Page 1

User Guide for

FEBFL7701_L31H008A

7.8 W LED Ballast Using FL7701

Featured Fairchild Product:

FL7701

Direct questions or comments

about this evaluation board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2012 Fairchild Semiconductor Corporation 1 FEBFL7701_L31H008A • Rev.1.0.2

Page 2

Table of Contents

1. Introduction ............................................................................................................................... 3

1.1. General Description ........................................................................................................ 3

1.2. Features .......................................................................................................................... 3

2. General Specifications for Evaluation Board ........................................................................... 5

3. Photographs of the Evaluation Board ....................................................................................... 6

4. Printed Circuit Board ................................................................................................................ 7

5. Schematic .................................................................................................................................. 8

6. Bill of Materials ........................................................................................................................ 9

7. Inductor Design ....................................................................................................................... 10

8. Performance of Evaluation Board ........................................................................................... 11

8.1. Typical Waveforms: Startup ........................................................................................ 12

8.2. Operating Frequency & Minimum Duty ...................................................................... 13

8.3. Typical Waveforms: Steady State ................................................................................ 14

8.4. Typical Waveforms: Abnormal Mode (LED Open) .................................................... 16

8.5. Typical Waveforms: Abnormal Mode (Inductor Short) .............................................. 17

8.6. System Efficiency ........................................................................................................ 18

8.7. Power Factor at Rated Load Condition ........................................................................ 19

8.8. THD Performance ........................................................................................................ 20

8.9. Thermal Performance ................................................................................................... 21

8.10. EMI Test Results .......................................................................................................... 23

9. Revision History ..................................................................................................................... 24

© 2012 Fairchild Semiconductor Corporation 2 FEBFL7701_L31H008A • Rev.1.0.2

Page 3

This user guide supports the evaluation kit for the FL7701. It should be used in

conjunction with the FL7701 datasheet as well as Fairchild’s application notes and

technical support team. Please visit Fairchild’s website at www.fairchildsemi.com

1. Introduction

This document describes the proposed solution for an universal input, 2.4W LED ballast

using the FL7701. The input voltage range is 187 V

output with a constant current of 250 mA at 31 V

description of FL7701, the power supply specification, schematic, bill of materials, and

the typical operating characteristics.

1.1. General Description

The FL7701 LED lamp driver is a simple IC with PFC function and integrated switching

MOSFET. The special “adopted digital” technique automatically detects input voltage

condition and sends an internal reference signal, resulting in high Power Factor (PF).

When AC input voltage is applied to the IC, PFC function is automatically enabled.

When DC input voltage is applied to the IC, PFC function is automatically disabled. The

FL7701 does not require a bulk capacitor (electrolytic capacitor) for supply rail stability,

which can significantly improve LED reliability.

– 264 V

RMS

. This document contains general

MAX

and there is one DC

RMS

.

1.2. Features

Digitally Implemented Active PFC Function

(No Additional Circuit Necessary for High PF)

Built-in HV Supplying Circuit: Self Biasing

Application Input Range: 80 V

~ 308 VAC

AC

AOCP Function with Auto-Restart Mode

Built-in Over-Temperature Protection (OTP)

Cycle-by-Cycle Current Limit

Current-Sense Pin-Open Protection

Low Operating Current: 0.85 mA (Typical)

Under-Voltage Lockout with 5 V Hysteresis

Programmable Oscillation Frequency

Programmable LED Current

Analog Dimming Function

Soft-Start Function

Precise Internal Reference: ±3%

© 2012 Fairchild Semiconductor Corporation 3 FEBFL7701_L31H008A • Rev.1.0.2

Page 4

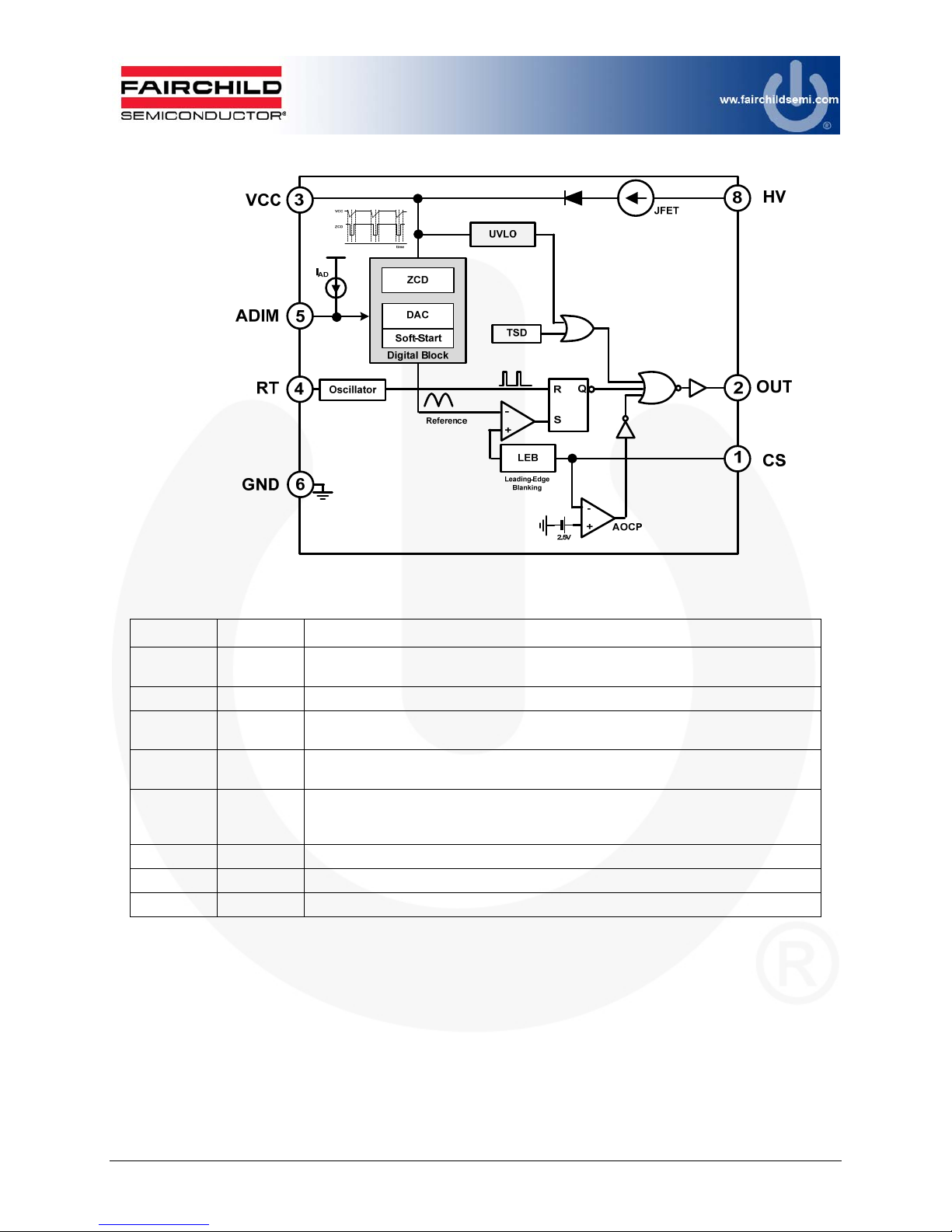

Figure 1. Block Diagram

Table 1. Pin Definitions

Pin No. Symbol Description

1 CS

2 OUT

3 VCC

4 RT

5 ADIM

6 GND

7 NC No Connection.

8 HV

Current Sense. Limits output current, depending on the sensing resistor voltage.

The CS pin is also used to set the LED current regulation.

OUT. Connects to the MOSFET gate.

VCC. Supply pin for stable IC operation, ZCD signal detection, and used for

accurate PFC function.

RT. Programmable operating frequency using an external resistor. The IC has a

fixed frequency when this pin is open or floating.

Analog Dimming. Connects to the internal current source and can change the

output current using an external resistor. If ADIM is not used, connect a 0.1 µF

bypass capacitor between ADIM and GND.

GROUND. Ground for the IC.

High Voltage. Connects to the high-voltage line and supplies current to the IC.

© 2012 Fairchild Semiconductor Corporation 4 FEBFL7701_L31H008A • Rev.1.0.2

Page 5

2. General Specifications for Evaluation Board

All data for this table was measured at an ambient temperature of 25°C.

Table 2. Summary of Features and Performance

Description Symbol Value Comments

V

187 V

IN,min

Input Voltage Range

Input Frequency

Output Voltage/Current

Output Power

(2)

Output Power 7.8 W

(1)

Efficiency >78% At Full Load

Temperature

PCB Size

Initial Application LED Bulb

Notes:

1. The output current has I

in parallel with the LED. Ensure the capacitor voltage rating is high enough to withstand an openLED condition or use a Zener diode for protection.

2. The output power is not equal to the apparent power due to the slight phase shift between the

output voltage and current.

V

220 V

IN,nom

V

264 V

IN,max

f

47 Hz

IN,min

f

64 Hz

IN,max

V

OUT

I

OUT

T

FL7701

T

MOSFET

T

DIODE

T

INDUCTOR

T

HV RESISTOR

250 mA

< 72°C

< 60°C

< 66°C

< 58°C

< 67°C

31 V

At Full Load (all at open-frame, room

temperature / still air)

20 mm (width) x32 mm (length)

x13 mm (height)

ripple. To reduce ripple current, use a large electrolytic capacitor

LEDPK

© 2012 Fairchild Semiconductor Corporation 5 FEBFL7701_L31H008A • Rev.1.0.2

Page 6

3. Photographs of the Evaluation Board

Figure 2. Top-View (PCB) (28 mmx52 mmx18 mm)

Figure 3. Top View (28 mm x 52 mm x 18 mm) (Mounted Housing)

Figure 4. Side View (28 mm x 52 mm x 18 mm)

© 2012 Fairchild Semiconductor Corporation 6 FEBFL7701_L31H008A • Rev.1.0.2

Page 7

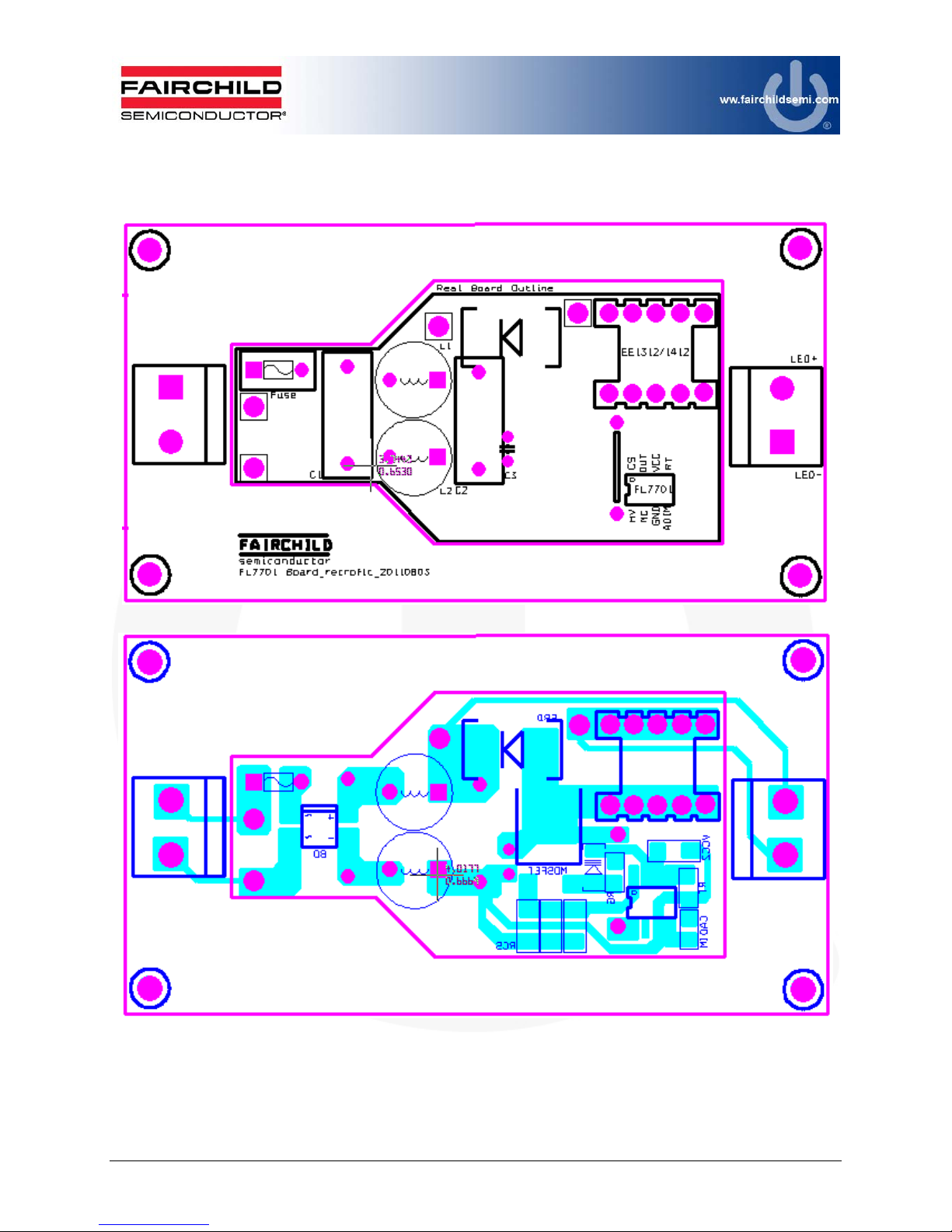

4. Printed Circuit Board

Figure 5. Top Side

Figure 6. Bottom Side

© 2012 Fairchild Semiconductor Corporation 7 FEBFL7701_L31H008A • Rev.1.0.2

Page 8

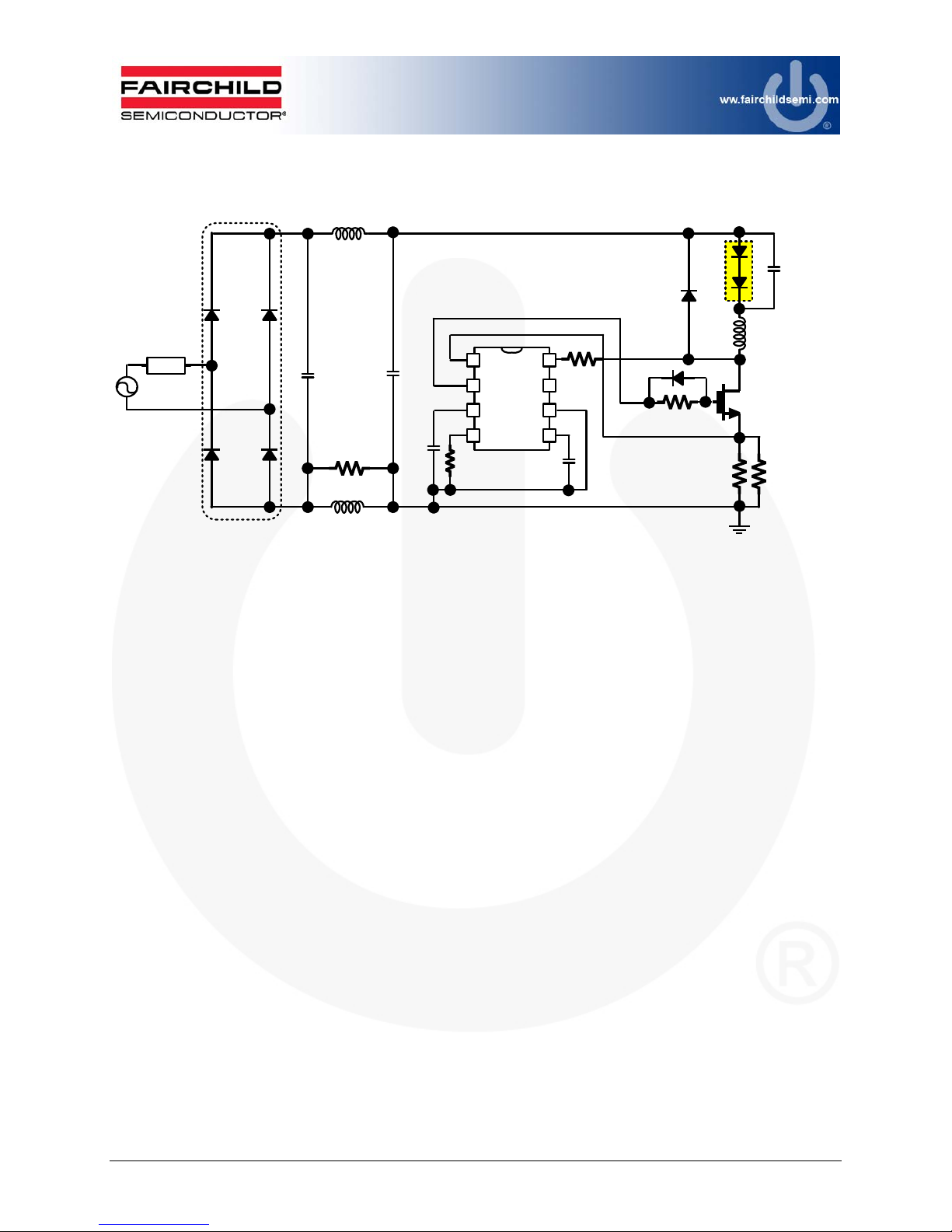

5. Schematic

L1 15mH

C5 1nF

D1 ES3J

Fuse

1A/250V

BD

47nF/630V

C1

33nF/630V

R1

560R

L2 10mH

D2

C3 100pF

1N4148

R3 510R

R4 2.4R

C2

C4 1µF

R6 OPEN

CS

OUT

VCC

RT

U1

HV

NV

GND

ADIM

R2 56k

L3

5.5mH

Q1

FQN1N60C

R5 2.4R

Figure 7. Schematic of Evaluation Board

© 2012 Fairchild Semiconductor Corporation 8 FEBFL7701_L31H008A • Rev.1.0.2

Page 9

6. Bill of Materials

Item

No.

1 Fuse SS-5-1A 1 1 A / 250 VAC Bussmann

2 U1 FL7701M 1 Controller

3 BD MB6S 1 0.5 A / 600 V, Bridge Diode

4 C1 MPE 630V333K 1 33 nF / 630 VAC, Film Capacitor Sungho

5 C2 MPE 630V473K 1 47 nF / 630 VAC, Film Capacitor Sungho

6 C3 C0805C101K3RACTU 1 100 pF / 25 V SMD Capacitor 2012 Kemet

7 C4 C1206C105K3PACTU 1 1 µF / 25 V SMD Capacitor 3216 Kemet

8 C5 C1206C102JBGACTU 1 1 nF / 630 V SMD Capacitor 3216 Kemet

9 Q1 FQD1N60C 1 1 A / 600 V D-PAK

10 D1 ES3J 1 3 A / 600 V, Ultra-Fast Recovery

11 D2 1N4148 1 0.2 A / 200 V Small Signal Diode

12 L1 R06153KT00 1 15 mH, Filter Inductor Bosung

13 L2 R06103KT00 1 10 mH, Filter Inductor Bosung

14 L3 EE1614 1 5.5 mH, Inductor TDK

15 R1 RC1206JR-07561RL 1 560 Ω, SMD Resistor 3216 Yageo

16 R2 RSMF1JB56K0 0 56k Ω / 1 W Metal Resistor Stackpole Elec.

Part

Reference

Part Number Qty. Description Manufacturer

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

17 R3

18 R4, R5 RC1206JR-072R4RL 1 2.4 Ω, SMD Resistor 3216 Yageo

19 R6 0 Open

© 2012 Fairchild Semiconductor Corporation 9 FEBFL7701_L31H008A • Rev.1.0.2

RC0805JR-07511RL

1 510 Ω, SMD Resistor 2012 Yageo

Page 10

7. Inductor Design

Follow Safe Standard

Inductor Core: EE1614 (TDK)

N1: 280 Turns

Inductance Value (1 6): 5.5 mH

Figure 8. Transformer Structure

Table 3. Inductor Specification

No. Winding Pin (S F) Wire Turns Winding Method

1 N1 1 6 0.2Ø 280Ts Solenoid Winding

2 Insulation: Polyester Tape t = 0.025 mm 3-Layer

© 2012 Fairchild Semiconductor Corporation 10 FEBFL7701_L31H008A • Rev.1.0.2

Page 11

8. Performance of Evaluation Board

Table 4. Test Condition & Equipments

Test Temperature

Test Equipment

AC Source: PCR500L by Kikusui

Power Meter: PZ4000 by Yokogawa

Oscilloscope: waverunner 64Xi by Lecroy

EMI Test Receiver: ESCS30 by ROHDE & SCHWARZ

Two-Line V-Network: ENV216 by ROHDE & SCHWARZ

Thermometer: CAM SC640 by FLIR SYSTEMS

LED: EHP-AX08EL/GT01H-P03 (3W) by Everlight

TA = 25°C

© 2012 Fairchild Semiconductor Corporation 11 FEBFL7701_L31H008A • Rev.1.0.2

Page 12

V

V

V

V

CH1: VCC, CH2:

8.1. Typical Waveforms: Startup

Figure 9 through Figure 12 show the typical startup performance at different input

voltage conditions. When AC input voltage is applied to the system, the FL7701

automatically operates in AC Mode after finishing an internally fixed, seven-cycle, softstart period. Figure 11 and Figure 12 show the soft-start characteristics when a DC input

voltage is applied.

, CH3: V

DRAIN

Figure 9. Soft-Start, AC Mode, 187 V

LED

, CH4: I

AC

LED

CH1: V

, CH2:

CC

DRAIN

, CH3: V

LED

, CH4: I

Figure 10. Soft-Start, AC Mode, 264 VAC

LED

CH1: VCC, CH2:

DRAIN

, CH3: V

Figure 11. Soft-Start, DC Mode, 150 V

© 2012 Fairchild Semiconductor Corporation 12 FEBFL7701_L31H008A • Rev.1.0.2

LED

, CH4: I

CH1: V

, CH2:

CC

DRAIN

, CH3: V

LED

Figure 12. Soft-Start, DC Mode, 200 VDC

DC

LED

, CH4: I

LED

Page 13

µ

8.2. Operating Frequency & Minimum Duty

The programmable switching frequency is between 20 kHz ~ 250 kHz, determined by

selecting the RT resistor value. If no RT resistor is used (RT pin OPEN), the FL7701

default switching frequency is set to 45 kHz. The maximum duty ratio is fixed below

50% and has a fixed minimum typical on-time of 400 ns. There are two crucial points to

design properly. The first is consideration of the minimum duty ratio at minimum input

voltage because the FL7701 is limited to 50% duty ratio. The second consideration is

minimum on-time at maximum input voltage condition. The FL7701 cannot control

output power when the operating conditions are such that the required on-time is less than

the 400 ns minimum on-time.

CH1: VCC, CH2: V

DRAIN

, CH3: V

, CH4: I

LED

Minimum On Time:

1.91

LED

s

Switching Frequency:

44.64kHz

Figure 13. Operating Frequency & Minimum Duty

© 2012 Fairchild Semiconductor Corporation 13 FEBFL7701_L31H008A • Rev.1.0.2

Page 14

8.3. Typical Waveforms: Steady State

V

V

Figure 14 through 19 show normal operation waveforms by input voltage and input

frequency. The output voltage and current maintains a certain output level with 120 Hz

ripple, as shown in the test results in the Table 5.

CH1: VCC, CH2:

Figure 14. Input Voltage: 187 VAC, Input Frequency:

DRAIN

, CH3: V

47 Hz

, CH4: I

LED

LED

CH1: V

, CH2:

CC

DRAIN

, CH3: V

LED

, CH4: I

LED

Figure 15. Input Voltage: 187 VAC, Input Frequency:

64 Hz

H1: VCC, CH2: V

DRAIN

, CH3: V

Figure 16. Input Voltage: 220 V

47 Hz

© 2012 Fairchild Semiconductor Corporation 14 FEBFL7701_L31H008A • Rev.1.0.2

, CH4: I

LED

, Input Frequency:

AC

LED

H1: V

Figure 17. Input Voltage: 220 V

, CH2: V

CC

DRAIN

64 Hz

, CH3: V

AC

, CH4: I

LED

, Input Frequency:

LED

Page 15

H1: VCC, CH2: V

DRAIN

, CH3: V

LED

, CH4: I

LED

Figure 18. Input Voltage: 264 VAC, Input Frequency:

47 Hz

Table 5. Output Characteristics by Input Voltage & Frequency

47 Hz 64 Hz

187 VAC

220 VAC

264 VAC

V

LED(RMS)

31.46 V 250.1 mA 31.42 V 250.1 mA

31.48V 250.5 mA 31.47 V 250.4 mA

31.49 V 251.1 mA 31.49 V 251.2 mA

I

LED(RMS)

H1: VCC, CH2: V

DRAIN

, CH3: V

LED

, CH4: I

LED

Figure 19. Input Voltage: 264 VAC, Input Frequency:

64 Hz

V

LED(RMS)

I

LED(RMS)

© 2012 Fairchild Semiconductor Corporation 15 FEBFL7701_L31H008A • Rev.1.0.2

Page 16

8.4. Typical Waveforms: Abnormal Mode (LED Open)

Figure 20 and Figure 21 show the open-load condition test method and result. When the LED

disconnects from the system, the IC cannot operate beca use the HV pin is discon nected.

L1 15mH

Fuse

1A/250V

L3

5.5mH

Q1

FQN1N50C

R5 2.4R

C5 1nF

D1 ES3J

C2

BD

47nF/630V

C1

33nF/630V

R1

560R

L2 10mH

C4 1uF

R6 OPEN

CS

OUT

VCC

RT

U1

GND

ADIM

HV

R2 56k

NV

1N4148

C3 100pF

OPEN

D2

R3 510R

R4 2.4R

Figure 20. Open-Load Condition Test

© 2012 Fairchild Semiconductor Corporation 16 FEBFL7701_L31H008A • Rev.1.0.2

CH1: VCC, CH2: V

DRAIN

, CH3: V

LED

, CH4: I

LED

Figure 21. Test Results of Open-Load Condition

Page 17

8.5. Typical Waveforms: Abnormal Mode (Inductor Short)

The Figure 22 and Figure 23 show the test method and result of an inductor short. The

FL7701 uses an abnormal over-current protection (AOCP) function, limiting the current

on RCS in the event of an inductor short.

Figure 22. Inductor-Short Condition

Figure 23. Test Results of Inductor-Short Condition

© 2012 Fairchild Semiconductor Corporation 17 FEBFL7701_L31H008A • Rev.1.0.2

CH1: VCS, CH2: V

DRAIN

, CH3: V

LED

, CH4: I

LED

Page 18

8.6. System Efficiency

[%]

[V]

The Figure 24 shows system efficiency results for different AC input voltage frequency

conditions. As shown, the input frequency has negligible effect on system efficiency.

Table 6. Test Results

Input Voltage Efficiency

187 VAC

220 VAC

264 VAC

Figure 24. System Efficiency

47 Hz 85.80

64 Hz 85.85

47 Hz 85.60

64 Hz 85.44

47 Hz 85.00

64 Hz 84.80

© 2012 Fairchild Semiconductor Corporation 18 FEBFL7701_L31H008A • Rev.1.0.2

Page 19

8.7. Power Factor at Rated Load Condition

[%]

[V]

The Figure 25 shows the system Power Factor (PF) performance for the entire input

voltage range (187 V to 264 V) at different input frequency conditions (47 Hz, 64 Hz).

The PF changes slightly according to the input frequency, but can achieve over 86% at

264 V

condition.

AC

.

Figure 25. Power Factor

Table 7. Test Results

Input Voltage Power Factor

187 VAC

220 VAC

264 VAC

47 Hz 95.37

64 Hz 95.59

47 Hz 95.28

64 Hz 94.98

47 Hz 94.31

64 Hz 93.91

© 2012 Fairchild Semiconductor Corporation 19 FEBFL7701_L31H008A • Rev.1.0.2

Page 20

8.8. Total Harmonic Discharge (THD) Performance

[V]

[%]

The Figure 26 shows the Total Harmonic Discharge (THD) performance at different

input frequencies. Test results are quite similar, but meet international regulations (under

30%).

Figure 26. Total Harmonic Discharge Performance

Table 8. Test Results

Input Voltage THD

187 VAC

220 VAC

264 VAC

47 Hz 27.18

64 Hz 27.94

47 Hz 27.72

64 Hz 28.72

47 Hz 29.10

64 Hz 29.40

© 2012 Fairchild Semiconductor Corporation 20 FEBFL7701_L31H008A • Rev.1.0.2

Page 21

8.9. Thermal Performance

V

V

V

V

Figure 27 through Figure 32 show the steady-state thermal test results with different input

voltage conditions. Inductor L3 has the highest temperature on the top side of the PCB

due to copper resistance. The FL7701 has the highest temperature on the bottom side of

the PCB due to power loss associated with the high-voltage device. The IC temperature is

66.5°C for the 220 V

input condition.

AC

MOSFET

TEMP: 63.6℃

Diode (D1) TEMP:

61.1℃

IC TEMP:

56.0℃

Figure 27. Bottom-Side Temperature at 187

Condition (IC)

MOSFET

TEMP: 67.6℃

IC TEMP:

61.1℃

HV Resistor(R2) TEMP:

60.6℃

Figure 28. Top-Side Temperature at 187

AC

(Inductor)

Inductor

TEMP: 49.9℃

Inductor

TEMP: 48.2℃

AC

Condition

Diode (D1) TEMP:

64.2℃

Figure 29. Bottom-Side Temperature at 220

Condition (IC)

© 2012 Fairchild Semiconductor Corporation 21 FEBFL7701_L31H008A • Rev.1.0.2

HV Resistor(R2) TEMP:

62.3℃

Figure 30. Top-Side Temperature at 220

AC

(Inductor)

Condition

AC

Page 22

V

V

MOSFET

TEMP: 69.6℃

Diode (D1) TEMP:

65.0℃

Figure 31. Bottom-Side Temperature at 264

Condition (IC)

IC TEMP:

64.5℃

Inductor

TEMP: 50.1℃

HV Resistor(R2) TEMP:

66.0℃

Figure 32. Top-Side Temperature at 264

AC

(Inductor)

Condition

AC

Table 9. Temperature Performance by Input Voltage

IC MOSFET Diode Inductor HV Resistor

187 VAC

220 VAC

56.0°C 63.6°C 61.1°C 48.2°C 60.6°C

66.5°C 55.0°C 64.2°C 54.6°C 62.3°C

264 VAC

71.5°C 59.5°C 65.0°C 57.7°C 66.0°C

© 2012 Fairchild Semiconductor Corporation 22 FEBFL7701_L31H008A • Rev.1.0.2

Page 23

8.10. EMI Test Results

EMI test measurements were conducted in observance of CISPR22 criteria, which has

stricter limits than to CISPR15 for lighting applications.

Figure 33. Conducted Emission-Line at 220 VAC Input Condition, Full Load (10-LED Series)

Figure 34. Conducted Emission-Neutral at 220 V

Input Condition, Full Load (10-LED Series)

AC

© 2012 Fairchild Semiconductor Corporation 23 FEBFL7701_L31H008A • Rev.1.0.2

Page 24

9. Revision History

Rev. Date Description

0.0.1 Jan. 2012. First issue

1.0.1 Feb. 2012. Modified, edited, formatted document

1.0.2 Sep. 2012.

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

This board is intended to be used by certified professionals, in a lab environment, following proper safety procedures. Use at your own risk. The

Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any kind

of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s published

specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without notice to

any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or, if no

contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a)

are intended for surgical implant into the body, or (b) support or

sustain life, or (c) whose failure to perform when properly used in

accordance with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the user.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

EXPORT COMPLIANCE STATEMENT

These commodities, technology, or software were exported from the United States in accordance with the Export Administration Regulations for the

ultimate destination listed on the commercial invoice. Diversion contrary to U.S. law is prohibited.

U.S. origin products and products made with U.S. origin technology are subject to U.S Re-export laws. In the event of re-export, the user will be

responsible to ensure the appropriate U.S. export regulations are followed.

Modified, edited, formatted document, Changed User Guide number from FEBL031-2 to FEBFL7701_H31L008A

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its

safety or effectiveness.

© 2012 Fairchild Semiconductor Corporation 24 FEBFL7701_L31H008A • Rev.1.0.2

Loading...

Loading...