MT Software Suite and USB-cabling. The MT Software Suite is full-featured, with

logging and visualization options, intuitive configuration windows and possibilities to

export data for use in other programs. The Software Development Kit contains source

code for communication and libraries for data processing.

The 24-pins header connects to all interfaces available on the FMT1000-series module.

Connections with development platforms for Cortex-M processors of different brands can

be made easy using the Fairchild examples on the mbed.org website.

Specifications of the FMT1000-series can be found in the FMT1000-series data sheet.

1.2. Features

1.3. Ordering Information

© 2015 Fairchild Semiconductor Corporation 3 FEBFMT1030_MEMS01 • Rev. 1.0

Figure 1. FEBFMT1030_MEMS01 Development Board

Easy to use Development Board

Complete MT Software Suite

o MT Manager Logging and Visualization GUI

Windows 7 and Linux

o SDK for Windows, Linux

o Source Code/Drivers (platform-independent)

o Magnetic Field Mapper

Drivers and Examples on ARM

®

mbedTM

Full Functionality

Delivered with FMT1030 Mounted

USB, RS232, UART, SPI, I

2

C Interfaces

Page 4

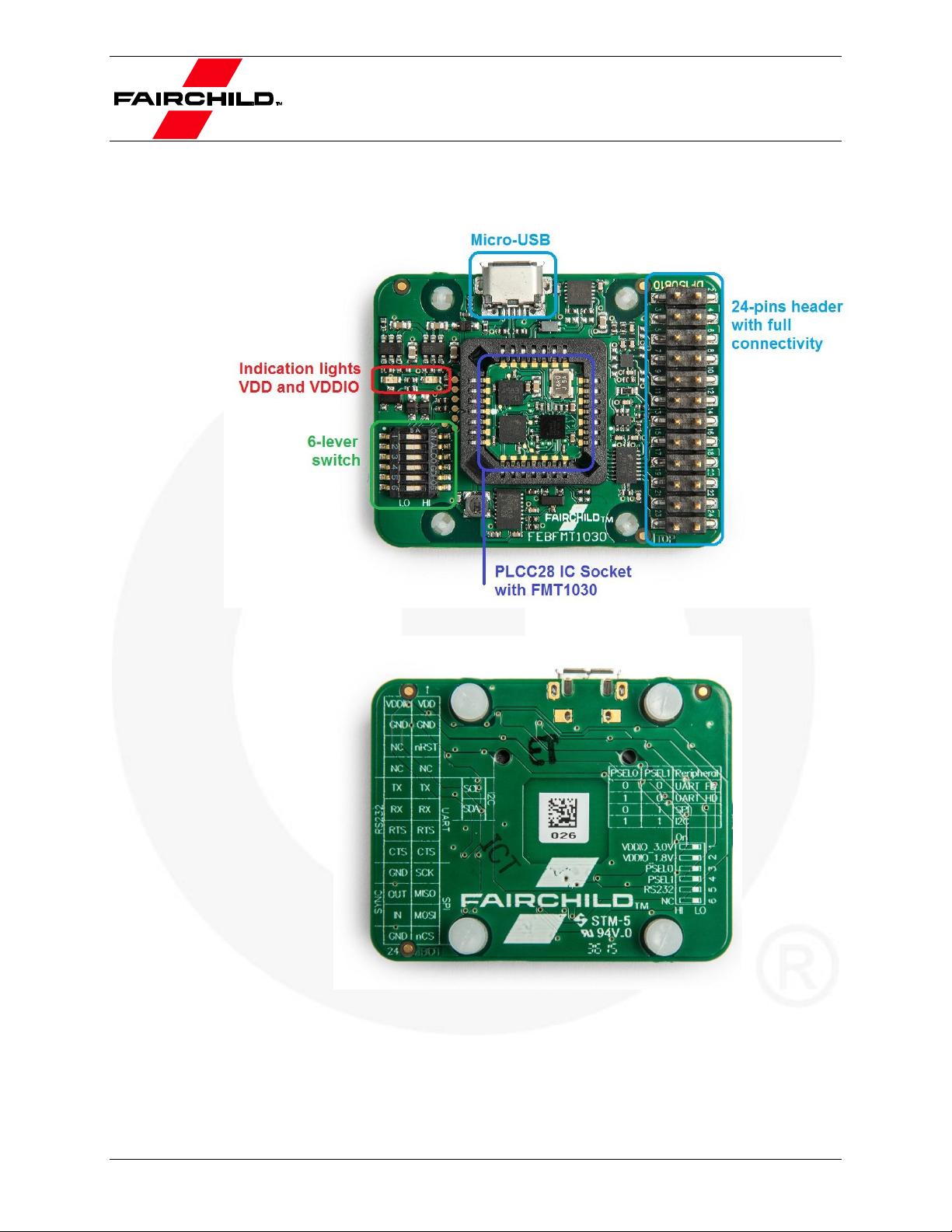

2. Photographs

Figure 2. Top View of the FMT1000-Series Evaluation Board with the Various Components

Figure 3. Bottom View of the FMT1000-Series Evaluation Board with the description of the

header and switch. Text is displayed as see-through.

© 2015 Fairchild Semiconductor Corporation 4 FEBFMT1030_MEMS01 • Rev. 1.0

Page 5

3. Getting Started

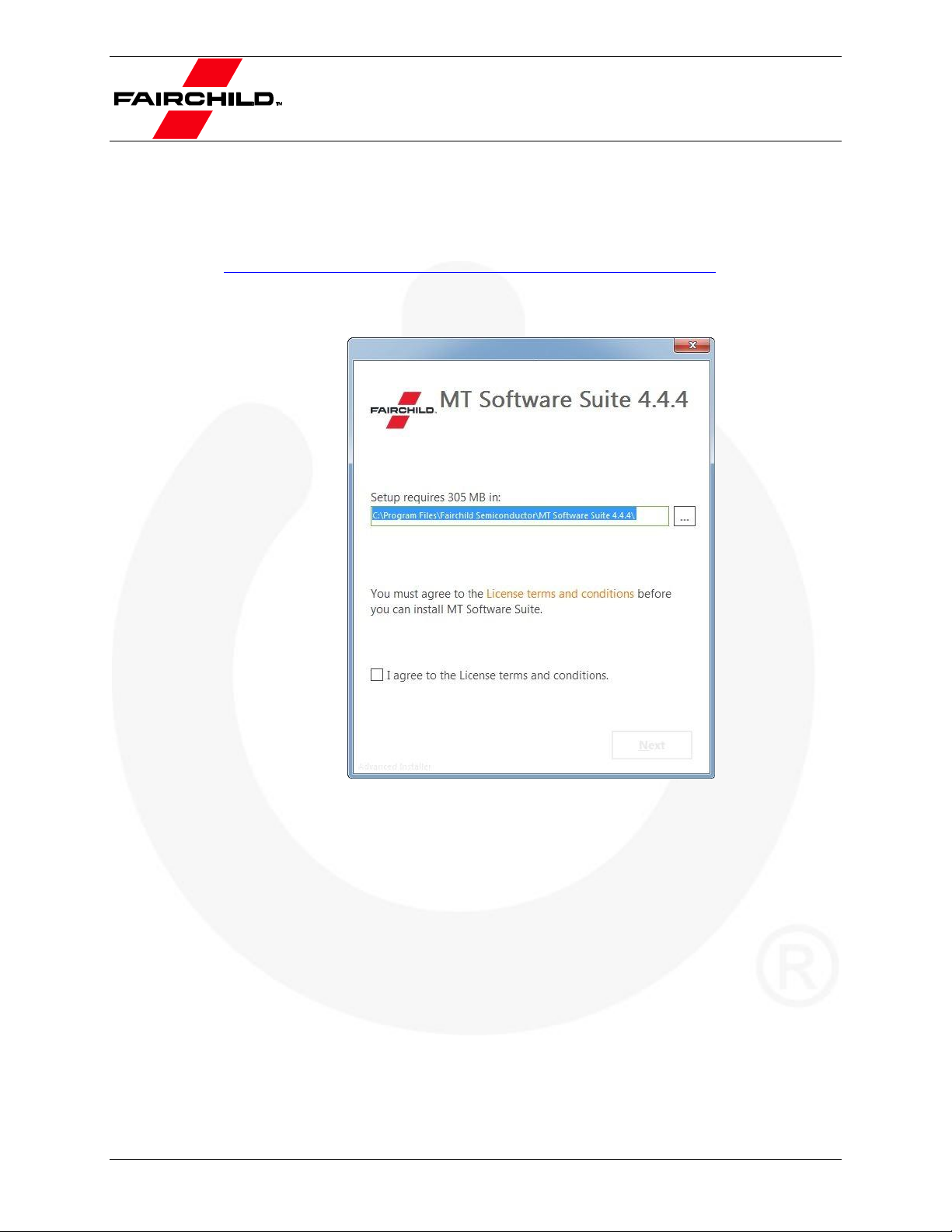

3.1. Installing MT Software Suite

The MT Software Suite is available on the Fairchild Motion Tracking website:

https://www.fairchildsemi.com/products/sensors/mems-motion-sensors/.

The installation procedure consists of a set of several installers and starts with this screen:

Figure 4. MT Software Suite Installer Home Screen

© 2015 Fairchild Semiconductor Corporation 5 FEBFMT1030_MEMS01 • Rev. 1.0

Page 6

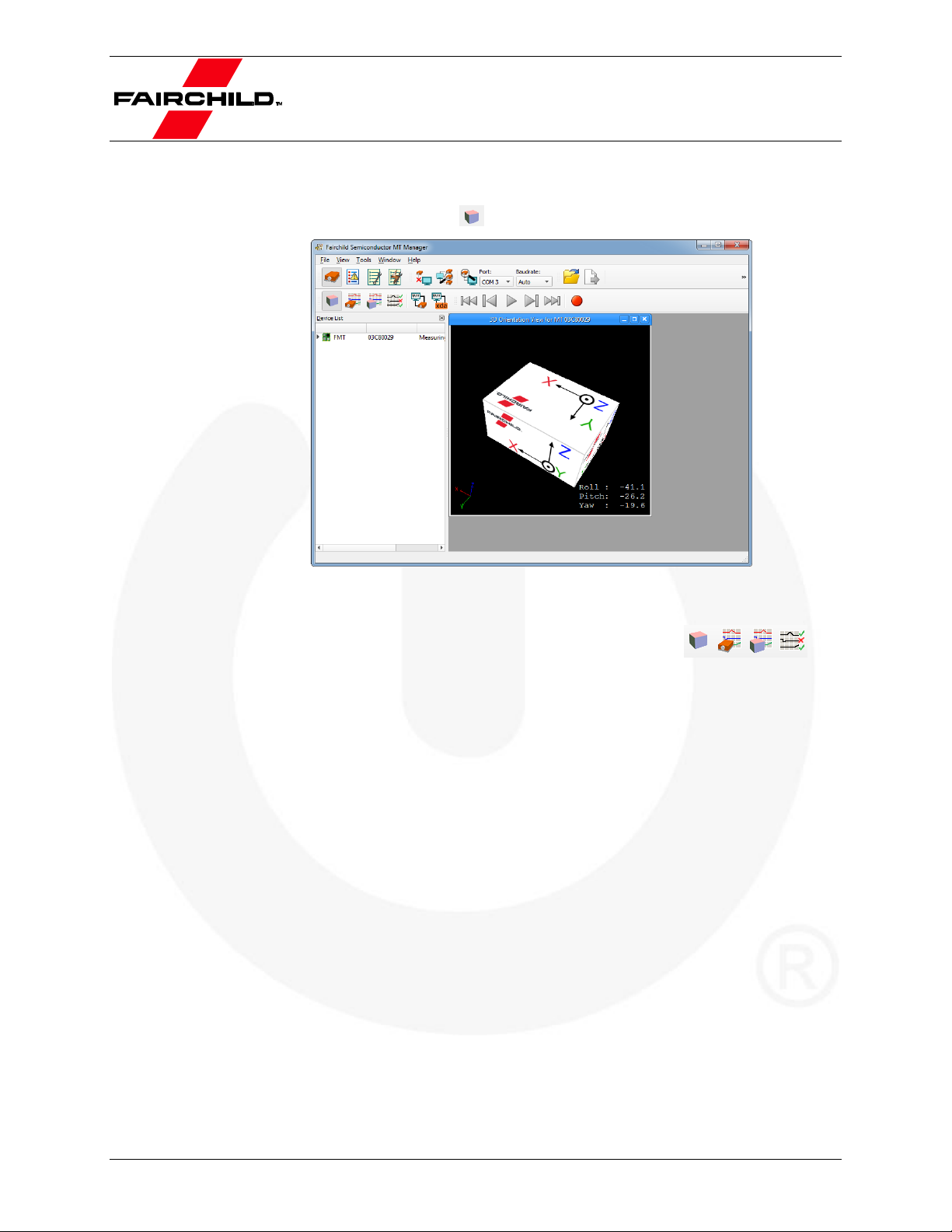

3.2. Displaying Data in MT Manager

When the FEBFMT1030 is connected (the FEBFMT1030 will automatically be

installed), click the 3D View icon: . This shows the 3D box representation of the FMT.

Figure 5. The 3D Box View of the MT Manager

The other visualizations can be opened using the windows toolbar: .

Refer to the MT Manager User Manual for more information on these graphs and their

features. The MT Manager User Manual can be found via Help – Documentation

© 2015 Fairchild Semiconductor Corporation 6 FEBFMT1030_MEMS01 • Rev. 1.0

Page 7

3.3. Configuring the FMT with MT Manager

MT Manager is an excellent tool to configure the FMT. Click the Output Configuration

button:

The following screen appears:

Figure 6. Output Configuration Window of a FEBFMT1030

By default, the output of the FMT is orientation only. Click “Inertial Data” (∆q/∆v or

Rate of Turn/Acceleration) and “Magnetic Field” to be able to show this data in MT

Manager.

© 2015 Fairchild Semiconductor Corporation 7 FEBFMT1030_MEMS01 • Rev. 1.0

Page 8

Data

Symbol

Reference Coordinate System

Acceleration

ax, ay, az

Sensor-fixed

Rate of turn

ωx, ωy, ω

z

Sensor-fixed

Magnetic Field

mx, my, mz

Sensor-fixed

Free Acceleration

a

Local Tangent Plane (LTP), default ENU

Velocity Increment

∆vx, ∆vy, ∆v

z

Local Tangent Plane (LTP), default ENU

Orientation Increment

∆q0, ∆q1, ∆q

2

, ∆q3

Local Tangent Plane (LTP), default ENU

Orientation

Euler Angles, Quaternions or

Rotation Matrix (DCM)

Local Tangent Plane (LTP), default ENU

3.4. Other Functionality of MT Manager

With the MT Manager, it is possible to record data and export that data for use in other

programs, configure synchronization options and to review the test and calibration report.

More information on the functions in MT Manager can be found in the MT Manager

User Manual.

3.5. Embedded Examples

The FMT is designed for easy integration in embedded systems. To aid in development

example code is provided for the ARM mbed platform. An example implementation of

the Xbus Low Level Communication Protocol is provided as generic C99 compliant

source code1, while an ARM mbed specific application demonstrates the use of the Xbus

library to communicate with a FEBFMT1030 Evaluation Board using UART, SPI or I2C

communications.

The example code has been tested with the following ARM mbed compatible boards:

ST Nucleo F302R8 – Cortex M4

FreeScale FRDM-KL46Z – Cortex M0+

NXP EA LPC 4088 – Cortex M4

The example code is available at http://www.mbed.org/teams/Fairchild-Semiconductor.

Documentation on how-to-use is provided on the description page and in the code. Note

that these examples are provided as is and are not supported by the Fairchild support

team. The examples are licensed under the Apache License version 2.0.

Several basic commands were used, it is easy to extend the program with commands

from the Low-Level Communication Protocol (LLCP). This protocol is documented in

detail in the MT Software Suite and in the Low-Level Communication Protocol

Documentation.

3.6. Frames of Reference used in FMT

The FMT uses a right-handed coordinate system as the basis of the sensor of frame.

The following data is outputted in corresponding reference coordinate systems:

Table 1. Reference frame in FMT

1

Xbus example code is not specific to ARM processors and should be compatible with other embedded

architectures.

© 2015 Fairchild Semiconductor Corporation 8 FEBFMT1030_MEMS01 • Rev. 1.0

Page 9

z

x

y

Local Tangent Plane (LTP) is a local linearization of the Ellipsoidal Coordinates

(Latitude, Longitude, and Altitude) in the WGS-84 Ellipsoid.

Figure 7. Default Sensor Fixed System for the FMT

It is straightforward to apply a rotation matrix to the FMT, so that the velocity and

orientation increments, free acceleration and the orientation output are using that

coordinate frame. The default reference coordinate system is East-North-Up (ENU) and

the FMT1000-series has predefined outputs for North-East-Down (NED) and NorthWest-Up (NWU). Any arbitrary alignment can be entered. These orientation resets have

effect on all outputs that are by default outputted with an ENU reference coordinate

system.

© 2015 Fairchild Semiconductor Corporation 9 FEBFMT1030_MEMS01 • Rev. 1.0

Page 10

4. Package and Handling

Note that this is a mechanical shock (g) sensitive device. Proper handling is required to

prevent damage to the part.

Note that this is an ESD-sensitive device. Proper handling is required to prevent damage

to the part.

Make sure not to apply force on the components of the MTi 1-series module, especially

when placing the MTi 1-series module in an IC-socket.

4.1. Evaluation Kit

The FMT1000-series is available as an Evaluation Kit. An FMT1030 AHRS is mounted

in a PLCC-28 socket and connects to USB, RS232, UART, I2C and SPI. The

FEBFMT1030_MEMS01 comes with MT Manager, an intuitive GUI for Linux and

Windows, example code and example applications.

The Development Board exposes the pins of the FMT on an easy to use 24-pins header

allowing easy connectivity during prototyping.

Figure 8. Layout of the FEBFMT1030_MEMS01 Evaluation Board

© 2015 Fairchild Semiconductor Corporation 10 FEBFMT1030_MEMS01 • Rev. 1.0

Page 11

Pin#

Name

Pin#

Name

1

VDD

2

VDDIO 3 GND

4

GND

5

nRST

6

NC 7 NC

8

NC

9

UART TX or I2C SCL

10

RS232-TX

11

UART RX or I2C SDA

12

RS232-RX

13

UART-RTS

14

RS232-RTS

15

UART-CTS or DRDY

16

RS232-CTS

17

SPI-SCK

18

GND

19

SPI-MISO

20

RESERVED

21

SPI-MOSI

22

SYNC_IN

23

SPI-nCS

24

GND

Lever nr

Name

Description

1

VDDIO_3.0V

Sets the VDDIO of UART, SPI and I2C to 3.0 V, if VDDIO is not supplied to pin

#2 of the 24-pins connector. Setting a VDDIO, either external or with this lever,

is required to properly define the voltage levels of SYNC_IN.

2

VDDIO_1.8V

Sets the VDDIO of UART, SPI and I2C to 1.8 V, if VDDIO is not supplied to pin

#2 of the 24-pins connector. When VDDIO_3.0 V is selected as well, VDDIO

will be 3.0 V. Setting a VDDIO, either external or with this lever, is required to

properly define the voltage levels of SYNC_IN.

3

PSEL0

PSEL0

PSEL1

Peripheral

(1)

0 0 UART_FD

1 0 UART_HD

0 1 SPI

1 1 I2C

4

PSEL1

5

RS232

Set this lever to 1 (high) to enable RS232 communication. Also, PSEL0 and

PSEL1 must be set to UART. This lever must be set to 0 to enable I2C

6

NC

N/A

Connections and Peripheral Switch

The MTi Development Board has the following connections and switches:

24-pins dual row header with a pitch of 2.54 mm: Table 2 shows the connections. For

information on the connections, refer to the pin description in Table 5. Refer to 0 how

to enable the various interfaces on the Evaluation Board.

Table 2. Connections on 24-Pins Header

Micro USB: the Evaluation Board has a micro USB connection that can be used to

connect directly to a USB port on a PC or laptop. To enable the communication via

USB, make sure to have the peripheral selection set to UART (full duplex).

Peripheral switch: This switch sets the interface configuration of the 12.1 x 12.1 mm

module in the socket of the Evaluation Board.

Table 3. Settings for Switch

Note:

1. The values for the peripheral selection on the switch are inverted with respect to the values on the module.

© 2015 Fairchild Semiconductor Corporation 11 FEBFMT1030_MEMS01 • Rev. 1.0

Page 12

Interface

PSEL0

PSEL1

RS232

Comments

UART FD

0 0 0

When USB is detected, interface is USB

UART HD

1 0 0 USB

0 0 0

When USB is detected, interface is USB

I2C

1 1 0

SPI

0 1 0 RS232

0 0 1

When USB is detected, interface is USB

Table 4. Switch Positions to Enable Interfaces on Development Board

Figure 9. Switch to I2C Interface and VDDIO of 3.0 V

© 2015 Fairchild Semiconductor Corporation 12 FEBFMT1030_MEMS01 • Rev. 1.0

Page 13

Name

Type

Description

Power Interface

VDD

Power

Power supply voltage for sensing elements

VDDIO

Power

Digital I/O supply voltage

Controls

PSEL0

Selection pins

These pins determine the signal interface. See 0. Note that when the

PSEL0/PSEL1 is not connected, its value is 1. When PSEL0/PSEL1 is connected

to GND, its value is 0

PSEL1

nRST

Active low reset pin, connect to VDDIO if not used

Signal Interface

I2C_SDA

I2C interface

I2C serial data

I2C_SCL

I2C serial clock

SPI_nCS

SPI interface

SPI chip select

SPI_MOSI

SPI serial data input (slave)

SPI_MISO

SPI serial data output (slave)

SPI_SCK

SPI serial clock

RTS

UART

interface

Hardware flow control in UART full duplex mode (Ready-to-Send)

CTS

Hardware flow control in UART full duplex mode (Clear-to-Send)

nRE

Receiver control signal in UART half duplex mode

DE

Transmitter control signal in UART half duplex mode

UART-RX

Receiver data input

UART-TX

Transmitter data output

RS232-TX

RS232

interface

Receiver data input

RS232-RX

Transmitter data output

RS232-RTS

Hardware flow control in RS232 mode (Ready-to-Send)

RS232-CTS

Hardware flow control in RS232 mode (Clear-to-Send)

SYNC_IN

Sync interface

SYNC_IN accepts a trigger which has the following functionality, depending on the

configuration set in the firmware:

It sends out the latest available data message, or

It adjusts the bias of the clock onboard the MTi

DRDY

Data ready

Data ready pin indicates that data is available (SPI / I2C)

4.1. Pin Descriptions

Table 5. Pin Descriptions of the FEBFMT1030_MEMS01

© 2015 Fairchild Semiconductor Corporation 13 FEBFMT1030_MEMS01 • Rev. 1.0

Page 14

Peripheral

selection

USB

24 pins header

4.2. Schematics

© 2015 Fairchild Semiconductor Corporation 14 FEBFMT1030_MEMS01 • Rev. 1.0

Page 15

RS232

Level

Translators

Power

© 2015 Fairchild Semiconductor Corporation 15 FEBFMT1030_MEMS01 • Rev. 1.0

Page 16

Input

Description

Min.

Typ.

Max.

Unit

VDD 3.3 5.5

V

VDDIO 1.6 5.5

V

SyncIn

VIH

0.75 * VDDIO

V

VIL

0.25 * VDDIO

V

4.3. Physical Dimensions

Figure 10. Physical Location of Components

Figure 11. Outer Dimensions of the FEBFMT Board (PCB spacers are placed).

4.4. Electrical Specifications

The FEBFMT1030 Evaluation Board has the same communication protocol as the

FMT1000-series module. Table 6 shows the electrical specifications for the Development

Board.

Table 6. System Specifications Evaluation Board

© 2015 Fairchild Semiconductor Corporation 16 FEBFMT1030_MEMS01 • Rev. 1.0

Page 17

Parameter

Min.

Max.

Unit

Comments

Storage Temperature

-40

+125

°C Operating Temperature

-30

+85

°C

VDD

0.3

6.0

V

VDDIO

0.3

VDD + 0.5

V

V

SYNC_IN

7.0

V

Acceleration

(2)

10,000

g

Any axis, unpowered, for 0.2 ms

ESD Protection

(3)

±2000

V

Human Body Model

4.5. Absolute Maximum Ratings

Table 7. Absolute Maximum Ratings FEBFMT1030

Notes:

2. This is a mechanical shock (g) sensitive device. Proper handling is required to prevent damage to the part.

3. This is an ESD-sensitive device. Proper handling is required to prevent damage to the part.

© 2015 Fairchild Semiconductor Corporation 17 FEBFMT1030_MEMS01 • Rev. 1.0

Page 18

Rev.

Date

Description

1.0

October 2015

Initial Release

5. Revision History

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

This board is intended to be used by certified professionals, in a lab environment, following proper safety procedures. Use at your own risk. The

Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any kind

of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s published

specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without notice to

any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or, if no

contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a)

are intended for surgical implant into the body, or (b) support or

sustain life, or (c) whose failure to perform when properly used in

accordance with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the user.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

EXPORT COMPLIANCE STATEMENT

These commodities, technology, or software were exported from the United States in accordance with the Export Administration Regulations for the

ultimate destination listed on the commercial invoice. Diversion contrary to U.S. law is prohibited.

U.S. origin products and products made with U.S. origin technology are subject to U.S Re-export laws. In the event of re-export, the user will be

responsible to ensure the appropriate U.S. export regulations are followed.

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its

safety or effectiveness.

© 2015 Fairchild Semiconductor Corporation 18 FEBFMT1030_MEMS01 • Rev. 1.0

Page 19

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Fairchild Semiconductor:

FEBFMT1030_MEMS01

Loading...

Loading...