Page 1

User Guide for

FEBFL77944_L80L012A

FEBFL77944_L80L012B

Evaluation Board

12 W Down Light AC LED Driver at Low-Line

Featured Fairchild Product:

FL77944

Direct questions or comments

about this evaluation board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2016 Fairchild Semiconductor Corporation 1 FEBFL77944_L80L012A_B • Rev. 1.0

Page 2

Table of Contents

1. Introduction ............................................................................................................................... 3

1.1. General Description of FL77944MX ............................................................................... 3

1.2. Controller Features........................................................................................................... 3

1.3. Controller Internal Block Diagram .................................................................................. 4

2. Evaluation Board Test Outline.................................................................................................. 5

3. Evaluation Board Specifications ............................................................................................... 6

4. Evaluation Board Operating Temperature ................................................................................ 7

5. Evaluation Board Bill of Materials (BOM) .............................................................................. 8

6. Low-Line without SVF Evaluation Board ................................................................................ 9

6.1. Evaluation Board Schematic ............................................................................................ 9

6.2. Key Performance Measurements ................................................................................... 10

6.3. Startup ............................................................................................................................ 11

6.4. Normal Operation .......................................................................................................... 12

6.5. Dimming Operation & Performance .............................................................................. 13

6.6. Electromagnetic Interference (EMI) .............................................................................. 14

7. Low-Line with SVF Evaluation Board ................................................................................... 15

7.1. Evaluation Board Schematic .......................................................................................... 15

7.2. Key Performance Measurements ................................................................................... 16

7.3. Dimming Performance ................................................................................................... 17

7.4. Electromagnetic Interference (EMI) .............................................................................. 17

8. Revision History ..................................................................................................................... 18

© 2016 Fairchild Semiconductor Corporation 2 FEBFL77944_L80L012A_B • Rev. 1.0

Page 3

This user guide supports the evaluation kit for the FL77944. It should be used in

conjunction with the FL77944 datasheet as well as Fairchild’s application notes and

technical support team. Please visit Fairchild’s website at www.fairchildsemi.com.

1. Introduction

This document describes a direct AC line LED driver with a minimal number of external

components. The input voltage range of the LED driver board are classed as low-line

application for 98 VAC ~ 142 V

the Rcs value. This document contains a general description of the FL77944, the normal

configuration specification, schematic, bill of materials, and typical operating

characteristics.

1.1. General Description of FL77944MX

The FL77944 is a direct AC line LED driver with a minimal number of external RC

passive components. In normal configuration, one resistor is to adjust LED power, and

one capacitor is to provide a stable voltage to an internal biasing shunt regulator.

The FL77944 provides phase-cut dimming with wide dimming range, smooth dimming

control and good dimmer compatibility. It achieves the high efficiency with high PF and

low THD which makes the FL77944 suitable for high-efficiency LED lighting systems.

The FL77944 has a dedicated DIM pin which can be used with analog or digital PWM

dimming. The FL77944 can also be used with a rheostat dimmer switch which is suitable

for desktop or indoor lamps.

with a single DC output, constant current depends on

AC,

High wattage design of the FL77904 can be implemented with multiple IC embedded in

parallel for street lighting and down lighting applications.

1.2. Controller Features

The simplest Direct AC LED Driver with Only Two External RC Passive

Component

Wide AC Input Range : 90~305 V

Four Integrated High-Voltage LED Constant Current Sinks of up to 150 mA

(RMS) Capability

TRIAC Dimmable (Leading/Trailing Edge)

Rheostat Dimmable

Analog/Digital PWM Dimming Function

High Power Factor (above 0.98 in normal configuration)

Adjustable LED Power with an External Current Sense Resistor

Low Harmonic Content (THD under 20% in normal configuration)

SOP16 EP Package

Flexible LED Forward Voltage Configuration

Power Scalability with Multiple Driver ICs

Over-Temperature Protection (OTP)

AC

© 2016 Fairchild Semiconductor Corporation 3 FEBFL77944_L80L012A_B • Rev. 1.0

Page 4

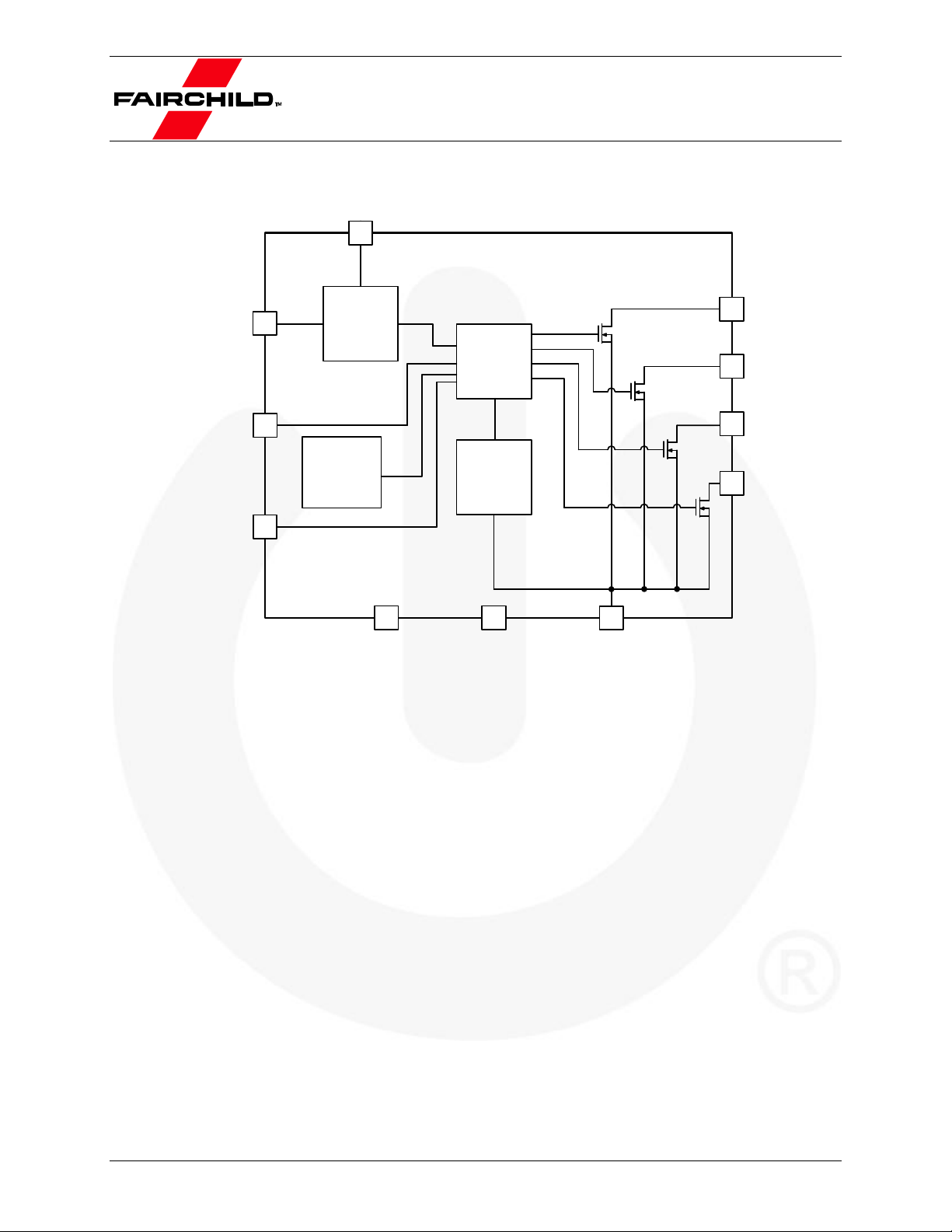

VIN

LED1

LED2

LED3

LED4

3

5

7

12

10

Shunt

Regulator

LED Current

Modulator

15

VDD

9

GND CS

1

14

11

DIM

MODE

GND

16

LED

Current

Feedback

Over-

Temperature

Protection

1.3. Controller Internal Block Diagram

Figure 1. Simplified FL77944 Block Diagram

© 2016 Fairchild Semiconductor Corporation 4 FEBFL77944_L80L012A_B • Rev. 1.0

Page 5

Evaluation Board #

FEBFL77944_L80L012A

Low-Line, 12 W, without SVF

FEBFL77944_L80L012B

Low-Line, 12 W, with SVF

Test Date

APRIL 2016

Test Equipment

AC Source: 6800 Series

Oscilloscope: LeCroy 104Xi-A

Power Meter: Yokogawa PZ4000

Multimeter: FLUKE 87 V

OL770: LED Test and Measurement System for Efficacy

Photo Sensor: Hamamatsu for Flicker Index

Test Items

1. Startup Performance

2. Normal Operation

3. Efficacy

4. Flicker Index

5. Power Factor

6. Total Harmonic Distortion(THD)

7. Dimming Performance

8. Conduction EMI

2. Evaluation Board Test Outline

Table 1. Evaluation Board Test Condition & Equipment List

© 2016 Fairchild Semiconductor Corporation 5 FEBFL77944_L80L012A_B • Rev. 1.0

Page 6

Version A

Version B

SVF Cap.

For Normal Electrolytic Capacitors

For SMD Electrolytic Capacitors

EVB

PHOTO

PCB

Diameter

100 mm

Material

Metal

Thickness

1.6 t

Input

Low-Line: 108 ~ 132 VAC

3. Evaluation Board Specifications

Table 2. Evaluation Board Specifications

© 2016 Fairchild Semiconductor Corporation 6 FEBFL77944_L80L012A_B • Rev. 1.0

Page 7

Without SVF

Test Condition

With Heat Sink: 110 mm * 105 mm * 5 mm

Ambient Temperature: 25°C

Spot

Spot 1 = LED 1(78.6°C), Spot 2= LED 2(67.6°C)

Spot 3 = LED 3(70.5°C), Spot 4= LED 12(75.3°C)

Spot 5 = LED 6(73.3°C), Spot 6= LED 11(74.8°C)

Spot 7 = Heat sink(53.4°C), Spot 8= PCB(56.4°C)

Circle = IC (71.9°C)

4. Evaluation Board Operating Temperature

Table 3. Evaluation Board Operating Temperature

© 2016 Fairchild Semiconductor Corporation 7 FEBFL77944_L80L012A_B • Rev. 1.0

Page 8

No.

Description

Specification

Type

Location

No.

Qty.

Vender

Remark

Common Parts

1

PCB

100Φ

Metal

1

2

IC

FL77944

SOIC16

U1

1

Fairchild

3

Bridge Diode

MB6S (1.0 A

600 V)

MBS

BD1

1

Fairchild

4

CHIP- CAP

0.1 µF 50 V

2012

C1

1

5

CHIP-RES

2 K

3216

R2

1

6

CHIP-RES

200 K

2012

R1, R3,

R6, R11

4

7

CHIP-RES

0

3216

J3

3

8

TVS DIODE

SMCJ100CA

DO214AA(SMB)

TVS1

1

Fairchild

9

REC DIODE

1000 V, 1 A: S1M

DO214AC(SMA)

D1, D2,

D3, D4

4

Fairchild

SVF Only

10

FUSE

2 A 250 VAC

MF2410F1.000TM

SMD

F1

1

AEM

11

CHIP-RES

0

3216

J4

1

12

CHIP-RES

0

3216

J1, J2

1

13

LED 1~12

32VF 40 mA

5250

LED 1~12

12

LGIT

14

Sensing R

6R8 F(1%)

2012

R4

1

SVF Only

15

E-CAP

100 µF 50 V

DIP

EC 1, 2, 3, 4

4

16

Varistor

10D221K

10Φ, 140 V

TNR1

1

Dimming Option

DIM-1

CHIP-RES

4.7 M

2012

R10

1

DIM-2

CHIP-RES

1 M

2012

R7, R9

2

DIM-3

CHIP-RES

470 K

2012

R8

1

Dim-4

IC

LM258

SOIC8

U2

1

Fairchild

Dim-5

CHIP- CAP

15 nF/K 25 V

1608 (0603)

C2, C3

2

Dim-6

Zener Diode

10 V, MM3Z10VB

SOD323F

ZD1

1

Fairchild

Dim-7

OP Amp

KSP2907

Q1, Q2

2

Fairchild

Dim-8

CHIP-RES

576 1%

2012

R5

1

5. Evaluation Board Bill of Materials (BOM)

© 2016 Fairchild Semiconductor Corporation 8 FEBFL77944_L80L012A_B • Rev. 1.0

Page 9

Parameter

Value

Unit

Evaluation Board #

FEBFL77944_L80L012A

Input Voltage

108 ~ 132

VAC

Output Power

12

W

LED

CCT

If(mA)

Vf(V)

Power(W)

Φv(lm)

Lm/W

5700K(G)

42 (Typ.)

31.8

1.27

169

133

Option

Dimming

0 V – 10 V

Dimmer

SF 10p-W by Cooper Wiring Devices

LED3

LG52xx

U1

FL77944

MODE

16

VIN

1

NC2VDD

15

LED13GND

14

NC

13

NC

4

LED2

5

NC

6

LED3

7

NC8GND

9

Isense

10

PWM

11

LED4

12

ZD1

10V

C2

153/2012

R1

LED7~9

LED4~6

Mode connects to GND: Enable PWM(DIM) function.

Mode connects to VDD: Disable PWM(DIM) function.

LED10~12

F1

250Vac/2A

R9

105/2012

Low-Line

-

+

U2A

LM258/SO

5

6

7

84

R10

475/2012

LED4

LG52xx

LED5

LG52xx

LED6

LG52xx

LED7

LG52xx

LED8

LG52xx

LED9

LG52xx

C3

153/2012LED10

LG52xx

LED11

LG52xx

Q2

KSP2907

LED12

LG52xx

C1

104/2012

Q1

KSP2907

D1

DIODE

DIM1

503/1W

R4

6R8/2012, 1%

J1

0R0/3216

D2

DIODE

J2

0R0/3216

D3

DIODE

D4

DIODE

TNR1

10D221K

N

L

R5

576R/2012

R7

105/2012

J3

0R0/3216

TVS1

SMCJ100CA

- +

BD1

MB6S

4

1

3

2

R8

474/2012

J4

0R0/3216

LED2

LG52xx

LED1

LG52xx

R2

103/3216

Isense = (0.92 * Vac) / (1.4 * Wattage)

6. Low-Line without SVF Evaluation Board

6.1. Evaluation Board Schematic

Figure 2. Typical Application Circuit of the 12 W Down Light for Low-Line without SVF Condition

Note:

1. The diode D1, D2, D3, D4 can be removed for the without SVF application.

Table 4. Evaluation Board Circuit Parameters for Low-Line without SVF

© 2016 Fairchild Semiconductor Corporation 9 FEBFL77944_L80L012A_B • Rev. 1.0

Page 10

Input

Condition

50 Hz

60 Hz

108 VAC

120 VAC

132 VAC

108 VAC

120 VAC

132 VAC

Power Factor

0.98

0.99

0.98

0.98

0.98

0.98

THD (%)

17.72

15.77

14.69

17.73

15.82

14.73

Pin (W)

9.90

11.70

13.60

9.90

11.80

13.60

IIN.RMS (A)

0.093

0.099

0.104

0.093

0.099

0.104

Lumen (lm)

922.42

1008.41

1073.28

928.05

1000.51

1080.86

Efficacy (lm/W)

88.98

82.31

75.37

89.52

80.97

75.90

Flicker Index

0.376

0.351

0.328

0.394

0.370

0.343

6.2. Key Performance Measurements

Table 5. Key Performance Measurements for Low-Line without SVF

Note:

2. Lumen (lm): Measured after one minute by initial turn-on * 0.955 (temperature saturation factor).

Table 5 shows the key performance measurements for low-line without Self Valley Fill (SVF) condition

according to the input voltage (min: 108 VAC, typical: 120 VAC, max: 132 VAC) and 50 Hz / 60 Hz. Power

factor is higher than 0.98 at the input voltage range from 198 to 242 VAC. THD is reduced by an increased

input voltage. However the efficacy is decreased by increasing the input voltage. The input power rate

should be larger than the rise of the lumen.

© 2016 Fairchild Semiconductor Corporation 10 FEBFL77944_L80L012A_B • Rev. 1.0

Page 11

108 VAC

120 VAC

132 VAC

50 Hz

60 Hz

Figure 3. Ch1: VDD 10.0 V/div, Ch2: V

IN.ac

100 V/div, Ch3: I

IN.ac

50.0 mA/div

6.3. Startup

Table 6. Startup Waveform According to Variable Input Voltage and Frequency

Table 6 shows the overall startup performance of low-line without SVF evaluation board at the variable

input voltage with 50 / 60 Hz when no dimmer is connected. The input current starts flowing at least 2 ms

after the AC input power switch turns-on for all condition.

© 2016 Fairchild Semiconductor Corporation 11 FEBFL77944_L80L012A_B • Rev. 1.0

Page 12

108 VAC

120 VAC

132 VAC

50Hz

60Hz

Figure 4. Ch2: V

IN.ac

, 100 V/div, Ch4: I

IN.ac

50.0 mA/div

6.4. Normal Operation

Table 7. Normal Operation Waveform According to Variable Input Voltage and Frequency

Table 7 shows the normal operation waveform of low-line without SVF evaluation board at the variable

input voltage with 50 / 60 Hz when no dimmer is connected. The condition of the LED 4 pin is turned on

when the input voltage is larger than at least all string LED forward voltage (35 V * 4 ea = 140 V). Also

the conduction time of the LED 4 pin is depend on the input voltage.

© 2016 Fairchild Semiconductor Corporation 12 FEBFL77944_L80L012A_B • Rev. 1.0

Page 13

DIM: 1 V

DIM: 5 V

DIM: 9 V

50 Hz

at 120 VAC

60 Hz

at 120 VAC

Figure 5. Ch2: V

IN.ac

, 100 V/div, Ch4: I

IN.ac

50.0 mA/div,Dimmer: SF 10p-W by Cooper Wiring Devices

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

01234567899.7

108Vac, 50Hz

120Vac, 50Hz

132Vac, 50Hz

108Vac, 60Hz

120Vac, 60Hz

132Vac, 60Hz

Output Current [mA]

A-DIM [V]

6.5. Dimming Operation & Performance

Table 8. Dimming Operation Waveform According to Variable Dimming Voltage

Figure 6. [Low-Line w/o SVF] Dimming Performance: Output Current vs. Analog Dimming

The FL77944 analog dimming function can be implemented with a few external components.

The converter output current at the rated line voltage can be adjusted within the range of 8.4% to 100% of

the nominal current value through 0 to 10 V A-DIM signal.

© 2016 Fairchild Semiconductor Corporation 13 FEBFL77944_L80L012A_B • Rev. 1.0

Page 14

Figure 7. 110 VAC, 60 Hz, <L>. At least 10 dB

Margin, Blue Trace: Peak Scan, Green Trace:

Average Scan

Figure 8. 110 VAC, 60 Hz, <N>At least 10 dB Margin,

Blue Trace: Peak Scan, Green Trace: Average

Scan

6.6. Electromagnetic Interference (EMI)

© 2016 Fairchild Semiconductor Corporation 14 FEBFL77944_L80L012A_B • Rev. 1.0

Page 15

Parameter

Value

Unit

Evaluation Board #

FEBFL77944_L80L012B

-

Input Voltage

108 ~ 132

VAC

Output Power

12

W

LED

CCT

If(mA)

Vf(V)

Power(W)

Φv(lm)

Lm/W

5700K(G)

42 (Typ.)

31.8

1.27

169

133

Option

Dimming

0 V – 10 V

Dimmer

SF 10p-W by Cooper Wiring Devices

LED3

LG52xx

U1

FL77944

MODE

16

VIN

1

NC2VDD

15

LED13GND

14

NC

13

NC

4

LED2

5

NC

6

LED3

7

NC8GND

9

Isense

10

PWM

11

LED4

12

ZD1

10V

EC3

100uF 50V

C2

153/2012

EC1

100uF 50V

EC2

100uF 50V

R1

LED4~6

Mode connects to GND: Enable PWM(DIM) function.

Mode connects to VDD: Disable PWM(DIM) function.

LED10~12

LED7~9

F1

250Vac/2A

* EC1, EC2, EC3, EC4 can be used for enable Self Valley Fill function

* Disable Self Valley Fill Function: EC1, EC2, EC3, EC4 ==>DNP

R9

105/2012

Low-Line

-

+

U2A

LM258/SO

5

6

7

84

R1

204/3216

R10

475/2012

LED4

LG52xx

LED5

LG52xx

R3

204/3216

LED6

LG52xx

LED7

LG52xx

LED8

LG52xx

R6

204/3216

LED9

LG52xx

C3

153/2012LED10

LG52xx

LED11

LG52xx

Q2

KSP2907

LED12

LG52xx

C1

104/2012

R11

204/3216

Q1

KSP2907

D1

DIODE

DIM1

503/1W

R4

6R8/2012, 1%

J1

0R0/3216

D2

DIODE

J2

0R0/3216

D3

DIODE

D4

DIODE

TNR1

10D221K

N

L

R5

576R/2012

R7

105/2012

J3

0R0/3216

TVS1

SMCJ100CA

- +

BD1

MB6S

4

1

3

2

R8

474/2012

J4

0R0/3216

LED2

LG52xx

LED1

LG52xx

EC4

100uF 50V

R2

103/3216

Isense = (0.92 * Vac) / (1.4 * Wattage)

7. Low-Line with SVF Evaluation Board

7.1. Evaluation Board Schematic

Figure 9. Typical Application Circuit of the 12 W Down Light for Low-Line with SVF Condition

Table 9. Evaluation Board Circuit Parameters for Low-Line with SVF

© 2016 Fairchild Semiconductor Corporation 15 FEBFL77944_L80L012A_B • Rev. 1.0

Page 16

Input

Condition

50 Hz

60 Hz

108 VAC

120 VAC

132 VAC

108 VAC

120 VAC

132 VAC

Power Factor

0.98

0.98

0.99

0.98

0.98

0.98

THD (%)

18.16

15.72

14.84

17.99

15.80

14.92

Pin (W)

9.90

11.80

13.60

10.00

11.80

13.70

IIN.RMS (A)

0.093

0.100

0.105

0.094

0.100

0.105

Lumen (lm)

899.40

976.35

1022.97

904.39

970.95

1023.61

Efficacy (lm/W)

90.85

82.74

75.22

90.44

82.28

74.72

Flicker Index

0.142

0.129

0.117

0.139

0.121

0.117

7.2. Key Performance Measurements

Table 10. Key Performance Measurements for Low-Line with SVF

Note:

3. Lumen (lm) : Measured after 1 minute by initial turn-on * 0.955 (temperature saturation factor).

Table 10 shows the key performance measurements for low-line with self valley fill Self Valley Fill

(SVF) condition according to the input voltage (min: 108 VAC, typical: 120 VAC, max: 132 VAC) and

50 Hz / 60 Hz. Power factor is higher than 0.98 at the input voltage range from 198 to 242 VAC. THD are

reduced by an increased input voltage. However the efficacy is decreased by increasing the input voltage.

The input power rate should be larger than the rise of the lumen.

© 2016 Fairchild Semiconductor Corporation 16 FEBFL77944_L80L012A_B • Rev. 1.0

Page 17

Figure 11. 120 VAC, 60 Hz, <L>, At Least 10 dB

Margin, Blue Trace: Peak Scan, Green Trace:

Average Scan

Figure 12. 120 VAC, 60 Hz, <N>, At least 12 dB

Margin, Blue Trace: Peak Scan, Green Trace:

Average Scan

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

01234567899.7

108Vac, 50Hz

120Vac, 50Hz

132Vac, 50Hz

108Vac, 60Hz

120Vac, 60Hz

132Vac, 60Hz

Output Current [mA]

A-DIM [V]

7.3. Dimming Performance

Figure 10. Dimming Performance: Output Current vs. Analog Dimming

The FL77944 analog dimming function can be implemented with a few external components.

The converter output current at the rated line voltage can be adjusted within the range of 8.2% to 100% of

the nominal current value through 0 to 10 V A-DIM signal.

7.4. Electromagnetic Interference (EMI)

© 2016 Fairchild Semiconductor Corporation 17 FEBFL77944_L80L012A_B • Rev. 1.0

Page 18

Rev.

Date

Description

1.0

April. 2016

Initial Release

8. Revision History

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

The Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any

kind of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s

published specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without

notice to any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or,

if no contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described

herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a) are

intended for surgical implant into the body, or (b) support or sustain

life, or (c) whose failure to perform when properly used in accordance

with instructions for use provided in the labeling, can be reasonably

expected to result in significant injury to the user.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its

safety or effectiveness.

© 2016 Fairchild Semiconductor Corporation 18 FEBFL77944_L80L012A_B • Rev. 1.0

Loading...

Loading...